- Page 1

Cash Media Dispenser Version 4 Service Manual… - Page 2

? Please contact the following address giving the order number of this manual in your message : Address : Wincor Nixdorf International GmbH Handbuchredaktion BD P34 33094 Paderborn Germany Fax: +49 (0) 52 51 693-62 09 manuals.hardware@wincor-nixdorf.com… - Page 3

Cash Media Dispenser Version 4 Service Manual Edition April 2003… - Page 4

Copyright © Information and trademarks © Wincor Nixdorf International GmbH 2003 All rights, including rights of translation and rights of reproduction by reprinting, copying or similar methods, even of parts, are reserved. Any violations give rise to a claim for… - Page 5

Contents..………………..……………..Introduction……..…..(Safety precautions, technical data) Function and Integration……….Device Overview and Operation……..Getting Started…………..Troubleshooting…..………..Removal / Installation of Components.. Maintenance and Service……. Pin Assignments……………..Spare Parts………………….. Index….…………………………. 01750060162 A Cash Media Dispenser Version 4 — Service Manual… - Page 6

Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 7: Table Of Contents

Contents Introduction ………………..1-1 Symbols used in this manual…………….1-1 Important safety precautions …………….1-2 General power interrupt……………… 1-4 Description of the device …………….1-5 Structure of the manual ……………… 1-7 Outline………………….. 1-7 Supplementary documentation …………..1-8 Technical data ………………..1-9 Cash media dispenser without output transport……..

- Page 8

Horizontal output transport …………… 2-1 Vertical output transport…………….2-2 Stacker and output transport …………..2-3 Components of dispensing unit and cassette ……….. 2-4 Procedures in the CMD-V4 (schematic)…………2-5 Dispensing in customer direction (vertical, frontload) ……. 2-6 Bundle reject………………… 2-7 Single reject ………………..2-8 Bundle retract when notes are not removed……….. - Page 9

Contents Control block ………………. 2-27 CPU ………………..2-28 Memory………………..2-28 Serial interface………………. 2-28 Status display ………………2-28 Function button……………… 2-28 Photosensor electronics…………….2-29 Measuring banknotes with the double detection unit (DDU)….2-30 Component control……………… 2-31 Dispensing unit control …………..2-31 Cassette control…………….. - Page 10

Checking the vertical transport …………… 5-23 Checking the dispensing areas…………… 5-24 Checking the stacker and output transport ……….5-25 Removal/Installation of Components…………6-1 Pulling out / pushing in the CMD-V4 ………….. 6-1 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… - Page 11

Contents CMD controller ………………..6-2 Stacker ………………….6-3 Horizontal output transport …………….6-5 Ouput transport ProCash 2000xe RL …………. 6-6 Output transport ProCash 2050xe…………..6-7 Ouput transport ProCash 2100xe RL …………. 6-8 Shutter ProCash 2000xe RL …………….6-9 Shutter ProCash 2050xe RL ……………. 6-10 Shutter ProCash 2100xe RL ……………. - Page 12

Contents Connection of door switch…………….8-17 Battery connector………………8-17 RS232C connection ………………8-18 CMD controller ………………… 8-19 4-channel distributor board…………….8-39 Spare Parts ………………..9-1 Overview of individual parts …………….9-1 Index………………….. I-1 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 13: Introduction

Introduction This service manual has been compiled for authorized service personnel only. The operating manual, the installation guide and the service manual of the basic device should also be read since certain details are only described in those manuals. Symbols used in this manual −…

-

Page 14: Important Safety Precautions

Important safety precautions Introduction Important safety precautions Please read the following notes carefully before doing any work on the device. This device complies with the relevant safety regulations for information processing equipment and is designed for use in a regular office environment. −…

-

Page 15: A Cash Media Dispenser Version 4 — Service Manual

(e.g. connection for an intruder alarm system). − To clean the device only use cleaning agents approved by Wincor Nixdorf International GmbH (see chapter «Maintenance and Service»).

-

Page 16: General Power Interrupt

– media dispenser. They will be transported to the reject/retract cassette of the CMD-V4 or they remain in the collecting position of the clamp after the device has been turned on again. Cash Media Dispenser Version 4 — Service Manual…

-

Page 17: Description Of The Device

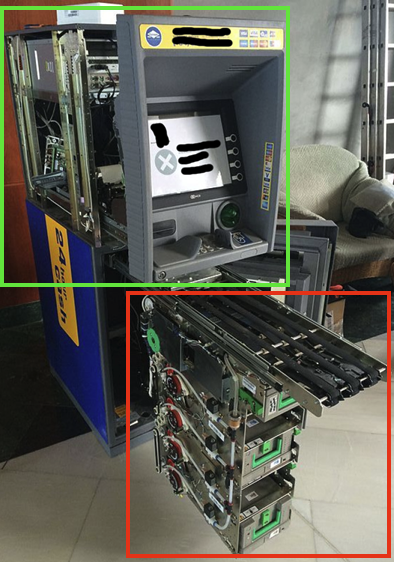

Function and use The most important components in an automated teller machine is the Cash Media Dispenser (CMD-V4). The CMD-V4 replaces the AZM-NG. The CMD-V4 and the AZM-NG are software-compatible but not hardware-compatible. CMD cassettes are basically upward- and downward-compatible with some restrictions.

- Page 18

Description of the device Introduction The CMD-V4 can be tailored to the user’s specific requirements thanks to model variants (frontload/rearload) and a variable number of dispensing units in the various housings. The CMD-V4 can consist of the following components, depending on the configuration: −… -

Page 19: Structure Of The Manual

The chapter «Introduction» describes the important safety precautions. It also gives an overview of the Cash Media Dispenser Version 4 (CMD-V4). The features of the CMD-V4 are also described in the chapter «Introduction» in the section «Technical data”. In the chapter «Function and Integration» you will find a description of the individual components of the cash media dispenser.

-

Page 20: Supplementary Documentation

For the operation and installation of the basic devices, separate manuals are available in several languages which also include a short description of the CMD-V4. These manuals can be ordered from our print partner. They are also available in the intranet.

-

Page 21: Technical Data

Introduction Technical data Technical data Cash media dispenser without output transport Power supply: 5.5 A operation 11 A peak (approx. 20 ms) Dimensions: The overall dimensions depend on the actual configuration of the CMD- Height Four cassettes: 758 mm Five cassettes: 895.5 mm Six cassettes: 1033 mm…

-

Page 22: Stacker

Technical data Introduction Stacker Dimensions Depth: 505 mm Width: 301 mm Height: 208 mm Weight with single reject: 8.820 kg without single reject: 8.500 kg Output transport Vertical output transport Frontload in ProCash 2000xe and ProCash 2100xe Dimensions Depth: 400 mm Width: 200 mm Height:…

- Page 23

Introduction Technical data Horizontal output transport Frontload 101 mm in ProCash 1500xe and ProCash BBA mini 3K Dimensions Depth: 130 mm Width: 200 mm Height: 50 mm Weight: 1 kg Horizontal output transport Frontload 241 mm in ProCash 2350xe and ProCash BBA UT Dimensions Depth:… -

Page 24: Shutter

Technical data Introduction Shutter Dimensions Shutter vertical Rearload and vertical Frontload Depth: 310 mm Width: 150 mm Height: 100 mm Weight: 0.5 kg Dimensions Shutter horizontal Rearload Depth: 305 mm Width: 126 mm Height: 67 mm Weight: 0.9 kg Dimensions Shutter horizontal Frontload Depth: 310 mm…

-

Page 25: Cmd Controller

Introduction Technical data CMD controller Processor: 80C188XL 20 MHz Memory: 512 Kbyte static RAM 512 Kbyte Flash-PROM (PUT, bootloader) Interface: V.24 (RS232), USB interface in preparation Transmission parameters Line speed: 19.2 / 56 KBaud automatic baud rate recognition Data format: Parity: Code width: 8 Bit + Parity…

-

Page 26: 4-Cassette Housing (Without Contents)

Technical data Introduction 4-cassette housing (without contents) Dimensions Depth: 450 mm Width: 305 mm Height: 600 mm Weight: 10.9 kg 1-cassette housing (without contents) Dimensions Depth: 450 mm Width: 305 mm Height: 162 mm Weight: 3.34 kg Double dispensing unit without DDU Dimensions Depth: 282 mm…

-

Page 27: Double Dispensing Unit With Ddu

Introduction Technical data Double dispensing unit with DDU Dimensions Depth: 282 mm Width: 305 mm Height: 200 mm Weight: 3.34 kg Single dispensing unit without DDU Dimensions Depth: Still open Width: Still open Height: Still open Weight: Still open Single dispensing unit with DDU Dimensions Depth: Still open…

-

Page 28: Reject / Retract Cassettes

Technical data Introduction Reject / retract cassettes Capacity Reject compartment: max. 400 notes Retract compartment: max. 100 notes Dimensions Depth: 250 mm Width: 100 mm Height: 100 mm Weight: 1.5 kg Cash-out cassettes Banknote dimensions Size: 54 x 85 mm to 92 x 182 mm Thickness: 0.08 mm to 0.12 mm Filling capacity:…

-

Page 29: Environmental Conditions

Introduction Technical data Environmental conditions Climatic environmental conditions in accordance with EN 60721 Class Ambient temperature Relative humidity °C % r.h. Operation + 5 to + 55* 5 to 85 Transport — 25 to + 70 10 to 95 (12 hours flying time) (12 hours flying time) Storage + 5 to + 40…

-

Page 30: Compliance With Standards And Certifications

− EMC Directive 89/336/EEC including the amending directive 93/68/EEC − Low Voltage Directive 73/23/EEC including the amending directive 93/68/EEC The corresponding statement of compliance has been issued by Wincor Nixdorf International GmbH Heinz-Nixdorf-Ring 1 33106 Paderborn Germany Notes concerning radio interference suppression and electrical safety…

- Page 31

Introduction Technical data FCC rules and Canadian Standard ICES — 003 NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules and Canadian Standard ICES — 003. -

Page 32: Environmental Protection

Environmental protection Introduction Environmental protection Environmentally friendly product design and development This product has been designed according to our corporate standard ‘Environmentally friendly product design and development’. This means that crucial criteria such as long life, choice of material and its labeling, emissions, packaging, ease of disassembly and recyclability have been taken into account.

