|

|

Ремонт сервопривода Baumuller

Также для восстановления подобного промышленного оборудования понадобится хорошая материально-техническая база. При выполнении всех выше перечисленных условий, шансы на успешный ремонт сервопривода Baumuller возрастают в геометрической прогрессии.

Именно поэтому за ремонтом сервоприводов, независимо от производителя лучше всего обращаться в специализированный сервисный центр, который отвечает всем техническим требованиям, такой как Кернел. Наш цент имеет отличную материально-техническую базу, а за время существования с 2002 года специалисты компании накопили бесценный опыт в том числе опыт в ремонте сервоприводов BAUMULLER.

Особенности ремонта сервопривода Baumuller

- Аппаратная часть;

- Программная часть.

В первую очередь ремонтируется аппаратная часть промышленного сервопривода. После глубокой диагностики неисправного блока выявляются все неисправные компоненты, которые в последствии заменяются на оригинальные запасные части (по возможности), в случае если сервопривод уже давно снят с производства и найти оригинальные запчасти просто невозможно они заменяются на аналоги.

Данный вид ремонта называется компонентным. От других видов его отличает две немаловажные детали.

- Значительное удешевление ремонта;

- Существенное сокращение времени ремонта.

По завершении ремонта аппаратной части сервопривода наступает очередь программной. В зависимости от серии выбирается программный продукт и зашивается в блок.

Заключительный этап ремонта сервопривода BAUMULLER это проверка на специализированном стенде. Все блоки проверяются без нагрузки и с нагрузкой не менее двух часов.

Коды ошибок сервопривода Baumuller

При обнаружении неисправности при работе сервопривода будет активирована соответствующая защита и выведено предупреждающее сообщение на дисплей сервоуслилителя или цифрового пульта. Коды неисправностей приведены в таблице ниже.

Все коды ошибок сервоприводов Baumuller BM4400, BM4600 и BM4700 представлены в руководстве пользователя (manual) в файле ниже.

Смотреть все выводимые ошибки сервопривода Baumuller BM4400, BM4600 и BM4700.

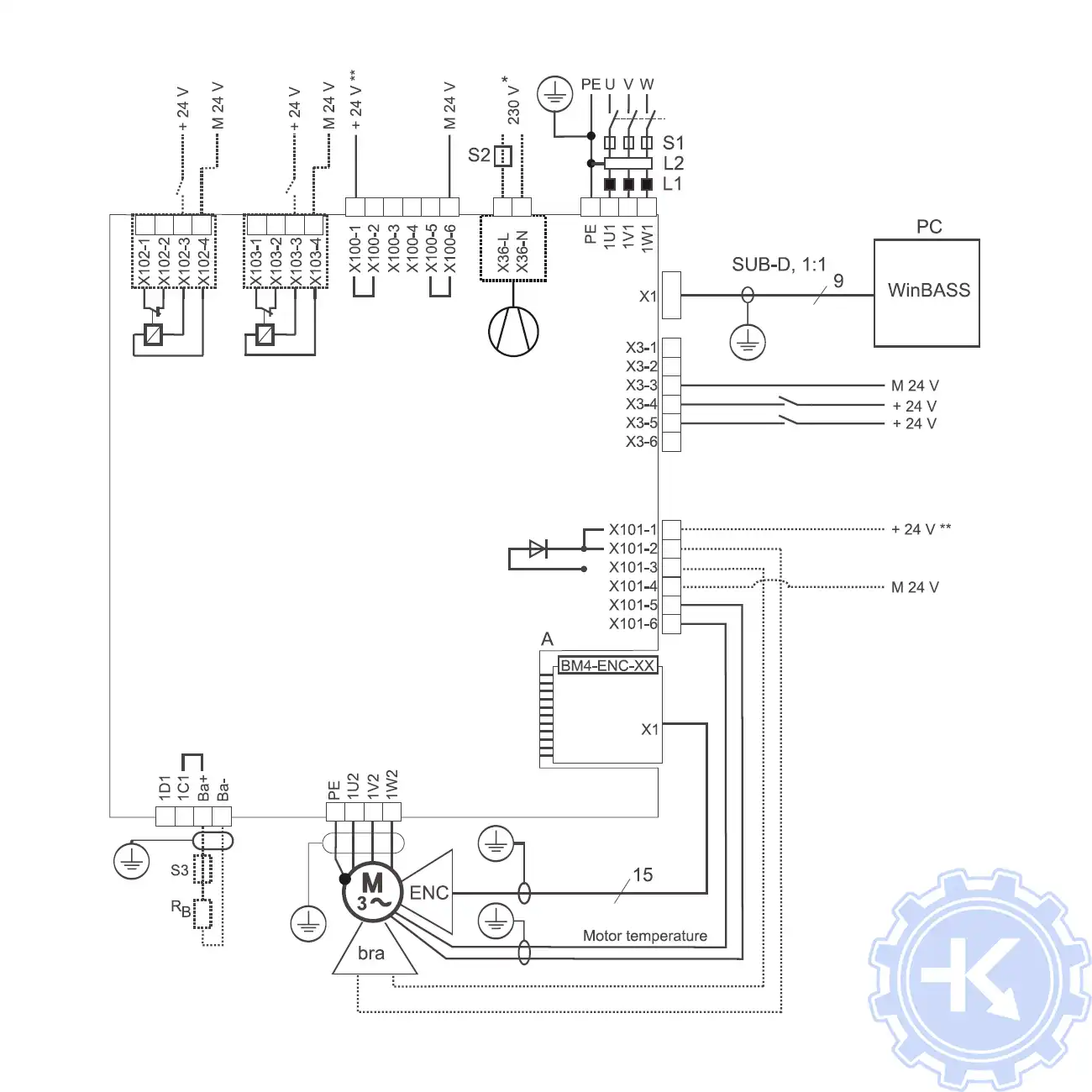

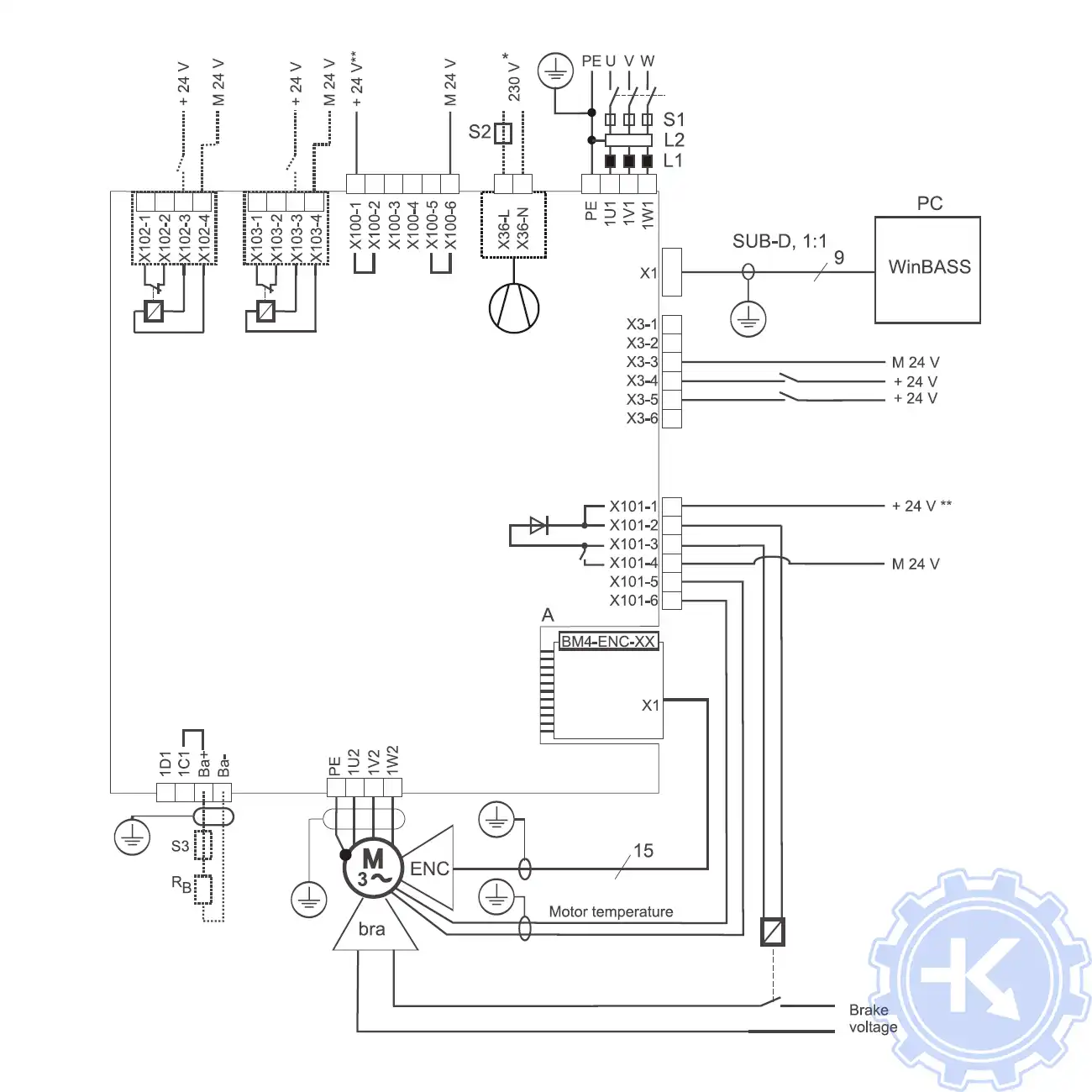

Схемы

Схемы типовых подключений сервоприводов Baumuller

В некоторых случает может понадобится схема подключения сервоприводов, ниже мы показаны схемы сервопривода BAUMULLER b maxx.

|

Схема подключения с напрямую управляемым моторным тормозом BAUMULLER BM4400, BM4600 и BM4700 |

Схема подключения с непосредственным управлением через дополнительное реле BAUMULLER BM4400, BM4600 и BM4700 |

|

|

|

Преимущество ремонта сервоприводов Baumuller в нашем сервисном центре

Во время эксплуатации электроприводов BAUMULLER может возникнуть проблема, далеко не всегда возникшую проблему можно исправить на месте своими силами, наш сервисный центр готов вам в этом помочь, выполнив качественный ремонт сервоприводов BAUMULLER в сжатые сроки с полугодовой гарантией.

