demyuri

- Регистрация

- 31.10.2019

- Сообщения

- 9 079

- Реакции

- 8 083

- Баллы

- 200

- Возраст

- 48

- Адрес

- РОССИЯ

- Веб-сайт

- youtu.be

- Город

- Барнаул

- Имя

- Юрий

- Станок

- 3018 ПРО, доработанный

- Плата

- Дятел 3.4

- Прошивка

- 1.1f

- #31

CTRL+X] < Grbl 0.9j [‘$’ for help]

[‘$H’|’$X’ to unlock]

[CTRL+X] < Grbl 0.9j [‘$’ for help]

[‘$H’|’$X’ to unlock]

S6100 < error: Alarm lock

$X < [Caution: Unlocked]

ok

S6100 < ok

$H < ALARM: Homing fail

ok

Grbl 0.9j [‘$’ for help]

[‘$H’|’$X’ to unlock]

S6100 < error: Alarm lock

Скрин покажите. Перепечатывать не надо.

Robinson1957

- Регистрация

- 07.01.2020

- Сообщения

- 3 778

- Реакции

- 4 868

- Баллы

- 188

- Возраст

- 65

- Город

- г.Новокузнецк

- Имя

- Владимир

- Отчество

- Александрович

- Станок

- 1610>2216

- Плата

- W 2.08

- Прошивка

- v1.1F

- 14.09.2021

- Последнее редактирование: 14.09.2021

- #32

Последнее редактирование: 14.09.2021

Sidi, короче, делай так: $5 ставишь в ноль, выдираешь разъёмы X и Y и пробуешь хоуминг, чтобы оси не упёрлись вовремя сбрасываешь. Если всё пойдет-поедет, звони конвевики.

И, да, достаточно ли отъезжает каретка Z? Концевик должен быть разомкнут.

homega

- Регистрация

- 04.07.2019

- Сообщения

- 606

- Реакции

- 295

- Баллы

- 103

- Город

- YEREVAN

- Плата

- dewelopower V2.0 green

- Прошивка

- grbl 1.1 g

- #33

Sidi, короче, делай так: $5 ставишь в ноль, выдираешь разъёмы X и Y и пробуешь хоуминг, чтобы оси не упёрлись …

Soft limit enable

Robinson1957

- Регистрация

- 07.01.2020

- Сообщения

- 3 778

- Реакции

- 4 868

- Баллы

- 188

- Возраст

- 65

- Город

- г.Новокузнецк

- Имя

- Владимир

- Отчество

- Александрович

- Станок

- 1610>2216

- Плата

- W 2.08

- Прошивка

- v1.1F

- #34

Чтобы sjdt limit сработал, надо для начала прихоумиться…

ну, в принципе если поставить что то около 100 для начала, а потом переписать, когда заработает…

homega

- Регистрация

- 04.07.2019

- Сообщения

- 606

- Реакции

- 295

- Баллы

- 103

- Город

- YEREVAN

- Плата

- dewelopower V2.0 green

- Прошивка

- grbl 1.1 g

- #35

Чтобы sjdt limit сработал, надо для начала прихоумиться…

ну, в принципе если поставить что то около 100 для начала, а потом переписать, когда заработает…

Сразу скажу, я инженер-электронщик

Sidi

Sidi

ЧТО-ТО УЖЕ ЧИРКАНУЛ

- Регистрация

- 14.09.2021

- Сообщения

- 1

- Реакции

- 6

- Баллы

- 3

- Город

- astro

- #36

Плата вообще стала реагировать на команды через раз.

Затем перестала реагировать вообще.

Отсоединил от компа, подключил автономный пульт (шел в комплекте, маленький такой, белый).

На пульт тоже не реагирует.

Сбрасываю и перезапускаю, — через 5-6 перезапусков выполняет одно перемещение с пульта и умирает.