-

Page 33: Returning, Recycling And Disposing Of Used Units And Consumables

Introduction Environmental protection Returning, recycling and disposing of used units and consumables Details regarding the return and recycling of used units and consumables can be obtained from your local branch office or from our Recycling Center in Paderborn: Tel.: +49 (0) 5251 8-1 80 10 Fax.: +49 (0) 5251 8-1 80 15 Further information…

-

Page 34: Abbreviations

Abbreviations Introduction Abbreviations ASCII American Standard Code for Information Interchange Communauté Européenne (European Community) Declaration of Conformity Comité Européen de Normalisation (European Committee for Standardization) Clutch Cash media dispenser CMOS Complementary metal oxide semiconductor Central processing unit Direct current motor Double detection unit Data Encryption Standard German Institute for Standardization…

- Page 35

Introduction Abbreviations Programmable logic device PROM Programmable read only memory Photosensor Photosensor Dispense (dispensing sensor) Photosensor Empty (cassette empty) Random access memory Rearload Switch Stacker and output transport SCOP Security cash out procedure Stepper motor Connector Motor Cassette Connector Software Timing disk Underwriters Laboratories 1-23… - Page 36

Abbreviations Introduction 1-24 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 37: Function And Integration

Function and Integration Sensors and electromechanical components Horizontal output transport SM2,3 DPS5,6 DPS5,6 DPS8,9 DPS2 DCM1 DPS14 DCM7 DPS15 DPS4 DPS7 PS18 DCM2,3 MA2/2 MA2/1 PSE1 MAC1 SMC1 PSD1 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

-

Page 38: Vertical Output Transport

Sensors and electromechanical components Function and Integration Vertical output transport DPS10 DPS11 PS27 PS28 SM2,3 DPS5,6 DPS5,6 DPS8,9 DPS2 DCM1 DPS14 DPS15 DPS4 DPS7 PS18 DCM2,3 MA2/2 MA2/1 PSE1 MAC1 SMC1 PSD1 Cash Media Dispenser Version 4 — Service Manual 01750060162 A…

-

Page 39: Stacker And Output Transport

Function and Integration Sensors and electromechanical components Stacker and output transport Compo- Designation Location nent Permanent magnets (2 units) – without sensors Clamp DPS 2 Stacker wheel position query Stacker wheel input DPS 4 Sensor: position of retract compartment Reject / retract box DPS 5 Sensor: home position Routing disk drive, left…

-

Page 40: Components Of Dispensing Unit And Cassette

Sensors and electromechanical components Function and Integration Compo- Designation Location nent MA 6 Magnet for retract comportment Reject box SW 1 Reject / retract box pushed in Reject box SM 1 Pressure on sliding surface for emptying Single reject SM 2 Routing disk motor Routing disk drive, left SM 3…

-

Page 41: Procedures In The Cmd-V4 (Schematic)

Procedures in the CMD-V4 (schematic) The following sections show and describe the most important procedures in the CMD-V4 step by step on the basis of this schematic drawing of the CMD- V4 with a vertical output transport (frontload). 1 Shutter…

-

Page 42: Dispensing In Customer Direction (Vertical, Frontload)

Procedures in the CMD-V4 (schematic) Function and Integration Dispensing in customer direction (vertical, frontload) 1. The required number of notes are dispensed successively from each cassette (total of max. 60) (k) 2. The individual notes are moved to the thickness measuring station (i) 3.

-

Page 43: Bundle Reject

Function and Integration Procedures in the CMD-V4 (schematic) Bundle reject 1. — 4. The procedure is the same as for dispensing in customer direction (vertical, frontload). 5. The routing disk moves to the reject/retract position (d). 6. The bundle of notes is transported to the reject compartment of the reject/ retract cassette (g).

-

Page 44: Single Reject

Procedures in the CMD-V4 (schematic) Function and Integration Single reject 1. — 3. The procedure is the same as for dispensing in customer direction (vertical, frontload). 3.1 If a bad note is detected it is rejected via the single reject switch (l) and placed in the single reject compartment (m).

- Page 45

Function and Integration Procedures in the CMD-V4 (schematic) 12. Bad notes are taken from the single reject compartment (m) via the stacker wheel (j) and placed in the stacking position of the clamp (e). 13. The routing disk moves to the reject/retract position (d). -

Page 46: Bundle Retract When Notes Are Not Removed

Procedures in the CMD-V4 (schematic) Function and Integration Bundle retract when notes are not removed 1. — 8. The procedure is the same as for dispensing in customer direction (vertical, frontload). 9. The notes are not removed within the defined time! 10.

-

Page 47: Procedures In The Cmd-V4

Procedures in the CMD-V4 Start-up behavior With a reset or after power-up it is checked whether the CMD-V4 is ready to operate. This is only the case if the command is executed without errors! After device reset, the CMD-V4 is in a defined status.

-

Page 48: Determination Of The Device Type

Procedures in the CMD-V4 Function and Integration Determination of the device type The device type is determined automatically via the components that are connected to the controller board (number of dispensing units, shutter present (yes/no), output direction). Checking the cassettes First of all, the type and quantity of cassettes which are physically available is determined.

-

Page 49: Checking Mechanical And Electronic Components

Function and Integration Procedures in the CMD-V4 Checking mechanical and electronic components Individual components are checked. The following errors may occur: <21> Thickness measuring station defective (DDU) <23> Routing disk defective / blocked (SM 2 / SM 3) <24> Reject / retract drive defective / blocked (MA 6) <25>…

-

Page 50: Dispensing

Procedures in the CMD-V4 Function and Integration Dispensing Checking the basic state A check is run to determine whether: − The transport paths are free. − All required cassette positions are ready for operation and logged on. The number of notes required via the system interface is dispensed from each cassette.

-

Page 51: Undefined Notes

<3x> (too many bundle rejects from cassette x). Dispensing of notes not possible If the CMD-V4 cannot separate a single note, the dispensing process is again initiated. The attempt to dispense is repeated a maximum of five times. The command is then cancelled by the CMD-V4 with the status display <4x>…

-

Page 52: Transport

Procedures in the CMD-V4 Function and Integration Transport The transport functions output notes that have been dispensed or places them in the reject/retract cassette. The term ‘transport’ covers the following functions: − Transport to waiting position − Bundle reject − Cash presentation (incl. waiting for removal) −…

-

Page 53: Cash Presentation (Incl. Waiting For Removal), Cash Output

Function and Integration Procedures in the CMD-V4 Cash presentation (incl. waiting for removal), cash output Before cash is actually transported, the shutter, if present, is opened. Then the notes that have been provided in the waiting position are presented to the customer.

-

Page 54: Retracting Cash Without Storing It

The flag remains set even in the event of a power failure; it is not reset if the device is reset. When the bundle of notes has been removed, the device lock has to be cancelled in order to be able to continue using the CMD-V4. 2-18…

-

Page 55: Cassette Handling

EUR. − Issue date The banknote issue date contains an additional 4-character indicator (YYMM of the issue). This means that the CMD-V4 can process notes which have the same face value but different note characteristics. − Denomination This value defines the note’s denomination (8 characters).

-

Page 56: Cmd Controller

CMD-V4. Data is transferred between the system unit and the CMD-V4 via an RS232 interface. The transfer parameters are identified automatically. The sequencer receives control commands from the higher-level system unit via the RS232C interface, acknowledges them and executes them.

- Page 57

2 24 V connection to SCOP card The figure above shows the component side of the CMD controller. The CMD controller controls all procedures in the CMD-V4 and communication with the higher-level system unit. The following functions have been integrated in the CMD controller: −… -

Page 58: Position Of Function Groups

CMD controller Function and Integration The CMD controller is split up into the following function blocks: − Control block − I/O block with motor control − Photosensor electronics − Thickness sensor electronics − Component control − Serial interface The SCOP can optionally be connected to the CMD controller. It is used to authenticate the dispensing job.