Мы не только восстановим неисправный блок, но и подскажем как действовать в той или иной ситуации для максимально долгой и безаварийной работы сервопривода.

Работы, проводимые при ремонте сервопривода Baumuller в :

- Предварительный осмотр на возможность восстановления бесплатный;

- Мы производим ремонт сервопривода BAUMULLER на компонентном уровне (экономия бюджета и времени)

- При ремонте сервоприводов ни каких конструктивных изменений не вносим;

- Ремонт блоков с применением оригинальных запасных частей (по возможности).

- Вы платите исключительно за результат — работающий сервопривод;

- Гарантия на ремонт сервопривода Baumuller и на запасные части замененные в процессе ремонта 6 месяцев;

- Сроки ремонта варьируются от 5 до 15 рабочих дней;

За два десятилетия существования сервисного центра нашими специалистами были успешно проведены тысячи подобных ремонтов с каждым разом поднимая квалификацию наших инженеров. Ниже представлен далеко не полный список сервоприводов BAUMULLER серии b maXX ремонтируемые в нашем сервисном центре.

|

Ремонт сервопривода Baumuller |

BM4412-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4413-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4422-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4423-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4424-ST0-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4426-ST1-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4432-Z16-01215-0309 |

|

Ремонт сервопривода Baumuller |

BM4433-SI0-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4434-SI1-01200-03-E80 |

|

Ремонт сервопривода Baumuller |

BM4435-SI0-01200-03 |

|

Ремонт сервопривода Baumuller |

BM4443-SI-01200-03 |

В таблице представлены исключительно сервопривода BAUMULLER серии b maXX ремонт которых мы вам предлагаем, также специалисты нашей компании ремонтируют сервопривода не зависимо от серии и под каким брендом они были выпущены.

Оставить заявку на ремонт сервопривода Baumuller

У вас остались вопросы, связанные с ремонтом или сбросом ошибок, а также программированием и настройкой сервоприводов BAUMULLER? Оставьте заявку на ремонт сервопривода Baumuller в нашим менеджерам. Связаться с ними можно несколькими способами:

- Заказав обратный звонок (кнопка в правом нижнем углу сайта)

- Посредством чата (кнопка расположена с левой стороны сайта)

- Позвонив по номеру телефона: +7(8482) 79-78-54; +7(917) 121-53-01

- Написав на электронную почту: 89171215301@mail.ru

За время существования сервисного центра нашими специалистами были отремонтированы тысячи единиц промышленной электроники. Вот далеко не полный список производителей промышленной электроники и оборудования, ремонтируемой в нашей компании.

Ошибки частотных преобразователей: примеры и коды ошибок

Частотные преобразователи — это электронные или электротехнические устройства, предназначенные для изменения и регулировки частоты электрического напряжения. Сфера их использования очень широка: насосные станции, системы тепло- и водоснабжения, линии производства, конвейеры, лифты, центрифуги, мельницы, металлургические агрегаты, буровое оборудование и т. д.

Использование частотных преобразователей на промышленных объектах дает следующие преимущества:

- Возможность отказаться от регулирующего оборудования: дросселей, вариаторов, редукторов и др. Это существенно упрощает работу механической системы, снижает расходы на эксплуатацию и повышает ее надежность.

- Плавный разгон управляемого двигателя, защищающий его от механических ударов и пусковых токов, что продлевает срок его службы.

- Частотные преобразователи в паре с асинхронными двигателями можно использовать в качестве альтернативы для приводов постоянного тока.

- Максимально рациональное регулирование скорости контролируемых двигателей и связанных с этим технологических процедур.

- Экономия электроэнергии, благодаря устранению ее неоправданных трат.

Но, несмотря на свою надежность и эффективность, частотные преобразователи, как и любые электронные приборы, подвержены износу. Инженерная компания 555 специализируется на ремонте промышленной электроники, и в частности — на устранении ошибок частотных преобразователей. Наши специалисты готовы отремонтировать вышедшее из строя оборудование в кратчайшие сроки.

Основные виды и причины неисправностей

Опознать неисправности частотников позволяют коды ошибок, высвечивающиеся на мониторе устройства. Каждая такая комбинация символов указывает на совершенно конкретную проблему, и это помогает специалистам выработать правильную стратегию ремонта. Для начала рассмотрим типовые виды ошибок частотных преобразователей:

- Over Current или OC. Данный сигнал на мониторе устройства свидетельствует о его перегрузке. Если подобная проблема возникла при тестовом запуске, необходимо проверить соответствие токов регулятора и электрической машины, а также исправность электроцепей управляемого двигателя. Следует учесть, что некоторые модели частотников высвечивают ошибку Over Current при торможении, работе и запуске электродвигателя.

- Over Heat или ОН. Это сообщение указывает на превышение номинально допустимой температуры частотного преобразователя. Проще говоря — на его перегрев. Устранить проблему можно посредством чистки внутреннего вентилятора или установки дополнительной вентиляционной системы в бокс, где располагается преобразователь. В качестве профилактики следует размещать частотник в месте, гарантирующем эффективный отвод тепла.

- Over Load или OL. Такая ошибка преобразователя может быть вызвана двумя обстоятельствами: превышением на валу момента силы или перегревом управляемого двигателя. Чтобы устранить проблему, необходимо выполнить корректную настройку тепловой защиты. Для этого во время программирования устройства нужно задать требуемую величину тока и время срабатывания защитной функции.

- Low Voltage или LV. Ошибка высвечивается при снижении напряжения питания или обрыве фаз (одной или двух). Существует два варианта решения этой проблемы: «насильственная» остановка двигателя или настройка его работы в однофазном режиме.

- Over Voltage или OV. Такую надпись можно увидеть на мониторе при замедлении вращения двигателя. Для устранения неисправности необходимо воспользоваться одним из трех способов: переводом устройства в режим генератора, активацией тормозного резистора или перенастройкой системы защиты от повышенного напряжения.

Среди других типовых неисправностей преобразователя следует выделить вращение двигателя в неправильном направлении, невозможность его запуска, проблемы с торможением и разгоном и т. д. Каждое повреждение имеет под собой конкретные причины. Например, если двигатель разгоняется очень медленно, скорее всего, дело в срабатывании функции токоограничения в момент разгона.

В число наиболее распространенных причин неисправностей входят:

- Заводской брак. Как правило, фабричные дефекты дают о себе знать в течение гарантийного срока. Поэтому для их устранения следует обращаться к поставщику или в брендовый сервисный центр.

- Ошибки при монтаже. Чаще всего причиной неисправностей становится некорректная сборка схемы привода или установка частотника в неподходящем месте.

- Нарушение норм эксплуатации. Регламент технического обслуживания изложен в инструкции, прилагаемой к устройству. Игнорирование регламента может привести к выходу из строя полупроводниковых элементов, перегреванию частотного регулятора и другим неисправностям.

- Несоответствие частотного преобразователя условиям его эксплуатации. Основные критерии выбора частотника — электрические характеристики двигателя, исполнение, набор функций и т. д. Несоответствие параметров условиям его эксплуатации приводит к некорректной работе устройства, выходу из строя и многочисленным поломкам.

Теперь поговорим об ошибках преобразователя частоты более подробно и предметно. В качестве примера рассмотрим привод известного китайского бренда INVT ELECTRIC CO, серии GDXXX. Предлагаем вашему вниманию таблицу, в которой представлены коды ошибок устройства, их расшифровка, вероятные причины неисправностей, а также способы их устранения.

| Код ошибки | Расшифровка | Вероятные причины | Способы устранения |

| OUt1, 2, 3 | Ошибка фазы. | Отсутствие заземления или контакта при подсоединении кабеля; слишком маленькое время разгона. | Увеличение времени разгона; замена модуля IGBT; устранение неисправностей внешнего оборудования; переподключение кабеля. |

| OC1, 2, 3 | Токовая перегрузка при разгоне, торможении или постоянной скорости. | Чрезмерное время торможения или разгона; слишком высокое напряжение в сети; недостаточная мощность привода; потеря фазы или короткое замыкание «на землю»; воздействие внешнего фактора. |

Сокращение времени разгона; оптимизация питающего напряжения; приобретение привода с более высокой мощностью; проверка конфигурации выхода; устранение внешних помех. |

| OV1, 2, 3 | Сверхнапряжение при разгоне, торможении или постоянной скорости. | Напряжение на входе не соответствует параметрам привода; чрезмерная энергия торможения. |

Проверка входного напряжения; оптимизация времени торможения/разгона. |

| UV | Слишком низкое напряжение шины. | Пониженное напряжение питания. | Проверка и оптимизация входного напряжения. |

| OL1 | Перегрузка электродвигателя. | Слишком низкое питающее напряжение; неверно заданные параметры тока; чрезмерная нагрузка на электродвигатель. |