Ни каких признаков ошибки, просто молчит и все…

Robinson1957

- Регистрация

- 07.01.2020

- Сообщения

- 3 778

- Реакции

- 4 868

- Баллы

- 188

- Возраст

- 65

- Город

- г.Новокузнецк

- Имя

- Владимир

- Отчество

- Александрович

- Станок

- 1610>2216

- Плата

- W 2.08

- Прошивка

- v1.1F

- #37

Похоже не вынесла пыток, в застенках инквизиции…

А при питании только от USB? Без блока питания.

homega

- Регистрация

- 04.07.2019

- Сообщения

- 606

- Реакции

- 295

- Баллы

- 103

- Город

- YEREVAN

- Плата

- dewelopower V2.0 green

- Прошивка

- grbl 1.1 g

- #38

Пришлось поставить резисторы по 2 ком на +5, на тех же разьемах.

а второй конец куда ?(2kom)

Alsan

- Регистрация

- 03.12.2018

- Сообщения

- 3 970

- Реакции

- 7 602

- Баллы

- 138

- Город

- Kazan

- Имя

- Алексей

- Плата

- woodpecker 3.2a

- Прошивка

- 1.1f

- 14.09.2021

- Последнее редактирование: 14.09.2021

- #39

Последнее редактирование: 14.09.2021

Плата вообще стала реагировать на команды через раз.

Затем перестала реагировать вообще.

Отсоединил от компа, подключил автономный пульт (шел в комплекте, маленький такой, белый).

На пульт тоже не реагирует.

Сбрасываю и перезапускаю, — через 5-6 перезапусков выполняет одно перемещение с пульта и умирает.

Ни каких признаков ошибки, просто молчит и все…

Проверяйте все напряжения на плате, помехи БП (стоковый блок этим грешит), есть резон перепрошить на 1,1.

Ваши сообщения автоматически объединены: 14.09.2021

$5 вообще вырубает концевики, — оставил = 0

S5 (top) — Инверсия входов концевых выключателей, логический По умолчанию, входы концевых выключателей подтягиваются к питанию встроенным резистором подтяжки Arduino. Когда сигнал на входе принимает низкий уровень, Grbl рассматривает это как срабатывание выключателя. Для противоположного поведения, просто инвертируйте входы, введя S5=1. Отключается командой S5=0. Может потребоваться перезапуск контроллера, чтобы изменения втупили в силу. ЗАМЕЧАНИЕ: Если вы инвертируете входы концевых выключателей, потребуется внешний резистор подтяжки к земле, чтобы предотвратить перегрузку по току и сгоранию входа.

Robinson1957

- Регистрация

- 07.01.2020

- Сообщения

- 3 778

- Реакции

- 4 868

- Баллы

- 188

- Возраст

- 65

- Город

- г.Новокузнецк

- Имя

- Владимир

- Отчество

- Александрович

- Станок

- 1610>2216

- Плата

- W 2.08

- Прошивка

- v1.1F

- #40

Сразу скажу, я инженер-электронщик

Интересно, в какой отрасли…

Сбрасываю и перезапускаю, — через 5-6 перезапусков выполняет одно перемещение с пульта и умирает.

Ни каких признаков ошибки, просто молчит и все…

А какие признаки ошибки должны быть? пульт их не отображает.

Sidi

Sidi

ЧТО-ТО УЖЕ ЧИРКАНУЛ

- Регистрация

- 14.09.2021

- Сообщения

- 1

- Реакции

- 6

- Баллы

- 3

- Город

- astro

- #41

Интересно, в какой отрасли…

А какие признаки ошибки должны быть? пульт их не отображает.

Фигня (пардон) заработала сама по себе. Теперь все восстановилось, но и прежняя ошибка (блокировка тоже).

Заметил, что если поставить откат после срабатывания концевика больше (4 -6 мм) то расстояние до ошибки тоже увеличивается с 1-2 см по Х Y до 3-4 см.

