2.12 Error Codes

After you write the program into the PLC, the illegal use of operands (devices) or incorrect syntax in the program

will result in flashing of ERROR indicator and M1004 = On. In this case, you can find out the cause of the error by

checking the error code (hex) in special register D1004. The address where the error occurs is stored in the data

register D1137. If the error is a general loop error, the address stored in D1137 will be invalid.

Error

code

0001

Use of device S exceeds the range

Using P* repeatedly or use of P* exceeds the

0002

range

Use of KnSm exceeds the range

0003

Using I* repeatedly or use of I* exceeds the

0102

range

0202

Use of MC N* exceeds the range

0302

Use of MCR N* exceeds the range

0401

Use of device X exceeds the range

0403

Use of KnXm exceeds the range

0501

Use of device Y exceeds the range

0503

Use of KnYm exceeds the range

0601

Use of device T exceeds the range

0604

Use of register T exceeds the range

0801

Use of device M exceeds the range

0803

Use of KnMm exceeds the range

0B01

Incorrect use of KH

Improper use of operands of DECO instruction

0D01

ES/EX/SS/EH: improper use of operands of

ENCO instruction

0D02

SA/SX/SC: illegal use of the first operand of

ANS instruction

Improper use of operands of DHSCS

0D03

instruction

Improper use of operands of DHSCR

0D04

instruction

Improper use of operands of pulse output

0D05

instruction

0D06

Improper use of operands of PWM instruction

Improper use of operands of FROM/TO

0D07

instruction

0D08

Improper use of operands of PID instruction

0D09

Improper use of operands of SPD instruction

0D0A

Incorrect operands in DHSZ instruction

DVP-PLC Application Manual

Cause of error

2 Functions of Devices in DVP-PLC

Error

code

Times of using TTMR, STMR instruction

0F0A

exceed the range

Times of using SORT instruction exceed the

0F0B

range

Times of using TKY instruction exceed the

0F0C

range

Times of using HKY instruction exceed the

0F0D

range

1000

Improper use of operands of ZRST instruction

Incorrect use of E, F, or the modification

10EF

exceeds the range

Times of using TTMR, PR, HOUR instructions

exceed the range.

2000

Improper use of operands of MRT, ARWS

instructions

C400

Illegal instruction

C401

General loop error

Continuously using LD/LDI instructions for

C402

more than 9 times

C403

Continuously using MPS for more than 9 times

C404

More than 6 steps in FOR – NEXT

Using STL/RET between FOR – NEXT

Using SRET/IRET between FOR – NEXT

C405

Using MC/MCR between FOR – NEXT

Using END/FEND between FOR – NEXT

C407

Continuously using STL for more than 9 times

C408

Using MC/MCR in STL, using I/P in STL

Using STL/RET in subroutine

C409

Using STL/RET in interruption subroutine

Using MC/MCR in subroutine

C40A

Using MC/MCR in interruption subroutine

MC/MCR does not start from N0, or is not

C40B

continuous

C40C Corresponding N of MC and MCR are different

C40D Improper use of I/P

IRET does not appear after the last FEND

C40E

SRET does not appear after the last FEND

Cause of error

2-125

Warning

This Instruction Sheet only provides descriptions for electrical specifications, general specifications, installation &

wiring, troubleshooting and peripherals. Other detail information about programming and commands is compatible

with SA/SC/SX series; please see PLC Application Manual. For more information about the optional peripheral,

please see individual product manual.

This is an OPEN TYPE PLC. The PLC should be kept in an enclosure away from airborne dust, humidity, electric

shock risk and vibration. Also, it is equipped with protective methods such as some special tools or keys to open the

enclosure, so as to avoid the hazard to users and the damage to the PLC.

Never connect the AC main circuit power supply to any of the input/output terminals, as it will damage the PLC.

Check all the wiring prior to power up. To avoid any electromagnetic noise, make sure the PLC is properly

grounded . DO NOT touch terminals when power on.

