-

10.06.2015 21:16

#1

Не удалось подключиться к ECU

Всем добрый вечер.

Купил беспроводной адаптер elm 327 и столкнулся с проблемой. При соединении с адаптером через canMaster-ELM v2.1 получаю проблему. К адаптеру коннект есть, к интерфейсу тоже, а вот к ECU не подключиться(error 99004). Почему так может быть?Адаптер точно рабочий, проверял на калине 2. У самого toyota crown jzs179

-

11.06.2015 01:15

#2

Сообщение от vodkamedved

Всем добрый вечер.

Купил беспроводной адаптер elm 327 и столкнулся с проблемой. При соединении с адаптером через canMaster-ELM v2.1 получаю проблему. К адаптеру коннект есть, к интерфейсу тоже, а вот к ECU не подключиться(error 99004). Почему так может быть?Адаптер точно рабочий, проверял на калине 2. У самого toyota crown jzs179мож по этому ?

содом и гоморра — генеральная репетиция ; земля ,наши дни — премьера

-

11.06.2015 01:31

#3

не читает этот адаптер эту авту

содом и гоморра — генеральная репетиция ; земля ,наши дни — премьера

-

11.06.2015 07:54

#4

Уточняйте протоколы работы поддерживаемые устройством и теми чио выдает эбу.

-

11.06.2015 19:25

#5

Сообщение от iex

не читает этот адаптер эту авту

читает через Torque, но пока нет возможности им воспользоваться…

Кто какими программами пользуется(PC)?

Вот недавно пришла с китая эта штучка. Коннектится нормально, но почему-то через Torque pro не видит ошибку(горит подушка), а Scanmaster выдает ошибки 99004 или неудачное подключение к интерфейсу. Может кто-нибудь подскажет в чем проблемки?

Цена вопроса: 300 ₽

Пробег: 71 000 км

Комментарии

19

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

для полного счастья нужен шнурок VAG COM

через нее можно включить тест стрелок приборки?

блютуз?

где брал, заделись ссылкой?

тоже надо…пару раз чек загорался и пропадал.

Carista больше ошибок видит, в разные блоки залезать умеет. Даже доп. функции может активировать, так что попробуй. У друга на audi она увидела ошибку датчика угла поворота руля, torque не видит.

И не увидит никогда. Серьезные ошибки эта безделушка не видит и не сотрет.

gammy81

И не увидит никогда. Серьезные ошибки эта безделушка не видит и не сотрет.

это безполезная штука мне стерла два раза ошибки и через неё активировал пять допов

Ну так помогите человеку аэрбег стереть.

DmitryJoiner

это безполезная штука мне стерла два раза ошибки и через неё активировал пять допов

через нее можно тест стрелок включить?

Нет. Тест только через шнур

slaiger

попробуй Carista OBD

Кариста какая то медленная . еще медленее чем торг. Мне больше сканмастер понравилась.

тут вопрос уже не в скорости — первые две человеку не помогли…

сканмастер может быть и помог бы, если подключился к ЭБУ

Сканмастер на наших машинах ничего кроме двигателя не видит

Все комментарии

Re: Виртуальный порт OBD II сканера

Nikolas писал(а):а где взять программу Scan Master Elm 1.7 rus?

Да диске (идущим в комплекте) должны быть папки:

ScanMaster 1.7 ru

ScanMaster 2.1 ru

- admin

- Администратор

- Сообщения: 6811

- Зарегистрирован: 02 апр 2009, 19:13

- Откуда: Украина, Киев

- Благодарил (а): 264 раз.

- Поблагодарили: 2553 раз.

-

- Сайт

Re: Виртуальный порт OBD II сканера

Igor1973 » 14 июн 2011, 17:43 | Cообщение: #102

niknik писал(а):

Nikolas писал(а):а где взять программу Scan Master Elm 1.7 rus?

да ничего Вы нею не увидите

Ну «ничего» тут немного не корректно. Все зависит от понимания того, что там можно увидеть и умения применить увиденное при локализации неисправности.

-

Igor1973 - Сообщения: 2959

- Зарегистрирован: 05 дек 2009, 22:24

- Откуда: Брест, Беларусь

- Благодарил (а): 402 раз.

- Поблагодарили: 446 раз.

Re: Виртуальный порт OBD II сканера

Сява » 25 янв 2012, 17:26 | Cообщение: #103

Подскажите молодому.

Напишу здесь чтоб не плодить тем или направьте куда, если не по адресу.

Сегодня попытался подключиться через МТ Про посредством ScanMaster-ELM к Шеви Лачети 2007 года, ошибки поглядеть, но соединении не получилось.

Подскажите что куда нажать, хоть направление?

Еще у меня есть адаптер ELM327 с блютузом, его можно запустить через ScanMaster-ELM?

Заранее спасибо за помощь.

- Сява

- Сообщения: 16

- Зарегистрирован: 23 дек 2011, 21:12

- Откуда: Екб

- Благодарил (а): 0 раз.

- Поблагодарили: 0 раз.

Re: Виртуальный порт OBD II сканера

vldp » 25 янв 2012, 17:42 | Cообщение: #104

Можно и тем и другим. Почитайте в хелпе всё написано, а так объяснять тяжело.

- vldp

- Сообщения: 565

- Зарегистрирован: 24 окт 2009, 16:41

- Откуда: Харьковская обл.

- Благодарил (а): 98 раз.

- Поблагодарили: 30 раз.

Re: Виртуальный порт OBD II сканера

admin » 25 янв 2012, 19:15 | Cообщение: #105

Тут описание:

viewtopic.php?f=2&t=179

Что у вас в журнале окна «Виртуальный порт OBD II сканера», сделайте скрин или выложите содержимое.

- admin

- Администратор

- Сообщения: 6811

- Зарегистрирован: 02 апр 2009, 19:13

- Откуда: Украина, Киев

- Благодарил (а): 264 раз.

- Поблагодарили: 2553 раз.

-

- Сайт

Re: Виртуальный порт OBD II сканера

Сява » 25 янв 2012, 21:21 | Cообщение: #106

admin писал(а):Тут описание:

viewtopic.php?f=2&t=179

Что у вас в журнале окна «Виртуальный порт OBD II сканера», сделайте скрин или выложите содержимое.

Извиняйте. Читать больше надо. Я не с той стороны подошел.

Следующий раз попробую вновь

- Сява

- Сообщения: 16

- Зарегистрирован: 23 дек 2011, 21:12

- Откуда: Екб

- Благодарил (а): 0 раз.

- Поблагодарили: 0 раз.

Re: Виртуальный порт OBD II сканера

Сява » 26 янв 2012, 11:52 | Cообщение: #107

Сява писал(а):Подскажите молодому.

Напишу здесь чтоб не плодить тем или направьте куда, если не по адресу.Сегодня попытался подключиться через МТ Про посредством ScanMaster-ELM к Шеви Лачети 2007 года, ошибки поглядеть, но соединении не получилось.

Подскажите что куда нажать, хоть направление?Еще у меня есть адаптер ELM327 с блютузом, его можно запустить через ScanMaster-ELM?

Заранее спасибо за помощь.

Сегодня получилось соединиться и ошибки увидел, но возникла ошибка при считывании параметров двигателя: «Error:99001 — Lost communication (RS232)». Скрин пока не знаю как выложить.

Подскажите куда двигаться?

Последний раз редактировалось Сява 26 янв 2012, 16:12, всего редактировалось 1 раз.

- Сява

- Сообщения: 16

- Зарегистрирован: 23 дек 2011, 21:12

- Откуда: Екб

- Благодарил (а): 0 раз.

- Поблагодарили: 0 раз.

Re: Виртуальный порт OBD II сканера

admin » 17 июл 2017, 13:47 | Cообщение: #110

Драйвер виртуального порта который шел с MT3 работает только до WinXp.

Тут можно скачать демо версию,

https://www.eltima.com/products/vspax/

, попробовать через нею установить.

- admin

- Администратор

- Сообщения: 6811

- Зарегистрирован: 02 апр 2009, 19:13

- Откуда: Украина, Киев

- Благодарил (а): 264 раз.

- Поблагодарили: 2553 раз.

