Mitsubishi FGC25N:

E30 Fault code

I have a problem with my FGC25N Mitsubishi, it begins to fail, shows an E30 fault code, I’m looking for technical info, because I need to fix others Forklifts, where can I find procedures to solve those problems?

thanks.

Showing items 1 — 2 of 2 results.

Sort messages by:

I found a wrong connection in the relays box, i fix it and the problem finished, thanks for your comments swoop223, best regards!!

code E30

— ECCS C/U Error signal. No power supplied to the ECM or ECM detects an insufficient voltage supply.

— No or low or high supplied power to the ECM.

The most common causes :

— EGI relay 1 open or short circuit

— EGI Relay 2 open or short circuit

— Main C relay open or short circuit

— Ignition relay open or short circuit

— Open ground circuit

— Open across fuse: F6- EGI relay 1 or F7- EGI relay 2 open circuit

— Corroded or broken wires at the ECM or lower left side step plate relay box and body ground.

— Internal open or short in the ECM

— Abnormally low or high ECM to sensor output voltage detected

From my experience the most common issue i have seen causing this issue is either a bad ground on the frame side of the truck where the grounds connect to the stud on the side of the frame under the battery. Remove the cables and wires and make sure there is no paint on the surface where the wire connectors make connection, if there is scrape the paint away and then reconnect the wires.

Secondly mcfa had issues with the relays on these units and had to do a parts update on the relays, the old ones were black and were updated to a green colored one. Intermittant signal from these relays can cause the EGI circuit to trigger a code.

If you find it still has the black ones in it replace them. It mentions above checking the black relay box under the foot step on the left side, i have rarely had to deal with these relays so that would only be a step to take if you do not find any problem with the other relays.

Also check the fuses in the fuse box and make sure none are blown, since this code indicates an open circuit in the EGI circuit it could just be a blown fuse. (uncommon)

Having trouble using the Discussion Forums? Contact us for help.

Forkliftaction.com accepts no responsibility for forum content and requires forum participants to adhere to the rules. Click here for more information.

Двигатель VQ 25, VQ 30 DD

Основные особенности, отличия, «тонкие» места, «болезни» и способы ремонта

Технические характеристики

Модель двигателя: VQ30DD бензиновый

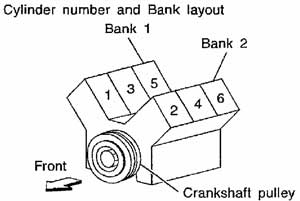

Тип ГБЦ: DOHC; Количество цилиндров: V6;

Объем двигателя, см3: 2987;

Мощность двигателя, л.с/оборотов-мин: 240/6400;

Крутящий момент, н-м, об.мин: 315/3600;

Диаметр, Ход поршня, мм: 93.0/73.3;

Степень сжатия: 11.00

Модель двигателя VQ25DD, бензиновый

Тип ГБЦ: DOHC; Количество цилиндров: V6;

Объем двигателя, см3 :2495;

Мощность двигателя, л.с/оборотов-мин 210/6400;

Крутящий момент, н-м/об.мин 270/4400;

Диаметр /Ход поршня, мм: 85.0/73.3;

Степень сжатия: 11.00

фото 1

Основные коды ошибок данных двигателей:

| Код ошибки | Описание кода неисправности |

| 0000 | неисправностей нет |

| 0100 |

MAF — датчик массового расхода воздуха |

| 0110 |

IAT sensor — датчик температуры воздуха на впуске |

| 0115 | THW sensor — датчик температуры охлаждающей жидкости |

| 0120 | THROTTLE SENSOR — электронная дроссельная заслонка и ее цепи |

| 0121 | ACCEL sensor (APPS) — датчик положения педали акселератора |

| 0130 | O2 sensor right bank (лямбда зонд) |

| 0150 | O2 sensor left bank (лямбда зонд) |

| 0180 | датчик температуры топлива (в баке) |

| 0190 | fuel pressure — датчик высокого давления (в магистрали форсунок) |

| 0325 | датчик детонации и его цепи |

| 0335 | POS sensor — датчик КВ |

| 0340 | PHASE sensor — датчик фазы распердвала |

| 0403 | EGR valve — клапан перепуска отработавших газов |

| 0500 | VSS — speed sensor — датчик скорости автомобиля |

| 0510 | idle swith — контактная группа холостого хода |

| 0600 | ENGINE-AT system — нет связи с AT (АКПП) |

| 0605 | ECCS C/U — неисправость ECU |

| 0650 | CHECK ENGINE LAMP — неисправность цепи контрольной лампы |

| 1065 | ECCS C/U — цепи питания ECU |

| 1110 | CVTC right bank valve — клапан система изменения фаз ГРМ |

| 1111 | IVT control solenoid valve электроклапан установки фаз(эл.часть) |

| 1121 | THROTTLE (actuator system) — привод электронной дроссельной заслонки |

| 1122 | THROTTLE (feedback system) — привод заслонки — обратная связь |

| 1123 | THROTTLE (motor relay system) — электропривод заслонки |

| 1135 | CVTC left bank valve — клапан системы изменения фаз ГРМ |

| 1136 | IVT control solenoid valve электроклапан установки фаз(эл.часть) |

| 1140 | CVTC phase sensor right bank — датчик фазы IVTC |

| 1145 | CVTC phase sensor left bank — датчик фазы IVTC |

| 1212 | ENGINE-TCS/ABS — нет связи с системой TCS/ABS |

| 1216 | DUI — driver unit injector — блок усилителя форсунок |

| 1217 | overheat — перегрев |

| 1232 | high pressure regulator — регулятор высокого давления |

| 1320 | сигнал системы зажигания — первичная сторона |

| 1335 | REF sensor — датчки КВ 120 град и ВМТ |

| 1706 | neutral swith — датчик нейтрали трансмисии |

| 1805 | stop lamp sw — датчик стоп сигналов |

| 1806 | brake low pressure sensor — датчик низкого давления ваккума в системе тормозов |

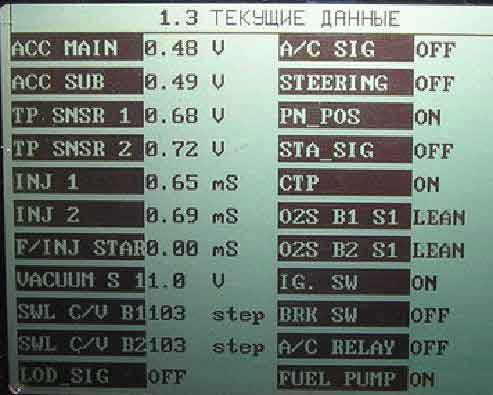

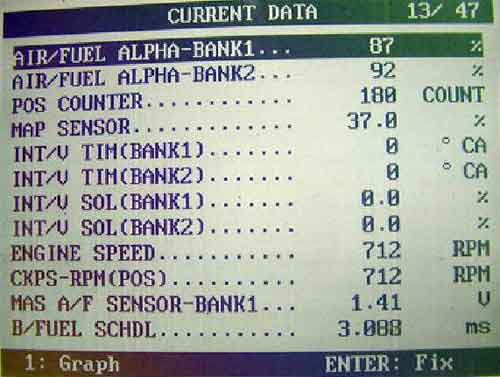

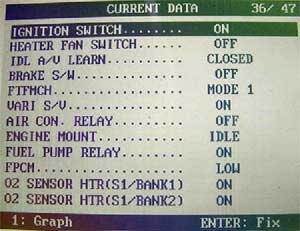

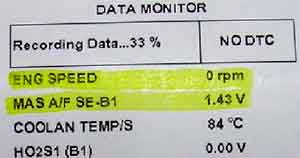

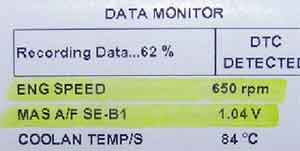

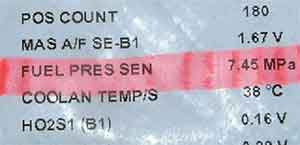

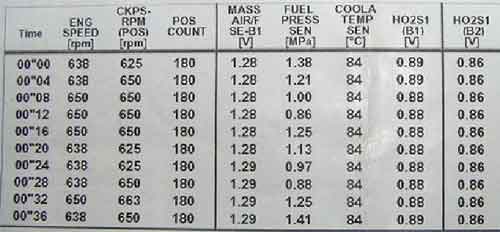

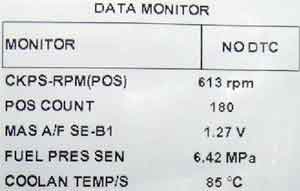

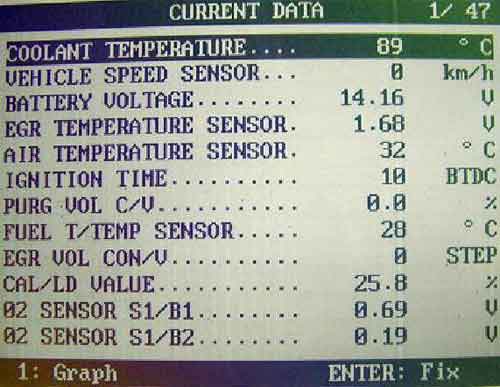

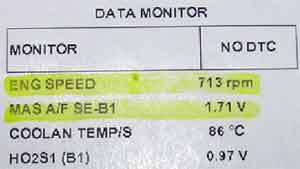

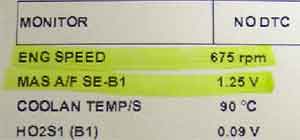

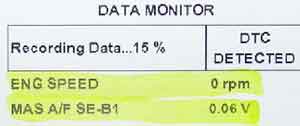

Данные Data monitor c разных сканеров

фото 2

фото 3

По данным сканера можно легко наблюдать в динамике за давлением топливного насоса, расходомером воздуха, датчиками кислорода, оборотами двигателя и другими датчиками. Для анализа доступно более 45 параметров, ознакомиться с которыми можно на следующих фото:

фото 4

фото 5

фото 6

CURRENT DATA

1.COOLANT TEMP/S [° C]

Датчик температуры охлаждающей жидкости

The engine coolant temperature (determined by the signal voltage of the engine coolant temperature sensor) is displayed.

