-

Rahman

Mimaki JV33-160 Датчик не видит носителя (Error 50)

Доброго всем дня, датчик не обнаруживает носитель

выходит «Error 50». В инструкции это значит что- Датчик не обнаруживает носитель

(носитель установлен неправильно либо установлен носитель недо-пустимого типа).

В чем может быть проблемка? Бумаги те же что и раньше. Помогите кто чем может.

-

Sokell

- Старожил

- Сообщения: 6703

- Зарегистрирован: 20 июл 2010 13:33

- Последний визит: 08 фев 2023 09:52

- Изменить репутацию:

Репутация:

Голосов: 165 - Откуда: Рязань

Сообщение Sokell » 07 фев 2014 14:08

Rahman

Внизу под «носителем» есть, утопленная в канавке черная «полоска» по ширине всего стала…

Убедитесь что она есть, не повреждена… Протрите ее… И убедитесь что датчик с левой стороны головы (не красный световой) подключен и не выскочил с своей позиции…

Спаси меня господь от тех кому я верю,

от тех кому не – верю уберегусь я сам

-

@natol

- Завсегдатай

- Сообщения: 515

- Зарегистрирован: 20 окт 2011 17:27

- Последний визит: 09 дек 2022 10:21

- Изменить репутацию:

Репутация:

Голосов: 17 - Откуда: Воронеж

Сообщение @natol » 07 фев 2014 15:18

В Mimaki есть тестовый режим, там можно откалибровать датчик.

-

Александр Яковлевич

- Активный участник

- Сообщения: 467

- Зарегистрирован: 20 мар 2009 10:46

- Последний визит: 04 авг 2022 16:14

- Изменить репутацию:

Репутация:

Голосов: 17 - Откуда: Москва

Сообщение Александр Яковлевич » 08 фев 2014 21:38

Rahman

Протри датчик спиртом (или в крайнем случае водкой) — должно помочь. Ну и край материала не должен быть очень близко к краю стола.

Тщательней надо, братцы, тщательней…, но без фанатизма!

-

vovka.ru

- Участник

- Сообщения: 99

- Зарегистрирован: 10 дек 2012 15:13

- Последний визит: 12 июл 2020 20:46

- Изменить репутацию:

Репутация:

Голосов: 2 - Откуда: Ярославль

Сообщение vovka.ru » 09 фев 2014 22:24

Александр Яковлевич верно написал У него глазок забило протри его только не водкой а изопропиловым спиртом

-

Goodymaster_1

- Завсегдатай

- Сообщения: 699

- Зарегистрирован: 21 ноя 2013 23:03

- Последний визит: 11 сен 2022 20:38

- Изменить репутацию:

Репутация:

Голосов: 15 - Откуда: Москва

Сообщение Goodymaster_1 » 10 фев 2014 12:29

Еще бывает темно в помещении Можно фонариком подсветить в место замера.

-

Немец

- Старожил

- Сообщения: 1732

- Зарегистрирован: 24 фев 2010 13:22

- Последний визит: 21 ноя 2022 16:30

- Изменить репутацию:

Репутация:

Голосов: 40 - Откуда: Волга

Сообщение Немец » 10 фев 2014 13:32

Rahman

Помогла ли вам помощь печатного сообщества ?

(в нашем случае пришлось когда то менять датчик)

Вернуться в «Принтеры MIMAKI»

Кто сейчас на конференции

Сейчас этот форум просматривают: нет зарегистрированных пользователей и 1 гость

Chapter 6 Troubleshooting

When an error message is displayed, eliminate the error according to the chart below.

If the same error message appears again, contact your dealer or an office of MIMAKI to call for service.

Message

ERROR 122

CHECK:SDRAM

ERROR 128

HDC FIFO OVER

ERROR 128

HDC FIFO UNDER

ERROR 129

BATTERY EXCHANGE

ERROR 130

HD DATA SEQ

ERROR 146

E-LOG SEQ

ERROR 151

Main PCB V1R2

ERROR 152

Main PCB V2R5

ERROR 153

Main PCB V3R3

ERROR 154

Main PCB V05

ERROR 157

Main PCB VTT

ERROR 16e

Main PCB V3R3B

ERROR 15f

HEAD DRIVE HOT

ERROR 171

NEW HEAD CONNECT

ERROR 186

HDC OVERFLOW

ERROR 186

HDC UNDERFLOW

ERROR 187

HDC SLEW RATE

ERROR 188

HDC MEMORY

ERROR 18a

Main PCB V_CORE

6-8

Cause

SDRAM is defective.

Head control circuit board is defective.

The battery life end of the internal clock

is detected.

Head data transferring sequence error

occurred.

Sequential number abnormality of the

event log occurred.

An error occurred in the main PCB .

COM driver becomes the high tempera-

ture.

New Print Head was recognized.

An error is detected on the waveform

printed on.

An error occurred in the main PCB .

Solution

• Turn off the power to the machine and turn it

on after a while.

• If the same error message appears again,

contact your local distributor to call for ser-

vice.

• Contact your local distributor to call for ser-

vice.

• Turn off the power to the machine and turn it

on after a while.

• If the same error message appears again,

contact your local distributor to call for ser-

vice.

Mimaki SWJ 320 -S4 — Проблема с шагом.

Mimaki SWJ 320 -S4 — Проблема с шагом.

Сообщение Granovskiy » 06 дек 2013 22:56

Имеется у нас в наличии 2 плоттера фирмы mimaki, jv33-160 и недавно приобрели Mimaki SWJ-S4. Так вот если на jv33 с шагом все просто, будь то рулон пленки 100,126,160 см. заправленный в станок или огрызок найденный в коробке с отходами, шаг постоянно одинаковый. А вот на SWJ-320, почему-то разный шаг на каждую ширину материала, будь то пленка или баннер. А про печать цвето пробы на огрызке, я вообще молчу ! Так например шаг на пленке шириной 100см равен нулю, а на 126см уже ша (МИНУС 215), на 160см. -535.

Подскажите пожалуйста, это нормально ? Или может мы материал как-то не правильно заправляем, а или секрет какой есть ))) С баннером такая же проблема.

Сообщение Алексей Береговой » 09 дек 2013 17:11

Granovskiy

Попробуйте обратиться к поставщику этого принтера.

Так же посмотрите на ссылочку: http://www.youtube.com/watch?v=AziSc40DDqg

Еще одно примечание — рулоны нужно позиционировать строго по центру зоны печати.

Добавлено спустя 4 минуты 1 секунду:

На JV33 на разных материалах шаг тоже разный. Просто это не сильно заметно

Сообщение kireyev » 11 дек 2013 13:43

Шаг — это имеется ввиду «коррекция скорости подачи носителя» (по англ. MEDIA COMP.)?

Если да, то в режиме LOCAL.X(1,2,3,4) заходите MENU->FUNCTION->SETUP->MEDIA COMP и там выставляете 0 (чтобы пропустить тестовую печать нажмите стрелку вправо). Далее делаете тестовый принт и регулируете на текущий материал.

Правда я скорее всего не правильно понял про шаг, так как у Вас уже 2 мимаки и про такую регулировку Вы наверное знаете.

Сообщение uosega » 08 янв 2014 14:32

Сообщение Евгений Жариков » 28 янв 2014 15:21

Источник

Mimaki SWJ 320 -S4 — Проблема с шагом.

Mimaki SWJ 320 -S4 — Проблема с шагом.

Сообщение Granovskiy » 06 дек 2013 22:56

Имеется у нас в наличии 2 плоттера фирмы mimaki, jv33-160 и недавно приобрели Mimaki SWJ-S4. Так вот если на jv33 с шагом все просто, будь то рулон пленки 100,126,160 см. заправленный в станок или огрызок найденный в коробке с отходами, шаг постоянно одинаковый. А вот на SWJ-320, почему-то разный шаг на каждую ширину материала, будь то пленка или баннер. А про печать цвето пробы на огрызке, я вообще молчу ! Так например шаг на пленке шириной 100см равен нулю, а на 126см уже ша (МИНУС 215), на 160см. -535.