-

- Сайт

Вернуться в Обновления

Кто сейчас на конференции

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 1

CNC SYSTEM

OSP-E100M

OSP-E10M

ALARM & ERROR LIST

(4th Edition)

Pub No. 4293-E-R2 (ME37-005-R4) Oct. 2000

4293-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety devices: they must also become fully familiar with the safety guidelines presented below to ensure accident-free operation.This instruction manual and the warning signs attached to the machine cover only those hazards which Okuma can predict. Be aware that they do not cover all possible hazards.

1.Precautions Relating To Machine Installation

(1)Install the machine at a site where the following conditions (the conditions for achievement of the guaranteed accuracy) apply.

•Ambient Temperature: 17 to 25°C

•Ambient humidity: 75% max. (no condensation)

•Site not subject to direct sunlight or excessive vibration; environment as free of dust, acid, corrosive gases, and salt spray as possible.

(2)Prepare a primary power supply that complies with the following requirements.

•Voltage: 200V

•Voltage fluctuation: ±10% max.

•Power supply frequency: 50/60 Hz

•Do not draw the primary power supply from distribution panel that also supplies a major noise source (for example an electric welder or electric discharge machine) since this could cause malfunction of the NC unit.

•If possible connect the machine to a ground not used by any other equipment. If there is no choice but to use a common ground, the other equipment must not generate a large amount of noise (such as an electric welder or electric discharge machine).

(3)Installation Environment

Observe the following points when installing the electrical control cabinet.

•Make sure that the NC unit will not be subject to direct sunlight.

•Make sure that the electrical control cabinet will not be splashed with chips, water, or oil.

•Make sure that the electrical control cabinet and operation panel are not subject to excessive vibrations or shock.

•The permissible ambient temperature range for the electrical control cabinet is 0 to 40°C.

•The permissible ambient humidity range for the electrical control cabinet is 30 to 95% (no condensation).

•The maximum altitude at which the electrical control cabinet can be used is 1000 m (3281 ft.).

2.Points To Check Before Turning On The Power

(1)Close all the doors of the electrical control cabinet and operation panel to prevent the entry of water, chips, and dust.

(2)Make absolutely sure that there is nobody near the moving parts of the machine, and that there are no obstacles around the machine, before starting machine operation.

4293-E P-(ii)

SAFETY PRECAUTIONS

(3)When turning on the power, turn on the main power disconnect switch first, then the CONTROL ON switch on the operation panel.

3.Precautions Relating To Operation

(1)After turning on the power, carry out inspection and adjustment in accordance with the daily inspection procedure described in this instruction manual.

(2)Use tools whose dimensions and type are appropriate for the work undertaken and the machine specifications. Do not use badly worn tools since they can cause accidents.

(3)Do not for any reason touch the spindle or tool while spindle indexing is in progress since the spindle could rotate: this is dangerous.

(4)Check that the workpiece and tool are properly secured.

(5)Never touch a workpiece or tool while it is rotating: this is extremely dangerous.

(6)Do not remove, chips by hand while machining is in progress since this is dangerous. Always stop the machine first, then remove the chips with a brush or broom.

(7)Do not operate the machine with any of the safety devices removed. Do not operate the machine with any of the covers removed unless it is necessary to do so.

(8)Always stop the machine before mounting or removing a tool.

(9)Do not approach or touch any moving part of the machine while it is operating.

(10)Do not touch any switch or button with wet hands. This is extremely dangerous.

(11)Before using any switch or button on the operation panel, check that it is the one intended.

4.Precautions Relating to the ATC

(1)The tool clamps of the magazine, spindle, etc., are designed for reliability, but it is possible that a tool could be released and fall in the event of an unforeseen accident, exposing you to danger: do not touch or approach the ATC mechanism during ATC operation.

(2)Always inspect and change tools in the magazine in the manual magazine interrupt mode.

(3)Remove chips adhering to the magazine at appropriate intervals since they can cause misoperation. Do not use compressed air to remove these chips since it will only push the chips further in.

(4)If the ATC stops during operation for some reason and it has to be inspected without turning the power off, do not touch the ATC since it may start moving suddenly.

5.On Finishing Work

(1)On finishing work, clean the vicinity of the machine.

(2)Return the ATC, APC and other equipment to the predetermined retraction position.

(3)Always turn off the power to the machine before leaving it.

(4)To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the main power disconnect switch.

4293-E P-(iii)

SAFETY PRECAUTIONS

6.Precautions During Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the following points when performing maintenance inspections or during checking when trouble has occurred.

(1)When trouble occurs, press the emergency stop button on the operation panel to stop the machine.

(2)Consult the person responsible for maintenance to determine what corrective measures need to be taken.

(3)If two or more persons must work together, establish signals so that they can communicate to confirm safety before proceeding to each new step.

(4)Use only the specified replacement parts and fuses.

(5)Always turn the power off before starting inspection or changing parts.

(6)When parts are removed during inspection or repair work, always replace them as they were and secure them properly with their screws, etc.

(7)When carrying out inspections in which measuring instruments are used — for example voltage checks — make sure the instrument is properly calibrated.

(8)Do not keep combustible materials or metals inside the electrical control cabinet or terminal box.

(9)Check that cables and wires are free of damage: damaged cables and wires will cause current leakage and electric shocks.

(10)Maintenance inside the Electrical Control Cabinet

a)Switch the main power disconnect switch OFF before opening the electrical control cabinet door.

b)Even when the main power disconnect switch is OFF, there may some residual charge in the servo amplifier and spindle drive unit, and for this reason only service personnel are permitted to perform any work on these units. Even then, they must observe the following precautions.

•Servo amplifier

•Discharge the residual voltage one minute after turning off the breaker inside the unit.

•Spindle drive unit

•Discharge the residual voltage one minute after turning off the main power disconnect switch.

c)The electrical control cabinet contains the NC unit, and the NC unit has a printed circuit board whose memory stores the machining programs, parameters, etc. In order to ensure that the contents of this memory will be retained even when the power is switched off, the memory is supplied with power by a battery. Depending on how the printed circuit boards are handled, the contents of the memory may be destroyed and for this reason only service personnel should handle these boards.

(11)Periodic Inspection of the Electrical Control Cabinet

a)Cleaning the cooling unit

The cooling unit in the door of the electrical control cabinet serves to prevent excessive temperature rise inside the electrical control cabinet and increase the reliability of the NC unit. Inspect the following points every three months.

•Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

4293-E P-(iv)

SAFETY PRECAUTIONS

•Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

7.General Precautions

(1)Keep the vicinity of the machine clean and tidy.

(2)Wear appropriate clothing while working, and follow the instructions of someone with sufficient training.

(3)Make sure that your clothes and hair cannot become entangled in the machine. Machine operators must wear safety equipment such as safety shoes and safety goggles.

(4)Machine operators must read the instruction manual carefully and make sure of the correct procedure before operating the machine.

(5)Memorize the position of the emergency stop button so that you can press it immediately at any time and from any position.

(6)Do not access the inside of the control panel, transformer, motor, etc., since they contain highvoltage terminals and other components which are extremely dangerous.

(7)If two or more persons must work together, establish signals so that they can communicate to confirm safety before proceeding to each new step.

8.Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of particular importance. Read the instructions marked with these symbols carefully and follow them.

NOTICE

Indicates an imminent hazard which, if not avoided, will result in death or serious injury.

Indicates unsafe practices which, if not avoided, could result in death or serious injury.

Indicates unsafe practices which, if not avoided, could result in minor injuries or damage to devices or equipment.

Indicates precautions relating to operation or use.

4293-E P-(i)

INTRODUCTION

INTRODUCTION

Before using this NC unit, read this manual thoroughly in order to ensure correct use.

This manual explains how to use and maintain the control so that it will deliver its full performance and maintain accuracy over the long term.

You must pay particular attention to the cautions given in this manual; read them carefully and make sure you fully understand them before operating the NC.

4293-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

|

CLASSIFICATION OF ALARMS |

…………………………………………………………..1 |

|

CPU ALARM ……………………………………………………………………………………… |

8 |

|

ALARM P ………………………………………………………………………………………… |

17 |

|

ALARM A ………………………………………………………………………………………… |

84 |

|

ALRAM B ………………………………………………………………………………………. |

156 |

|

ALARM C ………………………………………………………………………………………. |

302 |

|

ALARM D ………………………………………………………………………………………. |

357 |

|

ERRORS ………………………………………………………………………………………. |

414 |

|

APPENDIX ……………………………………………………………………………………. |

574 |

4293-E P-1

SECTION 1 CLASSIFICATION OF ALARMS

SECTION 1 CLASSIFICATION OF ALARMS

Alarms related with the OSP are classified into six types such as CPU alarm, Alarm P, A, B, C and D.