Проверка входного напряжения; настройка правильных параметров тока в двигателе; оптимизация нагрузки. |

| OL2 | Перегрузка преобразователя частоты. | Чрезмерно быстрый разгон; остановка двигателя; заниженное питающее напряжение; сверхнагрузка; длительная работа двигателя на низкой скорости. |

Увеличение времени разгона; снижение нагрузки на двигатель; проверка мощности двигателя и входного напряжения; приобретение привода с более высокой мощностью; замена двигателя. |

| OL3 | Перегрузка по электричеству. | Сигнализация перегрузки в соответствии с заданными параметрами. | Проверка нагрузки и точки перегрузки. |

| SPI | Потеря фаз входа. | Потеря колебания или фазы напряжения трех входных фаз. | Проверка и оптимизация входного напряжения и/или правильности монтажа. |

| SPO | Потеря фаз выхода. | Асимметричная нагрузка. | Проверка выхода, двигателя и кабеля. |

| OH1 | Перегревание выпрямителя. | Неисправность вентилятора или засорение вентиляционного канала; слишком высокая температура воздуха в помещении; чрезмерно затянутый запуск устройства. |

Замена вентилятора и проверка воздуховода; снижение температуры окружающей среды; проверка и восстановление воздухообмена; оптимизация мощности нагрузки; замена модуля IGBT; ремонт платы управления. |

| EF | Неисправность внешних элементов. | Повреждение клеммы SIn и/или других внешних клемм. | Замена пришедших в негодность клемм. |

| CE | Проблемы со связью. | Некорректная скорость в бодах; повреждение кабеля связи; неверно заданный адрес сообщения; серьезные помехи в кабеле. |

Оптимизация скорости в бодах; проверка кабеля связи; настройка правильного адреса сообщения; замена кабеля или оптимизация защиты от помех. |

| ItE | Проблемы с обнаружением тока. | Некорректное подключение платы управления; отсутствие вспомогательного напряжения; выход из строя индикаторов тока. |

Проверка разъема, датчиков и платы управления. |

| tE | Ошибка автоматической настройки. | Несоответствие мощностей двигателя и частотного преобразователя; неверно заданные параметры электродвигателя; серьезная разница между стандартными параметрами и параметрами автоматической настройки; выход времени на автонастройку. |

Установка параметров, указанных на шильдике двигателя; снижение нагрузки на двигатель; проверка параметров двигателя и его соединения; установка верхнего предела частоты на уровень «выше 2/3 номинальной частоты». |

| bCE | Неисправность тормозного модуля. | Разрыв тормозных коммуникаций или некорректная работа тормозной цепи; недостаток производительности внешнего тормозного резистора. |

Проверка тормозного модуля и замена тормозных кабелей; принудительное повышение мощности тормозного резистора. |

| ETH1, 2 | Короткое замыкание | Замыкание выхода преобразователя частоты «на землю»; неисправность в цепи определения тока. |

Проверка подключения двигателя и индикаторов тока; замена платы управления. |

| dEu | Отклонение скоростного режима. | Избыточная нагрузка. | Оптимизация нагрузки и увеличение времени обнаружения; проверка и при необходимости корректировка параметров управления. |

| STo | Несогласованность параметров. | Отсутствие параметров управления для синхронных электродвигателей; некорректно заданные параметры автоматической настройки; отсутствие подключения частотника к двигателю. |

Корректировка нагрузки на двигатель; установка корректных параметров управления; увеличение времени определения несогласованности. |

| PCE | Обрыв связи с блоком управления. | Повреждение проводов, обеспечивающих подключение к блоку управления; помехи в проводах, связанные с внешним фактором; некорректное функционирование цепи в основной плате и/или в клавиатуре. |

Замена проводов блока управления; проверка внешней среды и устранение источника помех; выполнение комплексного сервисного обслуживания устройства. |

| END | Сброс времени до заводских настроек. | Фактическое время функционирования преобразователя не соответствует внутреннему параметру продолжительности работы. | Корректировка настроек времени. |

| DNE | Проблема с загрузкой параметров. | Повреждение проводов, подключаемых к блоку управления; помехи в проводах; ошибка в базе данных панели управления. |

Замена проводов блока управления; сервисное обслуживание частотного преобразователя; повторная загрузка данных в панель управления. |

Преимущества ремонта в инженерной компании 555

- Огромный опыт в ремонте частотных преобразователей разных моделей и марок.

- Команда профессиональных специалистов.

- Экономия до 70 % средств по сравнению с приобретением нового оборудования.

- Оперативное выполнение работ (максимальный срок ремонта — 15 дней).

- Бесплатная консультация и предварительный осмотр для определения ремонтопригодности привода.

- Доступные цены и оплата только по результату работы.

- Гарантия на отремонтированное оборудование — 12 месяцев.

Обращайтесь к нам из любой точки России, через сайт или по телефону. Промышленная электроника — это очень сложное и специфичное оборудование, которое следует доверять только профессионалам.

Мы ремонтируем:

Компания ООО «Барс-Гидравлик Групп» на протяжении нескольких лет успешно сотрудничает с ООО «Инженерная компания 555» в вопросах ремонта сложного промышленного оборудования. За время работы наш партнер зарекомендовал себя с самой лучшей стороны. Заказы выполняются в кротчайшие сроки при соблюдении высокого качества работ. Организация приема и выдачи заказов четкая. Гарантийные обязательства выполняются в полном объеме.

Выражаем благодарность Вашим специалистам за профессионализм и оперативное решение поставленных задач.

Особенно хочется отметить высокую клиентоориентированность персонала Вашей компании, готовность помочь в самых сложных ситуациях.

Мы высоко ценим сложившиеся между нашими компаниями открытые и доверительные партнерские отношения и искренне желаем «Инженерной компании «555» долгих лет успеха и процветания.

Читать весь

отзыв

ООО «Инженерная компания «555» оказывала нашей компании услуги по ремонту электродвигателей и проявила пунктуальность, аккуратность и ответственность в работе.

Результат выполненных работ говорит о качественном оборудовании и высококвалифицированных кадрах.

Сотрудники компании готовы выполнить новые для себя виды работ и оказать консультационные услуги, что характеризует их как профессионалов своего дела.

Рекомендуем ООО «ИК «555» как ответственного и надежного поставщика услуг.

Читать весь

отзыв

Сообщаем, что наша организация сотрудничает с ООО «Инженерная компания «555» с мая 2016 года по настоящее время.

За этот период мы обращались к услугам компании более 10 раз.

Благодаря серьезному и квалифицированному подходу сотрудников ООО «Инженерная компания «555» ремонтные работы произведены качественно с учетом сроков, и обеспечены гарантийным сопровождением.

Планируем в дальнейшем работать с ООО «Инженерная компания «555»

Читать весь

отзыв

Уважаемый Дмитрий Васильевич!

ОАО «Октябрьский электровагоноремонтный завод» успешно работает с ООО «Инженерная компания «555» несколько лет, очень довольны данным сотрудничеством. В работе компании наибольшую ценность для нас представляет готовность работать на условиях, удобных Заказчику, качественный ремонт оборудования в заявленные сроки и самое главное, финансовая защищенность Заказчика. В инженерной компании работают внимательные, доброжелательные сотрудники, готовые в любой момент решить проблему Заказчика. Мы рады, что выбрали ООО «Инженерная компания «555» в качестве партнера. Гарантируем дальнейшее сотрудничество!

Читать весь

отзыв

ЗАО «Охтинское» выражает глубокую признательность и истинную благодарность ООО Инженерной компании «555» за качественную работу компании по ремонту сложного оборудования промышленной электроники, оперативность и технически грамотное отношение к работе в течении всего периода сотрудничества.

Мы надеемся на дальнейшее успешное развитие деловых отношений в сфере ремонта промышленной электроники.

Читать весь

отзыв

Преимущества сотрудничества с нами

Оплата только за результат — работающий блок

Гарантия на работоспособность блока целиком 12 месяцев

Срок ремонта от 5 до 15 дней

Бесплатный предварительный осмотр на предмет ремонтопригодности

Не вносим конструктивных изменений

Ремонт на компонентном уровне

Наша лаборатория расположена в Санкт-Петербурге, но обратиться за помощью вы можете из любой точки России.

Закажите обратный звонок или наберите в рабочее время многоканальный телефон

– +7 (800) 555-89-01 (звонок по России бесплатный).

Расскажите о своей проблеме и получите инструкцию к дальнейшим действиям.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Instruction handbook

English

Language

Translation

Document No. 5.19015.01

Part No.

485487

Status

08-Jan-2020

E

5.19015.01

Read the Instruction handbook before starting any work!

b maXX 5000

Add-on modules

Modbus/TCP

MOD

Related Manuals for Baumuller b maXX 5000 Series

Summary of Contents for Baumuller b maXX 5000 Series

-

Page 1

Instruction handbook English Language Translation Document No. 5.19015.01 Part No. 485487 Status 08-Jan-2020 b maXX 5000 Add-on modules Modbus/TCP Read the Instruction handbook before starting any work! 5.19015.01… -

Page 2

Copyright These Instruction handbook may be copied by the owner in any quantity, but only for internal use. This Instruction handbook may not be copied or reproduced, in whole or in part, for any other purposes. The use and disclosure of information contained in these Instruction handbook are not per- mitted. -

Page 3: Table Of Contents

Table of Contents General …………..Information on this Instruction Handbook .