2. Vehicle sped sensor

Датчик скорости автомобиля

The vehicle speed computed from the vehicle speed sensor signal sent from instrument cluster is displayed.

3. Battery voltage[ V ]

Напряжение в бортовой сети

The power supply voltage of ECM is displayed

4. EGR temperature sensor [V]

Датчик температуры канала EGR

The EGR temperature sensor detects temperature changes in the EGR passageway.

5. AIR temperature sensor[°C]

Датчик температуры воздуха на впуске

The intake air temperature determined by the signal voltage of the intake air temperature sensor is indicated.

6. IGN TIMING [BTDC]

Расчетный параметр угла опережения зажигания

Indicates the ignition timing computed by ECM according to the input signals. When the engine is stopped, a certain value is indicated.

7. PURG VOL C/V [%]

Индикатор работы электроклапана фильтра EVAP

Indicates the EVAP canister purge volume control solenoid valve control value computed by the ECM according to the input signals.

8. FUEL T / TMP SE [° C ]

Датчик температуры топлива

The fuel temperature judged from the fuel tank temperature sensor signal voltage is displayed.

9. EGR Vol CV [step]

Положение штока мотора EGR

The EGR volume control valve users a step motor to control the flow rate of EGR from exhaust manifold.

10. CAL/LD VALUE [%]

Расчетная нагрузка

«Calculated load value» indicates the value of the current airflow divided by peak airflow.

11. O2 Sensor S1/B1; HO2S1 (B1) [V]

Показание датчика кислорода в вольтах

The signal voltage of HO2S1 is displayed.

12. O2 Sensor S1/B2; HO2S2 (B1) [V]

Показание датчика кислорода в вольтах

The signal voltage of HO2S2 is displayed.

13 Air/Fuel ALPHA-Bank1 [%]

Соотношение топливо — воздушной смеси

The mean value of the air-fuel ratio feedback correction factor per cycle is indicated. When the engine is stopped, a certain value is indicated. This data also includes the data for the air-fuel ratio learning control.

14 Air/Fuel ALPHA-Bank2 [%]

Соотношение топливо — воздушной смеси

The mean value of the air-fuel ratio feedback correction factor per cycle is indicated. When the engine is stopped, a certain value is indicated. This data also includes the data for the air-fuel ratio learning control.

15. POS Counter [%]

Контур датчика положения коленчатого вала

16. MAP Sensor

Датчик разряжения (абсолютного давления)

the signal voltage of the absolute pressure sensor is displayed.

17. INT/V TIM (Bank1) [°CA]

Мониторинг угла опережения впускного распредвала

Indicates [°CA] of intake camshaft advanced angle.

18. INT/V TIM (Bank2) [°CA]

Мониторинг угла опережения впускного распредвала

Indicates [°CA] of intake camshaft advanced angle.

19. INT / V SOL (Bank 1) [%]- Управляющий клапан гидромуфты впускного распредвала(Bank 1). The control condition of intake valve timing control solenoid valve (determined by ECM according to input signals) is indicated. ON — intake valve timing control is operating. OFF — intake valve timing control is not operating.

20. INT / V SOL (Bank 2) [%] -Управляющий клапан гидромуфты впускного распредвала(Bank 2). The control condition of intake valve timing control solenoid valve (determined by ECM according to input signals) is indicated. ON — intake valve timing control is operating. OFF — intake valve timing control is not operating.

21. ENG SPEED [rpm]- Скорость двигателя Indicates the engine speed computed from crankshaft position sensor (POS) and camshaft position sensor (PHASE) signal.

22. CKPS — RPM (POS)-Скорость датчика положения коленчатого вала

23. MAS A / F SE — B 1 [ V ]-Показание датчика весового расхода воздуха. The signal voltage of the mass air flow sensor is displayed.

24. B / FUEL SCHDL [ msec ]-Указывает табличную расчетную ширину импульса открытия инжектора. … Indicates «Base fuel schedule» indicates the fuel injection pulse width programmed into ECM, prior to any learned on board correction.

25. ACCEL SEN 1 [V] Напряжение сигнала датчика положения педали акселератора Accelerator pedal position sensor signal voltage is displayed.

26. ACCEL SEN 2 [V]. Напряжение сигнала датчика положения педали акселератора Accelerator pedal position sensor signal voltage is displayed

27. THRTL SEN 1 [V] — Напряжение сигнала датчика положения дроссельной заслонки Throttle position sensor signal voltage is displayed

28. THRTL SEN 2 [V] — Напряжение сигнала датчика положения дроссельной заслонки Throttle position sensor signal voltage is displayed.

29. INJECT PULSE — BANK 1— Указывает фактическую ширину импульса открытия инжектора в первом «банке» … Indicates the actual fuel injection pulse width compensated by ECM according to the input signals.

30. INJECT PULSE — BANK 2. Указывает фактическую ширину импульса открытия инжектора во втором «банке». … Indicates the actual fuel injection pulse width compensated by ECM according to the input signals

31. FUEL Pressure Sensor [ MPa ] Показание датчика давления топлива

32. SWL C / V (Bank 1) Клапан заслонок

33. SWL C / V (Bank 2) Клапан заслонок

34. LOAD SIGNAL [ON/OFF] — Показание включения электрической нагрузки …Indicates [ON/OFF] condition from the electrical load signal and/or lighting switch.

35. AIR COND SIG [ON/OFF]- Сигнал включения кондиционера .Indicates [ON/OFF] condition of the air conditioner switch as determined by the air conditioner signal.

36. Power Steering Signal — Параметр включения гидроусилителя руля …PW/ST SIGNAL [ON/OFF] [ON/OFF] condition of the power steering oil pressure switch determined by the power steering oil pressure signal is indicated.

37. P/N Position Switch — Положение переключателя парковки нейтрали …P/N POSI SW [ON/OFF] Indicates [ON/OFF] condition from the park/neutral position (PNP) switch signal.

38. START SIGNAL [ON/OFF] — Сигнал стартера Indicates [ON/OFF] condition from the starter signal. After starting the engine, [OFF] is displayed regardless of the starter signal.

39. Closed Throttle POS. [ON/OFF]- Индикатор холостого хода (закрытый дроссель) Indicates idle position [ON/OFF] computed by ECM according to the throttle position sensor signal.

40 O2 Sensor Monitor S1/B1 (HO2S1 MNTR (B1) [RICH/LEAN]) Мониторинг богатой бедной смеси. Display of HO2S1 signal during air-fuel ratio feedback control: RICH — means the mixture became «rich», and control is being affected toward a leaner mixture. LEAN — means the mixture became «lean», and control is being affected toward a rich mixture.

41. O2 Sensor Monitor S1/B2HO2S1 MNTR (B2) [RICH/LEAN] Мониторинг богатой бедной смеси Display of HO2S1 signal during air-fuel ratio feedback control: RICH — means the mixture became «rich», and control is being affected toward a leaner mixture. LEAN — means the mixture became «lean», and control is being affected toward a rich mixture.

42. IGNITION SWITCH [ON/OFF] — Индикатор работы выключателя зажигания …Indicates [ON/OFF] condition from ignition switch.

43 Heater Fan SWITCH — Вентилятор охлаждения .

44 IDL A/V Learn. Display the condition of idle air volume learning. YET — Idle air volume learning has not been performed yet. CMPLT — Idle air volume learning has already been performed successfully. INCMP — Idle air volume learning has not been performed successfully.

45 BRAKE SW [ ON / OFF ] Индикатор включения педали тормоза. Indicates [ON/OFF] condition from ASCD brake switch signal, and ASCD clutch switch signal (M/T models) or park/neutral position relay signal (A/T models).