-

Page 59: Connectors On The Cmd Controller

Function and Integration CMD controller Connectors on the CMD controller Connec- Description Mechanical thickness sensor Shutter Transport module V.24 interface from PC Door switch and safety switch in safe V.24 interface SCOP card (AVT2800) Special electronics 24 V power supply 24 V connection to SCOP card (AVT2800) Motor M1 2-23…

-

Page 60: Logical Interface

The pin assignments are described in the «Pin Assignment» chapter. Logical interface All commands from the host system to the CMD-V4 and responses from the CMD-V4 to the host system follow the master/slave principle. This means that the CMD-V4 does not send any spontaneous messages.

-

Page 61: Command From Host System

Meaning Device identifier (dispenser) (ASCII) Command specification (ASCII) Additional specification for command(ASCII) XX … XX Any data (ASCII / HEXA) Acknowledgement by the CMD-V4 Length Contents Meaning Device identifier (dispenser) (ASCII) Command specification (ASCII) Additional specification for command(ASCII) Status code (ASCII) XX …

- Page 62

CMD controller Function and Integration Transport: Shutter test Transport: Target = stop over DDblank Cancel Component status Device status Properties Read firmware configuration Read SCOP status Confirm number of banknotes Confirm number of banknotes (without error) Confirm existing cassettes Note parameters II Write firmware configuration Cassette ID (standard) Set minimum quantity… -

Page 63: Control Block

Function and Integration CMD controller Software transfer: Activate booter Software transfer: Data Software transfer: Firmware hash Software transfer: Read firmware ID Software transfer: Read EEPROM (booter) Software transfer: Write EEPROM (booter) Set the real-time clock Read the real-time clock Read error statistics Delete error statistics Internal commands: Read error information Internal commands: Read EEPROM…

-

Page 64: Cpu

Refer to the «Troubleshooting» chapter for the meaning of the status codes. Function button In some cases it is advisable to check whether the CMD-V4 is ready for operation without using additional tools. For this purpose there is a function button on the controller – beneath the status display.

-

Page 65: Photosensor Electronics

(current and amplification). These parameters are constantly readjusted during operation. The photosensor parameters are stored in a table in CMOS and are not lost when the CMD-V4 is turned off. Upon initial start-up or after clearing of the photosensor CMOS area, initialization takes place automatically when the device is turned on.

-

Page 66: Measuring Banknotes With The Double Detection Unit (Ddu)

Measuring banknotes with the double detection unit (DDU) The DDU in the CMD-V4 is located in the upper dispensing unit. During transport, dispensed notes displace two touch levers with in-built magnets. The Hall sensors opposite them then generate a signal that corresponds to the note thickness.

-

Page 67: Component Control

For the basic version of the CMD-V4 with two double dispensing units in the 4- cassette housing, the drivers for the dispensing clutches, retaining springs and cassette stepper motors are located on the 4-channel distributor board.

- Page 68

CMD controller Function and Integration Shutter module control A shutter module can be attached to the controller as an option. Control of the shutter has been integrated in the CMD controller. It consists of the following parts: − Shutter motor driver −… -

Page 69: Stacker Transport

Function and Integration Stacker transport Stacker transport The stacker transport facility, with its retract function, is located in the upper rack. It can cope with all output variants. The variant is determined exclusively by the output transport facility. The single reject function is available outside EU countries.

- Page 70

Stacker transport Function and Integration the clamp with the aid of the in-built belts which are controlled via their own drive motor on the clamp. If a bundle is not removed in time the retract function will transport it from the customer output position to the retract compartment of the reject/retract cassette. -

Page 71: Stacker Transport — Eeprom

− Version of the EEPROM build − Checksum − Firmware name − Serial number − Type − Hardware configuration of the CMD-V4 − Single reject configuration − Routing disk positions − Offset routing disk The EEPROM must always stay on the stacker transport.

-

Page 72: Output Transport

Output transport Function and Integration Output transport The output transport facility varies depending on the device variant. The following illustration shows an output transport for a rearload device with horizontal cash-out. The output transport is attached to the stacker transport and driven via the CMD controller.

-

Page 73: Shutter

Function and Integration Shutter Shutter The shutter is a flap to keep cash under cover. It is controlled via the CMD controller. 2-37 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

-

Page 74: Dispensing Unit

Dispensing unit Function and Integration Dispensing unit 4-cassette housing without dispensing units 2-38 Cash Media Dispenser Version 4 — Service Manual 01750060162 A…

-

Page 75: 4-Cassette Housing With Two Double Dispensing Units And 4-Channel Distributor Board

Function and Integration Dispensing unit 4-cassette housing with two double dispensing units and 4-channel distributor board Every 4-cassette housing contains four cassette mounts and at least one dispensing unit featuring a thickness measuring station. The second dispensing unit is used when more than two cassettes are configured. The thickness measuring station must always be in the upper dispensing unit..

-

Page 76: Dispensing Unit With Dispensing Shaft And Magnetic Clutch

Dispensing unit Function and Integration The pressure that the notes exert on the dispensing shaft is identified via a pressure sensor. Banknotes are dispensed downward by means of friction. In each case, the dispensing unit extracts just one note and transports it to the stacking transport facility.

-

Page 77: Photosensors In The Dispensing Unit

Function and Integration Dispensing unit is polled via the pressure sensor. The cassettes can be unlocked via the unlocking lever on the housing. Voltages and signals are passed from the controller to the cassette via the cassette connector. The following elements are controlled in the dispensing unit: −…

-

Page 78: Reject / Retract Cassette

Reject / retract cassette Function and Integration Reject / retract cassette The reject / retract cassettes is available in two versions. Depending on the version, they can be opened by means of a key or a toggle. Both versions can be lead-sealed.

- Page 79

Function and Integration Reject / retract cassette Green: Cassette ready to be inserted Blue: Cassette has been opened by force The insertion mechanism is installed at the front. The notes are inserted in a slanted position from above at the front. A toothed wheel on the right-hand cassette side drives two intake rollers which transport the individual notes or bundles into the cassette. -

Page 80: Cash-Out Cassettes

Any subsequent attempt to insert the cassette with an open visor is stopped. If the indicator is blue and the visor is closed, the cassette can be inserted in the CMD-V4. Cash can be dispensed. The tamper indicator can be reset by opening the lid. A display window on the…

- Page 81

Function and Integration Cash-out cassettes The cassette shutter is designed as a visor. The pressure is created by a pressure carriage operated by a stepper motor. The pressure carriage is guided in the side panel of the cassette. The cassette number is preset at the production plant before shipment. It is stored in EEPROM and can be changed via a software command. - Page 82

Cash-out cassettes Function and Integration 2-46 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 83: Device Overview And Operation

Device Overview and Operation Device overview 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

-

Page 84: Horizontal Cash-Out Frontload

Device overview Device Overview and Operation Horizontal cash-out Frontload 1 Double dispensing unit with DDU 8 Reject / retract cassette 2 4-cassette housing 9 Status display 3 4-channel distributor print 10 Function key 4 Double dispensing unit 11 Cash-out cassette 1 5 Stacker 12 Cash-out cassette 2 6 CMD controller…

-

Page 85: Horizontal Cash-Out Rearload

Device Overview and Operation Device overview Horizontal cash-out Rearload 1 Horizontal output transport RL 8 Reject / retract cassette 2 Double dispensing unit with 9 Status display 10 Function key 3 4-cassette housing 11 Cash-out cassette 1 4 4-channel distributor print 12 Cash-out cassette 2 5 Double dispensing unit 13 Cash-out cassette 3…

-

Page 86: Vertical Cash-Out Frontload

Device overview Device Overview and Operation Vertical cash-out Frontload 1 Stacker 8 Reject / retract cassette 2 Double dispensing unit with 9 Status display 10 Function key 3 4-cassette housing 11 Cash-out cassette 1 4 4-channel distributor print 12 Cash-out cassette 2 5 Double dispensing unit 13 Cash-out cassette 3 6 Vertical output transport FL…

-

Page 87: Vertical Cash-Out Rearload

Device Overview and Operation Device overview Vertical cash-out Rearload 1 Vertical output transport RL 8 Reject / retract cassette 2 Double dispensing unit with DDU 9 Status display 3 4-cassette housing 10 Function key 4 4-channel distributor print 11 Cash-out cassette 1 5 Double dispensing unit 12 Cash-out cassette 2 6 Stacker…

-

Page 88: 1-Cassette Housing With Single Dispensing Unit

(DDU), and two plain single dispensing units. The CMD-V4 with 1-cassette housings can be shipped in all variants that are available for 4-cassette housings (see figures above). 1 Single dispensing unit with DDU…

-

Page 89: Function Elements And Controls

Device Overview and Operation Device overview Function elements and controls 1 Status display (two 7 segment displays, first digit above) 2 Function key 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

-

Page 90: The Cassettes

The cassettes Device Overview and Operation The cassettes Cash-out cassette 1 Pull-back handle 10 Inset for setting the banknote 2 Banknote rail height 3 Slide for low cash sensor 11 Latching button (optional) 12 Free space for validity 4 Pressure carriage identification 5 Tamper indicator blue/green 13 Free space for cassette label…

-

Page 91: Reject / Retract Cassette

Device Overview and Operation The cassettes Reject / retract cassette 1 Box lid 5 Tamper indicator blue/green 2 Retract compartment lever 6 Cassette handle 3 Retract compartment 7 Locking lever (optional lock) 4 Reject compartment 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

-

Page 92: Removing The Cassette

The released cassette is automatically pushed out of the dispenser by several centimeters. Raise the cassette handle (2) and pull the cassette out of the CMD-V4 by the handle (3). While pulling the cassette, support it from underneath with your free hand.