Такое впечатление, что там некий плавающий вход или непропай который все сбрасывает…

Смущает то, что возле разьемов вроде есть резисторы, но без моих дополнительных на входы не подавалось напряжение ВООБЩЕ (виселя почти земля). Неисправность или мои настройки?

Продавец обещал подвезти другу плату (с такого же станка), но говорит что это не поможет. Мол что-то я делаю не так или ошибка в самой прошивке.

Помеху на жгуты я исключаю, т.к. отсоединение разьемов концевиков не изменчет повведени.

Относительно (в какой облсти инженер?) — робототехника и МК, но именно поэтому лезть в прошивку не имея ни схемы ни исходников проги, я считаю высшей глупостью.

Надеюсь только на ВАШ коллективный ОПЫТ.

Спасибо

demyuri

- Регистрация

- 31.10.2019

- Сообщения

- 9 079

- Реакции

- 8 083

- Баллы

- 200

- Возраст

- 48

- Адрес

- РОССИЯ

- Веб-сайт

- youtu.be

- Город

- Барнаул

- Имя

- Юрий

- Станок

- 3018 ПРО, доработанный

- Плата

- Дятел 3.4

- Прошивка

- 1.1f

- #42

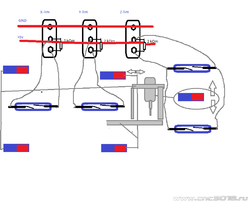

Sidi, набросайте на листочке схему подключения концевиков. Лучше раз увидеть, чем догадываться, чего куда подцепили. Тут инженеров-ляктронщиков тоже навалом, теория одно, а практика надёжней.

homega

- Регистрация

- 04.07.2019

- Сообщения

- 606

- Реакции

- 295

- Баллы

- 103

- Город

- YEREVAN

- Плата

- dewelopower V2.0 green

- Прошивка

- grbl 1.1 g

- #43

Продавец обещал подвезти другу плату (с такого же станка), но говорит что это не поможет.

И он в курсе что ты геркон используешь ?

OlegK

OlegK

Младший ненаучный сотрудник

- Регистрация

- 11.06.2019

- Сообщения

- 2 508

- Реакции

- 4 480

- Баллы

- 188

- Город

- Печора

- Имя

- Олег

- Станок

- CNC3018C

- Прошивка

- 1.1f

- #44

но именно поэтому лезть в прошивку не имея ни схемы ни исходников проги, я считаю высшей глупостью

Схема, как правило, однотипна и тут есть. Отличия могут быть в нюансах. Если надо — скину пару вариантов.

Исходники тоже в общем доступе имеются.

Такое впечатление, что там некий плавающий вход или непропай который все сбрасывает…

Смущает то, что возле разьемов вроде есть резисторы, но без моих дополнительных на входы не подавалось напряжение ВООБЩЕ (виселя почти земля). Неисправность или мои настройки?

По дефолту, в прошивке входы концевиков сконфигурированы для NO концевиков с внутренней подтяжкой к +.

Т.е. при разомкнутом концевике на входе лог. 1, при замкнутом — 0. При инвертировании поведения концевиков на NC конфигурация входа не изменяется, программно учитывается лишь то, что при срабатывании (размыкании концевика) уровень меняется с 0 на 1.

На некоторых платах есть внешние резисторы подтяжки входов, на некоторых могут не быть — это легко определяется мультиметром.

Sidi

Sidi

ЧТО-ТО УЖЕ ЧИРКАНУЛ

- Регистрация

- 14.09.2021

- Сообщения

- 1

- Реакции

- 6

- Баллы

- 3

- Город

- astro

- #45

Sidi, набросайте на листочке схему подключения концевиков. Лучше раз увидеть, чем догадываться, чего куда подцепили. Тут инженеров-ляктронщиков тоже навалом, теория одно, а практика надёжней.

![Смеюсь :) :)]()

-

cnc 3018 герконовые концевики.png

19.7 KB · Просмотры: 21

Welcome to Our Community

Some features disabled for guests. Register Today.