1.Alarm Classifications

|

Alarm |

Machine Conditions When ALARM Lamp |

Operative NC Functions Thereafter |

||

|

Comes ON |

||||

|

CPU |

Stops NC operation. |

All NC functions are inoperative. |

||

|

Concerning the control, cancel the alarm |

||||

|

axis feed |

||||

|

by turning power on again after turning it |

||||

|

Stops; |

spindle rotation |

|||

|

off once. |

||||

|

coolant supply |

||||

|

Axis drive power is switched OFF. |

||||

|

CPU status is displayed on the operation |

||||

|

panel. |

||||

|

P |

Stops NC operation. |

All NC functions are inoperative. |

||

|

Concerning the control, cancel the alarm |

||||

|

axis feed |

||||

|

by turning power on again after turning it |

||||

|

Stops; |

spindle rotation |

|||

|

off once. |

||||

|

coolant supply |

||||

|

Axis drive power is switched OFF. |

||||

|

Alarm display is given on the operation |

||||

|

panel. |

||||

|

A |

axis feed |

Operations for display are possible. |

||

|

The machine remains inoperative until |

||||

|

Stops; |

spindle rotation |

|||

|

the control is reset and the alarm condi- |

||||

|

coolant supply |

||||

|

tion is removed. |

||||

|

Axis drive power is switched OFF. |

||||

|

Alarm display is given on the operation |

||||

|

panel. |

||||

|

B |

The commands in the active block are com- |

Operations for display are possible. |

||

|

pleted. |

The machine remains inoperative until |

|||

|

the control is reset and the alarm condi- |

||||

|

Spindle rotation and coolant supply do not |

||||

|

tion is removed. |

||||

|

stop. |

||||

|

Axis drive power is not switched OFF. |

||||

|

Alarm display is given on the operation |

||||

|

panel. |

||||

|

C |

The part program being run is executed to |

Operations for display are possible. |

||

|

the end (up to M02 command). |

New program cannot be executed until |

|||

|

the alarm is released. |

||||

|

Spindle rotation and coolant supply do not |

||||

|

stop. |

||||

|

Axis drive power is not switched OFF. |

||||

|

Alarm display is given on the operation |

||||

|

panel. |

||||

|

D |

This alarm does not give any influence to |

Operations on the operation panel are all |

||

|

the machine operation. |

operative. Alarm status cannot be reset |

|||

|

Alarm display is given on the operation |

unless the cause of alarm is removed. |

|||

|

panel. |

||||

4293-E P-2

SECTION 1 CLASSIFICATION OF ALARMS

The display format of CPU alarm, alarm P, A, B, C and D is indicated on pages 2 and 4.

Display Format of CPU Alarms (Bus error)

(Indicates the CPU alarm number.) (Identification number of bus error)

|

1-3 |

CPU-Alarm |

BUS ERROR (CYCLE OVER) |

(Content of error is display only for BUS ERROR.)

(CPU alarm name)

|

Bus error status |

(SBER, SMPAR, CYO, PRT, DIA, LOP, ECC) |

= 20 |

Displayed in |

||||||||||||||||||||||||

|

(ECC error) |

hexadecimal |

||||||||||||||||||||||||||

|

(Loop error) |

|||||||||||||||||||||||||||

|

(Diagnose error) |

|||||||||||||||||||||||||||

|

(Protect error) |

|||||||||||||||||||||||||||

|

(Cycle Over error) |

|||||||||||||||||||||||||||

|

(System parity error) |

|||||||||||||||||||||||||||

|

(System bus error) |

|||||||||||||||||||||||||||

EIOEMALGE001r01

|

SPECIAL STATUS WORD = 0165 |

ACCESS ADDRESS = 00104250 |

|||

|

D0=43520000 |

D1=00000000 |

D2=0000000B |

D3=00000210 (Indicates the data reg- |

|

|

D4=0000000A |

D5=00000000 |

D6=00000000 |

D7=00000000 |

ister D0 through D7.) |

|

A0=FFFFCC06 |

A1=00000000 |

A2=FFFFF7C7 |

A3=00000000 |

(Indicates the data reg- |

|

A4=00000000 |

A5=00000000 |

A6=00000600 |

A7=0007FC84 |

ister A0 through A7.) |

|

US=0007FC84 |

IS=000FFEE4 |

MS=000CFB00 |

SR=0000100D |

|

|

PC=0002E704 |

4293-E P-3

SECTION 1 CLASSIFICATION OF ALARMS

Display Format of CPU Alarms (Address error)

(Indicates the CPU alarm number.)

|

2 |

(CPU alarm name) |

||||||||||

|

CPU-Alarm |

ADDRESS ERROR |

(Indicates the data |

|||||||||

|

D0=43520000 |

D1=00000000 |

D2=0000000B |

D3=00000210 |

||||||||

|

D4=0000000A |

D5=00000000 |

D6=00000000 |

D7=00000000 |

register D0 through D7.) |

|||||||

|

A0=FFFFCC06 |

A1=00000000 |

A2=FFFFF7C7 |

A3=00000000 |

(Indicates the data |

|||||||

|

A4=00000000 |

A5=00000000 |

A6=00000600 |

A7=0007FC84 |

register A0 through A7.) |

|||||||

|

US=0007FC84 |

IS=000FFEE4 |

MS=000CFB00 |

SR=0000100D |

||||||||

|

PC=0002E704 |

|||||||||||

|

3. |

CPU alarm Illegal instruction error |

15. |

CPU alarm User interrupt error |

||||||||

|

4. |

CPU alarm Zero divide error |

16. |

CPU alarm Coprocessor protocol error |

||||||||

|

5. |

CPU alarm CHK instruction error |

17. |

CPU alarm Format error |

||||||||

|

6. |

CPU alarm TRAPV instruction error |

18. |

CPU alarm Uninitialized interrupt error |

||||||||

|

7. |

CPU alarm Privilege violation error |

19. |

CPU alarm FPCP unordered condition error |

||||||||

|

8. |

CPU alarm Trace error |

20. |

CPU alarm FPCP inexact result error |

||||||||

|

9. |

CPU alarm Line 1010 emulator error |

21. |

CPU alarm FPCP divide by zero error |

||||||||

|

10. |

CPU alarm Line 1111 emulator error |

22. |

CPU alarm FPCP underflow error |

||||||||

|

11. |

CPU alarm Exception vector error |

23. |

CPU alarm FPCP operand error |

||||||||

|

12. |

CPU alarm Spurious interrupt error |

24. |

CPU alarm FPCP overflow error |

||||||||

|

13. |

CPU alarm Interrupt error |

25. |

CPU alarm Illegal signaling NAN error |

||||||||

|

14. |

CPU alarm TRAP instruction error |

||||||||||

EIOEMALGE002R01

4293-E P-4

SECTION 1 CLASSIFICATION OF ALARMS

Depending on the alarm content, the following display is given.

|

SPECIAL STATUS WORD = C005 |

ACCESS ADDRESS = 00025041 |

||

|

D0=43520000 |

D1=00000000 |

D2=00000000 |

D3=00000210 |

|

D4=0000000A |

D5=00000000 |

D6=00000000 |

D7=00000000 |

|

A0=FFFFCC06 |

A1=00000000 |

A2=FFFFF7C7 |

A3=00000000 |

|

A4=00000000 |

A5=00000000 |

A6=00000600 |

A7=0007FC84 |

|

US=0007FC84 |

IS=000FFEE4 |

MS=000CFB00 |

SR=0000100D |

PC=0002E704

Display Format of CPU Alarms (Typical exception) (Indicates the CPU alarm number.)

(Indicates the data register D0 through D7.)

(Indicates the data register A0 through A7.)

