Ошибки воздушных отопителей Airtronic D1LC Скания

Дополнительный автономный отопитель тягача Скания с внешними мозгами оснащен таймером — реостатом CTT который при неисправности выдает код ошибки на дисплей. Если таймер молчит то стоит проверить предохранитель 34 самого обогревателя и 41-й непосредственно пульта.

Пульт CCT может показать лишь один код неисправности и если их больше, новый код будет показываться после устранения причины предыдущего.

■ Для стирания ошибок нажмите центральную клавишу на таймере.

| Код ошибки | Возможная причина | Меры для устранения неисправности |

| BAT/EBAT | Низкое напряжение батарейки пульта. | Замените батарейку в таймере CTT на новую. |

| E 05 | Не верное напряжение канала диагностики. | Напряжение канала связи диагностики должно быть между 1,5-2,5В. |

| F 10 по F 14 | Не верное соединение. | Сверьте подключение со схемой, возможно штыри 8 и 6 подсоединены одновременно. Отключите 6 штырь в разъеме C402 и C187. Расположение в кабине: позади стенки отсека одежды, сзади вод. кресла на полу или на кожухе двигателя со стороны пассажира. |

| F 30 | Не верное обнаружение пламени | Стереть код средней клавишей и повторно запустить обогрев. |

| F 31 | Срыв пламени в режиме «низкой» и «средней» производительности. | Проверить топливо, его количество, скорость нагнетателя, впуск и выпуск. |

| F 32 | Срыв пламени в режиме «высокой» производительности. | Проверить топливо, его количество, скорость нагнетателя, впуск и выпуск. |

| F 33 | Ошибка свечи розжига. | Проверить свечу, ее реле и проводку. (Ее сопротивление около 2кОм) |

| F 34 | Отсутствие вращения нагнетателя или неисправность переключателя скорости вращения. | Проверить двигатель отдельно, скорость: высокая — 4500об./мин средняя и низкая — 300 об./мин. Проверьте переключатель скорости. (При неисправности заменить, но дешевле починить) |

| F 35 / F 36 | Низкое или высокое напряжение | Напряжение питающее отопитель должно быть в пределах 21В-30В, проверьте АКБ и генератор. |

| F 37 | Нет запуска после двух попыток включения. | Проверьте подачу топлива, нагнетатель, свечу, впуск и выпус воздуха. Устраните причину мешающую возникновению пламени. |

| F 39 | Неисправен температурный датчик или регулятор температуры CTT пульта. | Проверьте цепь датчика, жгут, контакт монтажной платы, соединения CTT пульта. |

| F 40 | Неисправноть топливного насоса, возможно КЗ. | Проверить и заменить дозирующий насос. Правильное сопротивление ТН 36 Ом. |

| F 41 | Неисправность датчика пламени | Проверить датчик пламени, должно быть сопротивление около 1кОм. |

| F 43 | Блок управления неисправен. | Заменить блок управления. |

| F 44 | Перегрев | Проверить циркуляцию воздуха через кожух, проверьте омметром датчик перегрева, должен быть замкнут. |

| F 45 | Предупреждение о неправильном напряжении. | Проверьте батарею и генератор. |

| F 46/ F 47 / F 48 | Не влияющие на работу коды | Стереть и включить подогреватель. |

| OIA6, E 91, E 92, E 93 | Специальные коды производителя. | Стереть и запустить подогрев, если не стирается то заменить пульт CTT. |

Сброс блокировки D1LC: на 2-3 секунды замкните ножки 9 и 11 в 14-ти контактном разъеме блока управления. После этого блокировка снимется и отопитель будет выводить Блинк-коды, в случае если он вместо пульта СTT оборудован крутилкой с индикатором.

Данные Блинк-коды подходят для отопителей с внешним блоком управления D1LC, D3LC, B5LC / D5LC

Работает (горит постоянно)………………………………. ________________________________

Предупреждение о неправильном напряжении…… ___ ___ ___ _______________

Отключение повышенное напряжение…………………______ ___ ___

Отключение пониженное напряжение………………… ______ ___

Свеча накала прерывание…………………………………. ___ ___ ___ ___

Свеча накала замыкание…………………………………… ___ _________

Нагнетатель воздуха нет вращения……………………. ______

Пламя при включении (датчик)…………………………… ___

Нет запуска……………………………………………………….. _______ ___ ___ ___

Перегрев……………………………………………………………. ___ ___ ___ ___ ___ ___ ___

Топливный насос обрыв или КЗ…………………………. ___ ___ ___ ________

Дефект датчика температуры…………………………….. ___ ___ _______

Дефект датчика пламени……………………………………. ___ ___ _________ ___

Срыв пламени на ступени малая………………………… ___ ___

Срыв пламени на ступени полная……………………….. ___ ___ ___

Дефект блока управления…………………………………… ______ ______

Ошибки воздушных отопителей Airtronic D2 / D3 / B4 / D4 / M / D4Plus / D4S / D5LC / D8LC

При наличии на отопителе стандартного или комби-таймера, аварийная блокировка выдает на дисплей таймера следующие коды неисправности:

|

Индикация кода неисправности |

Описание ошибки |

Комментарий • Меры по устранению |

|

(000) |

Без ошибок |

————————— |

|

(004) |

Внимание: Короткое замыкание в блоке управления, выход — свежий воздух |

• Разъедините штекерное соединение S1/B1 на отопительном приборе и проверьте на штекере В1 провод от штырька 16 до реле нагнетателя свежего воздуха на наличие короткого замыкания на массу если все в порядке —> замените блок управления. |

|

(005) |

Внимание: Короткое замыкание в блоке управления, выход — система противоугонной сигнализации |

• Разъедините штекерное соединение S1/B1 на отопительном приборе и проверьте на штекере В1 провод от штырька 15 до реле разъединителя или входа системы противоугонной сигнализации на наличие короткого замыкания на массу, если все в порядке — > замените блок управления. |

|

(006) |

Внимание: Непонятная информация о высоте над уровнем моря (индикация только у отопительных приборов с маркировкой «Н-Kit» на заводской табличке). |

Прибор управления не получил понятную информацию о высоте. • Прочитайте регистратор неисправностей в датчике давления воздуха при помощи диагностического инструмента EDiTH и устраните неисправность. |

|

(009) |

Отключение ADR |

Отключение ADR из-за смены сигнала с (+) на (-) на штекере S1, штырек 13 (D+) или плюсовой сигнал на штекере S1, штырек 14 (НА+). |

|

(010) |

Перенапряжение — отключение |

Перенапряжение на блоке управления сохраняется не менее 20 секунд непрерывно — > отопительный прибор отключается. • Разъедините штекерное соединение В1 / S1 на отопительном приборе, запустите двигатель транспортного средства, измерьте напряжение на штекере В1 между штырьком 1 (кабель 2,52 rt) и штырьком 10 (кабель 2,52 Ьг). Airtronic 12 В — напряжение >16 В — > проверьте регулятор генератора Airtronic 24 В — напряжение >32 В —> проверьте регулятор генератора |

|

(011) |

Пониженное напряжение -отключение |

Пониженное напряжение на блоке управления сохраняется не менее 20 секунд непрерывно —> отопительный прибор отключается. • Разъедините штекерное соединение В1 / S1 на отопительном приборе, заглушите двигатель транспортного средства, измерьте напряжение на штекере В1 между штырьком 1 (кабель 2,52 rt) и штырьком 10 (кабель 2,52 Br). Измеренное значение напряжения не должно отличаться от напряжения на аккумуляторе. При падении напряжения проверьте предохранители, питающие кабели, контакты на массу и плюсовую клемму аккумулятора на наличие коррозии и наличие контакта. |

|

(012) |

Перегрев на датчике перегрева |

Слишком высокая температура на датчике перегрева. • Проверьте магистрали подачи теплого воздуха на наличие перегибов —> устраните перегибы • Слишком большое число отводящих каналов от воздухопроводящих компонентов — > проверьте магистрали подачи воздуха, при необходимости проложите их заново — см. число отводящих каналов в каталоге дополнительного оборудования • Проверьте датчик перегрева, если все в порядке —> измерьте количество подаваемого топлива. |