-

Builder

- Joined:

- Feb 13, 2015

- Messages:

- 6

- Likes Received:

- 2

All, First of all, Love Open Builds. Thank you for putting this ‘out there’ enabling so many to produce great machines! Ok, to the point.

I’ve built a 4’x4′ cut-able area OX CNC. Build went great until I tried getting this baby to move. My first attempts to jog the machine around went great. had one stepper reverse polarity, fixed quickly. then moved to take some G-code from Sketchup — Phlatboyz combo (love it). Simple 2d cut pattern (4″x6″ approx). Loaded it to Grble 3.0, and it worked, but not to scale. The step scale for x,y,z were obviously off (OX CNC seemed to follow about a 4 foot by 6 foot pattern!). I was just excited to see it follow the pattern! So, I started tinkering with the grble settings, and in the process, had to do an emergency stop (it already hit a limit switch — which was wired up). This is where the fun ended. Now, I cannot move any axis. I get the «error: Alarm lock». This seems to be a common issue and I’ve seen a few other threads with same experience, however the remedy of:

Clear the error by command «$21=0», did not work, so I took the next step from the thread which was to issue «G01 F200» setting the feed rate, then clear «$21=0», and still nothing. Note, I removed all limit switches and have them floating (they are at +5V).I’ve also tried to ‘unlock grble controller’ in the advanced tab, and it seems to allow one to go to the manual jog buttons, but my poor ox still does not respond (I can hear the slightest little ‘sound’ coming from the steppers, like they are ‘trying to move’, but no go. I’ve also since removed the belt from the steppers, just to see if they were somehow overloaded, still no go. I hope I did not kill my steppers or controller some how..?

Any help/insight would be very much appreciated. PS. If anyone has suggestions of a better controller / software, I’m all ears. Thanks in advance! -Eric (Wisconsin)

-

Builder

- Joined:

- Nov 2, 2014

- Messages:

- 169

- Likes Received:

- 56

I had a lot of problems with GRBL Controller. Moved to either Universal Gcode Sender or Chilipeppr. I’m also running xPro Controller, upgraded to 0.9i GRBL.

-

Builder

- Joined:

- Feb 13, 2015

- Messages:

- 6

- Likes Received:

- 2

Hi John, thanks for the reply! do you have a link to show how to upgrade to 0.9i GRBL?

-

Builder

- Joined:

- Nov 2, 2014

- Messages:

- 169

- Likes Received:

- 56

-

Builder

- Joined:

- Feb 13, 2015

- Messages:

- 6

- Likes Received:

- 2

Thanks John, this helped alot! By just moving from GRBL Controller to Universal Gcode Sender, I was able to easily clear the alarm and jog/test each motor. Unfortunately, only 1 port from my Xpro controller seems to be working, the X. I was able to move jog the other steppers by moving the wires to the X port on Xpro board, and they all work, however my Z motor sounds bad. Big step forward in diagnosing the problem(s).

My next step is to upgrade to 0.9i GRBL, but not sure if that will do anything for me (seems all ports are bad other than the X port, in addition, I’ll buy a new steper for my Z as it sounds bad..). Still, an option I need to execute on before buying new controller.

I followed the link, and looked at the instruction breifly, and it seems somewhat complex (for me). I’ve downloaded the ‘software package’ which is a zip file containing drivers, libs, applications for what seems to be Arduino products. I may need to look closer, but it doesn’t seem straightforward as to what to do to upgrade my Xpro to 0.9i GRBL on my Xpro. Does it seem like I’m missing anything? I’m such a rookie at this.. I really hope I don’t need to buy a new Xpro, as I’m not sure exactly what happened to make it bad, worries me that it will just happen again..

-

Builder

- Joined:

- Nov 2, 2014

- Messages:

- 169

- Likes Received:

- 56

I wouldn’t worry about upgrading at this point, until things are actually working. Reach out to @Michael from Spark-Concepts. He recently updated the xPro Build, and indicated that GRBL Controller has been suspected of damaging (bricking?) xPro controllers. He may have some ideas on how to test.