(CPU alarm name)

4 CPU-Alarm ZERO DIVIDE ERROR

D0=43520000 D1=00000000 D2=0000000B D3=00000210

D4=0000000A D5=00000000 D6=00000000 D7=00000000

A0=FFFFCC06 A1=00000000 A2=FFFFF7C7 A3=00000000

A4=00000000 A5=00000000 A6=00000600 A7=0007C234

US=0007C234 IS=000FFEE0 MS=000CE470 SR=00001008

PC=00024250

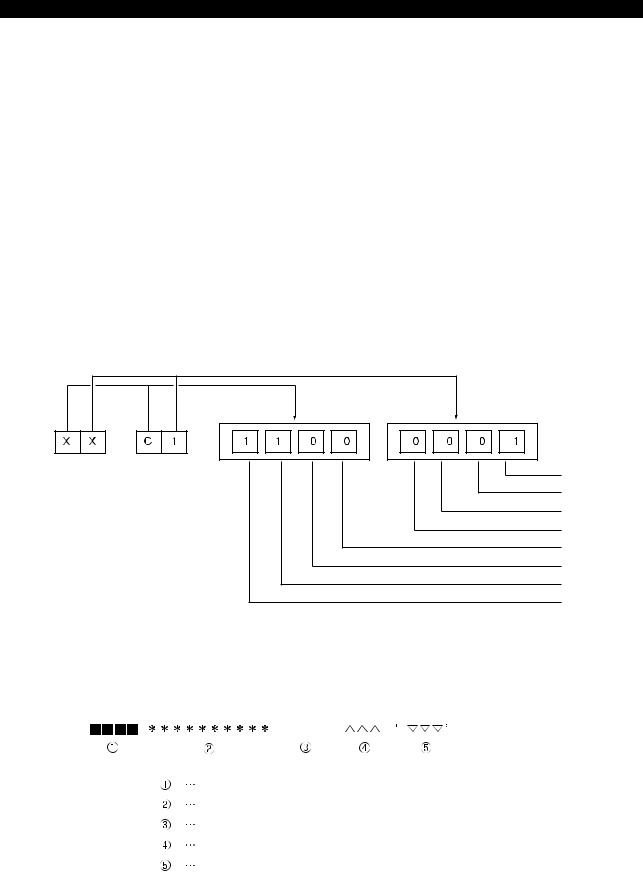

Display Format of Alarm P, A, B, C and D

ALARM-A

Alarm number

Object number

Alarm level

Alarm message

Object message

Alarm code

Alarm character-string

EIOEMALGE003R01

(Indicates the data register D0 through D7.)

(Indicates the data register A0 through A7.)

EIOEMALGE004r01

4293-E P-5

SECTION 1 CLASSIFICATION OF ALARMS

2.Object Number and Object Message

The object number and the object message show the programming system and the control axis where the alarm has occurred by the number and message as shown in the table blow:

|

Object No. |

Meaning |

Object message |

|

|

01 |

Linear axis |

X-axis |

|

|

02 |

Linear axis |

Y-axis |

|

|

03 |

Linear axis |

Z-axis |

|

|

04 |

Linear axis |

U-axis |

|

|

05 |

Linear axis |

V-axis |

|

|

06 |

Linear axis |

W-axis |

|

|

07 |

Rotary axis |

A-axis |

|

|

08 |

Rotary axis |

B-axis |

|

|

09 |

Rotary axis |

C-axis |

|

|

10 |

Crossrail (EC-W) axis |

WA-axis |

|

|

11 |

ATC magazine axis 1 |

MA-axis |

|

|

12 |

ATC magazine axis 2 |

MB-axis |

|

|

13 |

ATC magazine axis 3 |

MC-axis |

|

|

14 |

Tool change arm swing axis |

TS-axis |

|

|

15 |

Tool change arm insert/extract |

TI-axis |

|

|

axis |

|||

|

16 |

APC magazine axis 1 |

PA-axis |

|

|

17 |

APC magazine axis 2 |

PB-axis |

|

|

18 |

Multi-pallet magazine axis |

PL-axis |

|

|

19 |

Attachment axis |

AT-axis |

|

|

20 |

Attachment magazine axis 1 |

AA-axis |

|

|

21 |

Attachment magazine axis 2 |

AB-axis |

|

|

22 |

ATC carrier axis |

CA-axis |

|

|

23 |

ATC carrier axis |

CB-axis |

|

As indicated above, the object numbers and messages to be used are determined by the machine specifications.

4293-E P-6

SECTION 1 CLASSIFICATION OF ALARMS

2-1. Alarm Codes

In this manual, alarm codes are explained using such as «X», «XX», and «XXYY».

Explanation is given in the following methods:

(1)The alarm code indicated in this text can be used directly as the key to find the contents of error.

(2)The alarm code indicated in this text should first be converted into bit expression (pattern), which is then used as the key to find the contents of error.

In the case of 2), the procedure to convert the alarm code into bit pattern is shown below.

2-2. Bit conversion method

|

Alarm Code |

Alarm Code |

||||||||

|

(Expressed in hexadeci- |

Bit Pattern |

(Expressed in hexadeci- |

Bit Pattern |

||||||

|

mal) |

mal) |

||||||||

|

0 |

0 |

0 |

0 |

0 |

8 |

1 |

0 |

0 |

0 |

|

1 |

0 |

0 |

0 |

1 |

9 |

1 |

0 |

0 |

1 |

|

2 |

0 |

0 |

1 |

0 |

A |

1 |

0 |

1 |

0 |

|

3 |

0 |

0 |

1 |

1 |

B |

1 |

0 |

1 |

1 |

|

4 |

0 |

1 |

0 |

0 |

C |

1 |

1 |

0 |

0 |

|

5 |

0 |

1 |

0 |

1 |

D |

1 |

1 |

0 |

1 |

|

6 |

0 |

1 |

1 |

0 |

E |

1 |

1 |

1 |

0 |

|

7 |

0 |

1 |

1 |

1 |

F |

1 |

1 |

1 |

1 |

4293-E P-7

SECTION 1 CLASSIFICATION OF ALARMS

2-3. How to check alarm contents

The method to find the details of the alarm indicated by the bit pattern is explained below using an example.

Example:

[Code] XX

XX bit0->Battery error

bit1->EC I/O power shut off error

bit2->ECC error

bit3->Not used

bit4->Not used

bit5->EDRQ INT signal

bit6->ECP INT signal

bit7->ECP RUN signal

If an alarm occurs, a hexadecimal number is displayed.

If «$C1» is displayed, for example, first convert this «$C1» into bits.

bit 0 bit 1 bit 2 bit 3 bit 4 bit 5 bit 6 bit 7

After the conversion, it is known that Bit0, Bit6, and Bit7 are ON. See the information above and you will find that these error codes

correspond to «battery error», «ECP INT signal», and «ECP RUN signal», respectively.

Error Display Format

ERROR

Error number

Error message

Indication of ERROR

Error code

Error character-string

EIOEMALGE005r01

|

4293-E P-8 |

|

|

SECTION 2 |

CPU ALARM |

SECTION 2 CPU ALARM |

|

|

0001 BUS ERROR …………………………………………………………………………………….. |

9 |

|

0002 ADDRESS ………………………………………………………………………………………… |

9 |

|

0003 ILLEGAL INSTRUCTION …………………………………………………………………… |

10 |

|

0004 ZERO DIVIDE ………………………………………………………………………………….. |

10 |

|

0005 CHK INSTRUCTION …………………………………………………………………………. |

10 |

|

0006 TRAPV INSTRUCTION …………………………………………………………………….. |

10 |

|

0007 PRIVILEGE VIOLATION ……………………………………………………………………. |

11 |

|

0008 TRACE ……………………………………………………………………………………………. |

11 |

|

0009 LINE 1010 EMULATOR …………………………………………………………………….. |

11 |

|

0010 LINE 1111 EMULATOR …………………………………………………………………….. |

11 |

|

0011 EXCEPTION VECTOR ……………………………………………………………………… |

12 |

|

0012 SPURIOUS INTERRUPT ………………………………………………………………….. |

12 |

|

0013 INTERRUPT ……………………………………………………………………………………. |

12 |

|

0014 TRAP INSTRUCTION ……………………………………………………………………….. |

13 |

|

0015 USER INTERRUPT ………………………………………………………………………….. |

13 |

|

0016 COPROCESSOR PROTOCOL VIOLATION ………………………………………… |

13 |

|

0017 FORMAT …………………………………………………………………………………………. |

13 |

|

0018 UNINITIALIZED INTERRUPT …………………………………………………………….. |

14 |

|

0019 FPCP UNORDERED CONDITION ……………………………………………………… |

14 |

|

0020 FPCP INEXACT RESULT …………………………………………………………………. |

14 |

|

0021 FPCP DIVIDE BY ZERO …………………………………………………………………… |

14 |

|

0022 FPCP UNDERFLOW ………………………………………………………………………… |

15 |

|

0023 FPCP OPERAND …………………………………………………………………………….. |

15 |

|

0024 FPCP OVERFLOW …………………………………………………………………………… |

15 |

|

0025 FPCP SIGNALING NAN ……………………………………………………………………. |

15 |

4293-E P-9

SECTION 2 CPU ALARM

0001 BUS ERROR

This alarm is caused when the bus error exception has occurred with the CPU. Details of BUS error:

When the bus error occurs, the CPU status is displayed in hexadecimal numbers. At the same time, the red LED at the CPU rack lights up.