|

(013) |

Перегрев на датчике горения |

Датчик горения сообщает о слишком высокой температуре на теплообменнике. • Проверьте магистрали подачи теплого воздуха на наличие перегибов —> устраните перегибы • Слишком большое число отводящих каналов от воздухопроводящих компонентов —> проверьте магистрали подачи воздуха, при необходимости проложите их заново — см. число отводящих каналов в каталоге дополнительного оборудования • Проверьте датчик горения, если в порядке — > проверьте датчик перегрева около 60 кОм при комн.т., если датчик перегрева неисправен —> замените комбинированный датчик, если датчик перегрева в порядке — > измерьте количество подаваемого топлива. |

|

(014) |

Слишком большая разница температур между датчиком горения и датчиком перегрева |

Слишком большая разница температур между датчиком горения и датчиком перегрева. • Проверьте магистрали подачи теплого воздуха на наличие перегибов —> устраните перегибы • Слишком большое число отводящих каналов от воздухопроводящих компонентов —> проверьте магистрали подачи воздуха, при необходимости проложите их заново — см. число отводящих каналов в каталоге дополнительного оборудования • Проверьте датчик горения около 1 кОм, если в порядке — > проверьте датчик перегрева, около 60 кОм при комн.т., если датчик перегрева неисправен —> замените комбинированный датчик, если датчик перегрева в порядке — > измерьте количество подаваемого топлива, если количество подаваемого топлива в норме —> замените блок управления. |

|

(015) |

Функциональная блокировка |

Код неисправности 015 отображается, если после отображения кода неисправности 017 отопительный прибор был включен еще раз. Было превышено пороговое значение аппаратной части для датчика перегрева -> блок управления блокируется. • Замените блок управления. |

|

(017) |

Перегрев |

Было превышено пороговое значение аппаратной части для датчика перегрева, так как блок управления не опознал код неисправности 012 или 013 -> блок управления блокируется. Если отопительный прибор включить еще раз, отобразится код неисправности 015. • Замените блок управления. |

|

(018) |

Слишком малая энергия штифтового электрода при запуске (индикация только у отопительных приборов с маркировкой «Н-Kit» на заводской табличке). |

• Проверьте штифтовой электрод (см. коды неисправностей 020 и 021), если в порядке • Проверьте кабельный жгут штифтового электрода на правильность прокладки и на наличие повреждений, если все в порядке ~> проверьте кабельный жгут на проходимость, если он в порядке -> замените блок управления. |

|

(019) |

Недостаточная энергия воспламенения |

• Проверьте штифтовой электрод (см. коды неисправностей 020 и 021), если в порядке • Проверьте кабельный жгут штифтового электрода на правильность прокладки и на наличие повреждений, если все в порядке ~> проверьте кабельный жгут на проходимость, если он в порядке -> замените блок управления. |

|

(020) (021) |

Штифтовой электрод — обрыв Штифтовой электрод — короткое замыкание, перегрузка или замыкание на массу |

• Проверьте штифтовой электрод на функционирование и проходимость при температуре 20 °С. Отопительный прибор 12 В — от 0,42 Ом до 0,7 Ом Отопительный прибор 24 В — от 1,2 Ом до 2,5 Ом • Если значения в норме — > проверьте кабельный жгут штифтового электрода на наличие повреждений и на проходимость, если все в порядке —> замените блок управления. |

|

(022) |

Штифтовой электрод, выход (+) — короткое замыкание на UB (напряжение аккумулятора) |

• Проверьте кабельный жгут штифтового электрода на правильность прокладки и на наличие повреждений, если все в порядке — > проверьте кабельный жгут на проходимость, если он в порядке —> замените блок управления. |

|

(025) |

Диагностический кабель bl/ws — короткое замыкание — на UB (напряжение аккумулятора) |

Отображение кода неисправности невозможно. Этот код неисправности может быть просмотрен только после устранения неисправности. • Проверьте диагностический кабель на правильность прокладки и наличие повреждений. |

|

(031) |

Нагнетатель — обрыв |

• Проверьте кабельный жгут двигателя нагнетателя на правильность прокладки и на наличие повреждений, если все в порядке — > отсоедините кабельный жгут от блок управления и проверьте его на проходимость, если он в порядке — > замените блок управления. |

|

(032) |

Двигатель нагнетателя — короткое замыкание на массу |

• Выполните функциональную проверку двигателя нагнетателя, для этого отсоедините штекер от блока управления. Подайте тестовое напряжение на двигатель нагнетателя и через 40 секунд измерьте величину тока. Сила тока < 6,5 А —> двигатель нагнетателя в порядке —> замените блок управления. Сила тока > 6,5 А —> замените нагнетатель. • Проверьте проводку на наличие короткого замыкания. |

|

Обратить внимание! |

||

|

Непременно соблюдайте тестовое напряжение (10в для 12в или 18в для 24 вольтового прибора). В случае превышения величины напряжения компонент будет разрушен. Учитывайте устойчивость блока питания при коротких замыканиях — мин. 20 А. |

||

|

(033) |

Двигатель нагнетателя не крутится или короткое замыкание на массу |

Отклонение число оборотов > 10 % от заданного значения более 30 секунд. Измерьте число оборотов нагнетателя воздуха в камеру сгорания при помощи бесконтактного фотоэлектрического тахометра. • Слишком низкое число оборотов: Нагнетатель блокирован — проверьте инерционный выбег нагнетателя или удалите посторонний предмет, если в порядке —> проверьте нагнетатель (см. код неисправности 032). • Слишком высокое число оборотов: — Отсутствует магнит на крыльчатке нагнетателя —> замените нагнетатель. — Неисправен датчик числа оборотов в блоке управления —> замените блок управления. • Проверьте проводку на наличие короткого замыкания. |

|

Обратить внимание! |

||

|

Непременно соблюдайте тестовое напряжение (10в для 12в или 18в для 24 вольтового прибора). В случае превышения величины напряжения компонент будет разрушен. Учитывайте устойчивость блока питания при коротких замыканиях — мин. 20 А. |

||

|

(034) |

Двигатель нагнетателя, выход (+) короткое замыкание на UB (напряжение аккумулятора) |

• Проверьте кабельный жгут двигателя нагнетателя на правильность прокладки и на наличие повреждений, если все в порядке —> отсоедините кабельный жгут от блок управления и проверьте его на проходимость, если он в порядке —> замените блок управления. |

|

(047) |

Дозировочный насос — короткое замыкание или перегрузка |

• Отсоедините штекер от дозировочного насоса, если после этого отображается код неисправности 048 (обрыв), то дозировочный насос неисправен — замените дозировочный насос. • Если код 047 отображается и дальше, разъедините штекерное соединение S1 /В1 на отопительном приборе и проверьте на штекере В1 провод 12 gn/rt от штырька 5 к дозировочному насосу на наличие короткого замыкания на массу (штырек 10), если все в порядке —> замените блок управления. |

|

(048) |

Дозировочный насос — обрыв |

• Отсоедините штекер от дозировочного насоса и измерьте сопротивление дозировочного насоса 9,5 Ом ±0,50 или 36,0 Ом ±1,8 , если величина сопротивления в норме, вновь подсоедините кабельный жгут к дозировочному насосу. • Разъедините штекерное соединение S1/B1 на отопительном приборе и проверьте сопротивление между штырьками 5 и 10, если все в порядке — > замените блок управления. |

|

(049) |

Дозировочный насос, выход (+) Короткое замыкание — на UB (напряжение аккумулятора) |