Подскажите пожалуйста, это нормально ? Или может мы материал как-то не правильно заправляем, а или секрет какой есть ))) С баннером такая же проблема.

Сообщение Алексей Береговой » 09 дек 2013 17:11

Granovskiy

Попробуйте обратиться к поставщику этого принтера.

Так же посмотрите на ссылочку: http://www.youtube.com/watch?v=AziSc40DDqg

Еще одно примечание — рулоны нужно позиционировать строго по центру зоны печати.

Добавлено спустя 4 минуты 1 секунду:

На JV33 на разных материалах шаг тоже разный. Просто это не сильно заметно

Сообщение kireyev » 11 дек 2013 13:43

Шаг — это имеется ввиду «коррекция скорости подачи носителя» (по англ. MEDIA COMP.)?

Если да, то в режиме LOCAL.X(1,2,3,4) заходите MENU->FUNCTION->SETUP->MEDIA COMP и там выставляете 0 (чтобы пропустить тестовую печать нажмите стрелку вправо). Далее делаете тестовый принт и регулируете на текущий материал.

Правда я скорее всего не правильно понял про шаг, так как у Вас уже 2 мимаки и про такую регулировку Вы наверное знаете.

Сообщение uosega » 08 янв 2014 14:32

Сообщение Евгений Жариков » 28 янв 2014 15:21

Источник

Clamp up mimaki error 504

Answer: This error is displayed when the obstacle sensor detects an obstacle that can collide with the head.

Check that the setting value of “MEDIA THICKNESS” or “HEAD GAP” is appropriate against the actual thickness of the media. In addition, check on the followings.

・Dust or garbage is not sticking to the surface of table or media

・When the media is fixed with tape, the tape is not lifted

・The media is not rolled back

1. Required action against “ERROR505 !WORK High”

(1) Press the [ENTER] key while the error is displayed. The machine returns to mode.

(2) If [DATA REMAIN] is displayed, press the [DATACLEAR] key and then press the [ENTER] key.

(3) Press the [FUNCTION] key, and then press the [WORK SET] -> [ENTER] key. The Y bar moves backward, and the table moves down to the lowest point.

(4) Reset the media.

(5) Press the [REMOTE] key. The Y bar moves from the backside to the front when the machine enters mode. It is possible to start printing if no error is displayed until the Y bar stops at the front.

* Note that the head gap may be wider than the setting value even though it is set to 1.5mm in [Head Gap], if the value in [MEDIA THICKNESS] is larger than the thickness of the actual media.

2. Difference in action by setting

[FUNCTION] -> [HEAD HEIGHT] -> [GAP CHECK] is added to UJF-3042 firmware version 1.30. UJF-3042FX and UJF-3042HG have the [GAP CHECK] function regardless of firmware version.

・[GAP CHECK] is set as [OFF]:

When the obstacle sensor reacts, “ERROR505! WORK High” is displayed and the operation stops.

・[GAP CHECK] is set as [ON]:

When the obstacle sensor reacts, “ERROR505! WORK High” is not displayed, and the table moves down to the point that the obstacle sensor does not react.

* Because the table continues to move down until the obstacle sensor does not react even though [HEAD GAP] is set to 1.5mm, the actual head gap may not be 1.5mm. Note that movement of the head gap may cause a degraded drawing quality or ink mist if the obstacle sensor reacts during printing.

If the problem still remains, please contact us.

Источник

Что означает ошибка сервера 504 Gateway Time Out и как ее исправить

Иногда при посещении отдельных страниц сайта мы сталкиваемся с тем, что на экране вместо желаемого контента появляется сообщение об ошибке с цифровым кодом. Для «непосвященного» пользователя это просто набор цифр, но на самом деле в этих цифрах заложена определенная информация. Все они группируются по видам причин возникновения сбоя.

Сообщения, кодирующиеся в формате 5хх, говорят о проблеме на стороне сервера, например, когда невозможно выполнить запрос из-за нарушения связи между несколькими серверами. Ошибка 504 Gateway Time Out не является распространенной, но это не значит, что на нее не стоит обращать внимания, особенно владельцу сайта. Рассмотрим некоторые причины возникновения данной ошибки и способы ее устранения как на стороне обычного посетителя, так и администратором веб-ресурса.

Ошибка 504 Gateway Time Out – это код состояния HTTP, который появляется, когда в течение заданного периода времени один сервер не получает своевременный ответ от другого сервера, который действует как шлюз или прокси.

Описания ошибки могут иметь различную форму:

- 504 Gateway Timeout nginx

- Gateway Timeout Error

- HTTP Error 504

- 504 Gateway Time-out – The server didn’t respond in time

- HTTP Error 504 – Gateway Timeout

Наличие дополнительного словесного описания помогает конкретизировать причину возникновения сбоя.

Производительный хостинг в подарок при заказе лицензии 1С-Битрикс

Выбирайте надежную CMS с регулярными обновлениями системы и профессиональной поддержкой. А мы подарим вам год хостинга – специально для сайтов на 1С-Битрикс.

Что делать посетителю сайта при возникновении ошибки 504

Итак, вы столкнулись с появлением на экране сообщения «error 504». Не спешите уходить с сайта, ведь возникновение сбоя может говорить о неправильной работе вашего браузера или даже наличии более серьезных проблем на уровне пользовательского софта. Попробуйте произвести довольно простые действия, чтобы убедиться, что с вашим программным обеспечением и настройками все в порядке.

- Перезагрузите проблемную страницу или текущий браузер. Если проблема устранилась и не повторяется вновь, особенно при посещении других сайтов, о ней можно просто забыть. При регулярном возникновении однотипных ошибок во время посещения разных ресурсов стоит покопаться в настройках собственного ПО поглубже.

- Зайдите на тот же самый сайт, где возникла ошибка сервера 504, используя альтернативный браузер. В случае, когда страница во время тестирования открылась корректно, обновите браузер, в котором случился сбой, до последней версии.

- Проверьте, как открываются страницы этого же сайта с другого компьютера или смартфона. Это позволит вам понять, не связано ли появление ошибки 504 с ПО конкретного устройства.

- При регулярном появлении HTTP ошибок, в т.ч. с кодом 504, очистите кэш браузера, удалите файлы cookies. Со временем в любом браузере накапливается много «мусора». Произведя очистку, вы поможете программе работать более корректно и даже быстрее.

- Произведите сброс настроек роутера или модема, отключив оборудование на некоторое время от сети. Данная операция вряд ли приведет к устранению ошибки 504, но может улучшить качество интернет-соединения. Провайдеры регулярно вносят изменения в настройки собственного софта, обновляют его. Иногда это приводит к конфликту в корректном взаимодействии пользовательского оборудования и серверов оператора. Перезагрузка устройства по питанию в большинстве случаев решает такие проблемы.

- Очистите кэш DNS. Данная операция кажется сложной для обычного пользователя, но на деле выполнить ее достаточно легко. Способ очистки зависит от вашей операционной системы, найдите соответствующий мануал в интернете.

- Для опытных пользователей подойдет рекомендация временно переключить DNS-сервер на Google Public DNS , что как минимум поможет определить, возник ли ошибочный код состояния HTTP по причине DNS проблемы.

Если после проведения всех вышеозначенных рекомендаций любая ошибка, в т.ч. 504 Gateway Time Out, продолжает возникать регулярно, обратитесь в техподдержку проблемного интернет-ресурса.