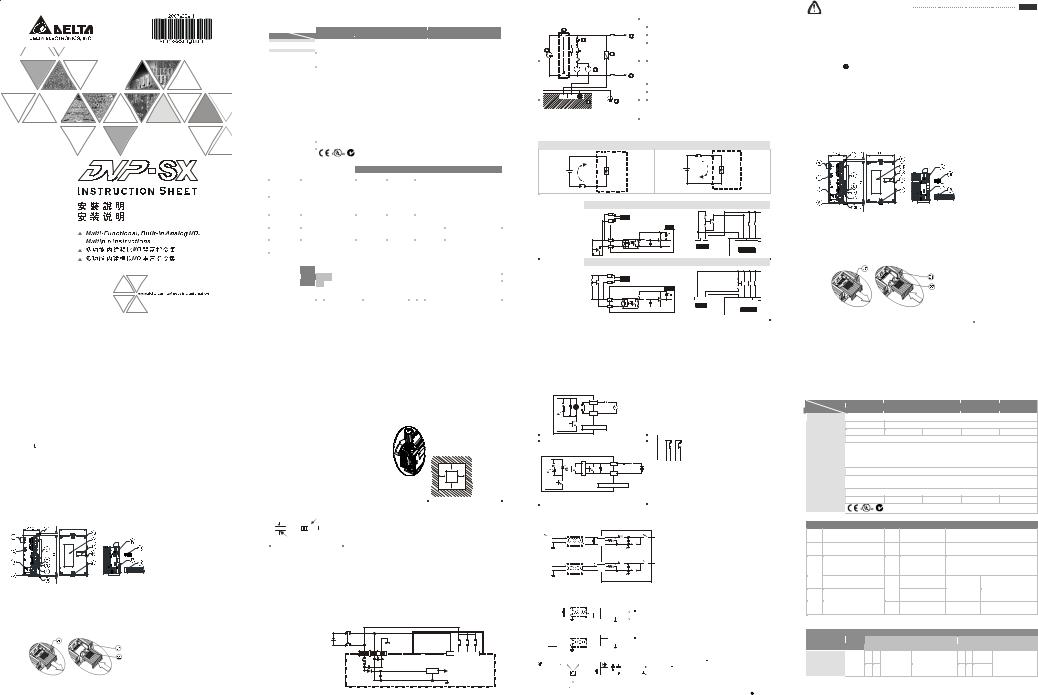

Introduction

Thank you for choosing DELTA’s PLC DVP series. The DVP-SX series is a 10-point (4DI+2DO+2AI+2AO)

special main processing unit. Besides the same commands and functions as DVP-SA/SX/SC series, 2-CH

12-bit analog voltage/current input and 2-CH 12-bit analog voltage/current output are all bipolar. There is

built-in 2-digit 7-segment display corresponds to internal register directly to display PLC station or

user-defined code.

Product Profile and Outline

1

Status indicator: POWER, RUN,

ERROR, BAT.LOW

2

RUN/STOP switch

3

2-digital 7-segment display

4

Digital I/O terminal

5

DIN rail clip

6

Analog I/O terminals

7

I/O point indicators

8

COM1 (RS-232) (Rx) indicator

9

COM2 (RS-485) (Tx) indicator

10

COM1 (RS-232)

Communication port (Slave)

Units: mm

11

Nameplate

12

Expansion port

13

Mounting hold of the expansion

unit

14

DIN rail (35mm)

15

Expansion unit clip

16

COM2 (RS-485)

Communication port

17

DC Power input

18

2 pin removable terminal

(standard accessory)

19

Power input cable

(standard accessory)

20

Battery Cover

21

Battery socket connection

Battery replacement: Please change the battery within 3 minutes, or the

internal data of the PLC (including the program area, RTC and latched

registers) could be lost or destroyed.

22

Battery mount

ENGLISH

Electrical Specifications

Electrical Specifications

Model

Item DVP10SX11R/T

DVP08SM11N DVP08SN11R/T

DVP08SP11R/T

DVP16SP11R/T

Power supply voltage

MPU: 24V DC (-15% ~ 20%) (with DC input reverse polarity protection),

Expansion Unit: supplied by the MPU

Fuse 2A / 250V AC —

Power Consumption 5W 1W 1.5W 1.5W 2W

Insulation Resistance

> 5 M at 500 V DC (Between all inputs / outputs and earth)

Noise Immunity

ESD: 8KV Air Discharge

EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O: 250V

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS: 26MHz~1GHz, 10V/m

Grounding The diameter of grounding wire cannot be smaller than the wire diameter of terminals L and N

(All DVP units should be grounded directly to the ground pole).

Environment

Operation: 0°C ~ 55°C (temperature), 50 ~ 95% (humidity), Pollution degree 2;

Storage: -25°C ~ 70°C (temperature), 5 ~ 95% (humidity); D/A output operation: 0°C ~ 50°C

(temperature)

Vibration / Shock

Resistance Standard: IEC61131-2, IEC 68-2-6 (TEST Fc)/IEC61131-2 & IEC 68-2-27 (TEST Ea)

Weight (approx.) (g) 138 / 133 64 88 / 68 90 / 70 96 / 76

Approvals

Electrical Specification of Input Point Electrical Specification of Output Point

Input Type DC (SINK or SOURCE) Output Type

Relay-R Transistor-T

Input Current 24V DC 5mA Current

Specification

1.5A/1 point

(5A/COM)

0.3A/1 point @ 40°C; When the output of Y0

and Y1 is high-speed pulse, Y0 and Y1 =

30mA

Off On,

X0,X1: above 18.5V DC

X2,X3: above 16.5V DC

Voltage

Specification

Below 250V

AC, 30V DC

30V DC

Active Level

On Off,

X0~X3 below 8V DC

75VA

(Inductive)

Maximum

Loading 90 W

(Resistive)

9W/1 point

When the output of Y0 and

Y1 is high-speed pulse, Y0

and Y1 = 0.9W (Y0 = 32

Y1 = 10kHz)

Responding

Time

About 10ms (An

adjustment range of 0 ~ 20

ms could be selected

through D1020 and D1021)

Responding

Time About 10 ms

Off On 20us

On Off 30us

Y0 and Y1 are specified

points for high—speed pulse

Model Name & I/O Configuration

Input Output

Point

Type Point

Type

Model Power

DI

AI

DI AI DO

AO

DO AO

DVP10SX11R

4

2

2

2

Relay

DVP10SX11T

24V

DC

+20%

-15%

4

2

DC24V/5 mA

Sink or Source

-20 ~ 20mA

range(-1,000 ~ +1,000)

-10 ~ +10V

range(-2,000 ~ +2,000)

2

2

Resistor

-20 ~ 20mA

(range:-2,000 ~ +2,000)

-10 ~ +10V

(range:-2,000 ~ +2,000)

Installation & Wiring

3.1 PLC Mounting Arrangements and Wiring Notes

Installation of the DIN rail:

The DVP-PLC can be secured to a cabinet by using the

DIN rail that is 35mm high with a depth of 7.5mm. When

mounting the PLC on the DIN rail, be sure to use the

end bracket to stop any side-to-side motion of the PLC,

thus to reduce the chance of the wires being pulled

loose. At the bottom of the PLC is a small retaining clip.