-

Page 4

Table of Contents Commissioning/Operation ……….31 Safety notes . -

Page 5: General

ENERAL Information on this Instruction Handbook The manual b maXX 5000 add-on module MOD is an addition to the Instruction hand- book b maXX 5000 (5.09021) or b maXX 5500 (5.13008) for devices with Ethernet/IP Type code: BM5XXX-XXXX-XX08-00XX The basic prerequisite for safe working also is compliance with all the safety and handling instructions stated in the instruction handbooks b maXX 5000 or b maXX 5500.

-

Page 6: Key To Symbols

Key to symbols Key to symbols Warning notes Warning notes are identified by symbols in this Instruction handbook. The notes are in- troduced by signal words that express the extent of the danger. It is imperative that these notes be complied with and are conscientiously regarded in or- der to prevent accidents, personal injury and material damage.

-

Page 7: Limitation Of Liability

General Limitation of liability All specifications and notes in these instruction handbook were compiled taking into ac- count the applicable standards and regulations, the state of the art and our knowledge and experience of many years. The manufacturer assumes no liability for damages due to: m non-compliance with the instruction handbook m usage for other than the intended purpose m usage by untrained personnel…

-

Page 8: Other Applicable Documents

Other applicable documents Other applicable documents Components of other manufacturers are integrated into the device. For these purchased parts, hazard assessments have been performed by the respective manufacturers. The compliance of the design construction with the applicable European and national regula- tions has been declared for the components by the respective manufacturers.

-

Page 9: 1.10 Used Terms

General 1.10 Used terms A list of the abbreviations used can be found in b maXX 5000 (5.09021) or b maXX 5500 (5.13008), Appendix A: Abbreviations. 1.11 List of associated documentations Instruction Handbook Doc No. Part No. Part No. German English Instruction handbook b maXX 5000 5.09021…

-

Page 10

1.11 List of associated documentations Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 11: Safety

AFETY This section provides an overview of all of the important safety aspects for optimum pro- tection of personnel as well as for the safe and problem-free operation. Contents of the Instruction Handbook Each person who is tasked with performing work on or with the device must have read and understood this Instruction Handbook and the Instruction Handbook of b maXX 5000 (5.09021) or b maXX 5500 (5.13008) before working with the device.

-

Page 12: Use, Compliant With Intended Purpose

Use, compliant with intended purpose Use, compliant with intended purpose The Modbus/TCP add-on module is considered as being used compliant with its intend- ed purpose if all notes and information of this Instruction handbook and the Instruction handbook b maXX 5000 (5.09021) or b maXX 5500 (5.13008) are adhered to. WARNING! Danger arising from usage for an unintended purpose! Any usage that goes beyond the intended purpose and/or any non-compliant use of…

-

Page 13: Training Of The Personnel

Safety Training of the personnel WARNING! Risk of injury due to insufficient qualifications! Improper handling can lead to significant personal injury and material damage. Therefore: m Certain activities can only be performed by the persons stated in the respective chapters of this Instruction handbook. In this Instruction handbook, the following qualifications are stipulated for various areas of activity: m Operating personnel…

-

Page 14: Special Hazards

Special hazards Special hazards In the following section, the remaining marginal risks will be stated that have been iden- tified as a result of the hazard analysis. Observe the safety notes listed here and the warning notes in the further chapters of this manual to reduce health risks and dangerous situations.

-

Page 15: Fire Fighting

Safety Moving components WARNING! Risk of injury from moving components! Rotating components and/or components moving linearly can result in severe injury. Therefore: m Do not touch moving components during operation. m Do not open any covering during operation. m The amount of residual mechanical energy depends on the application. Powered components still turn/move for a certain length of time even after the power supply has been switched off.

-

Page 16: Safety Equipment

Safety equipment Safety equipment WARNING! Risk of fatal injury due to non-functional safety equipment! Safety equipment provides for the highest level of safety in a facility. Even if safety equipment makes work processes more awkward, under no circumstances may they be circumvented.

-

Page 17: Technical Data

ECHNICAL Operation conditions The operation conditions of b maXX 5000 are valid, see Instruction Handbook b maXX 5000 (5.09021) or b maXX 5500 (5.13008). Transport temperature range — 25 °C to + 70 °C Transport climatic class 2 K 3 EN 60721-3-2 Storage temperature range — 25 °C to + 70 °C…

-

Page 18: Electrical Data

Electrical data Electrical data 3.2.1 Modbus/TCP, 2 channels ± Supply voltage (external supply) 5 % (without load) Supply current (external supply) max. 100 mA (without load) Signal level: output high voltage at I = — 20 mA 2,5 V Signal level: output high voltage at I = + 20 mA 0,5 V Output frequency, track signals…

-

Page 19: Design And Operation

PERATION Design The b maXX 5000 series consists of an (active) mains rectifier unit and one or more axis units or a basic unit with/without axis units. The possible number of axis units depends on the connected load of the DC link of the mains rectifier unit or is limited by the signal bus to a maximum of 12 axis units.

-

Page 20: Add-On Module Eip

Add-on module EIP Add-on module EIP NOTE! Only devices with type code BM5XXX-XXXX-XX08-00XX provide the add-on module Modbus/TCP The module is built-in and cannot be changed. It is forbidden to remove the yellow front cover. The Modbus/TCP provides 2 channels . Modbus Modbus Channel 1…

-

Page 21: Identification Of The Device

Design and Operation Identification of the device 4.3.1 Part number Figure 3: Part number — front Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 22: Type Plate

Identification of the device 4.3.2 Type plate Examples of the locations where the type plate is affixed are shown in the figure. Among other things, the type plate also shows the type code of the device. Figure 4: Location of the type plate Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH…

-

Page 23: Danger Areas

Design and Operation 4.3.3 Danger areas Please comply to all safety notes of the instruction handbooks of b maXX 5000 or b maXX 5500. Display and operation elements The add-on module Modbus/TCP (MOD) doesn’t provide display or operation elements. The LED H14 and H24 of b maXX 5000 / b maXX 5500 and the emulation of the LED in ProDrive displays all device errors, even the errors occurring in connection with the add- on modules IEE or MOD.

-

Page 24

Display and operation elements Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 25: Installation

NSTALLATION This chapter describes the electrical installation of the b maXX 5000 add-on module MOD. Safety notes DANGER! Risk of fatal injury from electrical current! Inevitably, when operating this electrical device, certain parts of it are energized with hazardous voltage. Therefore: m Pay heed to areas on the device that could be dangerous during the electrical in- stallation.

-

Page 26: Demands On The Power Supply

Demands on the power supply Demands on the power supply In order to comply with the standard EN 60 204-1 (electrical equipment of machines), the cable specified therein must be used. The connecting plugs must not drop — otherwise there is a danger of short circuits, external voltage, etc. NOTICE! The danger is: electrical voltage.

-

Page 27: Installation

Installation Installation 5.4.1 Connection diagram IEE Example 1 Example 2: Example 3: m Set value IEE from encoder m Set value IEE from encoder m Set value IEE from master control m Signal IEE to following axis m Signal IEE to master control m Signal IEE to following axis FELDBUS FIELDBUS…

-

Page 28: Installation Procedure Iee

Installation 5.4.2 Installation procedure IEE Depending on the desired application you now are able to connect the incremental en- coder emulation with further system components (see ZFigure 5– on page 27). 1 Make sure that the b maXX BM5000 has been switched off voltage. 2 Connect an output (e.g.

-

Page 29: Pin Assignment Iee

Installation 5.4.3 Pin assignment IEE Pin assignment of the Sub-D connectors (male) at the front of the Ethernet/IP slave EIP: Pin assignment Pin No. Meaning Channel 1 Ground incremental encoder emulation Channel 1 External power supply +5 V IEE Channel 1 Incremental encoder emulation track 0 Channel 1 Incremental encoder emulation track -0 Channel 1 Incremental encoder emulation track B Channel 1 Incremental encoder emulation track -A…

-

Page 30: Connection Cable Iee With B Maxx 5000

Installation NOTE! If both channels are used, a second cable with a further 26-pole sub D connector must be led through the 25-pole sub D connector (cable is splitted). View on solder pin side Æ 0.34 mm² Æ 0.34 mm² Channel 1 Æ…

-

Page 31: Commissioning/Operation

OMMISSIONING PERATION The commissioning ensures that the b maXX 5000 add-on module MOD was correctly detected and that it operates. For further information on commissioning and parameter- ization see parameter handbook b maXX 5000. The following conditions must be complied with before commissioning: 1 Wiring of the Modbus/TCP (MOD) is done properly (MOD as shown in example in ZFigure 5–…

-

Page 32: Commissioning Procedure Iee

Commissioning procedure IEE Commissioning procedure IEE The commissioning is divided into the following tasks: 1 Recognition of the incremental encoder emulation IEE 2 Configuring the incremental encoder emulation IEE 3 Testing the function 6.2.1 Recognition of the incremental encoder emulation IEE While starting the device, the controller reads out the identifier of the incremental encoder emulation(s) automatically.

-

Page 33: Drive Management, Reset Errors

Commissioning/Operation 4 Select sub-menu „Axis 1/management“ and reset any faults/error messages eventually existing in the b maXX 5000. These errors possibly were caused by faulty mounting (e.g. defect cables) or faulty in- stallation (e.g. missing voltage supply). After the errors were removed commissioning can be continued.