Решение проблем с появлением ошибки сервера 504 администратором веб-ресурса

Некорректная работа сайта чаще всего просто раздражает посетителя и приводит к тому, что пользователь находит альтернативный ресурс. Для владельца сайта такие сбои могут носить более глобальные последствия. Поэтому очень важно своевременно обнаруживать баги и максимально быстро устранять их. Для раннего мониторинга стоит использовать все возможные инструменты:

- проводить регулярную симуляцию пользовательского поведения на сайте;

- настроить автоматизированный мониторинг работоспособности ресурса как встроенными инструментами администрирования, так и с использованием специальных скриптов;

- обеспечить качественную работу службы технической поддержки сайта, своевременную обработку всех поступающих сообщений, особенно связанных с информацией о появлении разного рода ошибок на стороне пользователя.

Соблюдение последнего правила не только позволит практически без дополнительных затрат отслеживать все возможные проблемы, которые возникают при посещении сайта. Своевременная обработка пользовательских запросов, быстрый ответ, выдача рекомендаций и публичное обсуждение повышают лояльность и создают дополнительный PR-эффект.

Почти все ошибки с кодом 5хх, возникающие из-за невозможности обработки определенного количества запросов, поступающих на сервер, решаются методом апгрейда железа (использованием высокопроизводительного хостинга) либо оптимизацией работы программного обеспечения. Второй способ зависит от вида движка, на котором создан конкретный сайт. При использовании условно-бесплатных программ (WordPress, OpeneCart и других) все проблемы придется решать на уровне администрирования, с привлечением конкретного веб-программиста, разработавшего данный сайт. Если баги возникают на платных платформах (1С-Битрикс, UMI.CMS, NetCat CMS), напишите об ошибке 504 Gateway Time Out в техподдержку разработчика. Отправить сообщение о проблеме следует и разработчикам платных скриптов, если они установлены на вашем сайте, и вы считаете, что сбои возникают по причине их некорректного исполнения.

Вот некоторые причины, приводящие к возникновению ошибки 504 Gateway Time Out

- Резкий скачок нагрузки на сайт вследствие поступления большого количества внешних запросов, вызванного DDoS-атаками или действиями вирусного ПО, пиковым посещением сайта, например, в момент проведения различных акций в интернет-магазине, или единовременной загрузкой на сайт большого объема контента (импорт информации из CSV- или XML-файлов).

- Некорректная работа скриптов, плагинов и дополнений, конфликтующих как между собой, так и внутри.

- Превышение лимита доступных ресурсов при использовании виртуального хостинга.

Еще одна возможная причина возникновения ошибки 504 – исполняемый скрипт не укладывается в отведенный лимит времени. Это бывает, когда скрипт обращается к другим сайтам либо просто выполняет тяжелую операцию, например, строит поисковый индекс.

Рекомендации по устранению ошибки 504 Gateway Time Out методами администрирования сайта

Ошибка 504 Gateway Time Out может быть вызвана недавними изменениями или обновлениями на сайте. Если после отката к состоянию, предшествующему изменениям, баг исчез, следует найти конкретное действие, повлекшее возникновение ошибки. Для этого необходимо проверить журнал ошибок соответствующей CMS. Пользователи WordPress могут включить журналирование ошибок в файле wp-config.php добавлением следующих строк:

Все возникающие варианты ошибок будут записаны в файле wp-contents/debug.log.

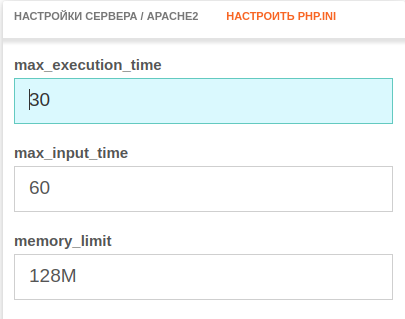

Для проверки работоспособности плагинов и расширений попробуйте отключить те, которые вызывают подозрение как источники возникновения ошибки 504. В первую очередь это касается устаревших скриптов, но причиной могут оказаться и обновления. Если проблема исчезла, далее следует найти некорректный плагин или дополнение и устранить или исправить его. Один из способов улучшения работы исполняемого скрипта – увеличить значение параметра PHP max_execution_time или облегчить скрипт.

При использовании CDN для более быстрого получения контента, в частности CloudFlare, который работает как CDN и как сервис предотвращения негативных последствий от DDoS, вы можете столкнуться с двумя типами ошибок 504. В случае возникновения проблемы на стороне CloudFlare лучшим решением будет связаться с поддержкой CloudFlare или отключить его. Второй вариант – когда сбой возникает на стороне хостинг-провайдера. В этой ситуации также необходимо обратиться в службу поддержки хостера.

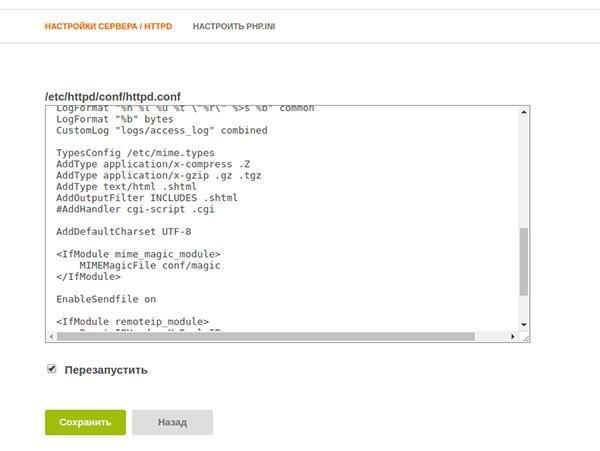

Часто ошибку 504 можно видеть на серверах, где используется VPS-хостинг и установлен Nginx в качестве фронтенда и Apache в качестве бэкенда. Для устранения проблемы в Apache можно увеличить значение timeout по умолчанию в файле httpd.conf:

Также увеличить лимит в max_execution_time в php.ini:

После внесения изменений следует перезапустить Apache. Ошибка 504 Gateway Time Out должна исчезнуть.

Аналогичным образом проблема с появлением ошибки HTTP 504 решается пользователями Nginx. Попробуйте увеличить такие параметры в файле /etc/nginx/conf.d/timeout.conf:

Также рекомендуется увеличить max_execution_time в php.ini:

Далее перезапустите Nginx и откройте сайт.

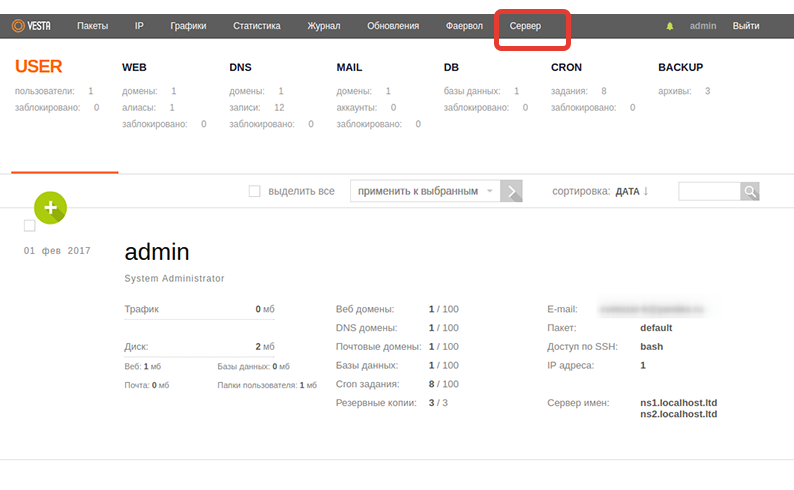

Более простым решением устранения данной проблемы является использование панели управления сервером.

Данный способ позволяет администрировать настройки веб-сервера без использования консоли, один раз настроить их под ваш проект и больше не подключаться к серверу без острой необходимости.

Например, в бесплатной панели управления Vesta Control Panel достаточно внести изменения в раздел «Сервер» и навсегда забыть о возможности возникновения ошибок на сайте.