To secure the PLC to the DIN rail, place it onto the rail

and gently push up the clip. To remove it, pull down the

retaining clip and gently pull the PLC away from the DIN

rail. As shown on the right:

When installing the DVP series

PLC, make sure that it is

installed in an enclosure with

sufficient space (as shown

below) to its surroundings so as

to allow heat dissipation.

DV P

M P

D

D

DD

Wiring:

1. Please use 22-

16AWG (1.5mm) wiring (either single or multiple core) for

I/O wiring terminals. The specification for the terminals is as shown on

the left. PLC terminal screws should be tightened to between 1.95

kg-cm (1.7 in-lbs). Use 60/75°C copper conductor only.

2. I/O signal wires or power supply should not run through the same

multi-wire cable or conduit.

3.2 Wiring Notes

Power Input Wiring

DVP-SX series input power supply is DC input. Please take a note of listed items when operating DVP-SX.

Series.

1. Please make sure the power is at terminals 24V DC and 0V (power range is 20.4V DC ~ 28.8V DC). When

voltage is lower than 20.4V DC, PLC will stop operating, all outputs will turn Off and ERROR LED will flash

continuously.

2. If the power-off time is less than 10ms, the PLC still operates unaffectedly. If the power-off time is too long or

the power voltage drops, the PLC will stop operating and all the outputs will be Off. Once the power is

restored, the PLC will return to operate automatically. (There are latched auxiliary relays and registers

inside of the PLC, please be aware when programming.)

DC Input Type

X0 X1 X2OV24V DC

2A

20.4V~2 8. 8V

Safety Wiring

Since the PLC is in control of numerous devices, motion of either one device could affect the motion of other

the breakdown of either one device would consequently be detrimental to the whole auto

control system, and danger will thus be resulted. Please use the recommended wiring below for the power

input:

Power supply for AC loads

Power Circuit Protection Fuse (3A)

Power On pilot indicator

Emergency stop

The machinery must provide a quick manual method

disconnecting all system power.

Circuit isolation device (System Power Disconnect)

Utilize the electromagnetic contactor and the relay to be the

isolation unit of the power circuit to prevent the possible

instability of the system when the power is supplied on and off.

DVP PLC MPU (main processing unit)

Grounding

MC

MC

NL

1

1

2

3

4

5

6

8

Gu ar d

Li mi t

7

Power supply:

AC: 100 ~ 240V AC, 50/60Hz

DC: 24V DC

Input Point Wiring

The input signal of the input point is the DC power DC input. There are two modes of DC type wiring: SINK and

SOURCE, defined as follows:

Sink = Current flows into the common terminal S/S Source = Current flows out of common terminal S/S

Sinkin g

S/S

X0

So u rci ng

S/ S

X0

Loop Equivalent Circuit of Input Point Wiring Loop

DC Type

(DC Signal IN)

SINK Mode

+24V

24G

S/S

X0

24VD C

+5V

+24V OV

Sin k Ty pe

X0

24V DC

Loop Equivalent Circuit of Input Point Wiring Loop

DC Type

(DC Signal IN)

SOURCE Mode

+24V

24 G

S/ S

X0

24 VDC

+5V

So urce Type

X0+24V OV

24V DC

Output Point Wiring

Y0

RY

LED

C0

RE LAY O UTP UT

LO A D

PO W ER

Y0

LED

C0

T

R

1. There are two kinds of DVP-SX Series PLC output

modules: Relay and Transistor. For relevant electrical

specification, please refer to the function specification.

2. Be careful with the connection of the common

terminals when wiring outputs. For example, when

wiring DVP12SX11R, output terminal Y0 uses one

common terminal C0, Y1 uses C1, as shown below:

Action indication: When the output point is active, the

corresponding indicator at the front will be on.

3. Isolated circuit: The optical coupler is used to isolate

signals between PLC internal circuits and input

modules.

Analog Input/Output Point Wiring

100K

250

V+

I+

COM

CH1

-20 mA ~+20 mA V+

I+

*3

*2

Current input

Shielded*1

Shielded*1

100K

CH0

100K

100K

Note 1:

Please isolate analog input and other power

wiring.

Note 2:

If input signal is in current, please short out

between V+ and I+ terminals.

Note 3:

If the noise interference from loaded input wiring

terminal is significant, please connect a

capacitor with 0.1 ~ 0.47µF 25V for noise

filtering.

V+

I+

COM

CH0

-10V~+ 10V

*5

CH0

V+

I+

CH1

-20mA~2 0mA CH1

24+

24-

DC24V DC /DC +15V

-15V

AG

current o utput

AC drive, re corder,

scale valv e… sh ieldin g cable *1

shie ldi ng cab le *4

AC drive, re corder,

scale valv e…

termi nal of

power modu le

class 3 gro unding

(100 or less)

convert er

Note 4:

Please isolate analog output and other power

wiring.

Note 5:

If the noise interference from loaded input wiring

terminal is significant, please connect a

capacitor with 0.1 ~ 0.47µF 25V for noise

filtering.

Note 6:

Please connect

power module terminal and

analog output module terminal to system

earth point and make system earth point be

grounded or connects to machine cover.