46. AIR COND RLY [ON/OFF] Индикатор включении кондиционера The air conditioner relay control condition (determined by ECM according to the input signal) is indicated

47. ENGINE MOUNT [IDLE/TRVL]- Контроль крепления двигателя The control condition of the electronic controlled engine mount (computed by ECM according to input signals) is indicated. IDLE — Idle condition; TRVL — Driving condition.

48. FUEL PUMP RLY [ON/OFF] Индикатор состояния реле топливного насоса Indicates the fuel pump relay control condition determined by ECM according to the input signals.

49. O2 Sensor HTR(S1/Bank1) HO2S1 HTR (B1) [ON/OFF] — Индикация состояния нагревателя датчика кислорода , вкл / выкл Indicates [ON/OFF] condition of heated oxygen sensor 1 heater (front) determined by ECM according to the input signals.

50. O2 Sensor HTR(S1/Bank2) HO2S1 HTR (B2) [ON/OFF] — Индикация состояния нагревателя датчика кислорода , вкл / выкл Indicates [ON/OFF] condition of heated oxygen sensor 1 heater (front) determined by ECM according to the input signals.

51. FUEL PUMP CONTROL MODULE (FPCM) [high/low] — Режим управления топливным насосом — высокий , низкий . (принимает значения high – low) это система контроля напряжения на насосе подкачки в баке в зависимости от оборотов мотора (подает частичное или полное напряжение на топливный насос)

52. VARI S / V— система изменения длины впускного коллектора variable switch / valve

Ориентация «Bank 12» на двигателе.

«Болезни»:

За несколько лет работы с данными двигателями выработался определенный опыт.

Вот основные уязвимые места в двигателе:

1. Неисправность датчика MAF, в простонародье – «расходомера воздуха»

2. Потеря давления в топливном насосе

3. Неисправность катушек зажигания

4. Плохой запуск или его отсутствие из-за неисправности стартера

5. Потеря мощности из-за «срыва» катализаторов (фото 30 — 33)

6. Постоянная детонация и повышенный расход топлива из-за большого количества сажи на клапанах (засаженность)

7. Нарушение фазы газораспределения

8. Неправильная работа инжекторов

Наверное, самая распространенная жалоба клиентов при посещении сервиса – горящий CHECK ENGINE

и, иногда, временное, а иногда постоянное «троение» двигателя. Как следствие — потеря мощности; как правило, это связано с нарушениями в системе зажигания. Блок управления оценивает работу катушек зажигания и при малейшем нарушении информирует водителя о проблеме (зажиганием лампы CHECK ENGINE).

При сканировании выявляется код Р1320 — сигнал системы зажигания, «первичная сторона».

Про эту проблему уже писали на страницах данного форума.

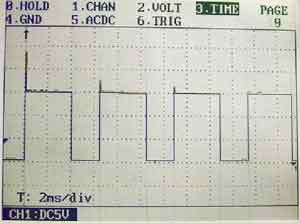

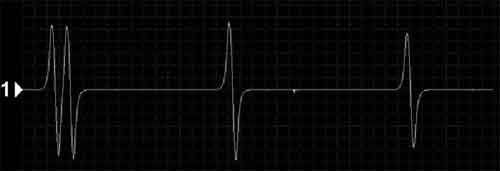

Хочу лишь добавить свою методику проверки неисправной катушки зажигания. На левой головке двигателя доступ к катушкам зажигания открыт и здесь совсем не составляет труда осциллографом проверить импульсы на управляющих выводах катушек. На правой же головке доступ, напротив, затруднен. Для нормальной проверки катушки приходится демонтировать. Я меняю их местами с разных «головок» для проверки. Делаю это для того, что бы визуально проверить состояние наконечников. Нередки случаи пробоев и «зеленения» контактов из-за воды или масла.

Важно проверить катушку на разряднике — на неисправной катушке будут видны явные пропуски искрообразования.

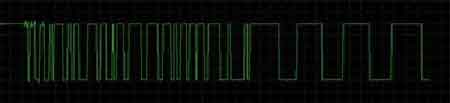

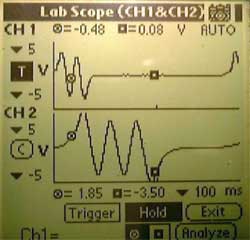

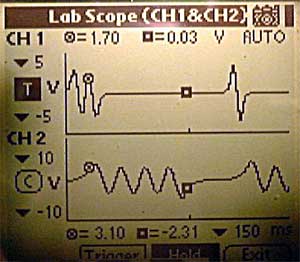

Вот несколько осциллограмм:

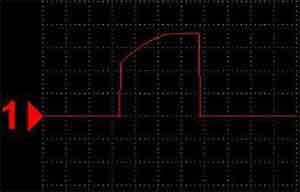

ФОТО 7 — правильная работа

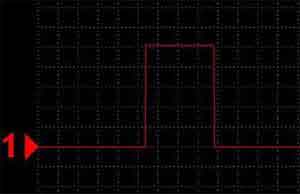

ФОТО 8 — катушка в «обрыве» (силовой транзистор или обмотка)

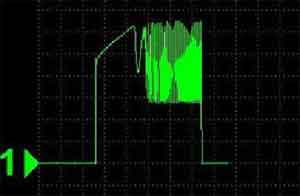

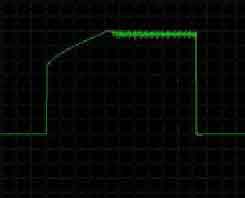

ФОТО 9 и 10 — неправильная работа силового транзистора в катушке.

фото 7

фото 8

Фото 9

Фото 10

При проверке нужно обращать внимание и на наличие масла в свечных колодцах (оно туда может попадать через «задубевший» сальник клапанной крышки). При наличии масла есть вероятность «пробоя» катушки либо коммутатора в ней.

Следующая проблема связана с отказом или нарушением правильной работы датчика MAF — датчик массового расхода воздуха.

При работе двигатель потребляет огромное количество воздуха и качество его фильтрования влияет коренным образом на работу данного датчика. В расходомере производители применили открытый кристалл. При постоянном воздействии частиц пыли на кристалл он мутнеет (от постоянного «пескоструя») или просто забивается грязью и, как результат, параметры датчика «уходят в сторону». Нормальная работа двигателя становится невозможной. Диагностика данного девайса очень проста – замеряем напряжение при включенном зажигании на сигнальном выводе датчика и сравниваем с нормативными показателями (1,03- 1,05 вольта).

Показания завышены:

фото 11

Завышенные показания при работе двигателя на хх

фото 12

При отклонениях в параметрах меняем датчик на исправный.

Правильные показания:

фото 13

При покупке (заказе) датчика следует учитывать цвет метки на расходомере и на его корпусе.

фото 14

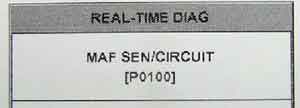

При полном обрыве датчика блок управления фиксирует код ошибки P 0100 MAF (Mass Air Flow) Sensor.

фото 15

При неисправном датчике (внутренний обрыв) на сканере «застынет» показание в 1,01-1,04вольт, и оно не будет меняться при перегазовках. При обрыве проводки к датчику

— показания на мониторе сканера будут нулевыми.

фото 16

Внутренний обрыв или « неудачная помывка датчика»

фото 17

В Интернете бытует мнение о возможности промывания в спирте загрязнённой части датчика. Мне несколько раз приходилось мыть датчик, но к положительному результату эта процедура не приводила.

Если же параметры датчика заметно «уплыли» (на хх 1,5 — 1,7 в), то временно восстановить работу двигателя можно изменив количество проходящего через него воздуха. Для этого нужно лишь на 10 — 15 градусов повернуть датчик по часовой стрелке. Болты крепления, конечно, нужно демонтировать.

фото 18

Более серьезная проблема – это износ ТНВД. При пониженном давлении двигатель способен работать, но наблюдается заметный черный выхлоп, «троение», потеря мощности и очень большой расход топлива. Регистрировать давление очень просто. На сканер выводится строчка с параметром с датчика давления, установленного на насосе. Давление изменяется соразмерно оборотам двигателя.

фото 19

Правильное давление — 6,8-7,4МРа на хх.

Если нет сканера, то можно проконтролировать давление с помощью вольтметра на разъёме датчика давления. Разъем датчика расположен в доступном месте и проделать эту процедуру не составит труда.

можно посмотреть зависимость напряжения от давления.

Форма импульса на клапане регуляторе давления:

фото 20

Фото 21

(Р1232) high pressure regulator — регулятор высокого давления

то Вам, как диагносту, следует сделать некоторые замеры. Вы должны проверить наличие управляющего импульса на клапане ТНВД и проверить, какое давление развивает подкачивающий насос в топливном баке.

Это необходимо делать, чтобы исключить неправильный диагноз по замене насоса и не стать впоследствии «счастливым его обладателем». Не исключается вероятность того, что при заклинивании насоса «срезало» привод ТНВД и «просто замена» не решит проблему, а время будет потеряно для Вас и для Клиента.