Аналогичным способом проблема устраняется и при использовании альтернативных панелей управления хостингом – Ajenti, CentOS Web Panel, ISPmanager и других.

Если вы считаете, что появление 504 Gateway Timeout вызвано превышением лимита использования ресурсов серверного железа, оптимальным решением будет аренда выделенного сервера или VPS. Когда ваш сайт уже размещен на виртуальном хостинге, но ни одна из рекомендаций не привела к исправлению error 504, обратитесь к хостинг-провайдеру. В этом случае подробно опишите причины, которые, как вы полагаете, привели к появлению сбоя.

Заключение

В данной статье мы рассмотрели основные причины возникновения ошибки HTTP 504 Gateway Timeout и популярные способы устранения неполадки. Уверен, некоторые администраторы веб-ресурсов сталкивались с подобными проблемами, выходящими за рамки приведенных примеров и рекомендаций.

Буду благодарен, если вы поделитесь своим опытом в комментариях.

Источник

MIMAKI ENGINEERING CO., LTD.

URL: https://mimaki.com/

You can also download the latest manual from our website.

D203176-23

Original instructions

UV INKJET Printer Cutter

i

CAUTION ........................................................................................vi

CAUTION ............................................................................................ vi

Requests ............................................................................................. vi

FCC Statement (USA) ......................................................................... vi

Interference to televisions and radios .................................................. vi

Foreword ........................................................................................vii

On This Operation manual ..................................................................vii

Safety Precautions .........................................................................vii

Symbols ...............................................................................................vii

Safety interlock .................................................................................... xi

Warning labels ...............................................................................xii

Chapter 1 Before Use

Moving This Machine ..................................................................... 1-2

Where to Install This Machine ...........................................................1-2

Working Environmental Temperature ................................................1-2

Moving This Machine ........................................................................1-2

Names of Parts and Functions ...................................................... 1-3

Front Side of the Machine .................................................................1-3

Rear Side and Right Side of the Machine .........................................1-4

Carriage .............................................................................................1-5

Operation Panel ................................................................................1-6

Media Sensor ....................................................................................1-8

Carriage .............................................................................................1-8

Cutter Blade and Cutting Slot ............................................................1-8

Capping Station .................................................................................1-8

Pinch Rollers and Grit Rollers ...........................................................1-8

Connecting Cables ........................................................................1-9

Connecting USB 2.0 Interface Cable ................................................1-9

Connecting a LAN Cable ...................................................................1-9

Connecting the Power Cable ...........................................................1-10

Ink Bottles .................................................................................... 1-11

Types of Inks You Can Use with the Machine .................................1-11

Precautions on Using the Ink Bottles ..............................................1-11

Installing the Ink Bottles ............................................................... 1-12

Media ........................................................................................... 1-17

The Size of Media That Can Be Used with This Machine ...............1-17

Precautions on Handling the Media ................................................1-17

Menu Mode ................................................................................. 1-18

Chapter 2 Basic Operations

Printing Procedure ......................................................................... 2-2

Turning the Power On/Off .............................................................. 2-3

Turning the Power On .......................................................................2-3

Turning the Power Off .......................................................................2-3

Table of Contents

ii

Setting Media .................................................................................2-4

Adjusting the Head Height .................................................................2-4

Adjusting the Positions of the Pinch Rollers to Suit the Media ..........2-5

Maximum Print/Cut Area .................................................................2-10

Precautions on Setting the Media ...................................................2-10

Setting a Roll Media ........................................................................2-11

Setting the Pinch Roller Pressure ...................................................2-13

Take-up Device ...............................................................................2-14

Setting Leaf Media ..........................................................................2-15

Changing the printing origin ............................................................2-16

Test Printing .................................................................................2-17

Test Printing ....................................................................................2-17

Perform test printing with the normal test pattern ............................2-18

Perform test printing with the test pattern for checking white ink ....2-18

Head Cleaning .............................................................................2-19

About Head Cleaning ......................................................................2-19

Perform head cleaning depending on the test printing result ..........2-19

Setting Media Correction .............................................................2-19

Setting of Media Correction .............................................................2-19

If the Positions of Dots Shift... ......................................................2-20

Printing Data ................................................................................2-20

Starting a Printing Operation ...........................................................2-20

Cancel printing (Data Clear) ............................................................2-21

Cutting Media ...............................................................................2-21

Workflow of cutting ......................................................................2-22

Installing Tools .............................................................................2-23

When a Cutter Is Used ....................................................................2-23

How to Install a Ballpoint Pen ..........................................................2-24

Setting the Cutting Conditions .....................................................2-26

About the Cut Conditions ................................................................2-26

Select the Tool Condition ................................................................2-27

Set the Cut Conditions ....................................................................2-27

Test Cutting .................................................................................2-28

Cutting Data .................................................................................2-29

Setting the Origin .............................................................................2-29

Start Cutting ....................................................................................2-29

Stopping a Cutting Operation (Data Clear) .....................................2-29

Removing the Cutter Unit Temporarily ............................................2-29

Cutting Media ...............................................................................2-30

Chapter 3 Setup

About SETUP MENU .....................................................................3-2

SETUP MENU table ..........................................................................3-3

Register the Optimal Print Conditions to Match the Use ...................3-4

Setting of Media Correction ...............................................................3-5

If the Positions of Dots Shift... ...........................................................3-6

Setting of Logical Seek ......................................................................3-7

Setting of Overprint ...........................................................................3-7

Setting of Drying Time .......................................................................3-7

Setting of Left and Right Margins ......................................................3-8

Setting of Vacuum Fan ......................................................................3-8

iii

Setting of Feed Speed .......................................................................3-8

Setting of MAPS ................................................................................3-9

Setting of Auto Cleaning ....................................................................3-9

Setting of Interval Wiping ................................................................3-10

Setting of the UV Mode ...................................................................3-10

Setting Ionizer (option) ....................................................................3-10

Setting of LT mode ..........................................................................3-11

About MACHINE SETUP MENU .................................................3-12

MACHINE SETUP MENUs table .....................................................3-13

Setting of AUTO Power-off ..............................................................3-14

Setting of Take-up Unit ....................................................................3-14

Setting of the Display of Media Residual .........................................3-15

Setting of Media Detection ..............................................................3-15

Setting of a LANGUAGE .................................................................3-16

Setting of Time ................................................................................3-16

Setting of Unit (Temperature/ Length) .............................................3-16

Setting of a KEY BUZZER ...............................................................3-16

Setting of the CONFIRM. FEED ......................................................3-17

Setting of the SPACE FEED MODE ................................................3-17

Setting of the Network .....................................................................3-17

Setting of Event Mail Function .........................................................3-18

Initializing the Settings .....................................................................3-22

About NOZZLE CHECK MENU ................................................... 3-23

INFORMATION MENU table ...........................................................3-23

Printing Check Flow ........................................................................3-24

Printing Operations at "Nozzle Missing" Judgment and Error

Occurrence ......................................................................................3-24

Setting of the Printing Check ...........................................................3-25

Setting of the NOZZLE RECOVERY ...............................................3-25

Setting of the Judgment Condition ..................................................3-25

About INFORMATION MENU ..................................................... 3-26

INFORMATION MENU table ...........................................................3-27

Displaying the Information ...............................................................3-27

Displaying the machine's information (LOCAL guidance) ...............3-28

Chapter 4 Cutting Function

Cut Out Data with Register Mark ................................................... 4-2

The Flow of Cutting out the Registered Data ....................................4-2

Enter register mark detection mode ..................................................4-2

Precautions for inputting data with register marks ............................4-2

Settings for Detecting register marks ................................................4-5

ID Cut ................................................................................................4-6

About CUTTING MENU ............................................................... 4-11

Cutting MENU table .........................................................................4-12