Warning:

DO NOT wire to the No function terminal

SA/SX/SC PLC

OPEN TYPE /

:

/

DVP DVP-SX 10 4DI+2DO+2AI+2AO SA/SX/SC

2CH 12-bit / 2CH 12-bit /

/ 2

1

2 RUN/STOP

3

2

4

I/O

5

DIN

6

I/O

7 /

8

COM1 (RS-232)

(Rx)

9

COM2 (RS-485)

(Tx)

10

COM1 (RS-232)

(Slave)

mm

11

12

13

14

DIN (35mm)

15

16

COM2 (RS-485)

(Master/Slave)

17

18

2 pin

19

20

21

3 PLC

22

DVP10SX11R/T DVP08SM11N DVP08SN11R/T DVP08SP11R/T DVP16SP11R/T

24V DC -15% ~ 20%

2A/250V AC —

5W 1W 1.5W 1.5W 2W

5MΩ/ 500V DC

ESD: 8KV Air Discharge

EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O: 250V

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS: 26MHz ~ 1GHz, 10V/m

L,N PLC

/ 0°C ~ 55°C 50 ~ 95% 2

-25°C ~ 70°C 5 ~ 95% D/A 0°C ~ 50°C

/ IEC61131-2, IEC68-2-6 (TEST Fc)/IEC61131-2 & IEC68-2-27 (TEST Ea)

, g 138 / 133 64 88 / 68 90 / 70 96 / 76

SINK SOURCE

-R -T

24V DC 5mA

1.5A/1 5A/COM

0.3A/1 @ 40°C

, Y0 Y1 30mA

Off → On,

X0 X1 18.5V DC

X2 X3 16.5V DC

250V AC,30V DC

30V DC

On → Off,

X0~X3 8V DC 75VA

90W

9W/1

Y0 Y1 0.9W

Y0 50KHz Y1 10KHz

10ms D1020 D1021

0 ~ 20ms

10 ms Off → On 20us

On → Off 30us

Y0 Y1

I/O

DI

AI

DI AI DO

AO

DO AO

DVP10SX11R 4

2

2

2

DVP10SX11T

24VDC

+20%

-15% 4

2

DC24V/5 mA

Sink Source

-20 ~ 20mA

( -1,000 ~ +1,000)

-10 ~ +10V

( -2,000 ~ +2,000)

2

2

-20 ~ 20mA

( -2,000 ~ +2,000)

-10 ~ +10V

( -2,000 ~ +2,000)

3.1

DIN

35mm DIN

PLC

PLC

PLC

PLC

PLC

PLC

PLC

DV P

M P

D

D

DD

D > 50 mm

1. 22-16AWG (1.5mm)

PLC 1.95kg-cm (1.7 in-lbs)

60/75°C

2.

3.2

SX

1. 24V DC 0V 20.4V DC ~ 28.8V DC 20.4V DC PLC

Off ERROR LED

2. 10ms PLC PLC

Off PLC PLC

S/ S X0 X1 X 2

OV24 VD C

DC /D C

2A

5V

20 .4V ~ 28 .8 V

PLC

(DVPPS01/DVPPS02)

(3A)

DVPPS01/DVPPS02

MC

MC

NL

1

1

2

3

4

5

6

8

Guard

Limit

7

MC

(AC) 100 ~ 240V AC, 50/60Hz

(DC) 24V DC

DC DC SINK SOURCE

Sink = S/S Source = S/S

Si nkin g

S/S

X0

Sourci ng

S/S

X0

DC Signal IN

SINK

+24V

24G

S/S

X0

24 VDC

+5V

+24V OV

Si nk Type

X0

24V D C

DC Signal IN

SOURCE

+24V

24 G

S/ S

X0

24 VDC

+5V

So urce Ty pe

X0+24V OV

24 VD C

Y0

RY

LED

C0

LOAD

Y0

LED

C0

TR ANSIS TOR OU TPUT

DV P — * * — ** — 1 1 — T

<0. 3 A

R

G

1. DVP-S PLC

2.

DVP10SX11R Y0

C0 Y1 C1

3. PLC

CH 0

10 0K

25 0

*1

-1 0V ~ +1 0 V

V+

I+

CO M

CH 0

10 0K

10 0K

25 0

*1

-2 0m A~ + 20 mA V+

I+

CO M

CH 1

10 0K

*3

*2

AG

AG

*1

…

*4

…

( )

CH0

CH1

CH1

I+

V+

I+

V+

DC24V 24+

24 —

DC/DC AG

+15V

-15V

-20mA~ 20mA

-10V~+10V

*5

1

2

V+ I+

3

0.1 ~ 0.47 µF 25V

4

5

0.1 ~ 0.47 F 25V

6

SA/SX/SC PLC

OPEN TYPE /

:

/

DVP DVP-SX 10 4DI+2DO+2AI+2AO SA/SX/SC

2CH 12-bit / 2CH 12-bit /

/ 2

1

2

RUN/STOP

3 2

4

I/O

5

DIN

6

I/O

7 /

8

COM1 (RS-232)

(Rx)

9 COM2 (RS-485)

(Tx)

10

COM1 (RS-232)

(Slave)

mm

11

12

13

14

DIN (35mm)

15

16 COM2 (RS-485)

(Slave)

17

18 2 pin

19

20

21

3 PLC

22

DVP10SX11R/T DVP08SM11N DVP08SN11R/T DVP08SP11R/T DVP16SP11R/T

24V DC -15% ~ 20%)