The bus error includes the following five types of errors: 1)Cycle time over error

2)ECC error 3)Protect error 4)Loop error 5)System bus error 6)Double-bus error

Note:Error display is not available in the case of double-bus error.

[Index]

None

[Character-string]

None

[Code]

CPU status

[Probable Faulty Locations]

•Printed circuit boards

•Mother board

•Loose card edge connector connection

•Loose flat cable connection

•Switch settings

[Measures to Take]

Depending on the type of error encountered, check the following points. 1)ECC errorMainboard, Memory board

2)Protect errorMain board

3)Cycle time over errorJudge the faulty PCB from the access address.

4)Loop errorPCB which generates the interruption in question; judge the interruption level from thestatus register. 5)System bus errorAll main boards

6)Double-bus errorAll PCB’s Then, carry out the following steps. 1)Check the switch settings.

Make sure that the boards are free of foreign material. Make sure that flat cables are inserted correctly. Make sure that card edge connectors are clean.

2)Change the card insertion slots; check if the problem occurrence status changes. 3)Replace the suspectable boards.

0002 ADDRESS

This error occurs when the CPU has accessed word operands, long word operands or instructions by an odd number address.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

4293-E P-10

SECTION 2 CPU ALARM

0003 ILLEGAL INSTRUCTION

This error occurs when the CPU has read an unallowable instruction.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0004 ZERO DIVIDE

This error occurs when the CPU executes a division command with a divisor of «0».

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0005 CHK INSTRUCTION

This error occurs when the CPU executes the CHK instruction under certain conditions (such that the register value is less than 0 or that the register value is greater than the upper limit in the operand word.)

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board

0006 TRAPV INSTRUCTION

This error occurs when the overflow condition bit is turned on in the status register when the TRAPV instruction is executed by the CPU.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

4293-E P-11

SECTION 2 CPU ALARM

[Measures to Take]

Replace the main board.

0007 PRIVILEGE VIOLATION

This error occurs when the CPU executes a privilege instruction (instructions that can be executed only in the supervisor condition) in the user condition.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0008 TRACE

This error occurs when the CPU executes an instruction in the trace condition.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0009 LINE 1010 EMULATOR

This error occurs when the instruction having the word pattern of «1010» is executed.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0010 LINE 1111 EMULATOR

This error occurs when the instruction having the word pattern of «1111» is executed.

[Index]

None

[Character-string]

None

[Code]

None

4293-E P-12

SECTION 2 CPU ALARM

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0011 EXCEPTION VECTOR

This error occurs when the CPU has referenced the exception vector which is not referenced normally.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0012 SPURIOUS INTERRUPT

This error occurs when a spurious interruption to the CPU has been made.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0013 INTERRUPT

This error occurs when an unusual interruption to the CPU has been made.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

•All printed circuit boards which generate interruption

•Error in setting interruption level

[Measures to Take]

•Check the setting of interruption level setting switches at individual printed circuit boards.

•Judge the interruption level from the value at the status register (SR) when an error has occurred. The third digit from the right-most digit indicates the interruption level.

Change the printed circuit board which generates the judged interruption.

•Replace the main board.

•Replace the mother board.

4293-E P-13

SECTION 2 CPU ALARM

0014 TRAP INSTRUCTION

This error occurs when the CPU has referenced the TRAP exception vector which is not referenced normally.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0015 USER INTERRUPT

This error occurs when unusual user interruption has occurred.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replace the main board.

0016 COPROCESSOR PROTOCOL VIOLATION

This error occurs when communication fails between the CPU and the coprocessor.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

0017 FORMAT

This error occurs when the CPU detects an improper value as a result of data check required for operation control.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

4293-E P-14

SECTION 2 CPU ALARM

Replaces the main board

0018 UNINITIALIZED INTERRUPT

This error occurs when an interruption occurs before initialization of the vector numbers of peripheral devices.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

0019 FPCP UNORDERED CONDITION

This error occurs when the floating-point coprocessor attempts execution of a comparison command with non-numerals.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

0020 FPCP INEXACT RESULT

This error occurs when the floating-point coprocessor loses some digits in arithmetic operation.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

0021 FPCP DIVIDE BY ZERO

This error occurs when the floating-point coprocessor attempts division by a number having a denominator of » 0″ in execution of a division command.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

4293-E P-15

SECTION 2 CPU ALARM

Main board

[Measures to Take]

Replaces the main board

0022 FPCP UNDERFLOW

This error occurs when the floating-point coprocessor obtains a value too small to express as a result of arithmetic operation.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

0023 FPCP OPERAND

This error occurs when the floating-point coprocessor executes an arithmetic instruction having no solution.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

0024 FPCP OVERFLOW

This error occurs when the floating-point coprocessor obtains a value too large to express as a result of arithmetic operation.

[Index]

None

[Character-string]

None

[Code]

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

0025 FPCP SIGNALING NAN

This error occurs when the floating-point coprocessor executes an arithmetic instruction having operands of signaling non-numer- als.

[Index]

None

[Character-string]

None

[Code]

4293-E P-16

SECTION 2 CPU ALARM

None

[Probable Faulty Locations]

Main board

[Measures to Take]