-

Page 93: Opening The Cassette

Device Overview and Operation The cassettes Opening the cassette The procedure for opening cash-out cassettes and reject/retract cassettes is the same. • Remove the cassette (see section «Removing the cassette»). When the cassette does not have a lock, turn the green locking lever in the direction of the arrow (1) and lift the cassette lid in the direction of the arrow (2).

-

Page 94: Emptying The Reject / Retract Cassette

The cassettes Device Overview and Operation Emptying the reject / retract cassette The reject / retract cassette is divided into a reject and a retract compartment. Banknotes which are not removed by the customer after the cash dispensing procedure are returned to the retract compartment. Cash which has been incorrectly dispensed or which was dispensed for test purposes is stored in the reject compartment.

-

Page 95: Setting The Low Cash Sensor

Device Overview and Operation The cassettes Setting the low cash sensor As an option, the cash-out cassettes can be equipped with a low cash sensor. With this function, a microswitch reports to the connected device that the cassette only contains a certain number of banknotes. To set to the desired minimum banknote quantity, proceed as follows: •…

-

Page 96: Setting The Banknote Width

The cassettes Device Overview and Operation Setting the banknote width The banknote width has to be set before the cassette is used for the first time or when a different currency or denomination is used in the cassette. • Remove and open the cassette (see section «Opening the cassette»). Removing banknotes Press the green latching button (1) while pushing the pressure carriage…

-

Page 97: Removing The Banknote Rails

Device Overview and Operation The cassettes Removing the banknote rails • Pull up the horizontal tab at the end of the banknote rail to lift the catch (2) above the crosspiece underneath the tab. At the same time push against the nose of the rail (3) with the thumb of your other hand in the direction of the cassette handle.

-

Page 98: Inserting The Banknote Rails

The cassettes Device Overview and Operation Put the tip of a screwdriver in the hole in the rail (1) and use it as a lever to move the rails in the direction of the arrow (2). Removing the banknote rail – note width less than 110 mm If the banknote rail is set to a banknote width of less than 110 mm, proceed as follows: •…

- Page 99

Device Overview and Operation The cassettes The left rail and the right rail are inserted in the same way. Slide the protruding end of the rail (1) under the lower edge of the pull-back handle if necessary and press the rail (on the dispensing side of the cassette) into the slot for the required banknote width. - Page 100

The cassettes Device Overview and Operation The banknote rail has been inserted correctly if you can see the dimension required in the cutout (1) and the rail is properly locked in place (2). The tab of the rail (1) must lie flat on the crosspiece. - Page 101

Device Overview and Operation The cassettes Inserting the banknote rail — note width less than 110 mm If the banknote width is less than 110 mm, please proceed as follows: • Push the pressure carriage all the way to the end of the cassette which has the cassette handle (see section «Removing the banknotes»). -

Page 102: Setting The Banknote Height

The cassettes Device Overview and Operation Setting the banknote height • Press the two catches (1) towards each other and remove the inset (2) in the direction of the lid center. 3-20 Cash Media Dispenser Version 4 — Service Manual 01750060162 A…

- Page 103

Device Overview and Operation The cassettes • Set the required note height (3) and push the insets back in (4) until they snap into place. Make sure that the insets are set to the same note height at all six positions. -

Page 104: Filling The Cash-Out Cassette

The cassettes Device Overview and Operation Filling the cash-out cassette Filling the cash-out cassettes includes the following steps: − Preparing the cash-out cassette − Preparing the banknote bundles − Inserting banknote bundles In general, all banknotes complying with the requirements of the national bank are suitable for use in the cash-out cassette.

- Page 105

Device Overview and Operation The cassettes Remove the cash-out cassette from the CMD-V4 (see section «Removing the cassette»). Place the cash-out cassette (1) on the loading aid as shown in the picture, and open the cassette lid (see the section «Opening the cassette»). -

Page 106: Preparing The Banknote Bundles

The cassettes Device Overview and Operation Preparing the banknote bundles Check the banknotes for damages before you put them into the cash-out cassettes. Sort out the damaged banknotes and/or remove clips, needles or other foreign objects. The following banknotes should be rejected: torn, glued, folded, creased, stapled or clipped banknotes.

-

Page 107: Inserting Banknote Bundles

Device Overview and Operation The cassettes Inserting banknote bundles Also follow the instructions for filling the cash-out cassette on the inside of the cassette cover. General instructions for filling the cassette Remove any existing bank wrappers made of paper, plastic or rubber before inserting the banknote bundle.

- Page 108

The cassettes Device Overview and Operation New and used banknote bundles If you use new and used banknote bundles in one cassette, always insert the bundles with the used banknotes into the cassette first. Then insert the bundles with the new banknotes after you separated them at the cut edges (see the section «Preparing the banknote bundles»). - Page 109

Device Overview and Operation The cassettes Always insert banknote bundles which are bent horizontally into the cash-out cassette in such a way that the side of the bundle bulging out is pointing towards the pressure carriage. Take the banknote bundles from the packaging, fan the banknotes and put them into the cassette as shown in the picture. -

Page 110: Special Comments For Deformed Banknotes

The cassettes Device Overview and Operation Special comments for deformed banknotes Possible deformation of banknotes Type A: Type B: Type C: Deformation near the S shape Wavy shape hologram Type A: Turn the bundle so that the deformed corner of the banknote is pointing towards the cassette end from which the banknotes are dispensed and not to the pressure carriage.

- Page 111

Device Overview and Operation The cassettes Type C: If the bundle has a wavy shape as a result from having been tied, turn it so that the deformed corners are pointing towards the end from which the banknotes are dispensed and not towards the pressure carriage. -

Page 112: Inserting The Cassette

The cassettes Device Overview and Operation Inserting the cassette The procedure for inserting cash-out cassettes and reject/retract cassettes is the same. Closing the cassette If the cassette does not have a lock, you must close the cassette lid (1) and turn the green locking lever (2) to the left.

-

Page 113: Inserting The Cassette

Device Overview and Operation The cassettes Inserting the cassette Normally the tamper indicator (1) is ’green’. If the indicator is blue, the cassette has been tampered with or has been forced open (tamper indicator). To switch the tamper indicator to green, proceed as follows: •…

-

Page 114: Cassette Initialization

Cassette initialization Device Overview and Operation Cassette initialization The initialization of the cassettes is necessary in case of new types of banknotes or cassettes. With the initialization the system will be informed about the cassette number, the currency and the denomination of the banknotes.

- Page 115

Device Overview and Operation Determining the reference value • Holding the green locking handle, pull out the CMD-V4 as far as possible (see chapter «Removal/Installation of Components», section «Pulling out / pushing in the CMD-V4»). If the locking handle jams and you cannot pull out the CMD-V4, you should always see the chapter «Troubleshooting». -

Page 116: Function Test

Function test Device Overview and Operation Function test In some cases it is useful to check whether the CMD-V4 is ready for operation without using other tools. There is a function button on the controller for this purpose. Pressing this button lets you cycle through the possible functions on the status display.

- Page 117

Device Overview and Operation Function test FW Build The version number is displayed in alternating mode. Example: As far as the firmware build is concerned (to be read with DEF), Build=1.137 the version number 1.137 is shown as follows: 11 for 2 seconds 37 for 1 second After nine attempts, the device returns to normal mode. - Page 118

Function test Device Overview and Operation 3-36 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 119: Start-Up

The following tasks have to be carried out in the specified sequence when the cash media dispenser (CMD-V4) is started up for the first time: 1. Adjust the cash cassettes to the note size if this was not done at the production plant 2.

-

Page 120: Start-Up After Component Replacement

Start-up after component replacement The following steps are necessary when you have replaced components in the CMD-V4: 1. Initialize the CMD-V4 2. Adjust the cash cassettes to the note size if this was not done at the production plant (if replacement makes this necessary) 3.

-

Page 121: Electronic Adjustments For The Cmd-V4

Shutter Remove cassettes before initializing photosensors; photosensors must not be covered (KDIAG: DXM) Remove cassette with the CMD-V4 turned on (normal mode but not in the process of dispensing) and reinsert it Calculate reference values with initialized/inserted cassettes containing real cash (KDIAG menu: Applications‚ Init. CMD-V4) **** Initialize cash cassettes (KDIAG menu: Applications‚…

-

Page 122: Initializing The Cmd-V4

All connectors on the CMD controller must have been plugged in. • Connect jumper 7 on the CMD controller (Clear CMOS) before turning on the device. Turn on the CMD-V4. Leave jumper 7 connected until the status display shows the value ‘io’. •…

-

Page 123: Jumper Settings On The Cmd Controller

Start-up Initializing the CMD-V4 Jumper settings on the CMD controller Position of the jumper panel on the CMD controller Position of the jumper panel on the CMD controller 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

- Page 124

Initializing the CMD-V4 Start-up The 10-position jumper panel beneath the status indicator controls the following settings: Jumper Name Open Connected Door Ignore door sensor Heed door sensor when when encryption is encryption is activated activated SCOP Disable SCOP Enable SCOP handling… -

Page 125: Default Settings

Start-up Initializing the CMD-V4 Default settings Jumper connected Battery Jumper connected to just one pin DOOR (possibility of enabling DOOR or SCOP) 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

-

Page 126: Adjusting Cash Cassettes To The Note Size

Adjusting cash cassettes to the note size Start-up Adjusting cash cassettes to the note size Refer to the «Setting the banknote width» and «Setting the banknote height» sections in the «Device Overview and Operating» chapter. Filling cassettes with real cash and inserting them When the device has been turned on and no errors have occurred, the cash- out cassettes have to be filled with real cash.