2A / 250V AC —

5W 1W 1.5W 1.5W 2W

5MΩ/ 500V DC

ESD: 8KV Air Discharge

EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O: 250V

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS: 26MHz~1GHz, 10V/m

L,N PLC

/ 0°C ~ 55°C 50 ~ 95% 2

-25°C ~ 70°C 5 ~ 95% D/A 0°C ~ 50°C

/ IEC61131-2, IEC68-2-6 (TEST Fc)/IEC61131-2 & IEC68-2-27 (TEST Ea)

, g 138 / 133 64 88 / 68 90 / 70 96 / 76

SINK SOURCE

-R -T

24V DC 5mA

1.5A/1 5A/COM

0.3A/1 @ 40°C

, Y0 Y1 30mA

Off → On,

X0, X1 18.5V DC

X2, X3 16.5V DC

250V AC,30V DC 30V DC

On → Off,

X0~X3 8V DC 75VA

90W

9W/1 Y0 Y1

0.9W(Y0 50KHz Y1 10KHz)

10ms D1020 D1021

0 ~ 20ms

10 ms Off → On 20us

On → Off 30us

Y0 Y1

I/O

DI

AI

DI AI DO

AO

DO AO

DVP10SX11R

4

2

2

2

DVP10SX11T

24V DC

+20%

-15% 4

2

DC24V/5 mA

Sink Source

-20 ~ 20mA

-1,000 ~ +1,000

-10 ~ +10V

-2,000 ~ +2,000

2

2

-20 ~ 20mA

-2,000~ +2,000

-10 ~ +10V

-2,000~ +2,000

3.1

DIN

35mm DIN

PLC

PLC

PLC PLC

PLC

PLC

PLC

DV P

M P

D

D

DD

D > 50 mm

1. / 22-16 AWG (1.5mm)

PLC 1.95kg-cm (1.7 in-lbs) 60/75°C

2.

3.2

SX

1. 24V DC 0V 20.4V DC ~ 28.8V DC 20.4V DC PLC

Off ERROR LED

2. 10ms PLC PLC

Off PLC PLC

X0 X 1 X 2OV2 4V DC

DC /DC

2A

20 .4V ~2 8 .8 V

PLC

DVPPS01/DVPPS02

(3A)

DVPPS01/DVPPS02

MC

MC

NL

1

1

2

3

4

5

6

8

Guard

Limit

7

MC

(AC) 100 ~ 240V AC, 50/60Hz

(DC) 24V DC

DC DC SINK SOURCE

Sink = S/S Source = S/S

Si nkin g

S/S

X0

Sourc i ng

S/ S

X0

(DC Signal IN)

SINK

+2 4V

24 G

S/ S

X0

24 V D C

SI N K

+5 V

+24V O V

X0

24 V D C

(DC Signal IN)

SOURCE

+2 4V

24 G

S/S

X0

24 V D C

+5 V

Source Type

X1 X 2S/S X 0+24V O V

24VDC

Y0

RY

LE D

C0

REL AY OUTP UT

LO AD

Y0

LE D

C0

TRA NSIS TOR OUTPUT

T

G

1. DVP-S PLC

2.

DVP10SX11R Y0

C0 Y1 C1

3. PLC

CH0

100K

250

*1

-10 V~+ 10 V

V+

I+

CH0

100K

100K

250

*1

-2 0mA~ +2 0mA V+

I+

CO M

CH1

100K

*3

*2

AG

*1

*4

CH 0

CH 1

CH 0

CH 1

CO M

I+

V+

CO M

I+

V+

DC 2 4V 24+

24 —

DC /D C A G

+1 5V

-1 5 V

-2 0 mA~ 2 0m A

-1 0V ~ +1 0V

*5

1

2

V+ I+

3

0.1 ~ 0.47 µF 25V

4

5

0.1 ~ 0.47µF 25V

6

This Instruction Sheet only provides descriptions for electrical specifications, general specifications, installation & wiring, troubleshooting and peripherals. Other detail information about programming and commands is compatible with SA/SC/SX series; please see PLC Application Manual. For more information about the optional peripheral, please see individual product manual.

This is an OPEN TYPE PLC. The PLC should be kept in an enclosure away from airborne dust, humidity, electric shock risk and vibration. Also, it is equipped with protective methods such as some special tools or keys to open the enclosure, so as to avoid the hazard to users and the damage to the PLC.

Never connect the AC main circuit power supply to any of the input/output terminals, as it will damage the PLC.

Check all the wiring prior to power up. To avoid any electromagnetic noise, make sure the PLC is properly grounded

Introduction

Thank you for choosing DELTA’s PLC DVP series. The DVP-SX series is a 10-point (4DI+2DO+2AI+2AO)

special main processing unit. Besides the same commands and functions as DVP-SA/SX/SC series, 2-CH

12-bit analog voltage/current input and 2-CH 12-bit analog voltage/current output are all bipolar. There is

built-in 2-digit 7-segment display corresponds to internal register directly to display PLC station or

user-defined code.

Product Profile and Outline

Units: mm

Battery replacement: Please change the battery within 3 minutes, or the internal data of the PLC (including the program area, RTC and latched registers) could be lost or destroyed.