Replaces the main board

4293-E P-17

SECTION 3 ALARM P |

|||

|

SECTION 3 |

ALARM P |

||

|

0800 |

Spindle D/A control data file read ……………………………………………………….. |

22 |

|

|

0801 |

TCP/IP illegal …………………………………………………………………………………… |

22 |

|

|

0802 |

Load information file not found …………………………………………………………… |

22 |

|

|

0803 |

File load illegal …………………………………………………………………………………. |

23 |

|

|

0804 |

MSB file is not same …………………………………………………………………………. |

23 |

|

|

0805 MOP-TOOL PARAMETER PBU LOAD ……………………………………………….. |

23 |

||

|

0806 MOP-TOOL TOOL-DATA PBU LOAD …………………………………………………. |

24 |

||

|

0807 |

ACP |

panel status receive error ………………………………………………………….. |

24 |

|

0808 |

Speed change ratio failure …………………………………………………………………. |

24 |

|

|

0809 |

FCP illegal ………………………………………………………………………………………. |

25 |

|

|

0810 |

NCIO data file read …………………………………………………………………………… |

26 |

|

|

0811 |

FCP IO link communication error ………………………………………………………… |

26 |

|

|

0812 |

MCS start ………………………………………………………………………………………… |

27 |

|

|

0813 |

MCS communication error …………………………………………………………………. |

28 |

|

|

0814 |

MCS data file …………………………………………………………………………………… |

29 |

|

|

0815 |

PLC Real time task loop error …………………………………………………………….. |

30 |

|

|

0816 |

PLC initial error ………………………………………………………………………………… |

31 |

|

|

0817 MCS Error ……………………………………………………………………………………….. |

31 |

||

|

0818 ADP START …………………………………………………………………………………….. |

31 |

||

|

0829 SPMC Program load …………………………………………………………………………. |

32 |

||

|

0830 |

SPMC Execution stop ……………………………………………………………………….. |

32 |

|

|

0831 |

SPM Exception processing ………………………………………………………………… |

32 |

|

|

0832 |

SPM System Call error ……………………………………………………………………… |

33 |

|

|

0833 |

MCS Option-program-file not send ……………………………………………………… |

33 |

|

|

0834 |

MCS Servo-data error ……………………………………………………………………….. |

33 |

|

|

0835 MCS Communication ………………………………………………………………………… |

34 |

||

|

0840 |

Super-Hi-NC specification mismatch …………………………………………………… |

34 |

|

|

0850 MCS Undefined alarm number …………………………………………………………… |

34 |

||

|

0851 |

MCS Exception processing ………………………………………………………………… |

34 |

|

|

0852 |

MCS Processing trouble ……………………………………………………………………. |

35 |

|

|

0853 MCS CON APA deviation ………………………………………………………………….. |

36 |

||

|

0854 |

MCS Power-Supply-Unit Error ……………………………………………………………. |

36 |

|

|

0855 |

MCS Converter-link error …………………………………………………………………… |

37 |

|

|

0856 |

MCS DC-bus voltage alarm ……………………………………………………………….. |

37 |

|

|

0857 |

MCS Motor over current ……………………………………………………………………. |

38 |

|

|

0858 |

MCS Power unit over heat …………………………………………………………………. |

38 |

|

|

0859 |

MCS Power unit over load …………………………………………………………………. |

38 |

|

|

0860 |

MCS Supply voltage flutter ………………………………………………………………… |

38 |

4293-E P-18

|

SECTION 3 ALARM P |

||

|

0861 |

MCS Power unit version error …………………………………………………………….. |

39 |

|

0862 |

MCS Winding-change failed ………………………………………………………………. |

39 |

|

0863 |

MCS Encoder-link error …………………………………………………………………….. |

39 |

|

0864 |

MCS Encoder error …………………………………………………………………………… |

40 |

|

0865 |

MCS Encoder initialize failed ……………………………………………………………… |

40 |

|

0866 |

MCS Encoder with shaft error …………………………………………………………….. |

41 |

|

0867 |

MCS Encoder with shaft initial ……………………………………………………………. |

41 |

|

0868 MCS ABSO SCALE error ………………………………………………………………….. |

41 |

|

|

0869 |

MCS ABSO SCALE initialize ……………………………………………………………… |

42 |

|

0870 |

MCS Magnetic encoder alarm ……………………………………………………………. |

42 |

|

0871 |

MCS Resolver alarm …………………………………………………………………………. |

42 |

|

0872 |

MCS Pulse generator count over ………………………………………………………… |

42 |

|

0873 |

MCS Motor over heat ………………………………………………………………………… |

43 |

|

0874 |

MCS Servo-link error ………………………………………………………………………… |

43 |

|

0875 |

MCS Servo-link disconnect ………………………………………………………………… |

44 |

|

0876 |

MCS Servo-link protocol error ……………………………………………………………. |

44 |

|

0877 |

MCS Servo data error ……………………………………………………………………….. |

44 |

|

0878 |

MCS Illegal command ……………………………………………………………………….. |

45 |

|

0879 MCS CON speed over ………………………………………………………………………. |

45 |

|

|

0880 MCS Speed command over ……………………………………………………………….. |

46 |

|

|

0881 MCS DIFF over ………………………………………………………………………………… |

46 |

|

|

0882 MCS APA speed over ……………………………………………………………………….. |

46 |

|

|

0883 |

MCS Full-closed APA error ………………………………………………………………… |

47 |

|

0884 MCS Over speed ……………………………………………………………………………… |

47 |

|

|

0885 |

MCS Velocity deviation over ………………………………………………………………. |

47 |

|

0886 |

MCS Collision detected …………………………………………………………………….. |

48 |

|

0887 |

MCS Urgent-stop time over ……………………………………………………………….. |

48 |

|

0888 |

MCS Belt is broken …………………………………………………………………………… |

48 |

|

0889 |

MCS Axis change control error …………………………………………………………… |

49 |

|

0890 |

MCS Independent encoder init …………………………………………………………… |

49 |

|

0891 MCS APA error ………………………………………………………………………………… |

49 |

|

|

0892 |

MCS Motor over load ………………………………………………………………………… |

50 |

|

0900 |

SVP start conditions uncertain ……………………………………………………………. |

50 |

|

0901 |

SVP processing trouble ……………………………………………………………………. |

50 |

|

0902 SVP CON APA deviation ………………………………………………………………….. |

51 |

|

|

0903 |

SVP error ………………………………………………………………………………………… |

51 |

|

0904 |

SVP exception processing ………………………………………………………………… |

51 |

|

0905 |

SVP APA pattern data ……………………………………………………………………… |

52 |

|

0906 SVP APA speed ……………………………………………………………………………… |

52 |

|

|

0907 SVP CON speed ……………………………………………………………………………… |

53 |

4293-E P-19

|

SECTION 3 ALARM P |

|||

|

0908 SVP |

DIFF over ………………………………………………………………………………… |

53 |

|

|

0909 SVP |

servo amp ……………………………………………………………………………….. |

54 |

|

|

0910 SVP APA check data ……………………………………………………………………….. |

54 |

||

|

0911 SVP speed command over ………………………………………………………………… |

54 |

||

|

0912 |

SVP |

servo data setting …………………………………………………………………….. |

55 |

|

0913 |

SVP |

Belt is broken …………………………………………………………………………… |

55 |

|

0914 |

SVP |

F-TYPE encoder error ………………………………………………………………. |

56 |

|

0915 |

SVP |

full closed loop error …………………………………………………………………. |

56 |

|

0916 |

SVP |

F-TYPE encoder with shaft error ………………………………………………… |

56 |

|

0917 |

SVP |

F with shaft APA pattern data …………………………………………………….. |

56 |

|

0918 |

SVP |

cannot plant error offset data ……………………………………………………… |

57 |

|

0919 |

SVP |

encoder application (MOTOR SHAFT) ………………………………………… |

57 |

|

0920 |

SVP |

encoder application (WITH SHAFT) ……………………………………………. |

57 |

|

0921 |

SVP collision detection ……………………………………………………………………… |

57 |

|

|

0922 SVP |

SA overload …………………………………………………………………………….. |

58 |

|

|

0923 |

SVP |

SA communication error …………………………………………………………… |

58 |

|

0924 |

SVP |

SA version error ………………………………………………………………………. |

58 |

|

0925 |

SVP |

SA motor cable overcurrent ………………………………………………………. |

58 |

|

0926 |

SVP |

SA inverter bridge short circuit ………………………………………………….. |

59 |

|

0927 |

SVP |

SA overheating ……………………………………………………………………….. |

59 |

|

0928 |

SVP |

SA power circuit overvoltage …………………………………………………….. |

59 |

|

0929 |

SVP |

SA power circuit low voltage ……………………………………………………… |

59 |

|

0930 |

SVP |

SA regenerative resistor overheat ……………………………………………… |

60 |

|

0931 |

SVP |

SA control circuit power voltage ………………………………………………… |

60 |

|

0932 |

SVP |

SA error …………………………………………………………………………………. |

60 |

|

0933 |

SVP |

board version error …………………………………………………………………… |

60 |

|

0934 |

SVP |

control error …………………………………………………………………………….. |

60 |

|

0935 |

SVP data file read …………………………………………………………………………….. |

61 |

|

|

0936 |

SVP data file data address ………………………………………………………………… |

61 |

|

|

0937 |

SVP data file check …………………………………………………………………………… |

62 |

|

|

0938 |

VAC start ………………………………………………………………………………………… |

62 |

|

|

0939 |

VAC |

data file read ……………………………………………………………………………. |

64 |

|

0940 |

Time sharing task control …………………………………………………………………… |

64 |

|

|

0941 |

Real time task control ……………………………………………………………………….. |

64 |

|

|

0942 |

Real time task loop error ……………………………………………………………………. |

65 |

|

|

0943 |

Main processor name incorrect …………………………………………………………. |

65 |

|

|

0944 |

Slave processor name incorrect …………………………………………………………. |

65 |

|

|

0945 |

Memory board / battery life ………………………………………………………………… |

65 |

|

|

0946 |

TFP illegal ……………………………………………………………………………………….. |

65 |

|

|

0947 |