Часто при разборе насосов видны следы износа плунжеров, подшипников, разрыва гофры, заклинивание плунжеров. Основными виновниками выхода из строя насоса являются вода, грязь, песок, которых предостаточно в нашем «чистом» отечественном топливе.

Показания сканера — низкое давление

фото 22

Неисправные плунжеры

Фото 23

Фото 24

Фото 25

Проверяйте после снятия ТНВД состояние привода,-

Привод «срезан»:

Фото 26

Исправный привод

фото 27

А здесь «разбитый» подшипник в насосе деформировал «гофру» из-за деформированного сальника на приводе (вытекло масло из насоса и произошёл перегрев подшипника)

фото 28

При снятии ТНВД обращайте внимание на направляющие втулки — их две. Они легко могут скатиться в полость головки, что приведет к непредсказуемым последствиям.

Следует отметить, что в новом насосе нужно обязательно проверить наличие масла, без которого насос не проработает и несколько часов.

фото 29

Многие проблемы на данных двигателях пересекаются. Одна является следствием другой. При проблемах в системе зажигания и отказах в работе катушек, несгоревший бензин догорает в катализаторах. Температура катализатора увеличивается до немыслимых значений. Коллектор накаляется докрасна, появляется вероятность возгорания автомобиля. На «Цедриках» и «Глориях» установлены три катализатора. Два непосредственно рядом с головками (они металлические) и один керамический под днищем автомобиля.

Катализаторы нередко срывает со штатного места и ими, буквально, выпускной тракт «запаковывается» как пробкой. Теряется мощность двигателя.

Фото 30

фото 31

Проконтролировать «забитость» можно при помощи датчика давления. Доступ к датчикам кислорода ограничен. Порт датчика давления подключается в отверстия лямбда-зондов. При диагностике «пытайте» Клиента — сколько времени он катается на «троящем» двигателе.

фото 32

фото 33

При работе на ХХ следует обращать внимание на температуру патрубков системы EGR. Были случаи, когда металлические частицы прогоревшего катализатора попадали под шток клапана, тем самым не давая ему закрыться.

Как результат — неровная работа двигателя и раскаленная подводная трубка.

фото 34

Еще одна серьезная проблема — это так называемая «засаженность» двигателя. Коллектор двигателя с прямым впрыском — он большого обьема. По моему мнению, это обусловлено необходимостью улавливания частиц сажи, оставшихся после полного сгорания смеси. Сажи накапливается огромное количество. В практике встречались автомобили с практически полностью перекрытыми клапанными каналами. Чистку коллектора следует производить при возникновении постоянной детонации при работе двигателя. Увидеть сажу можно просто при осмотре форсунки холодного пуска.

фото 35

Фото 36

Фото 37

фото 38

Очистка, как правило, не занимает много времени, так как кокс и сажа практически всегда имеют «сухую» структуру. Весь этот налет легко снимается скребками и всевозможными ёршиками. С чисткой коллектора не возникнет трудностей, а вот с клапанами придется повозиться. Ставим поршень цилиндра в ВМТ и счищаем сажу на днище клапана. Затем удаляем сажу пылесосом. Так все 12 отверстий.

Почищенный клапан

фото 39

фото 40

Остатки выдуваем сжатым воздухом. Если вам «не повезло» и колпачки «текут», то кокс будет сырой — здесь придется воспользоваться очистителями. А собирать растворённую грязь либо шприцем, либо «отсосом».

Результат очистки коллектора и клапанов

Фото 41

фото 42

Часто привозят автомобили с проблемами невозможности запуска. Блок управления регистрирует нарушение в работе датчика коленвала. Код P0335POS sensor — датчик КВ

Фото 43

фото 44

Блок управления постоянно фиксирует код ошибки.

Замена датчика не решает проблемы.

Импульс имеется, а запуска не происходит.

Проблема лежит глубже.

Этот «трабл» не раз обсуждался на нашем форуме, я просто повторю то, что уже писалось и добавлю из своего опыта.

Вся проблема заключается в «неровной работе стартера», «просадке» напряжения, разбитые втулки или изогнутый маховик, налипание частиц металла к датчику. Это приводит к тому, что начальный импульс датчика коленвала становится неправильным.

фото 45

(…на нашем форуме диагност из города Санкт-Петергбурга Vasaby так писал про эту проблему:

«Прикол в том, что электрические помехи от стартера тут ни при чем. Минусовой провод батарея-мотор можно поставить удлиненный, проложить мимо датчика и увести на болт крепления стартером. И все равно запуск станет легче. Дело в чувствительности датчика скорости вращения колена к большим угловым ускорениям-замедлениям венца при подклинивании якоря стартера или рывкам колена вблизи ВМТ из-за недостаточной мощности стартера».

Проблема решается либо заменой стартера, либо переносом дополнительного минусового провода на болт крепления стартера…).

фото 46

Регистрировать данную проблему можно, наблюдая за параметром POS COUNT в «дате» сканера его значение должно быть 180

http://forum.autodata.ru/1/3904/

Можно просматривать импульс с датчика коленвала.

фото 47

Проблема просмотра импульса в доступе к датчику. Импульс можно снять непосредственно на датчике либо на блоке управления.

фото 48

фото 49

Чем меньше участок с «грязным» импульсом, тем быстрее произойдет запуск.

Есть еще одна проблема с затруднённым запуском – DTC P1335.

REF sensor – датчк КВ 120 град и ВМТ

Отсутствие сигнала с датчика коленвала (переднего) также нарушает процесс синхронизации. При отсутствии этого сигнала двигатель все же запускается, но с трудом (долгое вращение стартера)

Правильный сигнал

фото 50

И сам датчик

фото 51

Одна интересная деталь — ВМТ это всегда REF двойной импульс, PHASE 3 импульса — 1 цилиндр, 4 импульса — 4 цилиндр.

Так можно проверить метки цепи не снимая крышки на двухканальном осциллографе. Так как датчики индуктивные, то можно вообще зажигание не включать (со снятыми коллекторами) просто подав «+» на стартер.

Синхронизация_ REF двойной импульс и PHASE 4 импульса — 4 цилиндр.

Синхронизация ВМТ и катушки 1 цилиндра

IGN — это положение импульса на катушку 1 го цилиндра и REF

На данных двигателях установлены низкоомные инжекторы, способные работать на обычном и на очень большом давлении, до 120кгсм2. Управляющий импульс вырабатывается специальным блоком — усилителем инжекторов. Усилитель вырабатывает импульс амплитудой до 100 вольт, который способен открыть и закрыть инжектор под большим давлением. За время эксплуатации сопла инжекторов загрязняются, загрязняется и игла.

Фото 52

фото 53

Тем самым нарушается нормальная работа форсунок, распыл и производительность.

Мыть форсунки следует в ультразвуке по аналогии с инжекторами от TOYOTA или MMC.

Подающая топливо «рейка» прикручивается к инжекторам специальными болтами. Для их демонтажа потребуется изготовить особый ключ.

Снимать форсунки следует с осторожностью, и использовать простейший съемник.

Фото 54

фото 55

Демонтаж форсунки надо производить плавно и равномерно во избежание ее повреждения. Предварительно на посадочное место надо распылить смазку, например VD-40.

«Закоксованные» форсунки также приводят к обеднению смеси, потери мощности, проявлениям детонации, не устойчивому ХХ.

Бывали случаи, когда из-за грязи форсунка начинает «лить» топливо. Увеличивается общий расход топлива. Заметен запах и «черный» выхлоп. Свеча зажигания не успевает очищаться, а датчик кислорода постоянно регистрирует «богатую» смесь. Такую форсунку редко удается «оживить».

Работу инжекторов можно наблюдать осциллографом прямо на усилителе инжекторов.

Осциллограмма с вывода усилителя относительно массы двигателя

фото 56

При изменении в сопротивлении обмотки инжектора фиксируется код неисправности P1216 injector D/U., эта ошибка может указывать и на отказ усилителя.

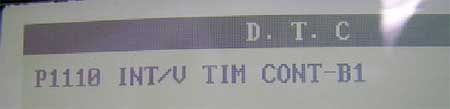

Следующая проблема связана с нарушением фаз газораспределения.

Блок управления двигателем фиксирует шесть кодов, связанных с данной проблемой. На распредвале установлена шестерня, способная изменять его положение в зависимости от давления подводимого к ней масла. В этой системе есть четыре ключевых элемента – клапан, муфта с шестерней, датчик положения муфты, датчик распредвала

фото 57

фото 58

фото 59

Датчик фазы и распредвала

фото 60

При нарушении в работе клапана (клапанов) блок управления фиксирует ошибку

DTC P1111, P1136 IVT control solenoid valve.

Эти коды указывают на электрические проблемы в управляющих клапанах (следует проверить сопротивление, наличие управляющего сигнала, питание). Сопротивление клапана 7,0 -7,7ом при температуре 20 градусов Цельсия.

При отсутствии импульса с датчиков положения муфты, ECM регистрирует ошибки

DTC P1140, P1145 IVT control position sensor.