Setting the CUT MODE ...............................................................4-13

Perform Multiple Cuttings (Copy function) ................................... 4-13

SETUP SUB MENU ..................................................................... 4-14

Make the media without uncut area (OVER CUT function) .............4-15

Other SETUP SUB MENU ..............................................................4-15

SETUP RESET ...............................................................................4-16

iv

Maintenance Function .................................................................4-17

Maintenance of Mark Sensor ..........................................................4-17

Perform SAMPLE CUT to Find out the Cause of Cutting Error. ......4-19

Cutting a Medium into Multiple Pieces with a Certain Length .........4-19

Cutting out Data without Register Marks (PC ORIGIN OFFSET) ....4-20

Setting the Scale Adjust ..................................................................4-21

Chapter 5 Maintenance

Maintenance ..................................................................................5-2

When the Machine Is Not Used for a Long Time ..............................5-2

Precautions for Maintenance .............................................................5-2

Cleaning the Exterior Surfaces ..........................................................5-2

Cleaning the Platen ...........................................................................5-2

Cleaning the Media Sensor ...............................................................5-3

Cleaning the Media Press .................................................................5-3

About MAINTENANCE MENU .......................................................5-4

MAINTENANCE MENUs table ..........................................................5-5

Maintaining the Capping Station ....................................................5-6

Cleaning the Wiper and Cap .............................................................5-6

Cleaning the mist filter....................................................................... 5-7

Clean the NCU .................................................................................. 5-8

Washing the Head Nozzle .................................................................5-9

Cleaning of ink discharge passage ...................................................5-9

When the Machine Is Not Used for a Long Time ............................5-10

Cleaning the Ink Head and the Area around It ............................5-12

Nozzle Recovery Function ...........................................................5-13

Reset the set value ..........................................................................5-14

Eliminate Ink Over Flow .............................................................5-14

Automatic Maintenance Function ................................................5-15

Setting the Refreshing Intervals ......................................................5-15

Setting the Cleaning Intervals and Type .........................................5-15

INK FILLING ................................................................................5-16

AIR PURGE .....................................................................................5-16

Replacing consumables ...............................................................5-18

Replacing the wiper .........................................................................5-18

Replacing the mist filter ................................................................... 5-18

If a Waste Ink Tank Confirmation Message Appears ......................5-19

Replace the waste ink tank with another .........................................5-19

Replacing the waste ink tank before the waste ink tank confirmation

message is displayed ......................................................................5-20

Replacing the Cutter Blade .............................................................5-20

Replacing and Adjusting the Cutter Blade ...................................5-21

Replacing the cutter ........................................................................5-21

Adjusting the Cutter Blade ...............................................................5-22

Replacing cutters other than supplied one ......................................5-22

Adjusting blade edge of cutters other than supplied one ................5-22

v

Chapter 6 Troubleshooting

Troubleshooting ............................................................................. 6-2

Power does not turn on .....................................................................6-2

The machine does not start printing ..................................................6-2

Media get jammed / media is soiled ..................................................6-2

Image quality is poor .........................................................................6-3

Nozzle is clogged ..............................................................................6-3

An error occurred in the ink bottle .....................................................6-3

When the ink leakage occurs ............................................................6-3

Warning / Error Messages .............................................................6-4

Warning messages ............................................................................6-4

Error messages .................................................................................6-7

Chapter 7 Appendix

Specification .................................................................................. 7-2

Printer Section Specifications ............................................................7-2

Cutter Section Specifications ............................................................7-3

Common Specifications .....................................................................7-4

Ink specifications ...............................................................................7-6

Ink bottle installation order .............................................................7-7

Sheet for inquiry ............................................................................ 7-8

vi

1

2

2

2

2

2

1

CAUTION

CAUTION

CAUTION

THIS LIMITED WARRANTY OF MIMAKI SHALL BE THE

SOLE AND EXCLUSIVE WARRANTY AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS, AND MIMAKI NEITHER ASSUMES NOR

AUTHORIZES DEALER TO ASSUME FOR IT ANY

OTHER OBLIGATION OR LIABILITY OR MAKE ANY

OTHER WARRANTY OR MAKE ANY OTHER

WARRANTY IN CONNECTION WITH ANY PRODUCT

WITHOUT MIMAKI’S PRIOR WRITTEN CONSENT.

IN NO EVENT SHALL MIMAKI BE LIABLE FOR

SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR FOR LOSS OF PROFITS OF DEALER

OR CUSTOMERS OF ANY PRODUCT.

Requests

• This Operation manual has been carefully prepared for

your easy understanding.However, please do not

hesitate to contact a distributor in your district or our

office if you have any inquiry.

• Description contained in this Operation manual are

subject to change without notice for improvement.

FCC Statement (USA)

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the Operation manual, may cause

harmful interference to radio communications.

Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will

be required to correct the interference at his own

expense.

In the case where MIMAKI-recommended cable is not

used for connection of this machine, limits provided by

FCC rules can be exceeded.

To prevent this, use of MIMAKI-recommended cable is

essential for the connection of this machine.

Interference to televisions and radios

The machine described in this manual generates high

frequency when operating. The machine can interfere with

radios and televisions if set up or commissioned under

improper conditions. The product is not guaranteed

against any damage to specific-purpose radio and

televisions.

The machine’s interference with your radio or television

will be checked by turning on/off the power switch of the

machine. In the event that the product is the cause of

interference, try to eliminate it by taking one of the

following corrective measures or taking some of them in

combination.

• Change the orientation of the antenna of the television

set or radio to find a position without reception difficulty.

• Separate the television set or radio from this product.

• Plug the power cord of this product into an outlet which

is isolated from power circuits connected to the

television set or radio.

vii

Foreword

Foreword

Congratulations on your purchase of MIMAKI UV ink jet

printer "UCJV300Series/150Series".

UV Inkjet Printer UCJV300Series/150Series uses

ultraviolet ray curing ink (UV ink).

Read this Operation Manual carefully and make the most

effective use of your printer.

On This Operation manual

• This Operation Manual is describing the operations

and maintenance of "UV inkjet printer UCJV300Series/

150Series" (hereinafter referred to as the machine).

• Read this Operation Manual carefully and understand

them thoroughly to use. It is also necessary to keep

this Operation Manual on hand.

• Make arrangements to deliver this Operation Manual to

the person in charge of the operation of this machine.

• This Operation Manual has been carefully prepared for

your easy understanding, however, please do not

hesitate to contact a distributor in your district or our

office if you have any inquiry.

• Descriptions contained in this Operation Manual are

subject to change without any notice for improvement.

• In the case when this Operation Manual should be

illegible due to destruction or lost by fire or breakage,

purchase another copy of the Operation Manual from

our office.

• You can also download the latest manual from our

website.

Reproduction of this manual is strictly prohibited.

© 2017 MIMAKI ENGINEERING Co., Ltd.

Safety Precautions

Symbols

Symbols are used in this Operation Manual for safe

operation and for prevention of damage to the machine.

The indicated sign is different depending on the content of

caution. Symbols and their meanings are given below.

Please follow these instructions as you read this manual.

Examples of symbols

Meaning

Failure to observe the instructions given

with this symbol can result in death or

serious injuries to personnel. Be sure to

read it carefully and use it properly.

Failure to observe the instructions given

with this symbol can result in injuries to

personnel or damage to property.

Important notes in use of this machine are

given with this symbol. Understand the

notes thoroughly to operate the machine

properly.

Important notes in use of this machine are

given with this symbol. Understand the

notes thoroughly to operate the machine

properly.

Indicates the reference page for related

contents.

The symbol " " indicates that the

instructions must be observed as strictly as

the CAUTION instructions (including

DANGER and WARNING instructions). A

sign representing a precaution (the sign

shown at left warns of hazardous voltage) is

shown in the triangle.