1Status indicator: POWER, RUN, ERROR, BAT.LOW

2RUN/STOP switch

3 2-digital 7-segment display

4 Digital I/O terminal

5DIN rail clip

6 Analog I/O terminals

7I/O point indicators

8 COM1 (RS-232) (Rx) indicator

9COM2 (RS-485) (Tx) indicator

10

COM1 (RS-232)

Communication port (Slave)

11Nameplate

12Expansion port

13Mounting hold of the expansion unit

14DIN rail (35mm)

15Expansion unit clip

16

COM2 (RS-485)

Communication port 17 DC Power input

18

2 pin removable terminal (standard accessory)

19

Power input cable (standard accessory)

20Battery Cover

21Battery socket connection

22Battery mount

Electrical Specifications

Electrical Specifications

|

Model |

DVP10SX11R/T |

DVP08SM11N |

DVP08SN11R/T |

DVP08SP11R/T |

DVP16SP11R/T |

|||

|

Item |

||||||||

|

MPU: 24V DC (-15% ~ 20%) (with DC input reverse polarity protection), |

||||||||

|

Power supply voltage |

||||||||

|

Expansion Unit: supplied by the MPU |

||||||||

|

Fuse |

2A / 250V AC |

— |

||||||

|

Power Consumption |

5W |

1W |

1.5W |

1.5W |

2W |

|||

|

InsulationResistance |

> 5 M at 500 V DC (Between all inputs / outputs and earth) |

|||||||

|

ESD: 8KV Air Discharge |

||||||||

|

Noise Immunity |

EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O: 250V |

|||||||

|

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV |

||||||||

|

RS: 26MHz~1GHz, 10V/m |

||||||||

|

Grounding |

The diameter of grounding wire cannot be smaller than the wire diameter of terminals L and N |

|||||||

|

(All DVP units should be grounded directly to the ground pole). |

||||||||

|

Operation: 0°C ~ 55°C (temperature), 50 ~ 95% (humidity), Pollution degree 2; |

||||||||

|

Environment |

Storage: -25°C ~ 70°C (temperature), 5 ~ 95% (humidity); D/A output operation: 0°C ~ 50°C |

|||||||

|

(temperature) |

||||||||

|

Vibration / Shock |

Standard: IEC61131-2, IEC 68-2-6 (TEST Fc)/IEC61131-2 & IEC 68-2-27 (TEST Ea) |

|||||||

|

Resistance |

||||||||

|

Weight (approx.) (g) |

138 / 133 |

64 |

88 / 68 |

90 / 70 |

96 / 76 |

|||

|

Approvals |

|

Electrical Specification of Input Point |

Electrical Specification of Output Point |

|||||||||||||||||

|

Input Type |

DC (SINK or SOURCE) |

Output Type |

Relay-R |

Transistor-T |

||||||||||||||

|

Current |

1.5A/1 point |

0.3A/1 point @ 40°C; When the output of Y0 |

||||||||||||||||

|

Input Current |

24V DC 5mA |

and Y1 is high-speed pulse, Y0 and Y1 = |

||||||||||||||||

|

Specification |

(5A/COM) |

|||||||||||||||||

|

30mA |

||||||||||||||||||

|

Off |

On, |

Voltage |

Below 250V |

|||||||||||||||

|

→ |

30V DC |

|||||||||||||||||

|

X0,X1: above 18.5V DC |

Specification |

AC, 30V DC |

||||||||||||||||

|

Active Level |

X2,X3: above 16.5V DC |

|||||||||||||||||

|

On Off, |

75VA |

When the output of Y0 and |

||||||||||||||||

|

→ |

(Inductive) |

|||||||||||||||||

|

X0~X3 below 8V DC |

Maximum |

9W/1 point |

Y1 is high-speed pulse, Y0 |

|||||||||||||||

|

Ω |

Loading |

90 W |

and Y1 = 0.9W (Y0 = 32kHz, |

|||||||||||||||

|

About 10ms (An |

(Resistive) |

Y1 = 10kHz) |

||||||||||||||||

|

Responding |

adjustment range of 0 ~ 20 |

|||||||||||||||||

|

Time |

ms could be selected |

Responding |

About 10 ms |

Off |

On 20us |

Y0 and Y1 are specified |

||||||||||||

|

through D1020 and D1021) |

Time |

On→Off 30us |

points for high-speed pulse |

|||||||||||||||

|

Model Name & I/O Configuration |

||||||||||||||||||

|

Input |

Output |

|||||||||||||||||

|

Model |

Power |

Point |

Type |

Point |

Type |

|||||||||||||

|

DI |

AI |

DI |

AI |

DO |

AO |

DO |

AO |

|||||||||||

|

DVP10SX11R |

24V |

4 |

2 |

-20 ~ 20mA |

2 |

2 |

Relay |

-20 ~ 20mA |

||||||||||

|

DC |

DC24V/5 mA |

range(-1,000 ~ +1,000) |

(range:-2,000 ~ +2,000) |

|||||||||||||||

|

DVP10SX11T |

+20% |

4 |

2 |

Sink or Source |

-10 ~ +10V |

2 |

2 |

Resistor |

-10 ~ +10V |

|||||||||

|

-15% |

range(-2,000 ~ +2,000) |

(range:-2,000 ~ +2,000) |

Installation & Wiring

3.1 PLC Mounting Arrangements and Wiring Notes

Installation of the DIN rail:

The DVP-PLC can be secured to a cabinet by using the

DIN rail that is 35mm high with a depth of 7.5mm. When

mounting the PLC on the DIN rail, be sure to use the

end bracket to stop any side-to-side motion of the PLC,

thus to reduce the chance of the wires being pulled

loose. At the bottom of the PLC is a small retaining clip.