• Проверьте кабельный жгут дозировочного насоса на правильность прокладки и на наличие повреждений, если все в порядке —> проверьте кабельный жгут на проходимость, если он в порядке —> замените блок управления. |

|

(050) |

Слишком много неудачных попыток запуска (функциональная блокировка) |

Блокировка блока управления после слишком большого число неудачных попыток запуска (макс. 255 попыток запуска). • Разблокирование прибора управления путем очистки регистратора неисправностей при помощи часового реле, диагностического прибора, диагностического инструмента EDiTH, радиоуправления TP5/EasyStart R+ и часового реле Schaltuhr EasyStartT делайте в крайнем случае, сохраненные ошибки ускоряют ремонт автономного отопителя. |

|

(051) |

Было определено наличие пламени при включении |

Если сопротивление датчика горения после включения составляет 1274 П (>70 °С), нагнетатель отопительного прибора в течение примерно 15 минут работает на охлаждение, если вышеуказанное значение сопротивления в течение 15 минут не снижается, происходит аварийное отключение. • Проверьте датчик горения, около 1кОм, если все в порядке — > замените блок управления. |

|

(052) |

Превышение безопасного лимита времени |

На этапе запуска не определяется наличие пламени. • Проверьте магистрали отвода выхлопных газов и подачи воздуха в камеру сгорания. • Проверьте систему подачи топлива / измерьте количество подачи топлива • Проверьте штифтовой электрод (см. коды неисправностей 020 и 021) • Проверьте датчик горения, около 1кОм,, если все в порядке — > замените блок управления. |

|

(053) (054) (055) (056) |

Обрыв факела на ступени „МОЩНОСТЬ» „ВЫСОКАЯ» „СРЕДНЯЯ» „МАЛАЯ» |

Отопительный прибор запускается (определено наличие пламени) и на одной из ступеней мощности сообщает об обрыве факела. • Проверьте магистрали отвода выхлопных газов и подачи воздуха в камеру сгорания. • Проверьте систему подачи топлива / измерьте количество подачи топлива. • Проверьте датчик горения, около 1кОм,, если все в порядке — > замените блок управления. |

|

(057) |

Обрыв факела на этапе запуска (индикация только у отопительных приборов с маркировкой «1—1-Kit» на заводской табличке). |

На этапе запуска определен обрыв факела. • Проверьте магистрали отвода выхлопных газов и подачи воздуха в камеру сгорания. • Проверьте систему подачи топлива / измерьте количество подачи топлива. • Проверьте штифтовой электрод (см. коды неисправностей 020 и 021). • Проверьте датчик горения, около 1кОм,, если все в порядке ~> замените блок управления. |

|

(060) |

Внешний датчик температуры — обрыв |

• Разъедините штекерное соединение S4 / В4 внешнего датчика управления и измерьте сопротивление на штекере В2, диаграмму и таблицу значений см. на стр. 12, если датчик температуры в порядке, восстановите штекерное соединение S4 / В4. • Разъедините штекерное соединение S1 / В1 на отопительном приборе и проверьте сопротивление между штырьками 6 и 12 в корпусе штекера В1. При обрыве в цепи сопротивление > 7175 Ом / > 3 кОм *. Если величина сопротивления в норме ~> замените блок управления. |

|

(061) |

Внешний датчик температуры — короткое замыкание |

• Разъедините штекерное соединение S4 / В4 внешнего датчика температуры, если отображается код неисправности 060 — > проверьте внешний датчик температуры, диаграмму и таблицу значений см. на стр. 32. Если датчик температуры в порядке —> проверьте провода 0,5 gr и 0,5 br/ws на короткое замыкание; если они в порядке, восстановите штекерное соединение S2 / В2. • Разъедините штекерное соединение S1 / В1 на отопительном приборе и проверьте сопротивление между штырьками 6 и 12 в корпусе штекера В1. При коротком замыкании сопротивление < 486 Ом / < 800 кОм *. Если ошибка 061 все равно отображается —> замените блок управления. |

|

(062) |

Отопительный прибор работает только на ступени «Высокая» • Отсоедините штекер от элемента управления и измерьте величину сопротивления задающего потенциометра, контактные штырьки. Если величина сопротивления в норме 1700-2000 Ом, вновь подсоедините штекер к элементу управления. • Разъедините штекерное соединение S1 / В1 на отопительном приборе, измерьте сопротивление между штырьками 6 и 7 в корпусе штекера В1, если величина сопротивления в порядке —> замените блок управления. При обрыве в цепи сопротивление > 7175 Ом / > 3 кОм. |

|

|

Элемент управления — обрыв |

||

|

(063) |

Элемент управления — короткое замыкание Определение пламени функционирует только в режиме обогрева. Если произошло короткое замы-кание и вследствие этого выполняется включение отопительного прибора, то активируется „Вентиляция (код неисправности не генерируется). |

• При наличии выключателя „Вентиляция отсоедините его и проверьте на функционирование. Если не в порядке —> замените выключатель. • Отсоедините штекер от элемента управления — если отобразится код ошибки 062, замените элемент управления. Если элемент управления в порядке, проверьте соединительные провода 0,52 gr/rt и 0,52 br/ws на короткое замыкание, если они в порядке —> снова подсоедините штекер к элементу управления. • Разъедините штекерное соединение S1 / В1 на отопительном приборе, если продолжает отображаться код ошибки 063 — > замените блок управления. При замыкании сопротивление > 486 Ом / < 800 кОм. |

|

(064) |

Датчик горения — обрыв |

• Снимите блок управления и отсоедините от него зеленый штекер. Проверьте датчик горения, диаграмму и таблицу значений см. на стр. 32, если датчик горения в порядке —> замените блок управления. При обрыве в цепи сопротивление > 7175 Ом / > 3 кОм *. |

|

(065) |

Датчик горения — короткое замыкание |

• Снимите блок управления, отсоедините от него зеленый штекер — если отображается код неисправности 064 —> замените комбинированный датчик. Если далее отображается код неисправности 065 — > неисправен блок управления. Сопротивление при коротком замыкании < 486 Ом/ < 500 Ом. |

|

(071) |

Датчик перегрева — обрыв |

• Снимите блок управления и отсоедините от него синий и зеленый штекер. Измерьте сопротивление на штырьке 1 синего штекера (кабель 0,52 Ы) и на штырьке 2 зеленого штекера (кабель 0,52 br/ws), если значение в порядке —> замените блок управления. Сопротивление при обрыве в цепи > 223 кОм/ > 1600 кОм. |

|

(072) |

Датчик перегрева — короткое замыкание |

• Снимите блок управления, отсоедините от него синий штекер — если отображается код неисправности 071 —> замените комбинированный датчик. Если далее отображается код неисправности 072 — > замените блок управления. Сопротивление при коротком замыкании < 183 Ом/ < 95 Ом. |

|

(074) |

Неисправен блок управления |

• Пороговое значение перегрева не определяется блоком управления — > замените блок управления. |

|

(090) |

Неисправен блок управления (внутренняя неисправность) |

• Замените блок управления. |

|

(091) |

Внешнее напряжение помех |

• Сбои в работе блока управления под действием напряжения помех в бортовой сети. Возможные причины: Разряжен аккумулятор, зарядное устройство —> устраните напряжение помех. |

|

(092) |

Неисправен блок управ-ления (неисправность ПЗУ) |

• Замените блок управления. |

|

(093) |

Неисправен блок управления |

• Замените блок управления. |

|

(094) |

Неисправен блок управ-ления (неисправность ЭСППЗУ) |

• Замените блок управления. |

|

(095) |

Неисправен блок управления |

• Замените блок управления. |

|

(096) |

Неисправен внутренний датчик температуры |

• Замените блок управления или используйте внешний датчик температуры. |

|

(097) |

Неисправен блок управления |

• Замените блок управления. |

|

(098) |

Неисправен блок управления |

• Замените блок управления. |

|

(099) |

Слишком много сбросов подряд Неисправен транзистор в блоке управления |

• Кратковременное напряжение < 5 — 6 В (12 В) или < 7 — 8 В (24 В). • При падении напряжения проверьте предохранители, питающие кабели, контакты на массу и плюсовую клемму аккумулятора на наличие коррозии и наличие контакта. Проверьте блок управления при помощи диагностического устройства, если он в порядке — > проверьте кабельный жгут внешних компонентов на правильность прокладки и на наличие повреждений, если он в порядке —> проверьте кабельный жгут на проходимость, если он в порядке — > замените блок управления. |

|

Индикация |

кода неисправности «Датчик давления воздуха» |

|

|

Индикация кода неисправности |

Описание ошибки |

Комментарий • Меры по устранению |

|

(0) |

Без ошибок |

— |

|

(11) |

Потеря подключения |

Прерывание диагностического подключения между прибором управления (отопительный прибор) и датчиком давления воздуха • Проверка проводки и штекерных соединений |

|

(12) |

Отсутствие регулировки по высоте |

Прибор управления (отопительный прибор) не поддерживает «высотный» режим с датчиком давления воздуха • Использование прибора управления (отопительный прибор), поддерживающего регулировку по высоте |

|

(13) |

Ошибка «Датчик давления воздуха» |

Неисправен датчик давления воздуха • Замените датчик давления воздуха. |

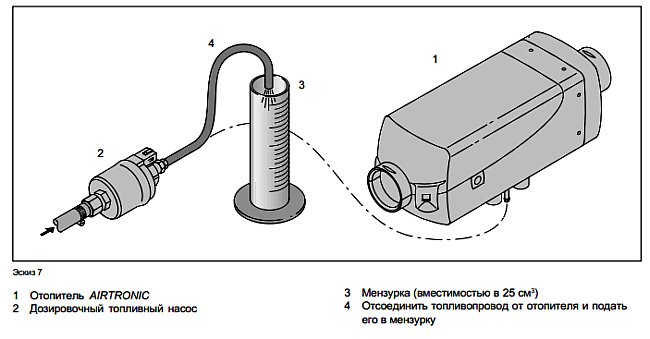

Проверка количества подаваемого топлива насосом дозатором:

Перед проверкой подачи топлива убедитесь в то что:

■ Фильтр в насосе не забит.