TFP |

data file read ……………………………………………………………………………. |

66 |

4293-E P-20

|

SECTION 3 ALARM P |

||||

|

0948 |

TFP Field net communication error …………………………………………………….. |

67 |

||

|

0949 |

IO DIAGNOSTICS data file read ………………………………………………………… |

67 |

||

|

0950 |

IO MACRO data file read …………………………………………………………………… |

68 |

||

|

0951 |

SMP illegal ………………………………………………………………………………………. |

68 |

||

|

0952 |

Processor Board not equip ………………………………………………………………… |

68 |

||

|

0953 |

Machine control processor start ………………………………………………………….. |

69 |

||

|

0954 |

Peripheral processor start ………………………………………………………………….. |

69 |

||

|

0955 |

Spec. code: data file …………………………………………………………………………. |

69 |

||

|

0956 |

Backup data file read ………………………………………………………………………… |

70 |

||

|

0957 |

Graphic Back up data file read …………………………………………………………… |

70 |

||

|

0958 |

Pitch compensate data file read …………………………………………………………. |

70 |

||

|

0959 |

IGF Specification unmatching …………………………………………………………….. |

71 |

||

|

0960 |

IGF Backup data file read ………………………………………………………………….. |

71 |

||

|

0961 |

IGF illegal ………………………………………………………………………………………… |

71 |

||

|

0962 |

CCP Roader file load ………………………………………………………………………… |

72 |

||

|

0963 |

CCP Application file load …………………………………………………………………… |

72 |

||

|

0964 |

CCP Parameter file load ……………………………………………………………………. |

72 |

||

|

0965 |

Configuration file format error …………………………………………………………….. |

72 |

||

|

0966 |

Configuration file open error ………………………………………………………………. |

73 |

||

|

0967 |

Array limit check table is bad ……………………………………………………………… |

73 |

||

|

0968 |

No specification ……………………………………………………………………………….. |

73 |

||

|

0969 |

Memory size is not same …………………………………………………………………… |

74 |

||

|

0970 |

Synchronous axis specification code …………………………………………………… |

74 |

||

|

0971 |

Cache data / initialization error …………………………………………………………… |

74 |

||

|

0972 |

SVP INDEXING high-speed indexing over ………………………………………….. |

74 |

||

|

0973 |

SVP INDEXING low-speed indexing over …………………………………………… |

75 |

||

|

0974 SVP INDEXING unclamp time over ……………………………………………………. |

75 |

|||

|

0975 SVP INDEXING clamp time over ……………………………………………………….. |

75 |

|||

|

0976 |

SVP INDEXING positioning direction …………………………………………………. |

75 |

||

|

0977 SVP INDEXING incorrect command …………………………………………………… |

76 |

|||

|

0978 |

SVP INDEXING servo data setting …………………………………………………….. |

76 |

||

|

0981 |

SVP LE sum check error …………………………………………………………………. |

77 |

||

|

0982 |

SVP LE data error …………………………………………………………………………… |

77 |

||

|

0983 |

SVP |

LE |

incre. abso. error ………………………………………………………………… |

77 |

|

0984 |

SVP LE comparator AD error …………………………………………………………… |

78 |

||

|

0985 |

SVP |

LE |

face rotation error ……………………………………………………………….. |

78 |

|

0986 |

SVP |

LE |

initial transfer data error ………………………………………………………. |

78 |

|

0987 |

SVP |

LE |

application error …………………………………………………………………. |

79 |

|

0989 |

CPU information table data unsuitable ………………………………………………… |

79 |

||

|

0990 |

TASK generate error …………………………………………………………………………. |

79 |

4293-E P-21

|

SECTION 3 ALARM P |

||

|

0991 |

TASK information table data unsuitable |

………………………………………………. 79 |

|

0992 |

PLC backup data file read …………………………………………………………………. |

80 |

|

0993 |

TCP/IP board error …………………………………………………………………………… |

80 |

|

0994 |

TCP/IP configuration file error ……………………………………………………………. |

80 |

|

0995 |

Machine axis data file ……………………………………………………………………….. |

81 |

|

0996 |

PLC axis data file ……………………………………………………………………………… |

81 |

|

0997 |

PLC monitor backup data file read ……………………………………………………… |

82 |

|

0998 |

PLC sequence program load ……………………………………………………………… |

82 |

|

0999 |

Synchronous tap’s data file read ……………………………………………………….. |

83 |

4293-E P-22

SECTION 3 ALARM P

0800 Spindle D/A control data file read

The NC failed to properly read the spindle D/A control data file.

[Index]

None

[Character-string]

None

[Code]

XY

X=Gear set number (Initially found problem gear set number. If Y = any of 1 to 6, X will not be displayed.)

Y =

1..No data file

2..Data file type is not PBU1. 3..Larger data file size 4..Improper data file size

5..The number of gear sets does not match the data file size. 6..The number of gear sets is other than 1 to 4.

7..Motor speed limit or spindle speed limit is 0. 8..Maximum spindle speed is 0.

[Probable Faulty Locations]

Error in creation of the spindle D/A control data file

[Measures to Take]

Correctly create a spindle D/A control data file.

[Related Specifications]

Spindle D/A control function

0801 TCP/IP illegal

During activation of DNC-T1, T2, T3,or DT function, a CPU error occurred on TCP/IP board.

[Index]

None

[Character-string]

None

[Code]

XXYYZZ

XX…Board status in hexadecimal

|

bit7 |

bit6 |

bit5 |

bit4 |

bit3 |

bit2 |

bit1 |

bit0 |

|

RUN |

HALT |

CPUOFF |

0 |

SNMI |

0 |

0 |

0 |

|

YY…Bus error status in hexadecimal |

|||||||

|

bit7 |

bit6 |

bit5 |

bit4 |

bit3 |

bit2 |

bit1 |

bit0 |

|

0 |

0 |

0 |

0 |

PROT |

DAI |

LOOP |

ECC |

ZZ…Always 0

[Probable Faulty Locations]

•Hardware error on TCP/IP board

•Software error on TCP/IP firmware

0802 Load information file not found

In file creation by the custom software production system, the load information file which agrees with the specification code was not found.

Or,a file described in the load information file was not found.

[Index]

None

[Character-string]

4293-E P-23

SECTION 3 ALARM P

Problem file name

[Code]

None

However, there may be a case where an error message is output in the console line.

[Probable Faulty Locations]

Defective installation, software production error, or specification code error

[Measures to Take]

•Reinstall the software.

•Reissue the install floppy disk.

0803 File load illegal

In file creation by the custom software production system, the software which agrees with the specification code was not found

[Index]

None

[Character-string]

Problem software file name

[Code]

1…The file ended without loading any character.

3…The file ended during file loading.

9…The device name was wrongly specified. 10..The file name was wrongly specified. 11..The file was not found.

[Probable Faulty Locations]

Defective installation, software production error, or specification code error

[Measures to Take]

•Reinstall the software.

•Reissue the install floppy disk.

0804 MSB file is not same

The MSB file used for IMAP-B and interactive programming B does not satisfy the NC software requirements.

[Index]

None

[Character-string]

None

[Code]

X=1

The MSB file for IMAP-B and interactive programming B is not compatible with the NC software.

[Probable Faulty Locations]

A wrong MSB file is selected for the NC software.

[Measures to Take]

Use an MSB file of revision B or later for IMAP-B and interactive programming B.

0805 MOP-TOOL PARAMETER PBU LOAD

The backup file (MMTUB*.PBU) is not found, or its type or size is wrong.

[Index]

None

[Character-string]

None

[Code]

X

1…The parameter PBU file (MMTUB*.PBU) is not found in MD0:

2…The parameter PBU file (MMTUB*.PBU) does not start from «PBU1» or has an improper length (other than 18 sectors).

4293-E P-24

SECTION 3 ALARM P

[Probable Faulty Locations]

•If the alarm occurred during normal NC operation, the PBU file has been deleted or its data has been destroyed.

•If the alarm occurred without NC operation after installation of control floppy disk, the PBU file type was wrong or no PBU file was stored in the memory.

[Measures to Take]

•If the alarm occurred before NC operation, create a correct control floppy.

•If the alarm occurred during NC operation, reinstall the control floppy disk.

[Related Specifications]

OSP7000M built-in type MOP-TOOL

0806 MOP-TOOL TOOL-DATA PBU LOAD

The backup file (MMTUA*.PBU) is not found, or its type or size is wrong.

[Index]

None

[Character-string]

None

[Code]

X

3…The tool data PBU file (MMTUA*.PBU) is not found in MD0:

4…The tool data PBU file (MMTUA*.PBU) does not start from «PBU1» or has an improper length (other than 125 sectors).

[Probable Faulty Locations]

•If the alarm occurred during normal NC operation, the PBU file has been deleted or its data has been destroyed.

•If the alarm occurred without NC operation after installation of control floppy disk, the PBU file type was wrong or no PBU file was stored in the memory.

[Measures to Take]

•If the alarm occurred before NC operation, create a correct control floppy.

•If the alarm occurred during NC operation, reinstall the control floppy disk.