To secure the PLC to the DIN rail, place it onto the rail

and gently push up the clip. To remove it, pull down the

retaining clip and gently pull the PLC away from the DIN

rail. As shown on the right:

When installing the DVP series PLC, make sure that it is installed in an enclosure with sufficient space (as shown below) to its surroundings so as to allow heat dissipation.

|

D |

||

|

D |

DV P |

D |

|

M P |

||

|

D |

D > 50 mm

Wiring:

|

1. |

Please use 22-16AWG (1.5mm) wiring (either single or multiple core) for |

|||

|

22-16AWG |

I/O wiring terminals. The specification for the terminals is as shown on |

|||

|

the left. PLC terminal screws should be tightened to between 1.95 |

||||

|

kg-cm (1.7 in-lbs). Use 60/75°C copper conductor only. |

||||

|

< 1.5mm |

2. |

I/O signal wires or power supply should not run through the same |

||

|

multi-wire cable or conduit. |

3.2 Wiring Notes

Power Input Wiring

DVP-SX series input power supply is DC input. Please take a note of listed items when operating DVP-SX. Series.

1.Please make sure the power is at terminals 24V DC and 0V (power range is 20.4V DC ~ 28.8V DC). When voltage is lower than 20.4V DC, PLC will stop operating, all outputs will turn Off and ERROR LED will flash continuously.

2.If the power-off time is less than 10ms, the PLC still operates unaffectedly. If the power-off time is too long or the power voltage drops, the PLC will stop operating and all the outputs will be Off. Once the power is restored, the PLC will return to operate automatically. (There are latched auxiliary relays and registers inside of the PLC, please be aware when programming.)

|

20.4V~28.8V |

||||

|

24VDC OV |

S/ S |

X0 |

X1 |

X2 |

|

DC Input Type |

||||

|

2A |

||||

|

DC /DC |

5V |

Safety Wiring

Since the PLC is in control of numerous devices, motion of either one device could affect the motion of other

devices, therefore the breakdown of either one device would consequently be detrimental to the whole auto control system, and danger will thus be resulted. Please use the recommended wiring below for the power input:

Power supply for AC loads

|

5 |

MC |

Power Circuit Protection Fuse (3A) |

||

|

1 |

Power On pilot indicator |

|||

|

4 |

||||

|

Emergency stop |

||||

|

8 |

The machinery must provide a quick manual method |

|||

|

G uard |

2 |

|||

|

disconnecting all system power. |

||||

|

Limit |

||||

|

Circuit isolation device (System Power Disconnect) |

||||

|

MC |

3 |

MC |

Utilize the electromagnetic contactor and the relay to be the |

|

|

1 |

isolation unit of the power circuit to prevent the possible |

|||

|

instability of the system when the power is supplied on and off. |

||||

|

DVP PLC MPU (main processing unit) |

||||

|

L N |

Grounding |

|||

|

6 |

7 |

Power supply: |

||

|

AC: 100 ~ 240V AC, 50/60Hz |

||||

|

DC: 24V DC |

Input Point Wiring

The input signal of the input point is the DC power DC input. There are two modes of DC type wiring: SINK and SOURCE, defined as follows:

|

Sink = Current flows into the common terminal S/S |

Source = Current flows out of common terminal S/S |

|

|

S/S |

X0 |

|

|

Sinkin g |

||

|

X0 |

S/S |

|

|

So urc ing |

||

|

Loop Equivalent Circuit of Input Point |

Wiring Loop |

|

+24V |

||||||

|

2 4VDC |

||||||

|

24G |

||||||

|

DC Type |

SINK |

|||||

|

(DC Signal IN) |

||||||

|

+5V |

||||||

|

S/S |

+24V |

OV |

S/S |

X0 X1 |

X2 |

|

|

X0 |

24VDC |

|||||

|

Sink Type |

||||||

|

SINK Mode |

||||||

|

Loop Equivalent Circuit of Input Point |

Wiring Loop |

|||||

|

+24 V |

||||||

|

DC Type |

24 G |

|||||

|

(DC Signal IN) |

+5V |

|||||

|

SO UR CE |

||||||

|

S/ S |

+24V |

OV |

S/ S |

X0 X1 |

X2 |

|

|

X0 |

24VD C |

|||||

|

Source Type |

||||||

|

SOURCE Mode |

|

Output Point Wiring |

|||

|

DVP-**-* *-11-R |

|||

|

L O AD |

1. There are two kinds of DVP-SX Series PLC output |

||

|

Y0 |

modules: Relay and Transistor. For relevant electrical |

||

|

LED |

RY |

P OW E R |

specification, please refer to the function specification. |

|

C0 |

2. Be careful with the connection of the common |

||

|

terminals when wiring outputs. For example, when |

|||

|

R E LAY O UT P U T |

wiring DVP12SX11R, output terminal Y0 uses one |

||

|

common terminal C0, Y1 uses C1, as shown below: |

|||

|

DVP- **-**-11-T |

|||

|

LOAD |

|||

|

T |

Y0 |

C0 Y 0 C1 Y 1 |

|

|

LED |

|||

|

R |

< 0 . 3 A |

Action indication: When the output point is active, the |

|

|

G |

C 0 |

corresponding indicator at the front will be on. |

|

|

3. Isolated circuit: The optical coupler is used to isolate |

|||

|

TRANSISTOR OUTPUT |

signals between PLC internal circuits and input |

||

|

modules. |

Analog Input/Output Point Wiring

|

Voltage input |

CH0 |

100K |

|||

|

-10V~+10V |

V+ |

CH0 |

|||

|

250 |

|||||

|

*3 |

I+ |

100K |

|||

|

COM |

|||||

|

Shielded*1 |

|||||

|

AG |

|||||

|

Current input |

CH1 |

100K |

CH1 |

||

|

-20mA~+20mA |

|||||

|

*2 |

V+ |

250 |

|||

|

I+ |

100K |

||||

|

COM |

|||||

|

Shielded*1 |

AG |

|

voltage output |

|||||||||||||||||||||||

|

*5 |

-10V~+10V |

CH0 |

|||||||||||||||||||||

|

V+ |

CH0 |

||||||||||||||||||||||

|

I+ |

|||||||||||||||||||||||

|

AC drive, recorder, |

COM |

||||||||||||||||||||||

|

shielding cable *1 |

|||||||||||||||||||||||

|

scale valve… |

|||||||||||||||||||||||

|

current output |

CH1 |

||||||||||||||||||||||

|

-20mA~20mA |

V+ |

CH1 |

|||||||||||||||||||||

|

I+ |

|||||||||||||||||||||||

|

COM |

|||||||||||||||||||||||

|

AC drive, recorder, |

shielding cable *4 |

||||||||||||||||||||||

|

scale valve… |

|||||||||||||||||||||||

|

terminal of |

|||||||||||||||||||||||

|

power module |

+15V |

||||||||||||||||||||||

|

DC24V |

24+ |

DC/DC |

AG |

||||||||||||||||||||

|

24- |

converter |

||||||||||||||||||||||

|

-15V |

|||||||||||||||||||||||

|

class 3 grounding |

|||||||||||||||||||||||

|

(100 |

or less) |

Note 1:

Please isolate analog input and other power wiring.

Note 2:

If input signal is in current, please short out between V+ and I+ terminals.

Note 3:

If the noise interference from loaded input wiring terminal is significant, please connect a capacitor with 0.1 ~ 0.47µF 25V for noise filtering.

Note 4:

Please isolate analog output and other power wiring.

Note 5:

If the noise interference from loaded input wiring terminal is significant, please connect a capacitor with 0.1 ~ 0.47µF 25V for noise filtering.

Note 6:

Please connect

Warning:

DO NOT wire to the No function terminal

|

SA/SX/SC PLC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OPEN TYPE |

/ |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

/ |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DVP |

DVP-SX |

10 |

4DI+2DO+2AI+2AO |

SA/SX/SC |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

2CH |

12-bit |

/ |

2CH |

12-bit |

/ |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

/ |

2 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

RUN/STOP |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3 |

2 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

I/O |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

DIN |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

I/O |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

7 |

/ |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

COM1 (RS-232) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(Rx) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

9 |

COM2 (RS-485) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(Tx) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

mm |

COM1 (RS-232) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(Slave) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

11 |

DIN (35mm) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3 |

PLC |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

15 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

COM2 (RS-485) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

(Master/Slave) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

17 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

2 pin |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

19 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

20 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

21 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

22 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DVP10SX11R/T |

DVP08SM11N |

DVP08SN11R/T |

DVP08SP11R/T |

DVP16SP11R/T |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

24V DC |

-15% ~ 20% |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

— |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2A/250V AC |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5W |

1W |

1.5W |

1.5W |

2W |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

5M |

/ |

500V DC |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ESD: 8KV Air Discharge |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O: 250V |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

RS: 26MHz ~ 1GHz, 10V/m |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

L,N |

PLC |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

/ |

0°C ~ 55°C |

50 ~ 95% |

2 |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

-25°C ~ 70°C |

5 ~ 95% |

D/A |

0°C ~ 50°C |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

/ |

IEC61131-2, IEC68-2-6 (TEST Fc)/IEC61131-2 & IEC68-2-27 (TEST Ea) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

, g |

138 / 133 |

64 |

88 / 68 |

90 / 70 |

96 / 76 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

SINK |

SOURCE |

-R |

-T |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

24V DC 5mA |

1.5A/1 |

5A/COM |

0.3A/1 |

@ 40°C |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

, Y0 |

Y1 |

30mA |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Off → On, |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

X0 |

X1 |

18.5V DC |

250V AC,30V DC |

30V DC |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

X2 |

X3 |

16.5V DC |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

On |

→ Off, |

75VA |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

X0~X3 |

8V DC |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

9W/1 |

Y0 Y1 0.9W |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

90W |

Y0 |

50KHz |

Y1 |

10KHz |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

10ms |

D1020 D1021 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

0 ~ 20ms |

10 ms |

Off → On 20us |

Y0 |

Y1 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

On → Off 30us |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

I/O |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DI |

AI |

DO |

AO |

|||||||||||||||||||||||||||||||||||||||||||||||||||

|

DI |

AI |

DO AO |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

-20 ~ 20mA |

-20 ~ 20mA |

|||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DVP10SX11R |

24VDC |

4 |

2 |

2 |

2 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

DC24V/5 mA |

( |

-1,000 ~ +1,000) |

( |

-2,000 ~ +2,000) |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

+20% |

Sink |

Source |

-10 ~ +10V |

-10 ~ +10V |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

-15% |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DVP10SX11T |

4 |

2 |

( |

-2,000 ~ +2,000) |

2 |

2 |

( |

-2,000 ~ +2,000) |

||||||||||||||||||||||||||||||||||||||||||||||