■ Топливопроводы не пережаты и не перетерты.

■ Все соединения нормально затянуты, не текут.

Порядок замера:

■ Снять трубку подачи топлива с отопителя и убедится что она не завоздушена, топливо поступает.

■ Вставить ее в мерную ёмкость, можно в шприц.

■ Включить отопитель и через 60 секунд дождаться ее наполнения, держать ее желательно на высоте автономки.

• Для Airtronic D1 / D2: по истечению 90 сек должно быть между 3,5 — 4,3 мл. топлива. (за одну попытку запуска)

• Для Airtronic D4: по истечению 110 сек должно быть между 5 — 6 мл. топлива. (за одну попытку запуска)

• Для Airtronic B4: по истечению 110 сек должно быть между 6,8 — 7,6 мл. топлива. (за одну попытку запуска)

Данные приведены примерные и в зависимости от модели авто (в случае заводской установки, прошивка ЭБУ) могут отличаться, желательно для более точного результата проверить насос отдельно от отопителя на стенде. Тест производится на 1000 качков что уменьшает погрешности. Также на это тестирование не коим образом не влияет блок управления.

Неисправности насоса обычно свидетельствуют такие внешние признаки как черное дымление и копоть — перелив, срыв пламени на режиме «мощный, полный», — недолив иногда при переливе топлива возникает перегрев.

В любом случае не спешите менять насос, как следует не проверив на стенде.

Оказываем услуги по ремонту Вашего автономного отопителя. Адекватные цены, максимальное качество услуг, звоните!

Установка предпускового подогревателя и автономных отопителей давно стала нормой среди автопроизводителей. По этой причине водители часто сталкиваются с неисправностями и различными поломками в системах. Отсюда рождается необходимость знать и уметь расшифровывать коды ошибок Эбершпехера и аналогичных устройств.

Содержание

- 1 Расшифровка кодов неисправностей Д1, Д2, Д3, Д4, Д5ВС, D10W

- 1.1 Ошибка F11 — Eberspacher

- 1.2 Эбершпехер: неисправность F12

- 1.3 Код 14

- 1.4 Ошибка F20

- 1.5 Поломка 30 — что делать

- 1.6 Неисправность 31 — как исправить

- 1.7 F33 — ошибка Eberspacher

- 1.8 Код ошибки 34

- 1.9 Автономный отопитель Эбершпехер выдает ошибку Е37

- 1.10 Ошибка Ф48

- 1.11 Ошибка F52 — что делать

- 1.12 Ошибка F53

- 1.13 Неисправность F54

- 1.14 Код 57

- 1.15 F62 — ошибка

- 1.16 Ошибка 71

- 1.17 Ошибка N5I

- 1.18 Ошибка err- Eberspacher

- 2 Эбершпехер: как посмотреть ошибки

- 3 Сброс ошибок Eberspacher

- 4 Эбершпехер: автономка не запускается — причины неисправности и способы устранения

- 5 Итог

Отопители данной марки устанавливаются на КАМАЗ 5490, Мане, Амане и Аскоре. Также отмечается конвейерная установка на Скании.

При необходимости предпускового подогрева силовой установки, изготовители ставят на машины жидкостные системы, встраиваемые в магистраль охлаждения ДВС. Если требуется обогреть салон машины, обычно монтируются сухие фены с мощностью около 2кВт под общепринятым названием Вебасто.

Расшифровка кодов неисправностей Д1, Д2, Д3, Д4, Д5ВС, D10W

Современные и продвинутые отопители Eberspacher Airtronic — удобные агрегаты, обеспечивающие обогрев салона автомобиля в суровые зимние морозы. Эффективность устройств подтверждается тем, что на некоторых авто, система устанавливается с завода. Яркими примерами считаются машины Iveco, Скания 124 и аналогичные модификации.

Несмотря на надежность сухой системы, агрегаты подвержены естественному износу и повреждениям специфического характера. Изготовитель предусмотрел систему самодиагностики, высвечивающую ошибки электронных и поломки механических систем.

Облегчает ситуацию то, что компания монтирует одну основу конструкции. Это позволяет использовать схожие прошивки и идентичные кодировки. Фактор значительно упрощает диагностику и последующий ремонт на разных ТС.

Рассмотрим наиболее часто встречающиеся поломки и методики устранения.

Ошибка F11 — Eberspacher

Устройство отключено по причине слишком низкого напряжения в бортовой сети. Если уровень держится меньше допустимого на 20 и более секунд, происходит аварийная остановка агрегата.

Для устранения поломки проверьте цепь на наличие повреждений, эффективности работы генератора и аккумуляторной батареи. Просмотрите силовые жилы устройства и контактные группы на предмет повреждений.

Эбершпехер: неисправность F12

Говорит о том, что датчик температуры указывает на поднятие показателя свыше допустимой нормы. В мокрой вариации нужно откачать часть воды из теплообменника и проверить наличие окислов. Для сухой модификации — протестировать датчики на наличие повреждений.

Код 14

Большая разница между показателями сенсора факела и температуры корпуса. Выполните диагностику системы.

Ошибка F20

Обрыв цепи питания штифтового электрода. Проверьте деталь и ее проводку. Причиной бывает отошедший контакт или окисление клеммы.

Поломка 30 — что делать

Крыльчатка нагнетателя воздуха в систему не вращается. Возможно причина находится в попадании мусора внутрь системы. Осмотрите мотор вентилятора на наличие подклинивания подшипника.

Неисправность 31 — как исправить

Силовая магистраль нагнетателя воздуха оборвана или сильно повреждена. Неисправность F31 устраняется путем восстановления проводки или ее замены на новую.

F33 — ошибка Eberspacher

Двигатель нагнетателя кислорода в камеру сгорания работает неправильно. Проверьте регулятор и мотор.

Код ошибки 34

Реле водяной помпы неисправно или функционирует некорректно. Осмотрите деталь на целостность обмотки и проводов питания.

Автономный отопитель Эбершпехер выдает ошибку Е37

Водяной насос не работает. Изначально отделите помпу и проверьте. Если с ней все в порядке — замените плату управления.

Ошибка Ф48

Дозирующий насос функционирует неправильно. При проверке устройства в норме сопротивление должно быть 20 Ом. Если все в порядке — продиагностируйте систему на наличие обрывов силовой магистрали.

Ошибка F52 — что делать

Неисправность указывает на то, что устройство неудачно запускалось несколько раз подряд. При попытке пуска пламя в горелке не обнаружено. Проверьте подачу топлива, воздуха и систему выхлопа. Диагностируется свеча накаливания.

Ошибка F53

На одной из позиций пламя срывается. Проверьте дозирующий насос. Возможно, элемент перекачивает или подает недостаточно горючего в рабочую камеру.

Неисправность F54

Аналогичная проблема только на максимальной мощности. Система требует обслуживания и диагностики.

Код 57

На датчике пламени присутствует короткое замыкание с касанием на массу. Проверьте проводку и устройство на наличие пробоев в силовой цепи.

F62 — ошибка

Потенциометр модуля вышел из строя, устранить проблему можно только полной заменой блока. Деталь не подлежит ремонту.

Ошибка 71

Датчик перегрева устройства сигнализирует о наличии температуры, выходящей за пределы измерения. Неисправность говорит о повреждении сенсора.