Следует проверить импульсы на датчиках и наличие питания. Если смотреть на двигатель, то код P1140 указывает на неисправный левый датчик, а код P1145 на правый.

Правильный импульс

фото 61

При невозможности установки заданного положения распредвала и при наличии импульсов с датчиков фазы фиксируются коды

DTC P 1110, P1135. INTAKE VALVE TIMING CONTROL PERFORMANCE

При возникновении этих кодов следует проверить гидравлическую часть системы, подклинивание клапана, грязь в сетке, неисправность самой гидравлической муфты.

фото 62

Форму сигналов можно посмотреть по ссылке

Форма сигнала с датчика распредвала:

фото 63

И напоследок небольшая хитрость по снятию и установке необычных разъемов на датчиках.

Под пружинки механизма попадает грязь, из-за чего разъеденить разъем очень сложно. Чтобы не сломать эту конструкцию, нужно брызнуть проникающей смазкой в место хода защелки и вся конструкция вновь заработает.

фото 64

Я попытался максимально коротко осветить наиболее часто встречающиеся проблемы с данной серией двигателей. Всем удачных ремонтов и добрых клиентов.

Владимир Бекренёв при поддержке Антона Воробьёва и Арида Гаджиева

© Легион-Автодата

Skip to content

How to clear forklift error codes

How to clear forklift error codes?

In all new generation of forklift and also some old models of forklift sometimes when you are using the forklift will see some error code on the monitor(dashboard) of the forklift.

In different forklift, each Error code means different things.

On Yale and Hyster forklift the error code can be showed or can be in the system.

Yale and Hyster Forklift Fault Codes List

for going inside the system you need the password that the company using or can be changed by the dealer before they ship it to the customer.

When you go inside the system you are able to see the error code and you will see how many time this error code showed in your forklift and also when (In witch hours of using the forklift), from the error code list that the company gives for each forklift to the dealers and forklift technician you will understand what is the problem and you can solve the issue with any headache.

In some other trucks same as Raymond, Toyota, and Nissan you will see the error code directly in the forklift and you can solve the issue and use the forklift easy.

How to detect and figure out forklift error codes?

In all forklift when the technician connect with computer to forklift all the issue and error will show up and he can fix for you, your forklift

Sometimes you see the error code in your forklift but you see your forklift work well, But it can be a point and you have to solve it because it is same as alarm and if you don’t ask the forklift technician for this issue in future you will be stuck with the bigger problem and big charge to repair your forklift.

Our suggestion is when you do your daily checklist please look and see your forklift doesn’t have any error code.

If you find any error code, don’t use the forklift to solve the issue.

How you can figure out forklift error codes?

Please leave the error code below this article then We and other specialists will answer you as soon as possible.

Our technician at Forklift Plus can detect and figure out your forklift problems as soon as possible.

Share This Story, Choose Your Platform!

Related Posts

Page load link

Go to Top

NISSAN Forklift Truck Fault Codes list

E03 VCM communication error

E04 ECM communication error

E05 DCM communication error

E06 HST communication error

E07 MP communication error

E08 TMS communication error

E21 Air flow meter error signal

E22 Water temperature sensor error signal

E23 Throttle sensor error signal

E24 Accelerator sensor error signal

E25 O2 sensor error signal

E26 O2 sensor heater error signal

E27 POS sensor error signal

E28 PHASE sensor error signal

E29 Self shutdown system diagnostic result error signal

E30 ECCS C/U error signal

E31 Electronic control throttle control error signal

E32 Overhear signal (STEP 1)

E33 Overheat signal (STEP 2)

E34 Spark system error signal

E35 LPG F/INJ disconnection diagnostic result signal

E36 LPG fuel pressure sensor diagnostic result signal

E38 LPG vaporizer diagnostic result signal

E39 Mast-high SW diagnostic result signal

E40 Oil pressure sensor diagnostic result signal

E41 Stop lamp SW error signal

F02 Battery voltage error

F57 Tilt backward solenoid error

F03 VCM communication error

F59 Tilt solenoid leak

F04 ECM communication error

F60 Attack-1A solenoid error

F05 DCM communication error

F62 Attach-1B solenoid error

F06 HST communication error

F64 Attach-1 solenoid leak

F07 MP communication error

F65 Attach-2A solenoid error

F08 TMS communication error

F67 Attach-2B solenoid error

F10 Lift lever neutral error

F69 Attach-2 solenoid leak

F11 Tilt lever neutral error

F70 Attach-3A solenoid error

F12 Attach-1 lever neutral error

F72 Attach-3B solenoid error

F13 Attach-2 lever neutral error

F74 Attach-3 solenoid leak

F14 Attach-3 lever neutral error

F75 Unload solenoid error

F16 Shift lever error

F77 Lift lock solenoid error

F17 Speed error

F7 Unload solenoid leak

E29 Self shutdown system diagnostic result error signal

F20 Lift lever error

F80 Knob position solenoid error

F22 Tilt lever error

F82 Tilt lock solenoid error

F24 Attach-1 lever error

F24 Knob position solenoid leak

F26 Attach-2 lever error

F85 T/M forward solenoid error

F28 Attach-3 lever error

F87 T/M backward solenoid error

F30 Main oil pressure sensor error

F89 T/M solenoid leak

F32 Lift oil pressure sensor error

F34 Speed sensor error

F36 Tire angle sensor error

F38 Tilt angle sensor error

F40 Steering error

F50 Lift up solenoid error

F52 Lift down solenoid error

F54 Lift solenoid leak

F01 Memory check error

F55 Tilt forward solenoid error

P03 VCM communication error

P04 ECM communication error

P05 DCM communication error

P06 HST communication error

P07 MP communication error

P08 TMS communication error

P22 Shift lever error signal

Самодиагностика Nissan Cedric & Nissan Gloria Y34. Считывание результатов: Поверните ключ зажигания в положение «ON», не запускайте двигатель; Замкните контакты («IGN» и «CHK») контакты 1 и 8 не менее чем на 2 сек.; уберите перемычку Некоторые пояснения по методике чтения кодов самодиагностики: «0» индицируется 10-ю вспышками; 4-ый разряд кода индицируется длинными вспышками длительностью 0.6 сек.; 3-ий разряд и ниже индицируется короткими вспышками длительностью 0.3 сек.; Промежутки между цифрами в коде (он 4-х значный) равны 1 сек.; Промежутки между кодами равны 1.8 сек.; Код «0000» означает — «неисправности не обнаружены».

Код ошибки

Описание кода неисправности

0000

неисправностей нет

0100

MAF — датчик массового расхода воздуха

0110

IAT sensor — датчик температуры воздуха на впуске

0115

THW sensor — датчик температуры охлаждающей жидкости

0120

THROTTLE SENSOR — электронная дроссельная заслонка и ее цепи

0121

ACCEL sensor ( APPS ) — датчик положения педали акселератора

0130

O2 sensor right bank ( лямбда зонд )

0150

O2 sensor left bank ( лямбда зонд )

0180

датчик температуры топлива ( в баке )

0190

fuel pressure — датчик высокого давления ( в магистрали форсунок )

0325

датчик детонации и его цепи

0335

POS sensor — датчик КВ

0340

PHASE sensor — датчик фазы распердвала

0403

EGR valve — клапан перепуска отработавших газов

0500

VSS — speed sensor — датчик скорости автомобиля

0510

idle swith — контактная группа холостого хода

0600

ENGINE-AT system — нет связи с AT ( АКПП )

0605

ECCS C/U — неисправость ECU

0650

CHECK ENGINE LAMP — неисправность цепи контрольной лампы

1065

ECCS C/U — цепи питания ECU

1110

CVTC right bank valve — клапан система изменения фаз ГРМ

1111

IVT control solenoid valve электроклапан установки фаз(эл.часть)

1121

THROTTLE ( actuator system ) — привод электронной

дроссельной заслонки

1122

THROTTLE (feedback system ) — привод заслонки — обратная связь

1123

THROTTLE ( motor relay system ) — электропривод заслонки

1135

CVTC left bank valve — клапан системы изменения фаз ГРМ

1136

IVT control solenoid valve электроклапан установки фаз(эл.часть)

1140

CVTC phase sensor right bank — датчик фазы IVTC

1145

CVTC phase sensor left bank — датчик фазы IVTC

1212

ENGINE-TCS/ABS — нет связи с системой TCS/ABS

1216

DUI — driver unit injector — блок усилителя форсунок

1217

overheat — перегрев

1232

high pressure regulator — регулятор высокого давления

1320

сигнал системы зажигания — первичная сторона

1335

REF sensor — датчки КВ 120 град и ВМТ

1706

neutral swith — датчик нейтрали трансмисии

1805

stop lamp sw — датчик стоп сигналов

1806

brake low pressure sensor — датчик низкого давления ваккума в

системе тормозов

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

MAN truck Fault Codes DTC

MAN truck Fault Codes DTC

MAN truck Fault Codes DTC.pdf

Adobe Acrobat Document

473.2 KB

MAN Truck Fault Codes DTC — EBS 5 Knorr

Code (SPN) Description Reason, verification and system response.