-

Page 127: Troubleshooting

Additional messages may be displayed during initialization, after powering up and after a reset. It is also possible to run an internal test to see if the CMD-V4 is ready for operation. You can find more on this in the «Function test» section of the «Device Overview and Operation»…

-

Page 128: Displays At Startup

Displays at startup Troubleshooting Displays at start-up Meaning Reaction No power supply Switch on the device. Controller faulty Replace the controller. Controller test after Power None On (displays are flashing and keep changing) Warning: Battery too weak Replace battery (controller) Controller faulty Replace the controller.

-

Page 129: Displays In Normal Operation

Troubleshooting Displays in normal operation Displays in normal operation Error Meaning Explanation / Measures code No power supply Switch on the device. Start-up (after RESET or Wait until power up is completed. electronics self-test) Burn; program controller Compare; check controller Controller OK No error Faulty software…

- Page 130

Displays in normal operation Troubleshooting Error Meaning Explanation / Measures code Controller faulty When starting the CMD-V4, the power-up test detected a serious fault in the electronics of the controller. The controller must be replaced. Software missing Reload firmware. (download) - Page 131

Verify that the connectors on the CMD controller or at the photosensor elements are plugged in properly. Then return the CMD-V4 to cash- out position in the safe, thereby closing the safety switch and starting the CMD-V4 again (Reset). If the status display continues to show ’18’… - Page 132

(SAT) or the controller has to be replaced. If the magnet moves all the way, the CMD-V4 can go back into operation. If the fault recurs within a short time and checking the single reject… - Page 133

Then return the CMD-V4 to cash- out position in the safe, thereby closing the safety switch and starting the CMD-V4 again (Reset). - Page 134

MA6 has been plugged in correctly. Check whether the digital photosensor is firmly attached to the switchover lever. Place the CMD-V4 in the safe in its dispensing position (safety switch closed). Reinsert the RR cassette, select test… - Page 135

Select ’1’ (Reset) on the function button. If the motor tries to start, but there is a loud running noise: check the cash paths of the CMD-V4 for a massive note jam. Check the inlet to the reject/retract cassette for jammed notes. - Page 136

CMD-V4 in the safe to cash-out position (safety switch closed) and select test function 2 (mechanical test) on the function button after starting up the CMD-V4: if this test function once again ends with status display ’26’, the SAT or the controller must be replaced. - Page 137

Verify that the connectors at the CMD-V4 are properly plugged in. Set the CMD-V4 in the safe to cash-out position (safety switch closed) and select test function 1 (Reset) on the function button. If status code ’29’ reappears after… - Page 138

Displays in normal operation Troubleshooting Error Meaning Explanation / Measures code Too many problems during Bundle rejects can be caused by dispensing from cassette x extremely skewed banknotes or (x = 1 – 6) banknotes that are extracted in an uncontrolled way or by problems with the photosensors. - Page 139

Troubleshooting Displays in normal operation Error Meaning Explanation / Measures code Too many problems during 5. Check whether the magnet for dispensing from cassette x the retaining shaft moves stiffly. (x = 1 – 6) Do this by pressing its anchor. (If necessary check the movement of the magnet with test function ‘2’ –… - Page 140

Displays in normal operation Troubleshooting Error Meaning Explanation / Measures code Cash could not be Verify that the connectors on dispensed or faulty amount the CMD controller and at the of pressure against the plug connection of dispensing banknotes when a unit ’x’… - Page 141

Troubleshooting Displays in normal operation Error Meaning Explanation / Measures code Cash could not be 2.) Re-insert the cassette. Can you dispensed or faulty amount hear the pressure carriage of pressure against the moving forward? banknotes when a cassette is inserted — If there is no noise, verify that (x = 1 — 6) the connectors on the CMD… - Page 142

Displays in normal operation Troubleshooting Error Meaning Explanation / Measures code Too many poor quality Too many double or excessively notes (x=1-6) wide/narrow notes were detected during dispensing from cassette x. Remove cassette x, and check whether the right type of banknote was inserted. -

Page 143: Dirty Photosensors / Sensors

Reset (set CMD-V4 to dispensing position). Note: When this error has occurred for the first time, the CMD-V4 will continue to function until operation shuts down automatically when the level of dirt increases. B) If a cassette cannot be inserted…

- Page 144

(x = 1 — 6) relevant dispensing unit and the associated prism in the pressure carriage of the cassette. Then execute a Reset (set CMD-V4 to dispensing position). Use the ’DYK’ self-test program (check status of photosensors/photosensor amplifiers) to check the level of dirt on all photosensors in KDIAG: Photosensors with status ’3’… - Page 145

(reset), remove the stacker unit and, from below, clean the surfaces of the prism between the stacker wheels. Put the CMD-V4 back in its dispensing position. If the status display continues to show error code ’90’ after powering up (reset), the stacker has to be replaced. - Page 146

(P; two reject) PS2 glass-clear surfaces opposite the transmitter/receiver) with a brush or compressed air. After cleaning, set the CMD-V4 to home position and Cash-out photosensor wait for start-up or select ’1’ (Reset) PS27 (P) on the function button. -

Page 147: Checking The Note Paths

• Open the safe door (see the operating manual of the basic device). • Holding the green locking handle, pull out the CMD-V4 as far as possible (see chapter «Removal/Installation of Components», section «Pulling out / pushing in the CMD-V4»).

-

Page 148: Locking/Unlocking Handle Blocked

If the banknote clamp is not in the stacking position, try carefully to move it down into the stacking position. When the banknote clamp is down, you can activate the emergency unlock function (1) on the CMD-V4 and pull out the CMD-V4. 5-22 Cash Media Dispenser Version 4 — Service Manual…

-

Page 149: Checking The Vertical Transport

Troubleshooting Locking/unlocking handle blocked Checking the vertical transport Raise the appropriate locking handle (1) or (2) of the dispensing unit and move the cover forward. Check the upper or lower area of the vertical transport facility and remove any notes that are there (1). Swing the cover back until you hear it click into place.

-

Page 150: Checking The Dispensing Areas

Locking/unlocking handle blocked Troubleshooting Checking the dispensing areas In the dispensing units the dispensing area (inside the device) must be checked. The dispensing areas can only be checked when the cassettes have been removed from the dispensing units (see chapter «Device Overview and Operation», section «Removing the cassette»).

-

Page 151: Checking The Stacker And Output Transport

Troubleshooting Locking/unlocking handle blocked Checking the stacker and output transport Do not try to open the clamp by force; you could damage it. Stacker wheel area Check the area round the vertical transport and if necessary remove any notes. 5-25 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

- Page 152

Locking/unlocking handle blocked Troubleshooting Single reject area The function of the single reject depends on the individual configuration. Push the green unlocking levers (1) out, and pull the flap (2) forward. Check the dispensing area and if necessary remove the banknotes. 5-26 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… - Page 153

Troubleshooting Locking/unlocking handle blocked Gear tracks of the stacker and output transport Horizontal output If the clamp has come to a standstill at a position outside the stacking position, you may need to check and clean the gear tracks (1). Gear tracks of the output transport Vertical output If the clamp has come to a standstill at… - Page 154

After checking the cash paths, proceed as follows: • After checking the cash paths push the CMD-V4 by the green locking lever back into the safe as far as possible (see the operating manual of the basic device). -

Page 155: Removal/Installation Of Components

V4, please be sure to check the «Troubleshooting» chapter. Pushing it in: Push the CMD-V4 in the device as far as possible by the green locking/unlocking handle (the CMD-V4 must audibly click into place). 01750060162 A Cash Media Dispenser Version 4 — Service Manual…

-

Page 156: Cmd Controller

CMD controller Removal/Installation of Components CMD controller The CMD controller is removed including the cover. To remove the CMD controller first detach all connectors from the controller. Push the fastening bolts (1) to (5) together and carefully remove the CMD controller. The EEPROM (6) must always stay on the stacker.

-

Page 157: Stacker

Removal/Installation of Components Stacker Stacker • Remove the CMD controller (see section «CMD controller»). • Remove the reject / retract cassette (see chapter «Device Overview and Operation», section «Removing the cassette»). Push the locking/unlocking lever to the left (see arrow 1) until it snaps into place.