Ошибка N5I

Нет связи с пультом управления, либо слишком замедлен отклик. Посмотрите клеммы и возможные обрывы в цепях.

Ошибка err- Eberspacher

Если на пульте управления система пишет поломку heatererror, это указывает на наличие критического сбоя во время работы модуля. Полностью перезагрузите устройство и попытайтесь запустить снова. Если действия не помогают — обратитесь в сервисную мастерскую.

Эбершпехер: как посмотреть ошибки

Проверить устройство на наличие поломок можно 3 способами.

- Внешним прибором. Метод наиболее точный, но требует наличие выносного сканера, что недоступно для многих водителей.

- Модульное реле. Деталь устанавливается стационарно и является частью агрегата. Запоминается до 5 ошибок стандартного порядка.

- Диагностическая программа. Тип поиска проблем больше подходит для сервисных станций. Потребуется компьютер с специальным ПО на борту.

Сброс ошибок Eberspacher

Скинуть поломки на приборе самостоятельно без компьютера и прочего оборудования можно. Чтобы сделать своими руками потребуется выполнить процедуру.

- На пульте управления войти в раздел сервис.

- Далее находим иконку с мигающими часами.

- Нажмите на клавишу в виде белого прямоугольника.

- Теперь зажимаем на индикатор DEL.

Если все сделано правильно, неисправности пропадут. Также имеется менее замороченный способ. Для этого потребуется вручную обесточить бортовые системы на 10-15 минут. После, устройство полностью перезагрузится и удалит ошибки.

Эбершпехер: автономка не запускается — причины неисправности и способы устранения

Помимо указанных выше причин, существует еще несколько вероятных поломок, способных крайне негативно отразиться на работе системы.

| № | Расшифровка |

| 10 | Перенапряжение на блоке управления. Модуль автоматически отключен. |

| 15 | Устройство сильно перегревается во время работы. Почистите канал подачи кислорода на горелку и теплообменник. |

| 50 | Было выполнено слишком много неудачных попыток запуска устройства. Перезапустите систему и продиагностируйте у специалистов. |

| 64 | Обрыв цепи на датчике горения. |

| 90 | Блок управления неисправен. Требуется тщательная диагностика прибора. |

Итог

Стандартные коды поломок Эберспехер — набор простых символов и значений, указывающих на наличие проблем в бортовом оборудовании. Подобные шифры значительно облегчают диагностику и ремонт устройства.

Специализация: Закончил государственный автомобильный университет, проработал 20 лет на ГАЗ-56, сейчас езжу на жигулях.

|

ECU Name |

SPN [Hex] |

Fault Component |

Description |

FMI [DEC] |

FMI [HEX] |

FMI Description |

Lamp status |

Comment |

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

air gap too large, sensor output voltage too low but just exceeds trigger level |

1 |

01 |

air gap |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

such proportion of tyre diameter/ pole wheel teeth number that wheel speed difference within front axle > 10 % or difference within wheels of different axles > 19 % . Pneus or number of polewheel teeth are different. Check wheel circumference and number of polewheel |

2 |

02 |

incorrect tyre or pole wheel |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Short circuit to ground is detected. |

4 |

04 |

Short to Ground |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Cyclic drop out detected at speed higher than 10 km/h. Several wheel revolution necessary. |

7 |

07 |

incorrect pole wheel |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

16 sec. slip duration detected. |

8 |

08 |

slip |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Wire IG or IGM of another sensor is detected. |

9 |

09 |

wires mismatched |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Temporarily loss of wheel speed signal. Air gap too large, sensor voltage |

10 |

0A |

speed drop-out |

ABS: wheel disabled |

|

|

exceeds trigger level at too late. |

ASR: disabled |

|||||||

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Brake squeezes or chatters. |

11 |

0B |

abnormal speed (chatter)not stored |

ABS: partial disabled ASR: disabled with standard parameter set not as fault interpretated FMI 11 not stored |

|

|

ABS Wabco D |

40B01 |

Wheel sensor left front fault. |

Not plausible sensor frequency measured |

12 |

0C |

frequency too high |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

air gap too large, sensor output voltage too low but just exceeds trigger level |

1 |

01 |

air gap |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

such proportion of tyre diameter/ pole wheel teeth number that wheel speed difference within front axle > 10 % or difference within wheels of different axles > 19 % . Pneus or number of polewheel teeth are different. Check wheel circumference and number of polewheel |

2 |

02 |

incorrect tyre or pole wheel |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Short circuit to ground is detected. |

4 |

04 |

Short to Ground |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Cyclic drop out detected at speed higher than 10 km/h. Several wheel revolution necessary. |

7 |

07 |

incorrect pole wheel |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

16 sec. slip duration detected. |

8 |

08 |

slip |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Wire IG or IGM of another sensor is detected. |

9 |

09 |

wires mismatched |

ABS: wheel disabled |

|

|

ASR: disabled |

||||||||

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Temporarily loss of wheel speed signal. Air gap too large, sensor voltage exceeds trigger level at too late. |

10 |

0A |

speed drop-out |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Brake squeezes or chatters. |

11 |

0B |

abnormal speed (chatter)not stored |

ABS: partial disabled ASR: disabled with standard parameter set not as fault interpretated FMI 11 not stored |

|

|

ABS Wabco D |

40B02 |

Wheel sensor right front fault |

Not plausible sensor frequency measured |

12 |

0C |

frequency too high |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

air gap too large, sensor output voltage too low but just exceeds trigger level |

1 |

01 |

air gap |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

such proportion of tyre diameter/ pole wheel teeth number that wheel |

2 |

02 |

incorrect tyre or pole wheel |

ABS: wheel disabled |

|

|

speed difference within front axle > 10 % or difference within wheels of different axles > 19 % . Pneus or number of polewheel teeth are different. Check wheel circumference and number of polewheel |

ASR: disabled |

|||||||

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Short circuit to ground is detected. |

4 |

04 |

Short to Ground |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Cyclic drop out detected at speed higher than 10 km/h. Several wheel |

7 |

07 |

incorrect pole wheel |

ABS: wheel disabled |

|

|

revolution necessary. |

ASR: disabled |

|||||||

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

16 sec. slip duration detected. |

8 |

08 |

slip |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Wire IG or IGM of another sensor is detected. |

9 |

09 |

wires mismatched |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Temporarily loss of wheel speed signal. Air gap too large, sensor voltage exceeds trigger level at too late. |

10 |

0A |

speed drop-out |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Brake squeezes or chatters. |

11 |

0B |

abnormal speed (chatter)not stored |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B03 |

Wheel sensor left rear fault |

Not plausible sensor frequency measured |

12 |

0C |

frequency too high |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

air gap too large, sensor output voltage too low but just exceeds trigger |

1 |

01 |

air gap |

ABS: wheel disabled |

|

|

level |

ASR: disabled |

|||||||

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

such proportion of tyre diameter/ pole wheel teeth number that wheel speed difference within front axle > 10 % or difference within wheels of different axles > 19 % . Pneus or number of polewheel teeth are different. Check wheel circumference and number of polewheel |

2 |

02 |

incorrect tyre or pole wheel |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Short circuit to ground is detected. |

4 |

04 |

Short to Ground |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short circuit |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Cyclic drop out detected at speed higher than 10 km/h. Several wheel revolution necessary. |

7 |

07 |

incorrect pole wheel |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

16 sec. slip duration detected. |

8 |

08 |

slip |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Wire IG or IGM of another sensor is detected. |

9 |

09 |

wires mismatched |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Temporarily loss of wheel speed signal. Air gap too large, sensor voltage exceeds trigger level at too late. |

10 |

0A |

speed drop-out |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Brake squeezes or chatters. |

11 |

0B |

abnormal speed (chatter)not stored |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B04 |

Wheel sensor right rear fault |

Not plausible sensor frequency measured |

12 |

0C |

frequency too high |

ABS: wheel disabled ASR: disabled |

|

|

ABS Wabco D |

40B07 |

Modulator left front failure |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B07 |

Modulator left front failure |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled |

|

|

ABS Wabco D |

40B07 |

Modulator left front failure |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short to Ground |

ABS: wheel disabled |

|

|

ABS Wabco D |

40B08 |

Modulator right front failure |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B08 |