597 Module foot brake switch 1. Short to Ground (FMI5). STOP warning light is amber. User functions are not limited. Electrical or mechanical failure of a foot brake module,

faulty wiring or contacts in the connectors. Check wiring and connections between the EBS unit (A402) and the sensor module foot brake (V337) for insulation and continuity. Disconnect from the

EBS unit (A402) and inspect the resistance between the contacts of a foot brake module _SIG1 (X1 / 5) and _GND (X1 / 4). R_SW1 open: R_SIG1 resistance value is less than 4.8 ohms or more 6.5

ohms. R_SW1 closed: resistance value R_SIG1 5.4-6.2

ohms. If the resistance values are outside of acceptable values, replace the module foot brake.

597 Module foot brake, switch on the power supply 1. Short Ubat (FMI6). STOP warning light is amber. User functions are not limited. Electrical or mechanical failure of a foot

brake module, faulty wiring or contacts in the connectors. Check wiring and connections between the EBS unit (A402) and the sensor module foot brake (V337) for insulation and continuity.

Disconnect from the EBS unit (A402) and inspect the resistance between the contacts of a foot brake module _SIG1 (X1 / 5) and _GND (X1 / 4). R_SW1 open: R_SIG1 resistance value is less than 4.8

ohms or more 6.5 ohms. R_SW1 closed: resistance value R_SIG1 5.4-6.2 ohms. If the resistance values are outside of acceptable values, replace the module foot brake.

603 Module foot brake switch 2. Short to Ground (FMI5). STOP warning light is amber. User functions are not limited. Electrical or mechanical failure of a foot brake module,

faulty wiring or contacts in the connectors. Check the wiring of a foot brake module. If the wiring is OK, replace the module foot brake.

603 Module foot brake switch 2. Short to power supply Ubat (FMI6). STOP warning light is amber. User functions are not limited. Electrical or mechanical failure of a foot brake

module, faulty wiring or contacts in the connectors. Check the wiring of a foot brake module. If the wiring is OK, replace the module foot brake.

609 The central control unit in the controller. Undefined fault (FMI0). STOP warning light lit in red, and red lights lamp total control of brakes. All user functions are

disabled. Interrupted software download, damaged EBS microcontroller unit (A402). Update the software in EBS unit (A402), clear the fault memory. If the fault code appears again, replace the EBS

unit (A402).

627 Power Supply. Not identified (FMI3). STOP warning light lit in red, and red lights lamp total control of brakes. All user functions are disabled. A break in the power supply

circuit or defective EBS unit (A402). Check the connection terminals 30, the power supply circuit: UB_1 (X1 / 17), UB_2 (X1 / 16), GND_1 (X1 / 12), GND_2 (X1 / 11).

The central control device, and controller. Undefined fault (FMI0). STOP warning light lit in red, and red lights lamp total control of brakes. All user functions are disabled. Temporary

fault condition. Temporarily switching to backup. For safety, the system performs a diagnostic test for the system.

639 Channel J1939 data CANtransmissii. No signal (FMI4). STOP warning light lit in red, and red lights lamp total control of brakes. All user functions are disabled. Defective

unit EBS (A402). Clear the fault memory. If the fault code appears again, replace the EBS unit (A402).

639 channel data J1939, CAN powertrain. Open (FMI10). STOP warning light is amber. Switches the retarder, control ESP, control the adjustment of reference torque (DTC),

dvigatelyaASR control, brake control ASR. Damaged wiring CAN data channel connection with the transmission, a fault in the power supply circuit or electromagnetic interference. Check wiring and

wiring data channel transmission unit for continuity and insulation. Check the correct functioning of the control units associated with CAN.

645 channel data connection with tachograph timeout. No signal (FMI4). STOP warning light is amber. User functions are not limited. Electromagnetic interference, an external

device is disconnected from the data channel, the external device sends a message, not all of a malfunction. Check wiring channel data for continuity and insulation. Check for proper operation of

the external device.

746 differential lock valve. Short to Ground (FMI5). STOP warning light is amber. differential lock function is limited. Damaged wiring in the interlock circuit or defective EBS

unit (A402). Clear the fault memory. Check wiring and connections between the EBS unit (A402) and lock the valve.

746 differential lock valve. Short to power supply Ubat (FMI6). STOP warning light lit in red, and red lights lamp total control of brakes. differential lock function is limited.

Damaged wiring in the interlock circuit or defective EBS unit (A402). Clear the fault memory. Check wiring and connections between the EBS unit (A402) and lock the valve.

789 Sensor wheel speed, wheel 1. No signal (FMI4). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The large gap between the sensor and gear, damaged wiring, contacts in the connectors, sensor is faulty, damaged or defective gear modulator. Check the

sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors between the modulator and the sensor. Check the integrity of gear. Check the clearance between the sensor and the

gear. Check wheel bearing play. If the wiring, the sensor, gear, wheel bearing is OK, replace the modulator.

789 Sensor wheel speed, wheel 1. Short (FMI7). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the engine

control ASR, brake control ASR. The closure between a wiring of different sensors or faulty modulator. Check the sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors

between the modulator and the sensor. If the wiring and the sensor is normal, replace the modulator.

790 Sensor wheel speed, wheel 2. No signal (FMI4). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The large gap between the sensor and gear, damaged wiring, contacts in the connectors, sensor is faulty, damaged or defective gear modulator. Check the

sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors between the modulator and the sensor. Check the integrity of gear. Check the clearance between the sensor and the

gear. Check wheel bearing play. If the wiring, the sensor, gear, wheel bearing is OK, replace the modulator.

790 Sensor wheel speed, wheel 2. Short (FMI7). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the engine

control ASR, brake control ASR. The closure between a wiring of different sensors or faulty modulator. Check the sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors

between the modulator and the sensor. If the wiring and the sensor is normal, replace the modulator.

791 Sensor wheel speed, wheel 3. No signal (FMI4). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The large gap between the sensor and gear, damaged wiring, contacts in the connectors, sensor is faulty, damaged or defective gear modulator. Check the

sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors between the modulator and the sensor. Check the integrity of gear. Check the clearance between the sensor and the

gear. Check wheel bearing play. If the wiring, the sensor, gear, wheel bearing is OK, replace the modulator.

791 Sensor wheel speed, wheel 3. Closing (FMI7). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The closure between a wiring of different sensors or faulty modulator. Check the sensor resistance: 950-1930 ohms. Check wiring and contacts in the

connectors between the modulator and the sensor. If the wiring and the sensor is normal, replace the modulator.

792 Sensor wheel speed, wheel 4. No signal (FMI4). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The large gap between the sensor and gear, damaged wiring, contacts in the connectors, sensor is faulty, damaged or defective gear modulator. Check the

sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors between the modulator and the sensor. Check the integrity of gear. Check the clearance between the sensor and the

gear. Check wheel bearing play. If the wiring, the sensor, gear, wheel bearing is OK, replace the modulator.

792 Sensor wheel speed, wheel 4. Closure (FMI7). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The closure between a wiring of different sensors or faulty modulator. Check the sensor resistance: 950-1930 ohms. Check wiring and contacts in the

connectors between the modulator and the sensor. If the wiring and the sensor is normal, replace the modulator.

793 Sensor wheel speed, wheel 5. No signal (FMI4). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The large gap between the sensor and gear, damaged wiring, contacts in the connectors, sensor is faulty, damaged or defective gear modulator. Check the

sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors between the modulator and the sensor. Check the integrity of gear. Check the clearance between the sensor and the

gear. Check wheel bearing play. If the wiring, the sensor, gear, wheel bearing is OK, replace the modulator.

793 Sensor wheel speed, wheel 5. Closing (FMI7). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The closure between a wiring of different sensors or faulty modulator. Check the sensor resistance: 950-1930 ohms. Check wiring and contacts in the

connectors between the modulator and the sensor. If the wiring and the sensor is normal, replace the modulator.

794 Sensor wheel speed, wheel 6. No signal (FMI4). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The large gap between the sensor and gear, damaged wiring, contacts in the connectors, sensor is faulty, damaged or defective gear modulator. Check the

sensor resistance: 950-1930 ohms. Check wiring and contacts in the connectors between the modulator and the sensor. Check the integrity of gear. Check the clearance between the sensor and the

gear. Check wheel bearing play. If the wiring, the sensor, gear, wheel bearing is OK, replace the modulator.

794 Sensor wheel speed, wheel 6. Closing (FMI7). STOP warning light is amber. Switches the control of ABS, control ESP, control the adjustment of reference torque (DTC), the

engine control ASR, brake control ASR. The closure between a wiring of different sensors or faulty modulator. Check the sensor resistance: 950-1930 ohms. Check wiring and contacts in the

connectors between the modulator and the sensor. If the wiring and the sensor is normal, replace the modulator.