- Page 158

Stacker Removal/Installation of Components The picture shows the position of the bordering screws for the stacker. 1 Bordering screw on the left 2 Bordering screw on the right The following table provides an overview of the bordering screws which are required for the individual systems. -

Page 159: Horizontal Output Transport

Removal/Installation of Components Horizontal output transport Horizontal output transport Remove connector (1) on the left-hand side of the CMD-V4 and remove the two screws (2) and (3). Remove screws (1) and (2) on the right-hand side. Pull the output transport apart slightly…

-

Page 160: Ouput Transport Procash 2000Xe Rl

Ouput transport ProCash 2000xe RL Removal/Installation of Components Ouput transport ProCash 2000xe RL • Pull the customer panel out of the device (refer to the operating and service manuals of the ProCash 2000xe). Detach connector (1) and remove the cable from the securing clips. Loosen screws (2) and (3) and pull the plate (4) a little out of the device (see arrow).

-

Page 161: Output Transport Procash 2050Xe

Removal/Installation of Components Output transport ProCash 2050xe Output transport ProCash 2050xe • Pull the cash media dispenser out of the device (refer to the operating and service manuals of the ProCash 2050xe). Detach connector (1) from the CMD controller. Remove screws (2) and (3). Remove screws (1) and (2) on the other side.

-

Page 162: Ouput Transport Procash 2100Xe Rl

Ouput transport ProCash 2100xe RL Removal/Installation of Components Ouput transport ProCash 2100xe RL • Open the door of the operating unit and pull the customer panel out of the device (see the operating and service manuals of the ProCash 2100xe). Detach connector (1) and remove the cable from the securing clips.

-

Page 163: Shutter Procash 2000Xe Rl

Removal/Installation of Components Shutter ProCash 2000xe RL Shutter ProCash 2000xe RL • Pull the customer panel out of the device (refer to the operating and service manuals of the ProCash 2000xe). Detach connector (1). Loosen screw (2) and unhook the ground strap.

-

Page 164: Shutter Procash 2050Xe Rl

Shutter ProCash 2050xe RL Removal/Installation of Components Shutter ProCash 2050xe RL • Pull the customer panel out of the device (refer to the operating or service manual of the ProCash 2050xe). Detach connector (1). Loosen screw (2) and unhook the ground strap (3).

-

Page 165: Shutter Procash 2100Xe Rl

Removal/Installation of Components Shutter ProCash 2100xe RL Shutter ProCash 2100xe RL • Open the door of the operating unit and pull the customer panel out of the device (see the operating or service manual of the ProCash 2100xe). Loosen screw (1) and detach connector (2).

-

Page 166: Shutter Procash 2150Xe Rl

Shutter ProCash 2150xe RL Removal/Installation of Components Shutter ProCash 2150xe RL • Pull out the customer panel (refer to the operating or service manual of the ProCash 2150xe). Loosen screw (1) on the bottom of the shutter. Push the cable (2) a little to the right, unhook it on the left side and remove it to the left.

-

Page 167: Distributor Board

Removal/Installation of Components Distributor board Distributor board • Remove all cassettes from the CMD-V4 (see chapter «Device Overview and Operation», section «Removing the cassette»). Detach tab connectors (1) and (2) from the controller and connectors (3) and (4) from the distributor board.

- Page 168

Distributor board Removal/Installation of Components While pushing catches (1) and (2) in the direction of the arrow, detach connector (3) forwards. Proceed in the same way for the other three connectors. Push the white pins (1) to (6) down and remove the distributor board with its cover. -

Page 169: Dispensing Units

Removal/Installation of Components Dispensing units Dispensing units The 4-cassette housing can accommodate two double dispensing units. The upper dispensing unit always includes the thickness measuring station. The two dispensing units must not be confused. Remove the cover (1) by pulling it off. Upper dispensing unit with thickness measuring station Removal…

- Page 170

Dispensing units Removal/Installation of Components The upper dispensing unit accommodates the thickness measuring station which is connected to the CMD controller via a cable. This cable must be unplugged (1). Detach connector (2) from the distributor board. Remove the dispensing unit in the direction of the arrow. -

Page 171: Lower Dispensing Unit

Removal/Installation of Components Dispensing units Connect the cables to the CMD controller (1) and the distributor board (2). • Mount the cover. Lower dispensing unit Turn the locking/unlocking levers (1) and (2) on the left side of the dispensing unit by 90° counterclock- wise.

- Page 172

Dispensing units Removal/Installation of Components Installation Carefully push the connecting cable (1) between the toothed wheels and the device panel. • Insert the dispensing unit and close the latches. If you cannot close them, check the proper fit of the dispensing unit. •… -

Page 173: Clamp

Removal/Installation of Components Clamp Clamp Removal Turn the two routing disks (1) and (2) in the direction of the arrow as far as possible. The clamp closes at the same time and has to engage. Turn the routing disks back by approx. 90°…

- Page 174

Clamp Removal/Installation of Components When removing the clamp remember that the ball bearings are loosely attached and can fall out. Remove the clamp upwards. Remove the ball bearings with the black hooks (1) and the toothed wheels (2) on both sides of the clamp. - Page 175

Removal/Installation of Components Clamp Push out the securing pin (1) and hold onto the cable. Loosen the cable fixing (1) and pull out the cable. Careful! Make sure that the cable is not pulled back again and secure it, if necessary. Installation Feed the cable in (1) as shown in the picture by moving it slightly back and… - Page 176

Clamp Removal/Installation of Components Pull the cable (1) taut. Insert the securing pin (2) with the clamp open. (In the illustration the cable is not yet pulled taut). Close the clamp. The two latches, one on each side, must be engaged manually. -

Page 177: Maintenance And Service

Maintenance Maintenance intervals Preventive maintenance is required for the CMD-V4 every two years or, at the latest, after 200,000 transactions. Performing maintenance All photosensors are only allowed to be cleaned in a dry state.

- Page 178

CMD has to be initialized and reference values have to be calculated for all note types (See the «Initializing the CMD-V4» section in the «Start-up» chapter. Then, using a test program or the actual application, you have to run a dispensing test in which at least five notes have to be dispensed from each cassette without errors. -

Page 179: Stacker

Maintenance and Service Maintenance Stacker • Visually inspect the stacker for damage and dirt. • Clean the stacker using a vacuum cleaner, brush, cloth or compressed air. • Clean all photosensors using a brush, cloth or compressed air. All photosensors are only allowed to be cleaned in a dry state. •…

-

Page 180: Reject / Retract Cassette

Maintenance Maintenance and Service • Clean the cash-out cassettes using a vacuum cleaner, brush, cloth or compressed air. • Check the settings for the correct note size (in the cover too). • Check the cassette pressure carriage to see that it is in its position properly, and adjust it if necessary.

-

Page 181: Approved Maintenance Materials

Maintenance and Service Maintenance Approved maintenance materials You can order the items listed below electronically or from our service partner. Orders: http://extranet.wincor-nixdorf.com http://its.siemens.de/lobs/its/its_log/ersin_gr.htm E-mail for logistics questions: mailto:serviceslogistic@wincor-nixdorf.com E-Mail for technical questions: mailto:servicesupport@wincor-nixdorf.com Commercial name / product name Code number Stock — number Ballistol oil…

- Page 182

You will find the address in the internet: http://www.wincor-nixdorf.com/internet/index.html You will find a list of all the cleaning and maintenance materials released by Wincor Nixdorf in the intranet or extranet. Please note the manufacturer’s specifications on the packaging and on the enclosed information sheet. -

Page 183: Pin Assignments

Pin Assignments Power supply connector (supply voltage) Connector: 2-pin AMP, pins 90° Signal name Meaning P24 V Supply voltage +24 V GNDNT Ground for +24 V Safety switch Connector: 3-pin DUBOX, 1 row, 90° Signal name Meaning Relay Safety cut-off relay Ground not connected Basic module…

- Page 184

Basic module Pin Assignments Connector: 20-pin DUBOX, 2 rows, 90° Signal name Meaning SM6PH1P Stepper motor SM6 phase 1, Plus connection SM6PH1M Stepper motor SM6 phase 1, Minus connection SM6PH2P Stepper motor SM6 phase 2, Plus connection SM6PH2M Stepper motor SM6 phase 2, Minus connection Single reject switch, Plus connection Single reject switch, Minus connection… -

Page 185: Main Motor M1

Pin Assignments Main motor M1 Main motor M1 Elements DCM1 Main motor Connector: 2-pin AMP, female connector 90° Signal name Meaning Main motor, Plus connection Main motor, Minus connection Stacker Elements DCM3 Swiveling motor for collecting tray DPS1/DPS3 Digital photosensors for collecting tray position DCM5 Stepper motor for bundle reject switch DPS8/DPS9…

- Page 186

Stacker Pin Assignments Connector: 34-pin DUBOX, 2 rows, 90° Signal name Meaning SM5PH1P Stepper motor DCM5 phase 1, Plus connection SM5PH1M Stepper motor DCM5 phase 1, Minus connection SM5PH2P Stepper motor DCM5 phase 2, Plus connection SM5PH2M Stepper motor DCM5 phase 2, Minus connection DC motor DCM3, Plus connection GNDL… -

Page 187: Frontload Module

Pin Assignments Frontload module Signal name Meaning IQLS Photosensor transmit current Plus (PS22, PS18, PS19) IQLS34VN Photosensor transmit current Minus Free Timing disk of main motor, Power supply T1OUT Timing disk of main motor, output signal Timing disk of main motor, Ground Free Free Free…