Modulator right front failure |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled |

|

|

ABS Wabco D |

40B08 |

Modulator right front failure |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short to Ground |

ABS: wheel disabled |

|

|

ABS Wabco D |

40B09 |

Modulator left rear failure |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B09 |

Modulator left rear failure |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled ASR: Diff brake disabled SMR: disabled EBL: wheel disabled |

|

|

ABS Wabco D |

40B09 |

Modulator left rear failure |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short to Ground |

ABS: wheel disabled ASR: Diff brake disabled SMR: disabled EBL: wheel disabled |

|

|

ABS Wabco D |

40B0A |

Modulator right rear failure |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B0A |

Modulator right rear failure |

Open circuit is detected |

5 |

05 |

open circuit |

ABS: wheel disabled ASR: Diff brake disabled SMR: disabled EBL: wheel disabled |

|

|

ABS Wabco D |

40B0A |

Modulator right rear failure |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short to Ground |

ABS: wheel disabled ASR: Diff brake disabled SMR: disabled EBL: wheel disabled |

|

|

ABS Wabco D |

40B0D |

DBR, Retarder |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Short to Battery |

DBR control disabled |

|

|

ABS Wabco D |

40B0D |

DBR, Retarder |

Open circuit is detected |

5 |

05 |

open circuit |

DBR control disabled |

|

|

ABS Wabco D |

40B0D |

DBR, Retarder |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short to Ground |

DBR control disabled |

|

|

ABS Wabco D |

40B0E |

ABS error |

Short circuit to ground is detected. |

4 |

04 |

Voltage, low voltage/open circuit |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B0E |

ABS error |

Open circuit is detected |

5 |

05 |

WL-Ground |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B0E |

ABS error |

Cyclic drop out detected at speed higher than 10 km/h. Several wheel revolution necessary. |

7 |

07 |

Valve Relay |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B0F |

ABS error |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Voltage, low voltage/open circuit |

Dif&aux output disabled ASR: Diff brake disabled |

|

ECU Name |

SPN [Hex] |

Fault Component |

Description |

FMI [DEC] |

FMI [HEX] |

FMI Description |

Lamp status |

Comment |

|

ABS Wabco D |

40B0F |

ABS error |

Short circuit to ground is detected. |

4 |

04 |

Voltage, low voltage/open circuit |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B0F |

ABS error |

Open circuit is detected |

5 |

05 |

WL-Ground |

Dif&aux output disabled ASR: Diff brake disabled |

|

|

ABS Wabco D |

40B0F |

ABS error |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Short to Ground |

||

|

ABS Wabco D |

40B0F |

ABS error |

Cyclic drop out detected at speed higher than 10 km/h. Several wheel revolution necessary. |

7 |

07 |

Valve Relay |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40B10 |

ABS error |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Voltage, low voltage/open circuit |

EBL: starts depending from deceleration |

|

|

ABS Wabco D |

40B10 |

ABS error |

Open circuit is detected |

5 |

05 |

Brake input open or shorted to ground |

EBL: starts depending from deceleration |

|

|

ABS Wabco D |

40B12 |

ABS error |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Diff. Brake Valve, shorted to UBATT |

ASR: Diff brake disabled |

|

|

ABS Wabco D |

40B12 |

ABS error |

Open circuit is detected |

5 |

05 |

Diff. Brake Valve, open circuit |

ASR: Diff brake disabled |

|

|

ABS Wabco D |

40B12 |

ABS error |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Diff. Brake Valve, shorted to ground |

ASR: Diff brake disabled |

|

|

ABS Wabco D |

40B13 |

ABS error |

DC voltage detected. Short circuit or impedance to battery voltage. |

3 |

03 |

Trailer Brake Valve, shorted to UBATT |

||

|

ABS Wabco D |

40B13 |

ABS error |

Open circuit is detected |

5 |

05 |

Trailer Brake Valve, open circuit |

||

|

ABS Wabco D |

40B13 |

ABS error |

Short circuit between sensorwires IG/IGM is detected |

6 |

06 |

Trailer Brake Valve, shorted to ground |

||

|

ABS Wabco D |

40B16 |

ABS error |

8 |

08 |

||||

|

ABS Wabco D |

40B17 |

ABS error |

Open circuit is detected |

5 |

05 |

Warning Light |

WL if grounded. Off if bumed out |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

Unplausibility between received vehicle speed and ABS vehicle speed. |

2 |

02 |

SAE J1939 VSC1 speed bad plausibility |

Supevision normally not activated |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

SAE J1939 communication impossible. SAE J1939 high open or short circuit to plus or ground or sae J1939 low or low/high are misured |

5 |

05 |

SAE J1939 open or short circuit |

ASR: disabled SMR: disabled SAE J1939 switched to inactive because communication is disturbed. |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

SAE J1939 communication impossible. SAE J1939 high open or short circuit to plus or ground or sae J1939 low or low/high are misured |

6 |

06 |

SAE J1939 no access |

ASR: disabled SMR: disabled ABS ECU tries to restart com. Within 10s it is not possible. SAE J1939 remains inactive. FMI 5 might be additionally stored. |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

Driveline integrated retarder sends message incorrecly. Timeout supervision detects faults if activated. |

7 |

07 |

SAE J1939 ERC_DR time-out |

Driveline retarder may cause instability. |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

Engine integrated retarder sends message incorrecly. Timeout supervision detects faults if activated. Standard is no timeout supervision. |

8 |

08 |

SAE J1939 ERC_ER (_EXR) time-out |

Engine retarder may cause instability. |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

Gearbox sends message incorrecly. Timeout supervision detects faults if activated. Standard is no timeout supervision. |

9 |

09 |

SAE J1939 ETC time-out |

Dragtorque control influenced. |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

Engine control sends torque message incorrectly. Timeout supervision detects fault. |

9 |

09 |

SAE J1939 EEC1 time-out |

Dragtorque control influenced. |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

Exaust integrated retarder sends message incorrecly. Timeout supervision detects faults if activated. Standard is no timeout supervision. |

10 |

0A |

SAE J 1939 ERC_EXR time-out |

Exaust retarder may cause instability. |

|

|

ABS Wabco D |

40BE7 |

ABS error.SAEJ1939 |

Internal fault |

12 |

0C |

SAE J1939, internal error |

ABS: disabled ASR: disabled SMR: disabled EBL: disabled |

|

|

ABS Wabco D |

40BFB |

ABS error. Overvoltage |

Supply voltage too high for more than 5s |

3 |

03 |

Overvoltage |

All valve disabled. No ABS, SMR, Diff Brake, EBL |

|

|

ABS Wabco D |

40BFD |

ABS error |

Wheel parameters are out of tolerance. No ABS, ASR, EBL, SM |

2 |

02 |

EEPROM, Wheel Parameter incorrect |

Wrong parameter |

|

|

ABS Wabco D |

40BFD |

ABS error |

Checksum of parameter or analog adjustment is wrong. |

12 |

0C |

EEPROM checksum |

No ABS, SMR, Diff Brake, EBL. No blink code. |

|

|

ABS Wabco D |

40BFE |

ABS error |

No modulators connected. |

5 |

05 |

Electronic w/o loads |

Normal for EOL testing of single cabin. Fault not memorized. No ABS, SMR, ASR, EBL. |

|

|

ABS Wabco D |

40BFE |

ABS error |

One axle was much faster than other. |

8 |

08 |

excessive slip/dynotester |

On rolling roads responce dynotester slip supervision time can be exceeded when fault detection is not disabled by diagnostic tools or blinkcode (3s). |

|

|

ABS Wabco D |

40BFE |

ABS error |

Control via modulator was too long. After a delay time function is normal. |

9 |

09 |

Modulator valve activation time |

75% 0f 5min modulator was activated. No ASR during fault activeness. |

|

|

ABS Wabco D |

40BFE |

ABS error |

Internal error |

12 |

0C |

Multiple possibilities |

Yellow |

No ABS, SMR, Diff Brake, EBL. No blink code. |

|

BC IBC2 |

22101 |

EEPROM checksum error |

12 |

0C |

||||

|

BC IBC2 |

22102 |

ECU Overheating |

The junction Temperature of the output drivers is greater than max. junction temperature(150°C). |