932 pressure control valve, inlet valve, left. Short to Ground (FMI5). STOP warning light lit in red, and red lights lamp total control of

brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS

unit (A402) and the modulator. If the wiring is OK, replace the modulator.

932 pressure control valve, inlet valve, left. Short to power supply Ubat (FMI6). STOP warning light lit in red, and red lights lamp total

control of brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between

the EBS unit (A402) and the modulator. If the wiring is OK, replace the modulator.

932 pressure control valve, inlet valve, left. Short (FMI7). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

932 pressure control valve, inlet valve, left. Open (FMI10). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

933 pressure control valve, inlet valve, right. Short to Ground (FMI5). STOP warning light lit in red, and red lights lamp total control of

brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS

unit (A402) and the modulator. If the wiring is OK, replace the modulator.

933 pressure control valve, inlet valve, right. Short to power supply Ubat (FMI6). STOP warning light lit in red, and red lights lamp total

control of brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between

the EBS unit (A402) and the modulator. If the wiring is OK, replace the modulator.

933 pressure control valve, inlet valve, right. Short (FMI7). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

933 pressure control valve, inlet valve, right. Open (FMI10). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

938 pressure control valve, exhaust valve, left. Short to Ground (FMI5). STOP warning light lit in red, and red lights lamp total control of

brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS

unit (A402) and the modulator. If the wiring is OK, replace the modulator.

938 pressure control valve, exhaust valve, left. Short to power supply Ubat (FMI6). STOP warning light lit in red, and red lights lamp total

control of brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between

the EBS unit (A402) and the modulator.

938 pressure control valve, exhaust valve, left. Short (FMI7). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

938 pressure control valve, exhaust valve, left. Open (FMI10). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

939 pressure control valve, exhaust valve, right. Short to Ground (FMI5). STOP warning light lit in red, and red lights lamp total control

of brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS

unit (A402) and the modulator. If the wiring is OK, replace the modulator.

939 pressure control valve, exhaust valve, right. Short to power supply Ubat (FMI6). STOP warning light lit in red, and red lights lamp

total control of brakes. Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring

between the EBS unit (A402) and the modulator. If the wiring is OK, replace the modulator.

939 pressure control valve, exhaust valve, right. Short (FMI7). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

939 pressure control valve, exhaust valve, right. Open (FMI10). STOP warning light lit in red, and red lights lamp total control of brakes.

Switches the control of ABS, the ESP control. Damaged wiring in the modulator circuit, defective or EBS modulator unit (A402). Clear the fault memory. Check the wiring between the EBS unit (A402)

and the modulator. If the wiring is OK, replace the modulator.

1042 ISO 11992 data channel (CAN trailer), the data channel is off. Open (FMI10). STOP warning light is amber. Limited braking force of the

trailer. Electromagnetic interference, faulty data channel wiring ISO 11992. Check CAN trailer wiring for breaks and short circuits. Check the correct operation of external devices connected to

the CAN trailer.

1056 module trailer control, adjustable maximum pressure. Not identified (FMI3). STOP warning light is amber. Disabled control brake force

train. Pressure transducer faulty trailer control module (Y278), too much air pressure at the inlet of the trailer control module (Y278). Check the air pressure at the inlet of the trailer

control module, if the pressure is normal, replace the module (Y278).

1057 Central control unit in the controller, there is no response to the air pressure sensor of the trailer control module if there is no

braking. Not identified (FMI3). STOP warning light lit in red, and red lights lamp total control of brakes. All user functions are disabled. Faulty microprocessor to EBS unit (A402). Replace EBS

unit (A402).

1058 module trailer control pressure sensor. Too high (FMI1). STOP warning light is amber. Limited braking force of the trailer. Faulty

wiring, or EBS pressure sensor unit (A402) .Ochistit recorder malfunctions, check the wiring and contacts in the connectors between the EBS unit (A402) and the trailer control module (Y278).

Check pressure sensor supply trailer control module. Disconnect the X4 from the EBS unit (A402), and check the voltage between EBS unit (A402) with the ignition on: between terminals X1 / 12

(mass) and X4 / 1 (power supply trailer control module) should be approximately 5 volts between contacts X1 / 12 (mass) and X4 / 3 (the mass of a trailer control module) must be equal to 0 volts

between contacts X1 / 2 (w) and X4 / 2 (signal a trailer control module) must be equal to 0V. If a fault in the wiring of the sensor is not found, and the supply voltage is correct, replace the

trailer control module (Y278).

1058 module trailer control pressure sensor. Too low (FMI2). STOP warning light is amber. Limited braking force of the trailer. Faulty

wiring, or EBS pressure sensor unit (A402). Clear fault memory, check the wiring and contacts in the connectors between the EBS unit (A402) and the trailer control module (Y278). Check the air

pressure at the inlet of the trailer control unit, must not exceed 8.5 bar. Check pressure sensor supply trailer control module. Disconnect the X4 from the EBS unit (A402), and check the voltage

between EBS unit (A402) with the ignition on: between terminals X1 / 12 (mass) and X4 / 1 (power supply trailer control module) should be approximately 5 volts between contacts X1 / 12 (mass) and

X4 / 3 (the mass of a trailer control module) must be equal to 0 volts between contacts X1 / 2 (w) and X4 / 2 (signal a trailer control module) must be equal to 0V. If a fault in the wiring of

the sensor is not found, and the supply voltage is correct, replace the trailer control module (Y278).

1058 module trailer control pressure sensor. Wrong signal (FMI8). STOP warning light is amber. Limited braking force of the trailer. Faulty

wiring, or EBS pressure sensor unit (A402). Clear fault memory, check the wiring and contacts in the connectors between the EBS unit (A402) and the trailer control module (Y278). Check pressure

sensor supply trailer control module. Disconnect the X4 from the EBS unit (A402), and check the voltage between EBS unit (A402) with the ignition on: between terminals X1 / 12 (mass) and X4 / 1

(power supply trailer control module) should be approximately 5 volts between contacts X1 / 12 (mass) and X4 / 3 (the mass of a trailer control module) must be equal to 0 volts between contacts

X1 / 2 (w) and X4 / 2 (signal a trailer control module) must be equal to 0V. If a fault in the wiring of the sensor is not found, and the supply voltage is correct, replace the trailer control

module (Y278).

1060 Wear indicators for brake pads, wheel 1. Too high (FMI1). STOP warning light is amber. Disabled wear control pad. Damaged wiring

between the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1060 Wear indicators for brake pads, wheel 1 is too low (FMI2). STOP warning light is amber. Disabled wear control pad. Damaged wiring

between the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1061 Wear indicators for brake pads, wheel 2. Too high (FMI1). STOP warning light is amber. Disabled wear control pad. Damaged wiring

between the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1061 Wear indicators for brake pads, wheel 2. Too Low (FMI2). STOP warning light is amber. Disabled wear control pad. Damaged wiring between

the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1062 Wear indicators for brake pads, wheel 3. Too high (FMI1). STOP warning light is amber. Disabled wear control pad. Damaged wiring

between the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1062 Wear indicators for brake pads, wheel 3. Too low (FMI2). STOP warning light is amber. Disabled wear control pad. Damaged wiring between

the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1063 Wear indicators for brake pads, wheel 4. Too high (FMI1). STOP warning light is amber. Disabled wear control pad. Damaged wiring

between the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1063 Wear indicators for brake pads, wheel 4. Too Low (FMI2). STOP warning light is amber. Disabled wear control pad. Damaged wiring between

the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1064 Wear indicators for brake pads, wheel 5. Too high (FMI1). STOP warning light is amber. Disabled wear control pad. Damaged wiring

between the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1064 Wear indicators for brake pads, wheel 5. Too low (FMI2). STOP warning light is amber. Disabled wear control pad. Damaged wiring between

the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1065 Wear indicators for brake pads, wheel 6. Too high (FMI1). STOP warning light is amber. Disabled wear control pad. Damaged wiring

between the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1065 Wear indicators for brake pads, wheel 6. Too Low (FMI2). STOP warning light is amber. Disabled wear control pad. Damaged wiring between

the modulator and the sensor pad wear, wear faulty sensor or modulator. Check wiring and replace the sensor wear. If the wiring and the sensor is normal, replace the modulator.

1066 Module foot brake. Undefined fault (FMI0). STOP warning light is amber. User functions are not limited. Foot brake not fully released

due to improper installation of a foot brake module. Incorrect module parameters or the foot brake is faulty EBS unit (A402). Check switch module 1 state of a foot brake with the diagnostic tool.

If the state of the passive switch, clear the fault logger, replace EBS unit (A402) during the second DTC. If the state of the switch active, verify the installation of a foot brake module.

Remove the foot brake module, plug connectors and check the condition of the circuit breaker 1 with the diagnostic tool, if the state of the passive switch, the installation of the module was not

true, if the condition of the remaining active, replace the module foot brake.