— John

-

Builder

- Joined:

- Feb 13, 2015

- Messages:

- 6

- Likes Received:

- 2

Hi John, I’m in touch with Mike at Spark, and I just sent him my ‘settings’. Mike commented it could be something in my settings. For the record in this forumn, my settings are below. I’ll continue to update this thread until resolution for reference to others with same problem. Thx again John for your help on this. -Eric

Grbl 0.9g [‘$’ for help]

[‘$H’|’$X’ to unlock]

>>> $$

$0=10 (step pulse, usec)

$1=25 (step idle delay, msec)

$2=0 (step port invert mask:00000000)

$3=6 (dir port invert mask:00000110)

$4=0 (step enable invert, bool)

$5=0 (limit pins invert, bool)

$6=0 (probe pin invert, bool)

$10=3 (status report mask:00000011)

$11=0.020 (junction deviation, mm)

$12=0.002 (arc tolerance, mm)

$13=0 (report inches, bool)

$14=1 (auto start, bool)

$20=1 (soft limits, bool)

$21=0 (hard limits, bool)

$22=1 (homing cycle, bool)

$23=232 (homing dir invert mask:11101000)

$24=1000.000 (homing feed, mm/min)

$25=500.000 (homing seek, mm/min)

$26=50 (homing debounce, msec)

$27=50.000 (homing pull-off, mm)

$100=250.000 (x, step/mm)

$101=250.000 (y, step/mm)

$102=250.000 (z, step/mm)

$110=500.000 (x max rate, mm/min)

$111=500.000 (y max rate, mm/min)

$112=500.000 (z max rate, mm/min)

$120=10.000 (x accel, mm/sec^2)

$121=10.000 (y accel, mm/sec^2)

$122=10.000 (z accel, mm/sec^2)

$130=200.000 (x max travel, mm)

$131=200.000 (y max travel, mm)

$132=200.000 (z max travel, mm) -

Builder

- Joined:

- Feb 13, 2015

- Messages:

- 6

- Likes Received:

- 2

Hi John, sorry it’s been a while. Life got in the way. I’ve been in touch with Michael at Spark-Concepts, and he is a big help as you are. I decided to buy another Xpro controller and never try grbl controller with it. Now using Universal G-Code Sender. I also put heat sinks on all chips (Easy, cheap, safeguard), and made sure to load the settings you have provided (which are spot on, for the distance travel, etc.).

With those changes, things are working great. I do believe their is something to Grbl Controller ‘Bricking’ the Xpro’s. For instance, I was connected up, done running, but Xpro was ‘powered’, and what looks like a FET, simply went up in spoke. Again, nothing was moving. Big reason why I added the heat sinks. The settings are key, and for a rookie like me, figuring out those from scratch, would have taken a good amount of time. Thank you for providing those.

So far, I’ve been able to drill out a vacuum hold table (4×4), and also made a dust boot using Sketch ucam and universal g-code sender. I have a few project I have brewing in my skull, but am working out the details on the ‘design side’. looking to use adobe illustrator to create some signs, etc.. Thanks again John. Hope I can return a favor some day. -Eric

Share This Page

Štěpán Rydval

unread,

Apr 14, 2017, 8:10:03 PM4/14/17

to Cyclone PCB Factory

I configured and uploaded GRBL firmware into my machine. I connected it to computer. For control I am using grbl controller 3.6.1 but every time when I try to send any g code int the machine it says: «error: Alarm lock» What I should do? How to fix it?

David Kahler

unread,

Apr 17, 2017, 12:15:23 AM4/17/17

to Cyclone PCB Factory

Štěpán Rydval

unread,

Apr 17, 2017, 12:36:00 AM4/17/17

to Cyclone PCB Factory

I have already fixed it.

Carlos García

unread,

Apr 17, 2017, 1:23:39 AM4/17/17

to cyclone-p…@googlegroups.com

Sorry for not answering earlier, I’m glad you fixed it!