-

Page 34: Drive Management, Iee Cannot Be Identified

Commissioning procedure IEE If the b maXX 5000 add-on module MOD has not been identified as correct or if it is not available, following error message is generated after activating the incremental encoder emulation. Figure 10: Drive management, IEE cannot be identified NOTE All error parameters of the incremental encoder emulation can be found in chapter ZTroubleshooting and fault correction–…

-

Page 35: Parameter Setting Iee

Commissioning/Operation 6.2.2 Parameter setting IEE The parameter setting influences the behavior of the incremental encoder emulation IEE while operating. The parameters are set in ProDrive. 1 Open ProDrive „Navigation“ 2 Choose in configuration/Encoder emulation „Encoder emulation 1“ or „Encoder emulation 2“ Figure 11: ProDrive, encoder emulation 3 In window „Encoder emulation 1“…

-

Page 36: Function Test Iee

Commissioning procedure IEE 6.2.3 Function test IEE The incremental encoder emulation can be tested with b maXX 5000, motor and encoder, only. Requirements Drive is in operating state (see parameter manual b maXX 5000). Encoder 1 connect- ed with X7 Encoder 1 for motor control. b maXX 5000 switched off again after successful first commissioning.

-

Page 37: Encoder Emulation 1 — Settings

Commissioning/Operation All values and selections must be made according following ZFigure 15– in this win- dow. The settings correspond with the signal of a square wave incremental encoder with 1024 increments. Mode (172.1) Figure 15: Encoder emulation 1 — settings This corresponds with the following settings of the parameter list.

-

Page 38: Window Encoder 2 — Configuration

Commissioning procedure IEE Choose in ProDrive Navigation „Configuration/Encoder/Encoder 2“ Set all values and selections according ZFigure 16– in this window. Figure 16: Window Encoder 2 — Configuration 10 Choose in ProDrive Navigation „Set value generator/Ramp function generator“. Figure 17: Window Ramp function generator 11 Set following parameters: m Ramp function generator input h Set value „10“…

-

Page 39: Ramp Function Generator — Window With Drive Manager Dialog

Commissioning/Operation 12 Click to the icon „Drive management“. In addition window „Drive manager dialog“ appears. Figure 18: Ramp function generator — window with drive manager dialog 13 Select in scroll list (1) the operation mode „Speed control“ 14 Switch on Pulse enable and No Quickstop 15 Click on button „Start“…

-

Page 40

Commissioning procedure IEE 18 Choose in ProDrive Navigation „Configuration/Encoder/Encoder 2“. 19 In this window: Speed smoothed: approx. 10 % NOTE If the generated signal of the add-on module MOD is processed in a higher level control, please check the position values there. Stop the drive after having checked the proper functioning of the add-on module MOD: h Click on „Stop“… -

Page 41: General Description

ENERAL ESCRIPTION Configure IP address The IP address either can be configured via ProDrive permanently or defined via the field- bus by DHCP or BOOTP. Static IP addresses can be assigned via the ProDrive only. Via the fieldbus statical IP addresses as well as DHCP or BOOTP addresses can be as- signed.

-

Page 42: Accept The Ip Address Of Prodrive

Configure IP address 7.1.1 Accept the IP address of ProDrive As long as from the IP address settings in ProDrive no host IP address of 0 results the IP settings in ProDrive for Modbus/TCP are accepted 1:1 Example 1: Network IP 192.168.1, host IP 21 via manually input Via the following settings the device can be configured to the IP address 192.168.1.21 Figure 19: Manual input…

-

Page 43: Setting Via The Dip Switch

General Description Example 2: Network IP 17 via dip switch Via the following settings the device can be configured to the IP address 192.168.0.17 Figure 20: Setting via the dip switch Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 44: Accept Ip Setting Of Fieldbus

Configure IP address 7.1.2 Accept IP setting of fieldbus So that the fieldbus can control the IP settings via the ProDrive settings the host IP must be 0. Then the IP settings can be made via DHCP or BOOTP. Example 3: Host IP = 0 via the dip switch All dip switches are on 0: Figure 21: Settings of the fieldbus…

-

Page 45: Modbus Function Codes

General Description Modbus function codes The Modbus/TCP add on module supports word access (16 bits) to Modbus register, on- The following function codes are supported: Function code Meaning Read multiple register (WORD access) Read input register (WORD access) Write single register (WORD access) FC16 Write multiple register (WORD access) FC23…

-

Page 46: Process Data Mapping

Process data (cyclic communication) 7.3.1 Process data mapping The process data mapping of the b maXX 5000 can be configured by the Modbus register 210 — 337 (actual process data mapping) and register 410 — 537 (set process data map- ping).

-

Page 47

General Description Mapping b maXX 5000 Single axis: Modbus Name Access Meaning register Actual PDO Mapping 0 Read- FB of the parameter, which is mapped on the first digit of the Write actual values. (Modbus address 2-3) Actual PDO Mapping 0 Read- PNR of the parameter, which is mapped on the first digit of the Write… -

Page 48

Process data (cyclic communication) Modbus Name Access Meaning register Set PDO Mapping 1 Read- Axis of the parameter, which is mapped on the second digit of axis Write the set values. (Modbus address 104-105) … Set PDO Mapping 15 Read- FB of the parameter, which is mapped on the last digit of the Write set values. -

Page 49

General Description Modbus Name Access Meaning register Set PDO Mapping 0 Read- FB of the parameter, which is mapped on the first digit of the Write set values. (Modbus address 102-103) Set PDO Mapping 0 Read- PNR of the parameter, which is mapped on the first digit of the Write set values. -

Page 50: Cycle Time Of The Process Data

Process data (cyclic communication) Example Two parameter should be mapped on the actual process data and a parameter should be mapped on the set process data. Actual process data (Actual PDO): PDO 0: FB = 126; PNR = 61; FBI = 0; first axis PDO 1: FB = 126;…

-

Page 51: Process Data Exchange

General Description 7.3.3 Process data exchange The b maXX process data can be read by Modbus register 2 to 65 (actual process data) and can be wirtten by Modus register 102 to 165 (set process data). The parameters are selected depending on the process data mapping (see ZProcess data mapping–…

-

Page 52

Process data (cyclic communication) Process data b maXX 5000 Double axis: Range Modbus Name Access Meaning register Actual 2 – 3 Actual Read-only First 32 bit Actual process data object. Depending on process data PDO 0 configured mapping. 4 – 5 Actual Read-only Second 32 bit Actual process data object. -

Page 53: Status Word And Control Word

General Description Status word and Control word 7.4.1 Status word The system state and the error state can be requested in the status word. The status word and the actual process data can be transmitted withing the same Modbus function code because the status word is in Modbus register 0 directly previous to the actual process data.

-

Page 54: Control Word

Status word and Control word 7.4.2 Control word The system state can be changed and the error states acknowledged via the control word. The control word and the set process data can be transmitted withing the same Modbus function code because the control word is in Modbus register 100 directly previ- ous to the set process data.

-

Page 55: Service Data (Acyclic Communication)

General Description Service data (acyclic communication) Independent to the process data the Modbus/TCP has access to all b maXX parameters. The Modbus register 600 — 652 is used: Modbus Name Access Meaning register F: Format Read- Permissible values: 0, 1 Write DS: Data set Read-…

-

Page 56: Example Service Data Communication

Service data (acyclic communication) The data of register 611 to max. 650 (depending on the length setting in register 610) is written to the selected parameter in case of an writing access to register 611. The b maXX firstly writes all values to the Modbus register and after that copies the values to the selected parameters in case of writing access to register 611 — 6xx with the function code «Write multiple register».

-

Page 57: States Of Communication

General Description States of communication 7.6.1 Pre-Operational In state Pre-Operational the device can be configured and an access to the controller pa- rameters via register range 600 — 652 is possible. No parameters are mapped to the process data register. 7.6.2 Operational With the transition Pre-Operational to Operational the cyclic communication is parame-…

-

Page 58: Actual Value Watchdog

Controller timeout 7.7.1 Actual Value Watchdog m The actual value watchdog is configured by Modbus register 203 m A value of 0 deactivates the watchdog m A value not equal 0 corresponds with the watchdog time in ms m The watchdog can be configured in state Pre-Operational only m The watchdog timer is restarted with the configured value in ms with every reading of the status word in state Operational.