The symbol " " indicates that the action

shown is prohibited. A sign representing a

prohibited action (the sign shown at left

prohibits disassembly) is shown in or

around the circle.

The symbol " " indicates that the action

shown must be taken without fail or the

instructions must be observed without fail. A

sign representing a particular instruction

(the sign shown at left instructs to unplug

the cable from the wall outlet) is shown in

the circle.

viii

1

2

2

2

2

2

1

Safety Precautions

Warning for Use Never do the following

WARNING

• The set of power cables provided with this machine

is for use with this machine only, and cannot be

used with other electrical devices. Do not use any

power cables other than the ones provided with the

machine. Failure to observe those instructions may

result in fire or electric shocks.

• Do not use this machine in an environment where

humidity is high or the machine may get wet.

Using the machine under such environment may

result in fire or electric shock, or cause malfunction.

• Use of the machine under an abnormal condition

where it produces smoke or strange smell can

result in fire or electric shocks. If such an

abnormality is found, be sure to turn off the power

switch immediately and unplug the cable from the

wall outlet. Check first that the machine no longer

produces smoke, and contact your distributor or a

sales office of MIMAKI for repair. Never repair your

machine by yourself since it is very dangerous for

you to do so.

• Never disassemble or remodel the main unit

of the machine or the ink bottle. Disassembly

or remodeling can result in an electric shock

or breakdown of the machine.

• Do not use extension cords. Doing so may result in

fire or electric shocks.

• Keep the power plug prong clear of any foreign

object such as a piece of metal. Failure to do so

may result in a fire or electric shocks.

• Do not plug too many leads into a single socket.

Doing so may result in fire or electric shocks.

• Do not use the machine if the power cord or plug is

damaged. Using the machine with damaged power

cord may result in fire or electric shocks. Contact

your service representative for replacement cord.

• Do not handle the power plug with wet hands.

Doing so may result in electric shocks.

• Grasp by holding the plug itself when removing the

power plug from wall outlet, and never hold by the

cord. Holding and pulling the cord may damage the

cord, leading to fire or electric shocks.

• When setting the roll media, be sure to do so with

at least one other person.

• In case of ink leakage, please turn off the main

power, unplug the power cable and contact our

service office or distributor.

• Do not use a flammable spray or solvent inside or

around the machine. Doing so may result in fire or

electric shocks.

• Do not place a vase, flower pot, water glass,

container with liquid such as water or chemicals

inside, or small metallic object near or on top of this

machine. Liquid or foreign object may get inside

the machine, leading to fire or electric shocks.

• Do not use this machine in an area where children

might be present.

• The ink used for this machine falls into the

category of UN No.3082 and UN Class 9. Since the

ink is flammable, never use fire when using the

machine.

WARNING

Do not disassemble or remodel the machine

• Never disassemble or remodel the main unit of

the machine or the ink bottles. Disassembly or

remodeling can result in an electric shock or

breakdown of the machine.

Power supply and voltage

• Use this machine with the indicated power

specifications. Be sure to connect the power

cable plug to a grounded outlet. Failure to do

so may result in fire or electric shocks.

• Never look at the illuminated LED UV with

your naked eyes. Doing so could cause pain in

your eyes or visual impairment. Be sure to

wear safety glasses.

• Do not expose your skin directly to ultraviolet

(UV) light. Doing so could cause skin irritation.

• To prevent electrical shock, be sure to turn off

the main power circuit breaker and disconnect

the power plug before carrying out

maintenance. For some units, it may take one

minute for the capacitors to discharge.

Therefore, wait three minutes after turning off

the main power circuit breaker and

disconnecting the power plug before starting

maintenance work.

• Although rare, LED UV units can become

damaged. We recommend replacing the LED

UV unit when it has reached its rated

operation life, or earlier.

• The main power circuit breaker should be

turned on only by personnel with sufficient

knowledge about the operation of this

machine.

• The LED UV unit is hot while it is on and

immediately after it has been turned off. Do

not touch it with your bare hands. Doing so

could result in burns.

Do not use this machine in damp places

• Do not use this machine in an environment

with high humidity or where the machine could

get wet. Using the machine under such

environment may result in fire or electric

shock, or cause malfunction.

Handling ink bottles

• Some of the ingredients (UV curing initiator)

are toxic to aquatic life. Avoid any leaks into

water systems or sewage systems.

• Store ink bottles and waste ink bottles in a

place that is out of the reach of children.

• If you get ink on your skin or clothing,

immediately wash it off with detergent or

water. If you get ink in your eyes, immediately

wash your eyes with a lot of clean water, and

then consult a doctor as soon as possible.

• Dispose of waste ink according to the local

regulations of the area where the machine

isused.

ix

Safety Precautions

Notes on maintenance

• When handling ink and cleaning solution, pay

close attention to ventilation and be sure to

wear the included safety glasses and gloves.

• The gloves supplied with the machine are

disposable. When all the gloves are

expended, purchase an equivalent product on

the market.

• Before using ink and cleaning solution, be

sure to read the Safety Data Sheet (SDS).

• Keep ink away from an open flame. Also keep

the room well ventilated when you use or

handle ink.

• If you get ink in your eyes, immediately wash

your eyes thoroughly with a lot of clean water

for at least 15 minutes. Then, consult a doctor

as soon as possible.

• If anyone drinks ink by mistake, keep him or

her quiet and see a doctor immediately. Do not

allow him or her to swallow the vomit. Then

contact the emergency number written on the

SDS.

• If you inhale a great deal of vapor and feel ill,

immediately move to a location with plenty of

fresh air, and keep yourself warm and quiet.

Consult a doctor as soon as possible.

• If the ink adheres to your skin, use a large

amount of water and soap or special detergent

for skin to remove the ink.

Periodic replacement parts

• Some parts of this machine must be replaced with new ones

periodically by service personnel. Be sure to make a

contract with your distributor or dealer for After sale service

to ensure a long life of your machine.

Protection of media from dust

• Store media in a bag. Wiping off dust accumulated on media

will adversely affect the media due to static electricity.

• When leaving the workshop after the working hours, do not

leave any media on the roll hanger. If any media is left on the

roll hanger, it can get dusty.

Clump lever

• Never raise the lever during printing. Raising the lever will

abort printing.

Notes on maintenance

• It is strongly recommended to use the machine in a room

that is not dusty.

• Dust in the heads can also cause drops of ink to fall

suddenly down on the media during printing. In such a case,

be sure to clean up the heads.

• Perform wiping (removal of dust and paper powder) of the

capping station and wiper frequently.

WARNING

Handling ink bottles

• The safety evaluation of this machine assumes that the ink

recommended by this company is used. For safe usage of

this machine, use the ink recommend by this company.

• Never refill the ink bottles with ink. Refilled ink cartridge can

cause a trouble. Remember that MIMAKI assumes no

responsibility for any damage caused by the use of the ink

cartridge replenished with ink.

• If an ink bottle is moved from a cold place to a warm place,

leave it at room temperature for at least three hours before

using it.

• Open the ink bottle just before installing it in the machine. If it

is opened and left for an extended period of time, normal

printing performance of the machine may not be ensured.

• Make sure to store ink bottles in a cool and dark place.

• Store ink bottles and waste ink bottles in a place that is out

of the reach of children.

• Once an ink bottle is opened, be sure to thoroughly

consume the ink within three months. If an extended period

of time has passed away after opening the cartridge tank,

printing quality would be poor.

• Do not pound ink bottles or shake them violently. Doing so

could cause the ink to leak.

• Consult with your sales or service representative regarding

the proper disposal of ink bottles and waste ink. When you

dispose them by yourself, follow the regulations stipulated

by the industrial waste disposer or the country or region you

live in.

Handling of media

• Use media recommended by MIMAKI to ensure reliable,

high-quality printing.

• Pay attention to the expansion and contraction of the media.