Iceflow

unread,

Apr 17, 2017, 1:24:04 AM4/17/17

to cyclone-p…@googlegroups.com

How? it would help others in the future to know it

Štěpán Rydval

unread,

Apr 17, 2017, 1:31:53 AM4/17/17

to Cyclone PCB Factory

It is okay. I know you font have free time every time. The fix Is very simple. Just send $X command. This will unlock it. But now I have another problem. When I uploader gcode and started milling it does not recognize endstop. But this is not a really big project because I Always set the zero manualy. Thanks for awesome support. I love open source projects.

Štěpán Rydval

unread,

Apr 17, 2017, 1:42:10 AM4/17/17

to Cyclone PCB Factory

Sorry for my bad words. My mobile phone tries to translate everything to Czech language and on my mobile phone I am not capable of editing older message.

Nando

unread,

Apr 17, 2017, 1:49:00 AM4/17/17

to Cyclone PCB Factory

Oh yes. When first plugged you always have to unlock it.

About the end stops that’s a option in the firmware you can enable.

junlp

unread,

Mar 3, 2019, 6:18:41 AM3/3/19

to Cyclone PCB Factory

i encountered the same error clock issue. How did you fixed it?

On Friday, April 14, 2017 at 10:10:03 AM UTC-7, Štěpán Rydval wrote:

junlp

unread,

Mar 3, 2019, 6:19:30 AM3/3/19

to Cyclone PCB Factory

I encountered the same issue. How did you fixed the error alarm clock issue. thanks

Arnošt Galuska

unread,

Mar 17, 2019, 8:18:06 PM3/17/19

to cyclone-p…@googlegroups.com

I am sorry, I can’t remember. It was a long time ahoj. Due to lack of usable software I dissassembled my cyclone and build another 3D printer instead.

I encountered the same issue. How did you fixed the error alarm clock issue. thanks

On Sunday, April 16, 2017 at 2:36:00 PM UTC-7, Štěpán Rydval wrote:

I have already fixed it.

Paweł Fabiszewski

unread,

Mar 17, 2019, 8:19:40 PM3/17/19

to cyclone-p…@googlegroups.com

You received this message because you are subscribed to the Google Groups «Cyclone PCB Factory» group.

Error 0 – STATUS_OK

All Good, This is an error code suggesting that there is NO error

Error 1 – STATUS_EXPECTED_COMMAND_LETTER

Gcodes should start with a Letter, what ever was just sent to GRBL did not

Error 2 – STATUS_BAD_NUMBER_FORMAT

The number part of the Gcode was invalid

Error 3 – STATUS_INVALID_STATEMENT

Usualy a bad GRBL Specific $ instruction

Error 4 – STATUS_NEGATIVE_VALUE

Negative value received for an expected positive value.

Error 5 – STATUS_SETTING_DISABLED

A call to a disabled function was issued – EG you issued $H for homing but your $20 (homing enable) parameter is set to 0 (off)

Error 6 – STATUS_SETTING_STEP_PULSE_MIN

Your $0 (step pulse time) is to short, set it back to its default value, $0=10

Error 7 – STATUS_SETTING_READ_FAIL

Corrupt EEPROM values, you will need to reconfigure all your $ values as they have been reset to default – this time once you have worked them all out, make a copy! This is a rare error.

Error 8 – STATUS_IDLE_ERROR

You have issued a command only allowed when the machine active state is Idle. Example you sent $$ while the Active state was run (job was in progress)

Error 9 – STATUS_SYSTEM_GC_LOCK

machine is locked in error of some sort, and you tried to issue a movement command. Did you forget to $X the machine? Or is it sitting on a Limit Switch?

Error 10 – STATUS_SOFT_LIMIT_ERROR

You will see this if you try to enable soft limits without also enabling homing cycle. Soft limits cannot work unless you first home the machine so it knows where it is!