12 |

0C |

|||

|

BC IBC2 |

22103 |

Supply Line 1 |

The acquired voltage is below or above the thresholds.The error shall be |

00 |

00 |

32V<V<36V |

||

|

debounced. |

01 03 04 |

01 03 04 |

8V<V<18V V>36V V<8V |

|||||

|

BC IBC2 |

22104 |

Supply Line 2 |

The acquired voltage is below or above the thresholds.The error shall be debounced. |

00 01 03 04 |

00 01 03 04 |

32V<V<36V 8V<V<18V V>36V V<8V |

||

|

BC IBC2 |

22105 |

Supply Line 3 |

The acquired voltage is below or above the thresholds.The error shall be debounced. |

00 01 03 04 |

00 01 03 04 |

32V<V<36V 8V<V<18V V>36V V<8V |

||

|

BC IBC2 |

22106 |

Supply Line 4 |

The acquired voltage is below or above the thresholds.The error shall be |

00 |

00 |

32V<V<36V |

||

|

debounced. |

01 03 04 |

01 03 04 |

8V<V<18V V>36V V<8V |

|||||

|

BC IBC2 |

22107 |

Supply Line 5 |

The acquired voltage is below or above the thresholds.The error shall be debounced. |

00 01 03 04 |

00 01 03 04 |

32V<V<36V 8V<V<18V V>36V V<8V |

||

|

BC IBC2 |

22108 |

Turn Lights Right |

The acquired load current is below the threshold (at least a load on three is a open circuit) |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

22109 |

Turn Lights Trailer Right |

On/Off diagnostic.The test is performed only when the driver is Off.The error is detected only when at open circuit. |

5 |

05 |

|||

|

BC IBC2 |

2210A |

Turn Lights Right or |

Driver Short Circuit to ground or Overload or Overheating protection.The |

6 |

06 |

|||

|

Turn Lights Trailer Right |

test is performed only when the driver is On. |

|||||||

|

BC IBC2 |

2210B |

Turn Lights Left |

The acquired load current is below the threshold (at least a load on three is a open circuit) |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

2210C |

Turn Lights Trailer Left |

On/Off diagnostic.The test is performed only when the driver is Off.The error is detected only when at open circuit. |

5 |

05 |

|||

|

BC IBC2 |

2210D |

Turn Lights Left or Turn Lights Trailer Left |

Driver Short Circuit to ground or Overload or Overheating protection.The test is performed only when the driver is On. |

6 |

06 |

|||

|

BC IBC2 |

2210E |

Parking Left &Marker Right Front Lights |

The acquired load current is below the threshold (at least a load on two is a open circuit). |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

2210F |

Parking Rear Right Lights |

The acquired load current is below the threshold (at least a load on two is a open circuit). |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

22110 |

License Plate Lights |

The acquired load current is below the threshold (at least a load on two is a open circuit). |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

22111 |

Parking Left & Marker Right Front Lights OR Parking Rear Right Lights OR License Plate Lights OR Trailer Lights |

Driver Short Circuit to ground or Overload or Overheating protection.The test is performed only when the driver is On. |

6 |

06 |

|||

|

BC IBC2 |

22112 |

Parking Right & Marker Left Front Lights |

The acquired load current is below the threshold (at least a load on two is a open circuit). |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

22113 |

Parking Rear Left Lights |

The acquired load current is below the threshold (at least a load on two is a open circuit). |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

22114 |

Marker Rear Lights |

The acquired load current is below the threshold (at least a load on two is |

5 |

05 |

I< IS |

||

|

a open circuit). |

(Is follows the I to V linear characteristic of the lamps) |

|||||||

|

BC IBC2 |

22115 |

Parking Right & Marker Left Front Lights OR Parking Rear Left Lights OR Marker Rear Lights OR Parking & Marker Trailer & Side Marker Left Lights |

Driver Short Circuit to ground or Overload or Overheating protection.The test is performed only when the driver is On. |

6 |

06 |

|||

|

BC IBC2 |

22116 |

Rear Fog Left & Right Lights |

The acquired load current is below the threshold (at least a load on two is a open circuit) |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

22117 |

Rear Fog Left&Right Lights OR Rear Fog Trailer Left&Right Lights |

Driver Short Circuit to ground or Overload or Overheating protection.The test is performed only when the driver is On. |

6 |

06 |

|||

|

BC IBC2 |

22118 |

Stop Light Left |

The acquired load current is below the threshold (the only load is a open circuit). |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

22119 |

Stop Light Right |

The acquired load current is below the threshold (the only load is a open circuit). |

5 |

05 |

I< IS (Is follows the I to V linear characteristic of the lamps) |

||

|

BC IBC2 |

2211A |

Stop Light Left or Stop Light Right or Stop Trailer Left&Right Lights |

Driver Short Circuit to ground or Overload or Overheating protection.The test is performed only when the driver is On. |

6 |

06 |

|||

|

BC IBC2 |

2211B |

Turn Lights Switches |

Turn Left and Turn Right Switchesare both activated.The Turn Left Lights Status and Turn Right Lights Status CAN parameters are ON but the Emergency Lights Status CAN parameter is OFF. |

2 |

02 |

|||

|

BC IBC2 |

2211C |

Windshield Wiper |

Windshield Wiper switches activated at the same time or every faulty on Windshield Wiper (fuse on supply line 6 faulty, engine blocked or short circuited, engine interrupted, cam always to ground, cam always open) |

2 |

02 |

|||

|

BC IBC2 |

2211D |

Engine Brake Preselection Mode Switches |

Engine Brake Mode Accelerator Idle and Engine Brake Mode Brake Pedal Switches are both activated. |

2 |

02 |

|||

|

BC IBC2 |

2211E |

Diff.Rear.Transv.Lock Rockwell Switches |

Diff.Rear Transv.Lock Rock.Switch2(Rear axle 1) andDiff.Rear Transv.Lock Rock.Switch1(Rear axle 1) are both activated. |

2 |

02 |

|||

|

BC IBC2 |

2211F |

Brake Front Air Pressure Sensor |

The acquired voltage is below or above the thresholds(see Figure 8). The error is detected only if there are no errors on the supply voltage of the sensor (Vc). (Vout/Vc)=0.08+0.04*(Bar+1) Vout ->output voltage of the sensor; Vc -> supply voltage of the sensor: Bar -> relative to atmospheric pressure |

00 01 03 04 |

00 01 03 04 |

0.6V<(Vout/Vc)<1V 0.14V<(Vout/Vc)< 0.38V Vout/Vc>1V Vout/Vc<0.14V |

||

|

BC IBC2 |

22120 |

Brake Rear Air Pressure Sensor |

The acquired voltage is below or above the thresholds(see Figure 8). |

00 |

00 |

0.6V<(Vout/Vc)<1V |

||

|

The error is detected only if there are no errors on the supply voltage of the sensor (Vc). (Vout/Vc)=0.08+0.04*(Bar+1) Vout ->output voltage of the sensor; Vc -> supply voltage of the sensor: Bar -> relative to atmospheric pressure |

01 03 04 |

01 03 04 |

0.14V<(Vout/Vc)< 0.38V Vout/Vc>1V Vout/Vc<0.14V |

|

ECU Name |

SPN [Hex] |

Fault Component |

Description |

FMI [DEC] |

FMI [HEX] |

FMI Description |

Lamp status |

Comment |

|

BC IBC2 |

2212B |

Brake Air Pressure Sensor Supply (Vc) |

The acquired supply voltage is below or above the thresholds. |

00 01 03 04 |

00 01 03 04 |

6V<V<8V 2V<V<4V V>8V V<2V |

||

|

BC IBC2 |

2212C |

Vehicle data bus CAN |

No CAN messages on Vehicle data bus or Bus-Off detection.The error can be read on CAN only if the CAN bus resets |

2 |

02 |

|||

|

BC IBC2 |

2212D |

ECU not programmed |

31 |

1F |

||||

|

BC IBC2 |

22130 |

Engine Starter |

03 04 |

03 04 |

Voltage Above Normal, Or Shorted To High Source Voltage Below Normal, Or Shorted To Low Source |

|||

|

BC IBC2 |

22131 |

Cabin Side White Lights (only if on pin E03) |

03 04 |

03 04 |

Voltage Above Normal, Or Shorted To High Source Voltage Below Normal, Or Shorted To Low Source |

|||

|

BC IBC3 |

22100 |

ECU not programmed |

31 |

1F |

Yellow |

|||

|

BC IBC3 |

22101 |

EEPROM checksum error |

12 |

0C |

Yellow |

|||

|

BC IBC3 |

22102 |

ECU Overheating |

The PCB ECU Temperature of the output drivers is greater than max. allowed temperature (100°C). |