-

Page 59: Project Example Schneider Electric Unity Pros

ROJECT EXAMPLE CHNEIDER LECTRIC NITY P34 2020 ODICON The b maXX 5000 was configured to the IP address 192.168.1.20 to demonstrate the fol- lowing examples. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 60: Create Projects Using The Corresponding Modbus Client

Create projects using the corresponding Modbus client Create projects using the corresponding Modbus client Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90…

-

Page 61: Add Modbus Tcp Network

Project example SCHNEIDER ELECTRIC UNITY PRO S Add Modbus TCP Network Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 62

Add Modbus TCP Network The model series and the IP address configuration of the Modbus TCP Client must be set in network settings. The address of the Modbus TCP Client is set via a DHCP Server in this example.The IP address of the Modbus TCP Client is set to 192.168.1.10 by the DHCP Server. -

Page 63

Project example SCHNEIDER ELECTRIC UNITY PRO S The provided network connection of the Ethernet interface must be assigned in the Ether- net configuration of the Modbus TCP Client. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90… -

Page 64

Add Modbus TCP Network Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 65: Create Program

Project example SCHNEIDER ELECTRIC UNITY PRO S Create program The variables used in the program must be defined. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 66

Create program The use of dynamic arrays must be activated within the project settings. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 67

Project example SCHNEIDER ELECTRIC UNITY PRO S Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90… -

Page 68

Create program A new program can be generated now. In this example a program with structured text (ST) is generated. A cyclic communication with 4 ms is configured on Modbus TCP Server with address 192.168.1.20. The parameters 126.1 of axis 1 and axis 2 are mapped cyclically as actual and set pro- cess data Furthermore the parameter 126.63 of axis 1 and the parameter 126.64 of axis 2 are writ- ten and read acyclically. -

Page 69

Project example SCHNEIDER ELECTRIC UNITY PRO S Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90… -

Page 70

Create program Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 71

Project example SCHNEIDER ELECTRIC UNITY PRO S (*—-Init variables—-start*) state = 0 then addressParam := ADDM(‘Ethernet_1{192.168.1.20}’); accessParams[0] := 0; accessParams[1] := 0; accessParams[2] := 2; (*Modbus access timeout in 100ms -> 200ms*) accessParams[3] := 0; (*Set timings*) fieldbusCycleTime := 4000; (*4000µs*) inputWatchdogTime := 80;… -

Page 72

Create program acyclicData[12] := 0; axis := 1; state := state + 1; (*—-Init variables—-end*) (*—-Set b maXX to PreOp—-start*) elsif state = 1 then (*Set control word to 16#3E -> go to PreOp and reset all errors*) outputData[0] := 16#3E; WRITE_VAR(addressParam, ‘%MW’, 100, 1, outputData, accessParams);… -

Page 73

Project example SCHNEIDER ELECTRIC UNITY PRO S WRITE_VAR (addressParam, ‘%MW’, 410, 12, outMapping, accessParams); (*Maximal 120 WORD*) state := state + 1; elsif state = 6 then (*WRITE_VAR was finished?*) accessParams[0].0 = false then (*Was any error while WRITE_VAR?*) accessParams[1] <> 0 then (*Error happened ->… -

Page 74

Create program := ‘%MW’, := 100, := 62, EMIS := outputData, GEST := accessParams); state := state + 1; elsif state = 10 then (*WRITE_VAR was finished?*) accessParams[0].0 = false then (*Was any error while WRITE_VAR?*) accessParams[1] <> 0 then (*Error happened ->… -

Page 75

Project example SCHNEIDER ELECTRIC UNITY PRO S inputData[0].2 = true then (*Output data watchdog expired -> reset the error by setting the same bit in control word*) outputData[0].2 := true; else outputData[0].2 := false; end_if; inputData[0].3 = true then (*Input data timeout in b maXX ->… -

Page 76

Create program (*Was any error while WRITE_VAR?*) accessParams[1] <> 0 then (*Error happened -> go to error state*) state := 100; else state := state + 1; end_if; end_if; (*—-Do acyclic communication write—-end*) (*—-Do acyclic communication read—-start*) elsif state = 16 then axis = 1 then… -

Page 77: Create User Window

Project example SCHNEIDER ELECTRIC UNITY PRO S Create User Window Cyclic and acyclic parameters can be displayed in a user window Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 78

Create User Window Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 79: Transfer Project To Plc

Project example SCHNEIDER ELECTRIC UNITY PRO S Transfer project to PLC The project can be transmitted to the PLC and the programm can be started then. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 80

Transfer project to PLC The project can be started with the commands SPS Connect SPS Transmit project to PLC SPS Start The counters of the corresponding input arrays of the user window are incremented. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 81: Troubleshooting And Fault Correction

ROUBLESHOOTING AND FAULT CORRECTION Behavior in case of malfunctions Basic information DANGER! Risk of fatal injury from electrical current! Inevitably, when operating this electrical device, certain parts of it are energized with hazardous voltage. Therefore: m Pay heed to areas on the device that could be dangerous. WARNING! Risk of injury due to improper fault correction! Therefore:…

-

Page 82: Error Detection

Error detection Error detection The fault can be caused by mechanical or electrical malfunctions. The occurrence of an error state is signalized by the lighting up of the red LED H14 or H24 on the front side of the housing. NOTE! In case of warnings or errors without error reactions, the LEDs H14 or H24 blink „Malfunction“.

-

Page 83: Error Handling

Troubleshooting and fault correction Error handling NOTE! The device is provided with predefined error reactions. You are able to set the error reaction of the device in „Depending on settings“ in the column „Reaction“ marked er- ror messages. An exception here are errors, which have to have an immediate pulse inhibit as a consequence.

-

Page 84: Error Messages

Error handling 9.3.2 Error messages In the column „Reaction“ the reaction of the system to the error is shown: m „adjustable“ = the error reaction can be set via ProDrive (Window „Drive management“, toolbar button „Error reaction“). Error Error description Reaction Troubleshooting Configuration error,…

-

Page 85: Table Of Figures

Table of Figures Table of Figures Pulse cycles, incremental encoder emulation IEE …………..Front view add-on module EIP………………..Part number — front ……………………Location of the type plate ………………….Connection diagram incremental encoder emulation IEE …………Connection cable IEE with b maXX 5000 ……………… .ProDrive Navigation ……………………

-

Page 86

Table of Figures Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 87: Index

Index Accidents Note Active mains rectifier unit Notice Axis unit Axis unit safety Operating personnel Operation Caution Output signals Commissioning procedure Connection diagram Parameter list Customer service Part number Personnel, qualified Danger Personnel, training Danger areas Pin assignment DC link discharge time ProDrive, Start Disposal Quit errors…

-

Page 88

Index Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 89: Survey Of Revisions

Survey of Revisions Survey of Revisions Version Edition Changes 5.19015.01 14-Jan-2020 First issue Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 90

Notes Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 92

Baumüller Nürnberg GmbH Ostendstraße 80-90 90482 Nürnberg T: +49(0)911-5432-0 F: +49(0)911-5432-130 www.baumueller.com All information given in this manual is customer information, subject to change without notice. We reserve the right to futher develop and actualize our products continuously using our permanent revision service. Please notice, that specifications/data/information are current values according to the printing date. These statements are not legally binding according to the measurement, computation and calculations.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Instruction handbook

English

Language

Translation

Document No. 5.19015.01

Part No.

485487

Status

08-Jan-2020

E

5.19015.01

Read the Instruction handbook before starting any work!

b maXX 5000

Add-on modules

Modbus/TCP

MOD

Related Manuals for Baumuller b maXX 5000 Series

Summary of Contents for Baumuller b maXX 5000 Series

-

Page 1

Instruction handbook English Language Translation Document No. 5.19015.01 Part No. 485487 Status 08-Jan-2020 b maXX 5000 Add-on modules Modbus/TCP Read the Instruction handbook before starting any work! 5.19015.01… -

Page 2

Copyright These Instruction handbook may be copied by the owner in any quantity, but only for internal use. This Instruction handbook may not be copied or reproduced, in whole or in part, for any other purposes. The use and disclosure of information contained in these Instruction handbook are not per- mitted. -

Page 3: Table Of Contents

Table of Contents General …………..Information on this Instruction Handbook .

-

Page 4

Table of Contents Commissioning/Operation ……….31 Safety notes . -

Page 5: General

ENERAL Information on this Instruction Handbook The manual b maXX 5000 add-on module MOD is an addition to the Instruction hand- book b maXX 5000 (5.09021) or b maXX 5500 (5.13008) for devices with Ethernet/IP Type code: BM5XXX-XXXX-XX08-00XX The basic prerequisite for safe working also is compliance with all the safety and handling instructions stated in the instruction handbooks b maXX 5000 or b maXX 5500.

-

Page 6: Key To Symbols

Key to symbols Key to symbols Warning notes Warning notes are identified by symbols in this Instruction handbook. The notes are in- troduced by signal words that express the extent of the danger. It is imperative that these notes be complied with and are conscientiously regarded in or- der to prevent accidents, personal injury and material damage.

-

Page 7: Limitation Of Liability

General Limitation of liability All specifications and notes in these instruction handbook were compiled taking into ac- count the applicable standards and regulations, the state of the art and our knowledge and experience of many years. The manufacturer assumes no liability for damages due to: m non-compliance with the instruction handbook m usage for other than the intended purpose m usage by untrained personnel…

-

Page 8: Other Applicable Documents

Other applicable documents Other applicable documents Components of other manufacturers are integrated into the device. For these purchased parts, hazard assessments have been performed by the respective manufacturers. The compliance of the design construction with the applicable European and national regula- tions has been declared for the components by the respective manufacturers.

-

Page 9: 1.10 Used Terms

General 1.10 Used terms A list of the abbreviations used can be found in b maXX 5000 (5.09021) or b maXX 5500 (5.13008), Appendix A: Abbreviations. 1.11 List of associated documentations Instruction Handbook Doc No. Part No. Part No. German English Instruction handbook b maXX 5000 5.09021…

-

Page 10

1.11 List of associated documentations Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 11: Safety

AFETY This section provides an overview of all of the important safety aspects for optimum pro- tection of personnel as well as for the safe and problem-free operation. Contents of the Instruction Handbook Each person who is tasked with performing work on or with the device must have read and understood this Instruction Handbook and the Instruction Handbook of b maXX 5000 (5.09021) or b maXX 5500 (5.13008) before working with the device.