- Page 188

Dispensing unit 1 (module positions 1 and 2) Pin Assignments Dispensing unit 1 (module positions 1 and Elements CL1, CL2 Electromagnetic clutch (dispensing unit — position 1, 2) HR1,HR2 Lifting magnet retaining spring (dispensing unit — position 1, 2) PSD1/2 Photosensor dispensing sensor, controlled (dispensing unit — position 1, 2) PSE1/2… -

Page 189: Dispensing Unit 1 (Module Positions 1 And 2)

Pin Assignments Dispensing unit 1 (module positions 1 and 2) Signal name Meaning Ground for pressure measurement (dispensing unit — position 1) Ground for pressure measurement (dispensing unit — position 2) UANDR1 Signal of pressure measurement (dispensing unit — position 1) UANDR2 Signal of pressure measurement (dispensing unit — position 2)

-

Page 190: Cassette Connector At Dispensing Unit 1

Cassette connector at dispensing unit 1 Pin Assignments Cassette connector at dispensing unit 1 (Module positions 1 and 2) Elements Serial EEPROM Stepper motor Connector: 20-pin DUBOX, 2 rows, 90° Signal name Meaning EEDAT serial EEPROMs: data line for cassette 1 EEDAT serial EEPROMs: data line for cassette 2 EETAKT…

-

Page 191: Dispensing Unit 2

Pin Assignments Dispensing unit 2 Dispensing unit 2 Module positions 3 and 4 Elements CL3, CL4 Electromagnetic clutch (dispensing unit — position 3, 4) HR3, HR4 Lifting magnet retaining spring (dispensing unit — position 3, 4) PSD 3/4 Photosensor dispensing sensor, controlled (dispensing unit — position 3, 4) PSE 3/4 Photosensor ‘cassette empty sensor’ (dispensing unit -…

- Page 192

Dispensing unit 2 Pin Assignments Signal name Meaning Ground for pressure measurement (dispensing unit — position 3) Ground for pressure measurement (dispensing unit — position 4) UANDR3 Signal of pressure measurement (dispensing unit — position 3) UANDR4 Signal of pressure measurement (dispensing unit — position 4) IAN34IN Transmit current for pressure measurement… -

Page 193: Cassette Connector At Dispensing Unit 2

Pin Assignments Cassette connector at dispensing unit 2 Cassette connector at dispensing unit 2 (module positions 3 and 4) Elements Serial EEPROM Stepper motor Connector: 20-pin DUBOX, 2 rows, 90° Signal name Meaning EEDAT serial EEPROMs: data line for cassette 3 EEDAT serial EEPROMs: data line for cassette 4 EETAKT…

-

Page 194: Extension Connector For Dispensing Unit 3

Extension connector for dispensing unit 3 Pin Assignments Extension connector for dispensing unit 3 (module positions 5 and 6) An extension PCB containing the power drivers, power sources, level converters and the like is used for dispensing unit 3 (positions 5 and 6). Logical signals (TTL level or analog level) are passed via the extension connector.

- Page 195

Pin Assignments Extension connector for dispensing unit 3 Signal name Meaning Ground P12V Power supply for pressure measurement in the dispensing unit UANDR5 Measuring signal for cassette 5 UANDR6 Measuring signal for cassette 6 IQLS56VN Photosensor transmit current Supply voltage ULANDR Analog voltage for pressure measurement power source… -

Page 196: Connector For Shutter (Incl. Z Module)

Connector for shutter (incl. Z module) Pin Assignments Connector for shutter (incl. Z module) Elements DCM7, DCM8 Shutter motor, DC DPS10/11, Digital photosensors for shutter position DPS12/13 DCM4 Stepper motor for Z module drive PS27 / PS28 Cash path monitoring in the Z module Connector: 15-pin DSUB, pins 90°…

- Page 197

Pin Assignments Connector for shutter (incl. Z module) When the cash has been transported to the output slot, the shutter is moved back to the ‘CLOSED’ position until the transition from L L to H H has been completed. (L = 0 V — H = +12 V) RMSH2N RMSH1N Meaning… -

Page 198: Connector For Thickness Measuring Station

Connector for thickness measuring station Pin Assignments Connector for thickness measuring station Elements Optical thickness measuring DMLED1, DMLED2 Transmit diodes DMPHT1, DMPHT2 Receive transistors Mechanical thickness measuring Reflective photosensors 1, 2 Connector: 10-pin DUBOX, pins, 2 rows, 90° Signal name Meaning DMLED1IN Transmit current for IR LED of reflective…

-

Page 199: Connection Of Door Switch

Pin Assignments Connection of door switch Connection of door switch Elements Solenoid-operated switch Door switch of safe door Bridge Reports that the solenoid-operated switch is connected Connector: 4-pin DUBOX, 1 row, 90° Signal name Meaning TUERM Solenoid-operated switch / Door switch of safe door Ground for solenoid-operated switch TUERB…

-

Page 200: Rs232C Connection

RS232C connection Pin Assignments RS232C connection The controlling system unit (PC) is connected via this RS232C interface. Connector: 9-pin Sub-D, pins 90° Signal name Meaning DCD1 Carrier Detect RXD1 Receive Data (IN) TXD1 Transmit Data (OUT) DTR1 Data Terminal Ready Ground DSR1 Data Set Ready…

-

Page 201: Cmd Controller

Pin Assignments CMD controller CMD controller Connectors at the left side of the controller: X1 mechanichal thickness sensor Dubox connector, 8-pin (Reihe = 2466407537, Sohn = 2466410537) Designation + 5 V Measuring input for the first analog Hall sensor + 5 V Measuring input for the second analog Hall sensor X2 shutter JST pin connector model PHD, 2 x 10-pin, S20B-PHDSS (90°)

- Page 202

CMD controller Pin Assignments Designation Measuring input for phototransistor of PS28 or PS29 (rear edge control) (PSR7) + current for transmit diodes from PS27, PS28 or PS26, PS29 (LSISH) Gate input of shutter1 Gate input of shutter2 Gate input of shutter3 Gate input of shutter4 Jumper coding Pin 19… - Page 203

Pin Assignments CMD controller X3 transport module JST pin connector model PHD, 2 x 6-pin, S12B-PHDSS (90°) (Reihe = A3C40015986, Sohn = A3C40015984) Designation + 5 V Gate input of HS4 (sensor for clamp end position) N.C. Gate input of transport1 Gate input of transport2 Gate input of transport3 Gate input of transport4… - Page 204

CMD controller Pin Assignments X4 V.24 interface from PC Designation + 5 V Gate input of HS4 (sensor for clamp end position) N.C. Gate input of transport1 Gate input of transport2 Gate input of transport3 Gate input of transport4 8-pin Western (Reihe = 5603107937;00 or A3C40016907, Sohn = 5603111937) Designation N.C. - Page 205

Pin Assignments CMD controller X5 USB interface from PC USB connector B-type, (Reihe: 0150507337;00) Designation N.C. USB-Data — USB-Data + Shielding Shielding X6 Door switch and disconnector in safe JST pin connector model PHD, 2 x 5-pin, S10B-PHDSS (90°) (Reihe = A3C40016307;00, Sohn = A3C40016306) Designation N.C. - Page 206

CMD controller Pin Assignments X7 V.24 interface to AVT2800 (SCOP card) JST pin connector model PH, 6-pin, B6B-PH-K-S (upright) (Reihe = 9405007037, Sohn = 9405010037) Designation n. c. (DSR not connected) DTR / RTS X8 NEN from special electronics module JST pin connector model PH, 2-pin, S2B-PH-K-S (90°) (Reihe = A3C40014712;11, Sohn = A3C40014711) Designation… - Page 207

Pin Assignments CMD controller Connectors at the top side of the controller: X10 24-V connection to AVT2800 (SCOP card) 2-pin Mini-Fit 39-30-1020 (Reihe = A3C40029754, Sohn = A3C40029755) Designation + 24 V X11 motor M1) 6-pin Mini-Fit 39-30-1060 (Reihe = A3C40030083, Sohn = A3C40009552) Designation Motor + N.C. - Page 208

CMD controller Pin Assignments X13 clamp motor ZIF connector, 4-pin, 1.25 mm, Molex, Reihe 5597, type 39-51-3043, Top contact (Reihe = A3C40029756, Sohn = A3C40029757) Designation + of clamp motor M2 — of clamp motor M2 + from belt drive on clamp M3 — from belt drive on clamp M3 X14 motors and lifting magnets at stacker / left and right sides JST pin connector model PHD, 2 x 9-pin, S18B-PHDSS (90°) - Page 209

Pin Assignments CMD controller X15 EEPROM at stacker ZIF connector, 8-pin, 1.00 mm, Molex, Reihe 52043, (90°), Bottom Contact (Reihe = A3C40030173, Sohn = A3C40030174) Designation + 5 V Chip-Select to EEPROM Clock to EEPROM Data output to EEPROM Data input from EEPROM N.C. - Page 210