Error 11 – STATUS_OVERFLOW

GRBL has a max number of charactors it will accept in one command, it received on that was too long – often happens when CAM software puts long comments in file

Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

You tried to set a Step rate that was too high, look at your $110, $111,$112 values!

Error 13 – STATUS_CHECK_DOOR

You have the safety door funtion turned on and it is showing not closed…close it

Error 14 – STATUS_LINE_LENGTH_EXCEEDED

You should not see this error and if you do you should know what it means!

Error 15 – STATUS_TRAVEL_EXCEEDED

You have got soft limits turned on and configured, and the job your trying to run is larger than you have told grbl that your machine actualy is. Either fix your soft limit values and if they are correct, look at why your cam setup is trying to use more space than you actually have.

Error 16 – STATUS_INVALID_JOG_COMMAND

Jogging command issued was not valid, possibly forgot the =… part

Error 17 – STATUS_SETTING_DISABLED_LASER

Probrably happened when you turned on $32 wthout enableing PWM – We don’t know a lot about this error – email us if you work it out and we can add it to this list

Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

Unsupported or invalid g-code command found in block.

Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

Read: http://linuxcnc.org/docs/html/gcode/overview.html#_modal_groups

Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

You cannot issue a movement if no feed rate has been set – so issue something like F1000 (feed at 1000mm/min) before sending a movement command. You will likely only see this error when bashing stuff into the command prompt and not when using a gui

Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

Look into the command you sent, did it include a non integer value?

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

Two G-code commands that both require the use of the XYZ axis words were detected in the block.

Error 25 – STATUS_GCODE_WORD_REPEATED

A G-code word was repeated in the block.

Error 26 – STATUS_GCODE_NO_AXIS_WORDS

A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.

Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

N line number value is not within the valid range of 1 – 9,999,999 – why not turn off line numbers in your CAM software

Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

A G-code command was sent, but is missing some required P or L value words in the line.

Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.

Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.

Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

There are unused axis words in the block and G80 motion mode cancel is active.

Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.

Error 33 – STATUS_GCODE_INVALID_TARGET

The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.

Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.

Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.

Error 36 – STATUS_GCODE_UNUSED_WORDS

There are unused, leftover G-code words that aren’t used by any command in the block.

Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.

Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

You sent a number higher than expected, maybe for a tool change you tried to select tool 50000 or something?

ALARM 1 – EXEC_ALARM_HARD_LIMIT

Hard Limit Error, A limit switch was triggered, this always results in the end of your job. The only time a limit switch should be hit is during a homing cycle, at any other time it will stop the system. Either your machine went to far in one direction and hit a switch or you have electrical noise getting into your limit switch wiring. Do not restart your jhob without rehoming or resetting / confirming the machines position, it will unliely be correct still!

ALARM 2 – EXEC_ALARM_SOFT_LIMIT

Soft Limit Error, Either you or a Gcode file tried to send some axis past further than you have suggested it can in your $130, $131 ,$132 parameters

ALARM 3 – EXEC_ALARM_ABORT_CYCLE

The Estop was hit! Same as a hard limit, just a different button – look at details above for Alarm 1

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

Grbl was expecting your probe to be in a state other than that it is before starting a probing cycle – ie your tool is already touching the probe or similar

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

Z axis was sent down as far as it dared (instructed) and did not hit a switch. Instead of digging to china it assumes you forgot to put an aligator clip on or that something else is wrong and so stops.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

Reset was issued during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment if your estop button is connected to the Abort pin and not to the reset pin that is

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

Safety door was opened during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

Grbl tries to pull back of a switch and hit it a second time (slowly) during a homing cycle. Your Homing Pulloff value was not sufficient to enable the axis to move far enough away from the switch. Increase $27 to maybe 3 or 5mm – $27=5.000

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

When homing, grbl will not travel further than the values in parameters $130, $131 ,$132 while trying to locate a limit switch. So even if your soft limits are off, make sure these values are correct or larger than your machine. Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.”