13 |

0D |

Yellow |

||

|

BC IBC3 |

22103 |

ECU Secondary Microprocessor Faulty |

The secondary microprocessor that executes the limp-home function is faulty |

14 |

0E |

Yellow |

||

|

BC IBC3 |

2210B |

Vehicle Data Bus CAN |

No CAN messages on Vehicle data bus or Bus-Off detection. The error can be read on VDB CAN only if the VDB CAN bus resets |

2 |

02 |

Red |

||

|

BC IBC3 |

2210C |

Body Control Bus CAN |

No CAN messages on Body control bus or Bus-Off detection. The error can be read on BCB CAN also if the BCB CAN bus is not reset |

2 |

02 |

Red |

||

|

BC IBC3 |

231FF |

Body Control Bus — ECU#1 CAN |

No CAN messages from ECU#1 — Bed Module |

2 |

02 |

Yellow |

||

|

BC IBC3 |

2ECFF |

Body Control Bus — ECU#2 CAN |

No CAN messages from ECU#2 — Driver Door Module |

2 |

02 |

Yellow |

||

|

BC IBC3 |

2EDFF |

Body Control Bus — ECU#3 CAN |

No CAN messages from ECU#3 — Co-Driver Door Module |

2 |

02 |

Yellow |

||

|

BC IBC3 |

245FF |

Body Control Bus — ECU#4 CAN |

No CAN messages from ECU#4 — Additional Heater Air |

2 |

02 |

Yellow |

||

|

BC IBC3 |

244FF |

Body Control Bus — ECU#5 CAN |

No CAN messages from ECU#5 — Additional Heater Water |

2 |

02 |

Yellow |

||

|

BC IBC3 |

2E9FF |

Body Control Bus — ECU#6 CAN |

No CAN messages from ECU#6 — Mirror Controller |

2 |

02 |

Yellow |

||

|

BC IBC3 |

26DFF |

Body Control Bus — ECU#7 CAN |

No CAN messages from ECU#7 — MET |

2 |

02 |

Red |

||

|

BC IBC3 |

219FF |

Body Control Bus — ECU#8 CAN |

No CAN messages from ECU#8 — Climate Control |

2 |

02 |

Yellow |

||

|

BC IBC3 |

22120 |

Fuel Level Interface |

Fuel Level interface failure detected. The input voltage is evaluated for in-range checking: |

00 01 |

00 01 |

00:Delta voltage below normal 01:Delta voltage above normal |

Yellow |

|

|

BC IBC3 |

22121 |

Engine Oil Level Interface |

Oil Level interface failure detected. The voltage difference between the first and the second acquisition are evaluated for in-range checking: |

00 01 0F 10 12 13 14 |

00 01 15 10 12 13 14 |

00:Delta voltage below normal 01:Delta voltage above normal 0F:Time/Date from TCO not available 10:Engine Starter Mode or Engine Speed from EDC not available 12:Date could not be stored in EEPROM 13:Time could not be stored in EEPROM 14:Oil Level could not be stored in EEPROM |

Yellow |

|

|

BC IBC3 |

22122 |

Ambient Air Temperature Interface |

Ambient Air Temperature interface failure detected. The input voltage is evaluated for in-range checking: |

03 04 |

03 04 |

03:Voltage above normal (s.c. to battery or open circuit) 04:Voltage below normal (s.c. to ground) |

Yellow |

|

|

BC IBC3 |

22130 |

Windshield Wiper Switches |

Windshield Wiper switches activated at the same time or every faulty on Windshield Wiper (engine blocked or short circuited, engine interrupted, cam always to ground, cam always open) |

2 |

02 |

Yellow |

||

|

BC IBC3 |

22131 |

Diff.Lock.State. Rear Axle1(Rockwell) Switches |

Diff.Lock.State. Rear Axle1-In1 and Diff. Lock State Rear Axle1-In2, are both activated |

2 |

02 |

Yellow |

||

|

BC IBC3 |

22140 |

Service Brake Air Pressure Circuit#2 sensor (Front) |

Service Brake Air Pressure Circuit#2 interface failure detected. |

03 04 |

03 04 |

03:Voltage above normal (s.c. to battery or open circuit) 04:Voltage below normal (s.c. to ground) |

Yellow |

|

|

BC IBC3 |

22141 |

Service Brake Air Pressure Circuit#1 sensor (Rear) |

Service Brake Air Pressure Circuit#1 interface failure detected. |

03 05 |

03 05 |

4:Voltage above normal (s.c. to battery or open circuit) 04:Voltage below normal (s.c. to ground) |

Yellow |

|

|

BC IBC3 |

22142 |

Service Brake Air Pressure Circuit#2 sensor (Front) |

The pressure charging is evaluated for in-range checking |

00 01 |

00 01 |

00:Delta voltage below normal 01:Delta voltage above normal |

Red |

|

|

BC IBC3 |

22143 |

Service Brake Air Pressure Circuit#1 sensor (Rear) |

The pressure charging is evaluated for in-range checking |

00 01 |

00 01 |

00:Delta voltage below normal 01:Delta voltage above normal |

Red |

|

|

BC IBC3 |

22144 |

Service Brake Air Pressure Sensor Supply Voltage (Vs) |

Service Brake Air Pressure Sensor Supply Voltage failure detected. The error is detected only when the maximum supply voltage is between 18V and 32V and Ignition Key 15 is On. |

00 01 03 04 |

00 01 03 04 |

00: 6V<V<8V 01: 2V<V<4V 03: V>8V 04: V<2V |

Yellow |

|

|

BC IBC3 |

22145 |

Brake Air Dryer |

Pressure plausability: |

01 00 02 |

01 00 02 |

01:The pressure is not increasing while charge mode 00:The pressure is not decreasing while rigeneration mode 02:Duty error (air loss because the S2 valve is locked) |

Yellow |

|

|

BC IBC3 |

22150 |

Dashboard Backlight & Headbeam Washer Supply & Body Builders Parking Lights |

On/Off Diagnostic: |

6 |

06 |

06:Short circuit to ground or Overload or Overheating protection. |

Yellow |

|

|

BC IBC3 |

22161 |

Marker Front Left & Right Lights |

Analog Diagnostic: The acquired load current is below the threshold (at least a load on two is a open circuit). The error is detected only when the relative supply voltage is between 18V and 32V. The Marker Front Left & Right Lights fault shall be recognized, stored and reported on DM1 message with a maximum delay of 10sec. |

5 |

05 |

05: I < IS |

Yellow |

|

|

BC IBC3 |

22166 |

Additional Lights or Additional Air Heater Disable |

On/Off Diagnostic: |

03 06 |

03 06 |

03:Short circuit to battery 06:Short circuit to ground or Overload or Overheating protection |

Yellow |

|

|

BC IBC3 |

22163 |

Step Lights |

Analog Diagnostic: The acquired load current is below the threshold (at least a load on two is a open circuit). The error is detected only when the relative supply voltage is between 18V and 32V. The Step Lights fault shall be recognized, stored and reported on DM1 message with a maximum delay of 10sec. |

5 |

05 |

05: I < IS |

Yellow |

|

|

BC IBC3 |

22164 |

Cabin Side Lights |

On/Off Diagnostic: |

03 06 |

03 06 |

03:Short circuit to battery 06:Short circuit to ground or Overload or Overheating protection |

Yellow |

|

|

BC IBC3 |

22165 |

Cabin Ceiling Lights |

Analog Diagnostic: The acquired load current is below the threshold (at least a load on two is a open circuit). The error is detected only when the relative supply voltage is between 18V and 32V. The Cabin Ceiling Lights fault shall be recognized, stored and reported on DM1 message with a maximum delay of 10sec. |

5 |

05 |

05: I < IS |

Yellow |

|

|

BC IBC3 |

22180 |

30A |

On/Off Diagnostic: |

4 |

04 |

Voltage below normal |

Yellow |

|

|

BC IBC3 |

22181 |

30B |

On/Off Diagnostic: |

4 |

04 |