CMD controller Pin Assignments X17 Hybrid photosensors and photosensors at single reject JST pin connector model PHD, 2 x 8-pin, S16B-PHDSS (90°) (Reihe = 0152307537;00, Sohn = 0152310537) Designation Gate input of DPS14 (sensor for switch position of single reject) Gate input of DPS15 (sensor for switch position of single reject) Gate input of DPS7 (sensor for basic position of the sliding… - Page 211

Pin Assignments CMD controller X18 Hybrid photosensors and photosensors at stacker / left side JST pin connector model PHD, 2 x 11-pin, S22B-PHDSS (90°) (Reihe = A3C40032102, Sohn = A3C40032103) Phototransistor of PS18 installed. Designation Gate input of DPS5 (polling the position of the left routing disk) Gate input of DPS8 (polling the position of the left routing disk) Gate input of DPS2 (sensor for stacker wheel position) Gate input of DPS4 (sensor for retract compartment) - Page 212

CMD controller Pin Assignments Connectors at the bottom of the controller: X30 dispensing units pin contact strips, 2 x 20-pin (even) (Reihe = 2383807837) Designation + 5 V + 5 V + 5 V + 5 V switched + 5 V switched + 5 V switched Last –… - Page 213

Pin Assignments CMD controller Designation Dispensing gear of dispensing unit 4 Retaining magnet of dispensing unit 4 Dispensing gear of dispensing unit 5 Retaining magnet of dispensing unit 5 Dispensing gear of dispensing unit 6 Retaining magnet of dispensing unit 6 Dispensing gear of dispensing unit 7 Retaining magnet of dispensing unit 7 Dispensing gear of dispensing unit 8… - Page 214

CMD controller Pin Assignments X31 dispensing units pin contact strips, 2 x 20-pin (even) (Reihe = 2383807837) Designation EEPROM-clock EEPROM-data CS-ICN CS-ReserveN CS-Dispensing unit1 CS-Dispensing unit2 CS-Dispensing unit3 CS-Dispensing unit4 CS-Dispensing unit5 CS-Dispensing unit6 CS-Dispensing unit7 CS-Dispensing unit8 ResetN Free Power source for LEDs (LSIPLUS) Current sink dispensing unit 1 (LSIV1) Current sink dispensing unit 2 (LSIV2) - Page 215

Pin Assignments CMD controller Designation Current sink dispensing unit 3 (LSIV3) Current sink dispensing unit 4 (LSIV4) Current sink dispensing unit 5 (LSIV5) Current sink dispensing unit 6 (LSIV6) Current sink dispensing unit 7 (LSIV7) Current sink dispensing unit 8 (LSIV8) Power supply photo transistors (LSVCC) Polling the first phototransistor for pressure sensor (LSANDR) Polling the second phototransistor for empty sensor (LSR1) - Page 216

CMD controller Pin Assignments X32 Hybrid photosensors and photosensors at stacker / right side JST pin connector model PHD, 2 x 7-pin, B14B-PHDSS (upright) (Reihe = A3C40032574, Sohn = A3C40032575) Designation Gate input of DPS6 (polling the position of the right routing disk) Gate input of DPS9 (polling the position of the right routing disk) - Page 217

Pin Assignments CMD controller X33 position switch and extensions JST pin connector model PHD, 2 x 17-pin, B34B-PHDSS (upright) (Reihe = A3C40036263, Sohn = A3C40036264) Designation + 5 V + 24 V Last — GND Chip-Select to reserve device at SPI2 Clock to reserve device at SPI2 Data output to reserve device at SPI2 Data input from reserve device at SPI2… - Page 218

CMD controller Pin Assignments Designation Special output for 7-segment display bottom / right Free Free Free Free 8-36 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… - Page 219

Pin Assignments CMD controller Connectors at the right side of the controller: X40 jumpers Berg pin connector, 2 x 10-pin (Reihe 5673507037;10) Designation ‘Door’ (pay attention to safe door), to be polled by firmware ‘SCOP’ connected, to be polled by firmware ‘Jump A’ (reserve input A), to be polled by firmware ‘Jump B’ (reserve input B), to be polled by firmware ‘Jump C’ (reserve input C), to be polled by firmware… - Page 220

CMD controller Pin Assignments Connectors in the center of the controller: X50 JTAG-PLD programming connector X51 Kontron test connector X52 Turbodebugger connector 8-38 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 221: 4-Channel Distributor Board

Pin Assignments 4-channel distributor board 4-channel distributor board First connection to CMD controller Designation + 5 V + 5 V + 5 V + 5 V switched + 5 V switched + 5 V switched Last — GND Last — GND Last — GND Last — GND Last — GND…

- Page 222

4-channel distributor board Pin Assignments Designation Dispensing gear of dispensing unit 4 Retaining magnet of dispensing unit 4 Dispensing gear of dispensing unit 5 Retaining magnet of dispensing unit 5 Dispensing gear of dispensing unit 6 Retaining magnet of dispensing unit 6 Dispensing gear of dispensing unit 7 Retaining magnet of dispensing unit 7 Dispensing gear of dispensing unit 8… - Page 223

Pin Assignments 4-channel distributor board Designation CS-Dispensing unit4 CS-Dispensing unit5 CS-Dispensing unit6 CS-Dispensing unit7 CS-Dispensing unit8 ResetN Free Power source for LEDs (LSIPLUS) Current sink dispensing unit 1 (LSIV1) Current sink dispensing unit 2 (LSIV2) Current sink dispensing unit 3 (LSIV3) Current sink dispensing unit 4 (LSIV4) Current sink dispensing unit 5 (LSIV5) Current sink dispensing unit 6 (LSIV6) - Page 224

4-channel distributor board Pin Assignments 1 or 4 cassette connectors (ISEP) Designation Data from and to EEPROM Clock to EEPROM Chip-Select to EEPROM GND for Logic + 5 V switched + 24 V Stepper motor Stepper motor Stepper motor Stepper motor Last — GND Connector for the 1-channel distributor board Designation… - Page 225

Pin Assignments 4-channel distributor board Connector for the two double dispensing units at the 4-channel distributor board Designation Power source for the transmit diodes (LSIPLUS) Dispensing unit x current sink (LSIVx), activates the three transmit diodes of the only dispensing unit Power supply for the pressure photo transistor (LSVCC) Input from pressure photo transistor (LSANDR) (PS at the side) - Page 226

4-channel distributor board Pin Assignments 8-44 Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 227: Spare Parts

Cash-out cassettes 1750053501 Cash-out cassette CMD-V4 1750053503 Cash-out cassette CMD-V4 lead-sealed 1750053504 Cash-out cassette CMD-V4 FSM 1750053506 Cash-out cassette CMD-V4 FSM lead-sealed 1750053511 Cash-out cassette BBA-UT CMD-V4 1750053512 Cash-out cassette BBA-UT CMD-V4 lockable 1750053513 Cash-out cassette BBA-UT CMD-V4 lead-sealed 1750053540…

- Page 228

1-cassette housing complete without latching mechanism Dispensing units 1750051760 Double dispensing unit CMD-V4 (without thickness measuring station) 1750051761 Double dispensing unit CMD-V4 (with thickness measuring station) 1750051758 Single dispensing unit CMD-V4 (without thickness measuring station) 1750051759 Single dispensing unit CMD-V4 (with thickness measuring… - Page 229

AGT CMD-V4 vertical Rearload 1750045360 AGT CMD-V4 vertical Frontload 1750057875 AGT CMD-V4 horizontal FL 101 mm (for ProCash 1500 FL) 1750059116 AGT CMD-V4 horizontal RL 232 mm (for ProCash 2150 RL) 1750059284 AGT CMD-V4 horizontal RL 124 mm (for ProCash 1500 RL) - Page 230

Overview of individual parts Spare Parts Cash Media Dispenser Version 4 — Service Manual 01750060162 A… -

Page 231: Index

Index Banknote width 3-14 Function button 2-28 Bundle reject 2-7 Function test 3-34 Bundle retract 2-10 Initial start-up 4-1 Cash-out cassette 3-8 Initialization 3-32, 4-4 Cash-out cassettes 2-44 Cassette handling 2-19 Cassette initialization 3-32 Jumper settings 4-5 CMD controller 2-20 Connectors 2-23 Component control 2-31 Lithium batteries 1-4…

- Page 232

Index Shutter ProCash 2100xe RL 6- Photosensor electronics 2-29 Shutter ProCash 2150xe RL 6- Pin assignments 8-1 Retract cassette 2-42, 3-9 Power interrupt 1-4 Safety precautions 1-2 Reference value 3-32 SAT 2-33 Reject cassette 2-42, 3-9 Sensors 2-1 Removal/Installation 6-1 Clamp 6-19 Serial interface 2-28 CMD controller 6-2… - Page 233

Notes 01750060162 A Cash Media Dispenser Version 4 — Service Manual… - Page 234

Published by Wincor Nixdorf International GmbH 33094 Paderborn Germany Printed in Germany Order No.: 01750060162 A…

Документация по Wincor

Документация по банкоматам Wincor.

Последний раз редактировалось Shoroh 05 июн 2010, 11:57, всего редактировалось 1 раз.

Test

-

Shoroh - Администратор

- Сообщения: 5432

- Зарегистрирован: 12 май 2010, 18:55

Re: Документация по Wincor

terendyak » 12 янв 2019, 23:02