-

Page 12: Use, Compliant With Intended Purpose

Use, compliant with intended purpose Use, compliant with intended purpose The Modbus/TCP add-on module is considered as being used compliant with its intend- ed purpose if all notes and information of this Instruction handbook and the Instruction handbook b maXX 5000 (5.09021) or b maXX 5500 (5.13008) are adhered to. WARNING! Danger arising from usage for an unintended purpose! Any usage that goes beyond the intended purpose and/or any non-compliant use of…

-

Page 13: Training Of The Personnel

Safety Training of the personnel WARNING! Risk of injury due to insufficient qualifications! Improper handling can lead to significant personal injury and material damage. Therefore: m Certain activities can only be performed by the persons stated in the respective chapters of this Instruction handbook. In this Instruction handbook, the following qualifications are stipulated for various areas of activity: m Operating personnel…

-

Page 14: Special Hazards

Special hazards Special hazards In the following section, the remaining marginal risks will be stated that have been iden- tified as a result of the hazard analysis. Observe the safety notes listed here and the warning notes in the further chapters of this manual to reduce health risks and dangerous situations.

-

Page 15: Fire Fighting

Safety Moving components WARNING! Risk of injury from moving components! Rotating components and/or components moving linearly can result in severe injury. Therefore: m Do not touch moving components during operation. m Do not open any covering during operation. m The amount of residual mechanical energy depends on the application. Powered components still turn/move for a certain length of time even after the power supply has been switched off.

-

Page 16: Safety Equipment

Safety equipment Safety equipment WARNING! Risk of fatal injury due to non-functional safety equipment! Safety equipment provides for the highest level of safety in a facility. Even if safety equipment makes work processes more awkward, under no circumstances may they be circumvented.

-

Page 17: Technical Data

ECHNICAL Operation conditions The operation conditions of b maXX 5000 are valid, see Instruction Handbook b maXX 5000 (5.09021) or b maXX 5500 (5.13008). Transport temperature range — 25 °C to + 70 °C Transport climatic class 2 K 3 EN 60721-3-2 Storage temperature range — 25 °C to + 70 °C…

-

Page 18: Electrical Data

Electrical data Electrical data 3.2.1 Modbus/TCP, 2 channels ± Supply voltage (external supply) 5 % (without load) Supply current (external supply) max. 100 mA (without load) Signal level: output high voltage at I = — 20 mA 2,5 V Signal level: output high voltage at I = + 20 mA 0,5 V Output frequency, track signals…

-

Page 19: Design And Operation

PERATION Design The b maXX 5000 series consists of an (active) mains rectifier unit and one or more axis units or a basic unit with/without axis units. The possible number of axis units depends on the connected load of the DC link of the mains rectifier unit or is limited by the signal bus to a maximum of 12 axis units.

-

Page 20: Add-On Module Eip

Add-on module EIP Add-on module EIP NOTE! Only devices with type code BM5XXX-XXXX-XX08-00XX provide the add-on module Modbus/TCP The module is built-in and cannot be changed. It is forbidden to remove the yellow front cover. The Modbus/TCP provides 2 channels . Modbus Modbus Channel 1…

-

Page 21: Identification Of The Device

Design and Operation Identification of the device 4.3.1 Part number Figure 3: Part number — front Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 22: Type Plate

Identification of the device 4.3.2 Type plate Examples of the locations where the type plate is affixed are shown in the figure. Among other things, the type plate also shows the type code of the device. Figure 4: Location of the type plate Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH…

-

Page 23: Danger Areas

Design and Operation 4.3.3 Danger areas Please comply to all safety notes of the instruction handbooks of b maXX 5000 or b maXX 5500. Display and operation elements The add-on module Modbus/TCP (MOD) doesn’t provide display or operation elements. The LED H14 and H24 of b maXX 5000 / b maXX 5500 and the emulation of the LED in ProDrive displays all device errors, even the errors occurring in connection with the add- on modules IEE or MOD.

-

Page 24

Display and operation elements Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 25: Installation

NSTALLATION This chapter describes the electrical installation of the b maXX 5000 add-on module MOD. Safety notes DANGER! Risk of fatal injury from electrical current! Inevitably, when operating this electrical device, certain parts of it are energized with hazardous voltage. Therefore: m Pay heed to areas on the device that could be dangerous during the electrical in- stallation.

-

Page 26: Demands On The Power Supply

Demands on the power supply Demands on the power supply In order to comply with the standard EN 60 204-1 (electrical equipment of machines), the cable specified therein must be used. The connecting plugs must not drop — otherwise there is a danger of short circuits, external voltage, etc. NOTICE! The danger is: electrical voltage.

-

Page 27: Installation

Installation Installation 5.4.1 Connection diagram IEE Example 1 Example 2: Example 3: m Set value IEE from encoder m Set value IEE from encoder m Set value IEE from master control m Signal IEE to following axis m Signal IEE to master control m Signal IEE to following axis FELDBUS FIELDBUS…

-

Page 28: Installation Procedure Iee

Installation 5.4.2 Installation procedure IEE Depending on the desired application you now are able to connect the incremental en- coder emulation with further system components (see ZFigure 5– on page 27). 1 Make sure that the b maXX BM5000 has been switched off voltage. 2 Connect an output (e.g.

-

Page 29: Pin Assignment Iee

Installation 5.4.3 Pin assignment IEE Pin assignment of the Sub-D connectors (male) at the front of the Ethernet/IP slave EIP: Pin assignment Pin No. Meaning Channel 1 Ground incremental encoder emulation Channel 1 External power supply +5 V IEE Channel 1 Incremental encoder emulation track 0 Channel 1 Incremental encoder emulation track -0 Channel 1 Incremental encoder emulation track B Channel 1 Incremental encoder emulation track -A…

-

Page 30: Connection Cable Iee With B Maxx 5000

Installation NOTE! If both channels are used, a second cable with a further 26-pole sub D connector must be led through the 25-pole sub D connector (cable is splitted). View on solder pin side Æ 0.34 mm² Æ 0.34 mm² Channel 1 Æ…

-

Page 31: Commissioning/Operation

OMMISSIONING PERATION The commissioning ensures that the b maXX 5000 add-on module MOD was correctly detected and that it operates. For further information on commissioning and parameter- ization see parameter handbook b maXX 5000. The following conditions must be complied with before commissioning: 1 Wiring of the Modbus/TCP (MOD) is done properly (MOD as shown in example in ZFigure 5–…

-

Page 32: Commissioning Procedure Iee

Commissioning procedure IEE Commissioning procedure IEE The commissioning is divided into the following tasks: 1 Recognition of the incremental encoder emulation IEE 2 Configuring the incremental encoder emulation IEE 3 Testing the function 6.2.1 Recognition of the incremental encoder emulation IEE While starting the device, the controller reads out the identifier of the incremental encoder emulation(s) automatically.

-

Page 33: Drive Management, Reset Errors

Commissioning/Operation 4 Select sub-menu „Axis 1/management“ and reset any faults/error messages eventually existing in the b maXX 5000. These errors possibly were caused by faulty mounting (e.g. defect cables) or faulty in- stallation (e.g. missing voltage supply). After the errors were removed commissioning can be continued.

-

Page 34: Drive Management, Iee Cannot Be Identified

Commissioning procedure IEE If the b maXX 5000 add-on module MOD has not been identified as correct or if it is not available, following error message is generated after activating the incremental encoder emulation. Figure 10: Drive management, IEE cannot be identified NOTE All error parameters of the incremental encoder emulation can be found in chapter ZTroubleshooting and fault correction–…

-

Page 35: Parameter Setting Iee

Commissioning/Operation 6.2.2 Parameter setting IEE The parameter setting influences the behavior of the incremental encoder emulation IEE while operating. The parameters are set in ProDrive. 1 Open ProDrive „Navigation“ 2 Choose in configuration/Encoder emulation „Encoder emulation 1“ or „Encoder emulation 2“ Figure 11: ProDrive, encoder emulation 3 In window „Encoder emulation 1“…

-

Page 36: Function Test Iee

Commissioning procedure IEE 6.2.3 Function test IEE The incremental encoder emulation can be tested with b maXX 5000, motor and encoder, only. Requirements Drive is in operating state (see parameter manual b maXX 5000). Encoder 1 connect- ed with X7 Encoder 1 for motor control. b maXX 5000 switched off again after successful first commissioning.

-

Page 37: Encoder Emulation 1 — Settings

Commissioning/Operation All values and selections must be made according following ZFigure 15– in this win- dow. The settings correspond with the signal of a square wave incremental encoder with 1024 increments. Mode (172.1) Figure 15: Encoder emulation 1 — settings This corresponds with the following settings of the parameter list.

-

Page 38: Window Encoder 2 — Configuration

Commissioning procedure IEE Choose in ProDrive Navigation „Configuration/Encoder/Encoder 2“ Set all values and selections according ZFigure 16– in this window. Figure 16: Window Encoder 2 — Configuration 10 Choose in ProDrive Navigation „Set value generator/Ramp function generator“. Figure 17: Window Ramp function generator 11 Set following parameters: m Ramp function generator input h Set value „10“…

-

Page 39: Ramp Function Generator — Window With Drive Manager Dialog

Commissioning/Operation 12 Click to the icon „Drive management“. In addition window „Drive manager dialog“ appears. Figure 18: Ramp function generator — window with drive manager dialog 13 Select in scroll list (1) the operation mode „Speed control“ 14 Switch on Pulse enable and No Quickstop 15 Click on button „Start“…

-

Page 40

Commissioning procedure IEE 18 Choose in ProDrive Navigation „Configuration/Encoder/Encoder 2“. 19 In this window: Speed smoothed: approx. 10 % NOTE If the generated signal of the add-on module MOD is processed in a higher level control, please check the position values there. Stop the drive after having checked the proper functioning of the add-on module MOD: h Click on „Stop“… -

Page 41: General Description

ENERAL ESCRIPTION Configure IP address The IP address either can be configured via ProDrive permanently or defined via the field- bus by DHCP or BOOTP. Static IP addresses can be assigned via the ProDrive only. Via the fieldbus statical IP addresses as well as DHCP or BOOTP addresses can be as- signed.