Do not use media immediately after unpacking. The media

can be affected by the room temperature and humidity, and

thus it may expand and contract. The media have to be left

in the atmosphere in which they are to be used for 30

minutes or more after unpacked.

• Do not use curled media.

The use of curled media can not only cause a media jam but

also affect print quality.

Straighten the sheet of media, if significantly curled, before

using it for printing. If a regular-sized coated sheet of media

is rolled and stored, the coated side has to face outside.

Disposition of this machine

• Consult your sales or service representative for proper

disposal of this machine. Otherwise, commission an

industrial waste disposal company.

WARNING

x

1

2

2

2

2

2

1

Safety Precautions

Precautions in Use

Cautions on Installation

CAUTION

Handling of the power cable

• Connect to a socket-outlet with determinate

polarity.

• For PLUGGABLE EQUIPMENT, the socket-

outlet shall be installed near the equipment

and shall be easily accessible.

• Unplug the cord from the wall outlet and

remove dust from the power plug periodically,

at least once a year. Failure to do so may

result in fire or electric shocks.

• Do not use the machine unless it is connected

to a power supply that satisfies the displayed

voltage condition.

• Check the voltage of the wall outlet and the

capacity of the circuit breaker before you plug

the power cords. Plug each power cord to

different outlet that has independent circuit

breaker If you plug more than one power cord

to wall outlets that share the same circuit

breaker, the power may be cut off by the

breaker.

Power supply

• Leave the breaker turned ON.

• Do not turn off the main power switch on the

right side of this machine.

Ultraviolet (UV) light

• Some leakage of ultraviolet light occurs

around the LED UV unit. Exposing skin and

eyes to ultraviolet light could cause

inflammation and skin cancer. Even if weak

ultraviolet light does not cause inflammation,

chronic disorders could develop due to

repeated exposure. Avoid exposing your skin

and eyes to ultraviolet light.

• Visual impairments that can occur as a result

of exposure to ultraviolet light include acute

disorders such as pain or excess tearing in

response to foreign matter, and chronic

disorders such as cataracts. When using this

machine, be sure to wear gloves, long-sleeved

clothing, a visor over your face, and the

shaded glasses that are included with the

machine.

Notes on the LED UV unit

• When handling the glass on the bottom of the

LED UV unit, be sure to wear the included

gloves. Never touch the glass with your bare

hands. Otherwise, the UV ink curing level may

drop significantly. If the glass becomes dirty,

wipe it with clean gauze moistened with

alcohol. (Do not use alcohol for cleaning the

exterior cover, or the paint will peel off.)

• The LED UV performance and service life are

significantly affected by the UV irradiation and

UV power supply units that are used. Only use

UV devices that are recommended by

Mimaki.Mimaki shall bear no responsibility for

any trouble due to the use of UV devices other

than those that are recommended.

Be careful with the movable parts

• Do not touch the rolling grit roller. Otherwise,

you could hurt your fingers or tear off your

finger nails.

• Keep your head and hands away from any

moving parts during cutting (plotting)

operation. Otherwise, your hair could become

caught in the machine. Wear proper clothes.

(Do not wear loose-fit clothes or accessories).

Bind a long hair.

Caution with cutters

• The cutter blades are very sharp. Do not touch

them.

• Do not shake or swing the cutter holder.

Otherwise, the blade may come off.

Hot parts

• The LED UV unit is very hot. Before

performing maintenance work, wait until the

temperature has dropped sufficiently after the

LED UV unit has been turned off.

• If touching hot parts is unavoidable, be sure to

wear heat-insulating gloves to protect your

hands.

CAUTION

A place exposed to direct

sunlight

On an inclined surface

A place that vibrates

A place exposed to direct

air flow from an air

conditioner

A place where the

temperature or humidity

varies significantly

Around a place where fire

is used

• Use the

machine under

the following

environmental

conditions:

• Operating

environment:

20 to 30 °C

(68 to 86 °F)

35 to 65 % (Rh)

CAUTION

Safety Precautions

xi

Safety interlock

For your safety, this machine is equipped with interlocks to stop all operations if a cover is opened while the machine is

printing.

(parts circled in red in the figure below)

Warning labels

xii

1

2

2

2

2

2

1

Warning labels

Warning labels are attached to the machine. Be sure to fully understand the warning given on the labels.

If a warning label is illegible due to stains or has come off, purchase a new one from a distributor or our sales office.

3

4

7

5

2

2

3

6

1

1

8

Around the carriage

When the maintenance cover is open

Warning labels

xiii

No. Reorder Label

1

M910931

2

M907833

3

M903330

4

M903405

5

M907935

6

M905811

7

M913419

8

M905935

This chapter

tells you what you should know before using this machine, including the name of each

part and the installation procedures.

Moving This Machine .................................... 1-2

Where to Install This Machine ..................... 1-2

Working Environmental Temperature ......... 1-2

Moving This Machine .................................. 1-2

Names of Parts and Functions...................... 1-3

Front Side of the Machine ........................... 1-3

Rear Side and Right Side of the Machine ... 1-4

Carriage ...................................................... 1-5

Operation Panel .......................................... 1-6

Media Sensor .............................................. 1-8

Carriage ...................................................... 1-8

Cutter Blade and Cutting Slot ...................... 1-8

Capping Station ........................................... 1-8

Pinch Rollers and Grit Rollers ..................... 1-8

Connecting Cables........................................ 1-9

Connecting USB 2.0 Interface Cable ...........1-9

Connecting a LAN Cable .............................1-9

Connecting the Power Cable .....................1-10

Ink Bottles ................................................... 1-11

Types of Inks You Can Use with the

Machine .....................................................1-11

Precautions on Using the Ink Bottles .........1-11

Installing the Ink Bottles .............................. 1-12

Media .......................................................... 1-17

The Size of Media That Can Be Used with

This Machine .............................................1-17

Precautions on Handling the Media ...........1-17

Menu Mode ................................................. 1-18

Chapter 1

Before Use

Chapter 1 Before Use

1-2

Moving This Machine

Where to Install This Machine

Secure a suitable installation space before assembling

this machine.

The place of installation must have enough space for not

only this machine itself but also for the printing operation.

Working Environmental Temperature

Use this machine in an environment of 20 to 30°C to

ensure reliable printing.

Moving This Machine

Follow the procedure described below when you have to

move this machine to a different place within the same

floor that does not have any steps.

1

Remove the caster blocks.

2

Move this machine as shown in the figure.

• This machine must be moved by at least 4

people. This work shall be performed in

accordance with the regulations of each country

and region.

• Do not push the cover to move this machine

because doing so can cause the cover to crack.

3

Put the caster blocks back in place.

Model Width Depth Height

Gross

weight

UCJV300-160

2900mm

(114.2 in)

776mm

(30.6 in)

1475mm

(5801 in)

188kg

(414.5 lb)

UCJV300-130

2650mm

(104.3ln)

776mm

(30.6 in)

1475mm

(5801 in)

177kg

(390.2lb)

UCJV300-107

2380mm

(93.7in)

776mm

(30.6 in)

1475mm

(5801 in)

161kg

(354.9lb)

UCJV300-75

2090mm

(82.3in)

776mm

(30.6 in)

1475mm

(5801 in)

144kg

(317.5lb)

UCJV150-160

2900mm

(114.2 in)

776mm

(30.6 in)

1475mm

(5801 in)

183kg

(410.1 lb)

• If you need to move the machine to any other

places, contact your distributor or our service

office.

Moving the machine by yourself may cause failure

or damage to the machine.

Be sure to request your distributor or our service

office to move this machine.

• When moving this machine, take care not to sub-

ject it to excessive shocks.

• Be sure to lock the casters after moving this

machine.