1066 Module foot brake. Not identified (FMI3). STOP warning light lit in red, and red lights lamp total control of brakes. All user

functions are disabled. Mechanical failure in the foot brake module, sensor wear, incorrect resistance at the contacts. Check wiring and contacts in the connectors between blokomEBS (A402) and

the corresponding sensor module load brake foot brake for continuity and insulation. If the wiring is OK, disconnect the EBS unit (A402) and inspect the resistance potentiometers between the

contacts module foot brake SIG1 (X1 / 5) and GND (X1 / 4) between the contacts module foot brake SIG1 (X1 / 5) and SPL (X1 / 7) from the cable: R_SIG1 = from 4.2 ohms to 7.5 ohms (with increasing

stroke length: resistance between signal and ground is increased between the signal and power decreases). Check the resistance between the potentiometer of the module contacts the foot brake SIG2

(X1 /

resistance between the signal and the mass decreases, between the signal and power increases). If the resistance value is outside the permitted area, replace the module foot brake.

1066 Module foot brake. Short (FMI7). STOP warning light lit in red, and red lights lamp total control of brakes. All user functions are

disabled. Electrical fault in the sensor unit in the wiring or a faulty unit EBS (A402). Check wiring and contacts in the connectors between the EBS unit (A402) and the corresponding sensor

module load brake foot brake for continuity and insulation. If the wiring is OK, disconnect the EBS unit (A402) and inspect the resistance potentiometers between the contacts module foot brake

SIG1 (X1 / 5) and GND (X1 / 4) between the contacts module foot brake SIG1 (X1 / 5) and SPL (X1 / 7) from the cable: R_SIG1 = from 4.2 ohms to 7.5 ohms (with increasing stroke length: resistance

between signal and ground is increased between the signal and power decreases). Check the resistance between the potentiometer of the module contacts the foot brake SIG2 (X1 /

between the contacts of a foot brake module SIG2 (X1 /

signal and the mass decreases, between the signal and power increases). If the resistance value is outside the permitted area, replace the module foot brake.

1066 Module foot brake. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp total control of brakes. All user functions

are disabled. the brake pedal may not return to the released state due to a mechanical lock or damaged foot brake module. Check and, if necessary, correct the installation of a foot brake module

(especially in the case of a mechanical lock). If the foot brake module is correctly installed, replace the module foot brake.

1067 Module foot brake, signal 1. Short to Ground (FMI5). STOP warning light lit in red, and red lights lamp total control of brakes. All

user functions are disabled. Mechanical failure in the foot brake module, sensor wear, incorrect resistance at the contacts. Check wiring and contacts in the connectors between the EBS unit

(A402) and the corresponding sensor module load brake foot brake for continuity and insulation. If the wiring is OK, disconnect the EBS unit (A402) and inspect the resistance potentiometers

between the contacts module foot brake SIG1 (X1 / 5) and GND (X1 / 4) between the contacts module foot brake SIG1 (X1 / 5) and SPL (X1 / 7) from the cable: R_SIG1 = from 4.2 ohms to 7.5 ohms

(with increasing stroke length: resistance between signal and ground is increased between the signal and power decreases). Check the resistance between the potentiometer of the module contacts

the foot brake SIG2 (X1 /

length of the course: the resistance between the signal and the mass decreases, between the signal and power increases). If the resistance value is outside the permitted area, replace the module

foot brake.

1067 foot brake module, the signal 1 circuit to supply Ubat (FMI6). STOP warning light lit in red, and red lights lamp total control of

brakes. Mechanical failure in the foot brake module, sensor wear, incorrect resistance at the contacts. Check wiring and contacts in the connectors between the EBS unit (A402) and the

corresponding sensor module load brake foot brake for continuity and insulation. If the wiring is OK, disconnect the EBS unit (A402) and inspect the resistance potentiometers between the contacts

module foot brake SIG1 (X1 / 5) and GND (X1 / 4) between the contacts module foot brake SIG1 (X1 / 5) and SPL (X1 / 7) from the cable: R_SIG1 = from 4.2 ohms to 7.5 ohms (with increasing stroke

length: resistance between signal and ground is increased between the signal and power decreases).

4032 Central control unit, EEPROM memory checksum error in the block, the overall configuration of the ISR. Wrong signal (FMI8). STOP warning light lit in red, and red lights

lamp total control of brakes. All user functions are disabled. Failure in the memory, the failure of one of the communication microcontroller hardware damage EBS unit (A402). Download software

EBS unit (A402).

4033 Central control unit, EEPROM memory, an unknown value in the block, its own configuration ISR. Not identified (FMI3). STOP warning light lit in red, and red lights lamp

total control of brakes. All user functions are disabled. in memory failure or not fully installed the software in EBS unit (A402). Download software EBS unit (A402).

4034 Central control unit, EEPROM memory checksum error in the block, its own configuration of the ISR. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp

total control of brakes. All user functions are disabled. Failure in the memory, the failure of one of the communication microcontroller hardware damage EBS unit (A402). Download software EBS

unit (A402).

4035 Central control unit, EEPROM memory, an unknown value in the block, a private konfiguratsiyaABS. Not identified (FMI3). STOP warning light lit in red, and red lights lamp

total control of brakes. All user functions are disabled. in memory failure or not fully installed the software in EBS unit (A402). Download software EBS unit (A402).

4036 Central control unit, EEPROM memory checksum error in the block, a private konfiguratsiyaABS. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp total

control of brakes. All user functions are disabled. Failure in the memory, the failure of one of the communication microcontroller hardware damage EBS unit (A402). Download software EBS unit

(A402).

4037 Central control unit, EEPROM memory, an unknown value in the block, a private konfiguratsiyaASR. Not identified (FMI3). STOP warning light lit in red, and red lights lamp

total control of brakes. All user functions are disabled. in memory failure or not fully installed the software in EBS unit (A402). Download software EBS unit (A402).

4038 Central control unit, EEPROM memory checksum error in the block, a private konfiguratsiyaASR. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp total

control of brakes. All user functions are disabled. Failure in the memory, the failure of one of the communication microcontroller hardware damage EBS unit (A402). Download software EBS unit

(A402).

4039 Central control unit, EEPROM memory, an unknown value in the block, the overall configuration of the ESP. Not identified (FMI3). STOP warning light lit in red, and red

lights lamp total control of brakes. All user functions are disabled. in memory failure or not fully installed the software in EBS unit (A402). Download software EBS unit (A402).

4040 Central control unit, EEPROM memory checksum error in the block, the overall configuration of the ESP. Wrong signal (FMI8). STOP warning light lit in red, and red lights

lamp total control of brakes. All user functions are disabled. Failure in the memory, the failure of one of the communication microcontroller hardware damage EBS unit (A402). Download software

EBS unit (A402).

4041 Central control unit, EEPROM memory, an unknown value in the block, ESP own configuration. Not identified (FMI3). STOP warning light lit in red, and red lights lamp total

control of brakes. All user functions are disabled. in memory failure or not fully installed the software in EBS unit (A402). Download software EBS unit (A402).

4042 Central control unit, EEPROM memory checksum error in the block, ESP own configuration. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp total control

of brakes. All user functions are disabled. Failure in the memory, the failure of one of the communication microcontroller hardware damage EBS unit (A402). Download software EBS unit (A402).

4043 Central control unit, EEPROM memory, an unknown value in the block configuration of the site identification. Not identified (FMI3). STOP warning light lit in red, and red

lights lamp total control of brakes. All user functions are disabled. in memory failure or not fully installed the software in EBS unit (A402). Download software EBS unit (A402).

4044 Central control unit, EEPROM memory checksum error in the block, site identification configuration. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp

total control of brakes. All user functions are disabled. Failure in the memory, the failure of one of the communication microcontroller hardware damage EBS unit (A402). Download software EBS

unit (A402).

4045 Central control unit, EEPROM memory, the unknown value of the fault recorder. Not identified (FMI3). STOP warning light lit in red, and red lights lamp total control of

brakes. All user functions are disabled. Failure memory EBS unit (A402). Switch off the ignition for at least 10 seconds after turning on the clear fault logger. If the error appears again,

replace the EBS unit (A402).

4046 Central control unit, EEPROM memory checksum error of the fault recorder. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp total control of brakes.

All user functions are disabled. Failure memory EBS unit (A402). Switch off the ignition for at least 10 seconds after turning on the clear fault logger. If the error appears again, replace the

EBS unit (A402).

4047 Central control unit, EEPROM memory, an unknown value in the block configuration of the bridge. Not identified (FMI3). STOP warning light lit in red, and red lights lamp

total control of brakes. All user functions are disabled. in memory failure or not fully installed the software in EBS unit (A402). Download software EBS unit (A402).

4048 Central control unit, EEPROM memory checksum error in the block, aligning EBS data. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp total control of

brakes. All user functions are disabled. Failure memory EBS unit (A402). Switch off the ignition for at least 10 seconds after turning on the clear fault logger. If the error appears again,

replace the EBS unit (A402).

4049 Central control unit, EEPROM memory checksum error in the block, its own test. Wrong signal (FMI8). STOP warning light lit in red, and red lights lamp total control of