[Related Specifications]

OSP7000M built-in type MOP-TOOL

0807 ACP panel status receive error

The ACP board received abnormal data on operation panel status.

ObjectNone

[Character-string]

None

[Code]

XX (operation panel status data) bit7: Invalid panel status

bit6: Operation panel CPU error

bit3 to 5: Software version applied to operation panel firmware bit0 to 2: Operation panel type

0808 Speed change ratio failure

For the machine with scroll machining function, a speed change ratio of X, Y, Z, or C-axis is defectively set. Or, a wrong type of position encoder is used.

[Index]

None

[Character-string]

None

[Code]

1…X-axis speed change ratio is set by a code. 2…Y-axis speed change ratio is set by a code. 3…Z-axis speed change ratio is set by a code.

4293-E P-25

SECTION 3 ALARM P

4…C-axis speed change ratio is set by a code. 5…X-axis speed change ratio exceeds the setting range. 6…Y-axis speed change ratio exceeds the setting range. 7…Z-axis speed change ratio exceeds the setting range. 8…C-axis speed change ratio exceeds the setting range. 9…A wrong type of position encoder is used.

[Probable Faulty Locations]

Defective speed change ratio data in the servo data PBU file or wrong encoder type

[Measures to Take]

Correct the data in the servo data PBU file.

[Related Specifications]

Scroll machining function

0809 FCP illegal

The FCP board is in abnormal state.

[Index]

None

[Character-string]

’AAAABB’

AAAA->Name of task being processed

BB->Program module number (hexadecimal) being executed

However, no character-string appears when transmission of the module is stopped or double bus error occurs.

[Code]

XXYYZZ XX:

01->Transmission module has stopped. YYZZ=0000

02->Exception error YY:Exception error number(*1) ZZ:FCP Bus error status(*2)

03->Double bus error YY:Exception error number(*1) ZZ:FCP Bus error status(*2)

04->FCP was reset as soon as SNMI occurred at FCP. YY:SNMI status(*3)

ZZ:FCP Bus error status(*2) *1->Exception error No. 01..Bus error

02..Address error 03..Illegal instruction 04..Zero divide

05..CHK instruction error 06..TRAPV instruction error 07..Privilege violation error 08..Trace error

09..Line 1010 emulator 0A..Line 1111 emulator 0B..Exception vector error 0C..Spurious interruption error 0D..Interruption error 0E..TRAP instruction error 0F..User interruption error *2->FCP Bus error status bit7…System bus error bit6…System bus parity error bit5…Cycle over error bit4…Protect error

bit3…Loop error bit2…Loop error cancel bit1…Memory parity error bit0…Always 0 *3->SNMI status bit7->Bus error at FCP

4293-E P-26

SECTION 3 ALARM P

bit6->FCP executed SNMI command. bit5->Oscillator module stopped oscillation. bit4->Always 0

bit3->Always 0 bit2->Always 0 bit1->Always 0 bit0->Always 0

0810 NCIO data file read

The NC failed to read I/O data file.

[Index]

None

[Character-string]

None

[Code]

I/O data file load status (in hexadecimal) 2->File open error (no file)

3->File read error (no data)

4->File attribute error (not PBU1)

5->File close error

6->File size error (smaller size)

7->File size error (larger size)

100->Wrong PLC machine type

200->Wrong PLC class

300->Wrong file version

[Measures to Take]

Consult the machine maker.

0811 FCP IO link communication error

A communication error occurred in the I/O link on FCP board.

[Index]

None

[Character-string]

None

[Code]

XxYYZZZZ XX:

01->Channel number where FCP board error was detected x=0->Errors (other than below)

x=1->Faulty connection of optical fibers x=2->Initialization error

YY:

bit7->Double transmission error bit6->Double reception error bit5->Format error

bit4->CRC error

bit3->Parity error (transmission/reception buffer) bit2->Disconnection command detected bit1->Time out error

bit0->Undefined ZZZZ:

bit15->Slave station error detected bit14->Undefined bit13->Undefined

bit12->Start bit error bit11->Stop bit error bit10->Undefined

bit9, 8->00 … Master station, slave station ->01 … Repeater No. 1

->10 … Repeater No. 2

bit7 to 0->Slave station number where the error was detected (master station: $00)

4293-E P-27

SECTION 3 ALARM P

[Measures to Take]

Consult the machine maker.

0812 MCS start

An error occurred in initialization of MCS when the power was supplied.

[Index]

None or axis name

[Character-string]

Varies with the code.

[Code]

XXXXYYYY

XXXX:Kind of generated alarm

YYYY:Further information on the alarm (Varies with XXXX.)

XXXX

FFFF…YYYY is 00UV. Where, U: Faulty channel number — 1 0= Channel 1

1= Channel 2 2= Channel 3

V:Cause of alarm (V=1 indicates that servo link mode has not been established.) FF01…Memory error occurred in read/write test of the servo link I/O buffer. YYYY= 0 (always)

Character-string shows the address where the error occurred.

FF00…Communication LSI caused an error in read/write test of the servo link I/O buffer. YYYY= Error status

Character-string shows the address where the error occurred. F000…

YYYY=bit 7:Same ID number used bit 6:Improper ID number

bit 5:Missing ID number

bit 4:Too many CH4 controllers bit 3:Too many CH3 controllers bit 2:Too many CH2 controllers bit 1:Too many CH1 controllers bit 0:

With this error, connection data appears in the screen center.

EF00…The servo link does not connect with all the required axes or connects with an improper axis. YYYY= ID number of required axis controller

Character-string shows the problem axis name.

With this alarm, connection data appears in the screen center. EE00…An error occurred in downloading an optional file.

High-order digit of YYYY shows the cause while low-order part is an error code. If high-order digit=

1: File is not in OSP format.

2: File attribute is not contiguous.

3: File opening error. Low-order part is an error code.

4: Error in initial data reading. Low-order part is an error code. 5: File does not start with «MCS1».

6: File name is not followed by «OPFS». 7: The number of file sets is 0.

8: Data reading error. Low-order part is an error code. 9: File data has a sector length of 0.

A: The number of bytes transferred is 0.

B: File data has a sector length smaller than the number of bytes transferred. C: Data reading error. Low-order part is an error code.

ED00…An error occurred when manual mode is switched to auto mode. High-order digit of YYYY shows the cause while loworder part is an error code.

High order digit=1: World clock does not start. EC01…Time difference occurred in setting CH1 timer. YYYY is the difference.

EC02…Time difference occurred in setting CH2 timer. YYYY is the difference.

EC03…Time difference occurred in setting CH3 timer. YYYY is the difference.

4293-E P-28

SECTION 3 ALARM P

D001…In buffering the initial data in AT (auto) receive mode, the software synchronization bit does not come on within 3 seconds.

YYYY is always 0.

D002…In buffering the initial data in AT (auto) receive mode, the buffer A received a wrong format code. Two low-order characters of YYYY are the received format code.

D003…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the first block. YYYY is the received format code.

D004…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the second block. YYYY is the received format code.

D005…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the third block. YYYY is the received format code.

D006…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the fourth block. YYYY is the received format code.

D007…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the fifth block. YYYY is the received format code.

D008…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the sixth block. YYYY is the received format code.

D009…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the seventh block. YYYY is the received format code.

D00A…In buffering the initial data in AT (auto) receive mode, the buffer B received a wrong format code in the eighth block. YYYY is the received format code.

D010…In buffering the initial data in AT (auto) receive mode, the received self-diagnostic data is not $55. YYYY is the received diagnostic data.

D011…In buffering the initial data in AT (auto) receive mode, the buffer A received the bit data which is wrong at bit No. 0 and No. 1.

YYYY is the received data.

D012…In buffering the initial data in AT (auto) receive mode, the buffer A received the bit data which is wrong at bit No. 2 and No. 3.

YYYY is the received data.

D013…In buffering the initial data in AT (auto) receive mode, the buffer A received the bit data which is wrong at bit No. 4 and No. 5.

YYYY is the received data.

D080…Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 441C. YYYY is the received data.

D081…Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 2428. D090…Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 4405. YYYY is the received data.

D091…Initial data buffered in AT (auto) receive mode includes wrong data at ID data No. 4404. YYYY is the received data.

D092…Initial data buffered in AT (auto) receive mode includes wrong offset data for compensating positioning points. YYYY is the received data.