500 mm (19.7 in)

minimum

3900

m

m (

15

3

.5 i

n)

m

i

ni

mum (

1

60Mod

el

)

3

650 mm

(

143

.7 i

n)

m

i

n

i

m

um (

1

3

0Mod

el

)

3

380 mm

(

133.

0

i

n)

mi

ni

m

um (

10

7Mode

l

)

30

90 mm

(

121.

7 i

n)

mi

ni

m

u

m (

75

Mo

del

)

2

7

7

6

m

m

(

1

0

9

.

3

i

n

)

500 mm (19.7 in)

minimum

1

0

0

0

m

m

(

3

9

.

3

i

n

)

m

i

n

i

mu

m

1

0

0

0

mm

(

3

9

.

3

i

n

)

m

i

n

i

m

u

m

1-3

Chapter 1 Before Use

1

2

2

2

2

Names of Parts and Functions

Front Side of the Machine

Operation panel

This panel has the operation keys

required for operating the machine and

the LCDs for displaying setting items,

etc.

Clamp lever (front)

Moves the pinch rollers up and down to hold or

release the media.

Waste ink tank

Waste ink gathers in this tank.

Stand

Supports the main body of the machine. It is

provided with casters that are used to move

this machine.

After cover

The printed media is output

along the after cover.

Ink supply unit

The ink bottles are inserted here. ( P.1-12)

Take-up device

Automatically winds up the printed roll media.

Carriage

The print head moves from side to side.

Maintenance cover

Open these covers only when you have to perform

maintenance. Normally, keep all covers closed even

when the power switch is off,

Platen

Area where media is flattened

and printed.

1-4

Chapter 1 Before Use

Rear Side and Right Side of the Machine

AC inlet

Connect the power cable to the AC inlet.

Clamp lever (rear)

Interlocks with the clamp lever in

the font of this machine.

USB connector

This is a USB 2.0 interface connector.

Main power switch (INLET 1)

Turns on/off the main power for this machine. Leave

the main power turned on to prevent ink clogging.

Vent filter box

Vents the ink mist

generated during printing.

Roll holder

Grabs the roll media by the ends of

its paper core to hold the media in

place. It supports 2-inch and 3-inch

paper cores.

LAN connector

Use this connector when you use network functions.

Chapter 1 Before Use

1-5

1

2

2

2

2

Carriage

The carriage is equipped with a print head and an LED-

UV unit for printing.

• Do not look into the light emitted from the LED-UV

unit directly with the naked eye, regardless of

whether the front cover is placed on top of it. The

emitted light can be extremely bright under some

printing conditions.

• Remember to wear the UV protective glasses sup-

plied with the machine.

UV light

Front cover

1-6

Chapter 1 Before Use

Operation Panel

Use the operation panel to specify print settings or to operate this machine.

*1: Ink status

The display shows icons indicating the status (remaining ink, error, etc.) of ink bottles.

The following table describes each icon:

Icon Meaning

The ink bottle icons are arranged in the same order as the actual ink bottles are arranged in the ink supply unit. For

each ink bottle icon, the remaining ink is indicated in nine levels.

The following icons are arranged in descending order of remaining ink level:

This icon is displayed at ink end or ink near end.

Be aware that the ink is running low.

Indicates that the cartridge cannot be used due to ink end or ink error (remaining ink 0, cartridge not attached, etc.).

Indicates that ink has expired or that one month has passed since the expiration date. Please replace the ink bottle

as soon as possible. After two months from the expiration date, the ink bottle can no longer be used.

width:1340mm

REMOTEMENU

TEST PRINT

CLEANING

LOCAL

Status indicator lamp

Indicates the machine's status (printing, an error has occurred, etc).

Lamp state Machine state

Off

The machine is in LOCAL mode, which means that there is no

incoming print data or error occurring on the machine.

Solid light blue The machine is in REMOTE mode.

Blinking light

blue

The machine is currently printing data.

The machine is performing a test print or other similar

operation (that is, the machine is printing the patterns stored in

it).

Solid blue There is remaining print data in the machine.

Blinking red An error has occurred.

Solid red An error (SYSTEM HALT) has occurred.

Display

The display shows the following

information:

• Status of the machine

• Width of the set media

•Ink status

*1

• Functions assigned to [FUNC1],

[FUNC2] and [FUNC3]

*2

button

Press this button to select a function to

be assigned to each function button

([FUNC1], [FUNC2] and [FUNC3]).

//

buttons

Press one of these buttons to set a

function or to perform test printing. With

each pressing of the [SEL] button, you

can change the function assigned to the

selected function button.

JOG button

Use these buttons to move the head or

media during LOCAL mode or to select

a setting.

button

Use this button to cancel the entered

setting or to go back to the previous

level of the setting menu. You can also

use this button to turn the power on or

off. (Give it a long press to turn the

power off.)

button

• When the power is turned on using the [END/POWER] key, the [ENTER] key lights up blue and turns off when the

power switch is turned off. While the main power switch ( P.1-4) is on, the ink clogging prevention function is peri-

odically operated even when the power is turned off using the [END/POWER] key.

Ink full

Approximatel

y 1/8

consumed

Approximatel

y 1/4

consumed

Approximatel

y 3/8

consumed

Approximatel

y 1/2

consumed

Approximatel

y 5/8

consumed

Approximatel

y 3/4

consumed

Approximatel

y 7/8

consumed

Near end

1-7

Chapter 1 Before Use

1

2

2

2

2

*2: Functions assigned to [FUNC1], [FUNC2], and [FUNC3]

The following table describes the functions assigned to [FUNC1], [FUNC2], and [FUNC3], respectively:

Icon Meaning

Displays a menu for setting functions.

Displays maintenance functions such as test print, cleaning, etc.

Exits LOCAL mode and enters REMOTE mode to start printing.

Displays adjustment functions such as FEED COMP, DROP.POScorrect, etc.

Clears data.

Suspends printing in REMOTE mode and enters LOCAL mode.

Cuts the media.

Moves to the previous page when multiple items are displayed on a screen (for example, on the MENU screen).

Moves to the next page when multiple items are displayed on a screen (for example, on the MENU screen).

Used for confirmation of a displayed message (for example, a warning message).

Used to turn off or disable a function.

Indicates that some setting or function has been assigned here. Use the assigned setting or function by

following the instructions provided for it.

Enables or disables the operation specified for the selected items (applicable when multiple items are selected,

for example, when multiple heads are selected for cleaning).

Sets cutting conditions.

Confirms or sets cutting-related functions, including test cutting.

Sets the pressure of the pinch rollers.

• The color of the icons changes according to the state of the printer.

When the icon is green: The machine is in REMOTE mode.

When the icon is dark blue: The machine is in LOCAL mode.

When the icon is yellow: A warning has been issued.

When the icon is red: An error has occurred.

Chapter 1 Before Use

1-8

Media Sensor

The media sensor detects the presence of the media and

the media length.

This machine has one media sensor on the platen (in the

rear).

Carriage

The carriage consists of the printer unit and the cutter

unit.

Printer unit

Cutter unit

Cutter Blade and Cutting Slot

The cutter unit is equipped with a cutter blade for cutting

the media.

The cutter cuts off the sheet of media along the cutting

slot on the platen.

Capping Station

The capping station consists of the ink caps, the wiper for

cleaning the heads, etc.

The ink caps prevent the nozzles in the ink heads from

drying up.

The wiper cleans the nozzles in the heads.

The wiper is a consumable. If the wiper becomes

deformed or the media gets stained, replace the wiper

with a new one.

Pinch Rollers and Grit Rollers

The pinch rollers and grit rollers hold the media in place.

• When setting media, be sure to cover the media

sensor located on the rear of the platen. The

media cannot be detected unless it is placed over

the sensor.

Media sensor

Printer unit

Cutter unit

• Remember to wear the protective safety glasses

supplied with the machine when cleaning the

inside of the capping station. This precaution is

necessary to prevent ink from getting in your eyes.