-

Page 42: Accept The Ip Address Of Prodrive

Configure IP address 7.1.1 Accept the IP address of ProDrive As long as from the IP address settings in ProDrive no host IP address of 0 results the IP settings in ProDrive for Modbus/TCP are accepted 1:1 Example 1: Network IP 192.168.1, host IP 21 via manually input Via the following settings the device can be configured to the IP address 192.168.1.21 Figure 19: Manual input…

-

Page 43: Setting Via The Dip Switch

General Description Example 2: Network IP 17 via dip switch Via the following settings the device can be configured to the IP address 192.168.0.17 Figure 20: Setting via the dip switch Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 44: Accept Ip Setting Of Fieldbus

Configure IP address 7.1.2 Accept IP setting of fieldbus So that the fieldbus can control the IP settings via the ProDrive settings the host IP must be 0. Then the IP settings can be made via DHCP or BOOTP. Example 3: Host IP = 0 via the dip switch All dip switches are on 0: Figure 21: Settings of the fieldbus…

-

Page 45: Modbus Function Codes

General Description Modbus function codes The Modbus/TCP add on module supports word access (16 bits) to Modbus register, on- The following function codes are supported: Function code Meaning Read multiple register (WORD access) Read input register (WORD access) Write single register (WORD access) FC16 Write multiple register (WORD access) FC23…

-

Page 46: Process Data Mapping

Process data (cyclic communication) 7.3.1 Process data mapping The process data mapping of the b maXX 5000 can be configured by the Modbus register 210 — 337 (actual process data mapping) and register 410 — 537 (set process data map- ping).

-

Page 47

General Description Mapping b maXX 5000 Single axis: Modbus Name Access Meaning register Actual PDO Mapping 0 Read- FB of the parameter, which is mapped on the first digit of the Write actual values. (Modbus address 2-3) Actual PDO Mapping 0 Read- PNR of the parameter, which is mapped on the first digit of the Write… -

Page 48

Process data (cyclic communication) Modbus Name Access Meaning register Set PDO Mapping 1 Read- Axis of the parameter, which is mapped on the second digit of axis Write the set values. (Modbus address 104-105) … Set PDO Mapping 15 Read- FB of the parameter, which is mapped on the last digit of the Write set values. -

Page 49

General Description Modbus Name Access Meaning register Set PDO Mapping 0 Read- FB of the parameter, which is mapped on the first digit of the Write set values. (Modbus address 102-103) Set PDO Mapping 0 Read- PNR of the parameter, which is mapped on the first digit of the Write set values. -

Page 50: Cycle Time Of The Process Data

Process data (cyclic communication) Example Two parameter should be mapped on the actual process data and a parameter should be mapped on the set process data. Actual process data (Actual PDO): PDO 0: FB = 126; PNR = 61; FBI = 0; first axis PDO 1: FB = 126;…

-

Page 51: Process Data Exchange

General Description 7.3.3 Process data exchange The b maXX process data can be read by Modbus register 2 to 65 (actual process data) and can be wirtten by Modus register 102 to 165 (set process data). The parameters are selected depending on the process data mapping (see ZProcess data mapping–…

-

Page 52

Process data (cyclic communication) Process data b maXX 5000 Double axis: Range Modbus Name Access Meaning register Actual 2 – 3 Actual Read-only First 32 bit Actual process data object. Depending on process data PDO 0 configured mapping. 4 – 5 Actual Read-only Second 32 bit Actual process data object. -

Page 53: Status Word And Control Word

General Description Status word and Control word 7.4.1 Status word The system state and the error state can be requested in the status word. The status word and the actual process data can be transmitted withing the same Modbus function code because the status word is in Modbus register 0 directly previous to the actual process data.

-

Page 54: Control Word

Status word and Control word 7.4.2 Control word The system state can be changed and the error states acknowledged via the control word. The control word and the set process data can be transmitted withing the same Modbus function code because the control word is in Modbus register 100 directly previ- ous to the set process data.

-

Page 55: Service Data (Acyclic Communication)

General Description Service data (acyclic communication) Independent to the process data the Modbus/TCP has access to all b maXX parameters. The Modbus register 600 — 652 is used: Modbus Name Access Meaning register F: Format Read- Permissible values: 0, 1 Write DS: Data set Read-…

-

Page 56: Example Service Data Communication

Service data (acyclic communication) The data of register 611 to max. 650 (depending on the length setting in register 610) is written to the selected parameter in case of an writing access to register 611. The b maXX firstly writes all values to the Modbus register and after that copies the values to the selected parameters in case of writing access to register 611 — 6xx with the function code «Write multiple register».

-

Page 57: States Of Communication

General Description States of communication 7.6.1 Pre-Operational In state Pre-Operational the device can be configured and an access to the controller pa- rameters via register range 600 — 652 is possible. No parameters are mapped to the process data register. 7.6.2 Operational With the transition Pre-Operational to Operational the cyclic communication is parame-…

-

Page 58: Actual Value Watchdog

Controller timeout 7.7.1 Actual Value Watchdog m The actual value watchdog is configured by Modbus register 203 m A value of 0 deactivates the watchdog m A value not equal 0 corresponds with the watchdog time in ms m The watchdog can be configured in state Pre-Operational only m The watchdog timer is restarted with the configured value in ms with every reading of the status word in state Operational.

-

Page 59: Project Example Schneider Electric Unity Pros

ROJECT EXAMPLE CHNEIDER LECTRIC NITY P34 2020 ODICON The b maXX 5000 was configured to the IP address 192.168.1.20 to demonstrate the fol- lowing examples. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 60: Create Projects Using The Corresponding Modbus Client

Create projects using the corresponding Modbus client Create projects using the corresponding Modbus client Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90…

-

Page 61: Add Modbus Tcp Network

Project example SCHNEIDER ELECTRIC UNITY PRO S Add Modbus TCP Network Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 62

Add Modbus TCP Network The model series and the IP address configuration of the Modbus TCP Client must be set in network settings. The address of the Modbus TCP Client is set via a DHCP Server in this example.The IP address of the Modbus TCP Client is set to 192.168.1.10 by the DHCP Server. -

Page 63

Project example SCHNEIDER ELECTRIC UNITY PRO S The provided network connection of the Ethernet interface must be assigned in the Ether- net configuration of the Modbus TCP Client. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90… -

Page 64

Add Modbus TCP Network Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 65: Create Program

Project example SCHNEIDER ELECTRIC UNITY PRO S Create program The variables used in the program must be defined. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90…

-

Page 66

Create program The use of dynamic arrays must be activated within the project settings. Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 67

Project example SCHNEIDER ELECTRIC UNITY PRO S Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90… -

Page 68

Create program A new program can be generated now. In this example a program with structured text (ST) is generated. A cyclic communication with 4 ms is configured on Modbus TCP Server with address 192.168.1.20. The parameters 126.1 of axis 1 and axis 2 are mapped cyclically as actual and set pro- cess data Furthermore the parameter 126.63 of axis 1 and the parameter 126.64 of axis 2 are writ- ten and read acyclically. -

Page 69

Project example SCHNEIDER ELECTRIC UNITY PRO S Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 of 90… -

Page 70

Create program Instruction handbook b maXX 5000 add-on module MOD Document No.: 5.19015.01 Baumüller Nürnberg GmbH of 90… -

Page 71

Project example SCHNEIDER ELECTRIC UNITY PRO S (*—-Init variables—-start*) state = 0 then addressParam := ADDM(‘Ethernet_1{192.168.1.20}’); accessParams[0] := 0; accessParams[1] := 0; accessParams[2] := 2; (*Modbus access timeout in 100ms -> 200ms*) accessParams[3] := 0; (*Set timings*) fieldbusCycleTime := 4000; (*4000µs*) inputWatchdogTime := 80;… -

Page 72

Create program acyclicData[12] := 0; axis := 1; state := state + 1; (*—-Init variables—-end*) (*—-Set b maXX to PreOp—-start*) elsif state = 1 then (*Set control word to 16#3E -> go to PreOp and reset all errors*) outputData[0] := 16#3E; WRITE_VAR(addressParam, ‘%MW’, 100, 1, outputData, accessParams);… -

Page 73

Project example SCHNEIDER ELECTRIC UNITY PRO S WRITE_VAR (addressParam, ‘%MW’, 410, 12, outMapping, accessParams); (*Maximal 120 WORD*) state := state + 1; elsif state = 6 then (*WRITE_VAR was finished?*) accessParams[0].0 = false then (*Was any error while WRITE_VAR?*) accessParams[1] <> 0 then (*Error happened ->… -

Page 74

Create program := ‘%MW’, := 100, := 62, EMIS := outputData, GEST := accessParams); state := state + 1; elsif state = 10 then (*WRITE_VAR was finished?*) accessParams[0].0 = false then (*Was any error while WRITE_VAR?*) accessParams[1] <> 0 then (*Error happened ->… -

Page 75

Project example SCHNEIDER ELECTRIC UNITY PRO S inputData[0].2 = true then (*Output data watchdog expired -> reset the error by setting the same bit in control word*) outputData[0].2 := true; else outputData[0].2 := false; end_if; inputData[0].3 = true then (*Input data timeout in b maXX ->… -

Page 76