Hello guys, I was trying to do a simple shape and noticed it was doing a bad movement, it then started to reset X,Y positions and well it broke all the milling it was doing, the code it was trying to execute is this one:

G0 X192.95862944162437 Y52.79746192893401

G1 Z-0.5 F95

G1 X170.251269035533 Y52.796954314720814 F110

G3 X169.18781725888326 Y52.58629441624365 I0 J-2.7766497461928936

G3 X168.28680203045684 Y51.984771573604064 I1.0634517766497462 J-2.565989847715736

G3 X167.68274111675126 Y51.08121827411168 I1.9644670050761421 J-1.9644670050761421

G3 X167.47208121827413 Y50.017766497461935 I2.5685279187817263 J-1.0634517766497462

G3 X167.68274111675126 Y48.95685279187817 I2.7741116751269033 J0

G3 X168.28680203045684 Y48.05583756345178 I2.565989847715736 J1.0634517766497462

G3 X169.18781725888326 Y47.45177664974619 I1.9644670050761421 J1.9644670050761421

G3 X170.251269035533 Y47.24111675126903 I1.0634517766497462 J2.5685279187817263

G1 X192.9593908629442 Y47.24111675126903

The code was generated from the parka website. and I am using version 0.9i, any ideas?

Grbl has a line limit of 80 characters. Several of these lines exceed it.

I doubt you need all that precision, you could probably round to 4 or 5

decimal places and be more accurate than your machine.

On Tue, Jun 2, 2015 at 11:36 PM, beckmx notifications@github.com wrote:

Hello guys, I was trying to do a simple shape and noticed it was doing a

bad movement, it then started to reset X,Y positions and well it broke all

the milling it was doing, the code it was trying to execute is this one:G0 X192.95862944162437 Y52.79746192893401

G1 Z-0.5 F95

G1 X170.251269035533 Y52.796954314720814 F110

G3 X169.18781725888326 Y52.58629441624365 I0 J-2.7766497461928936

G3 X168.28680203045684 Y51.984771573604064 I1.0634517766497462

J-2.565989847715736

G3 X167.68274111675126 Y51.08121827411168 I1.9644670050761421

J-1.9644670050761421

G3 X167.47208121827413 Y50.017766497461935 I2.5685279187817263

J-1.0634517766497462

G3 X167.68274111675126 Y48.95685279187817 I2.7741116751269033 J0

G3 X168.28680203045684 Y48.05583756345178 I2.565989847715736

J1.0634517766497462

G3 X169.18781725888326 Y47.45177664974619 I1.9644670050761421

J1.9644670050761421

G3 X170.251269035533 Y47.24111675126903 I1.0634517766497462

J2.5685279187817263

G1 X192.9593908629442 Y47.24111675126903The code was generated from the parka website. and I am using version

0.9i, any ideas?—

Reply to this email directly or view it on GitHub

#724.

@beckmx : @ashelly is right. There is an 80-ish character limit per line in Grbl, but you should have gotten a Line overflow error to let know something went wrong. Do you not get these?

I was using UniversalGcodeSender and it splits the decimals down to 4, but

I have been seen errors with the GCODE I have, but I don’t know why, if you

want to, I can share it with you, it is an enclosure with many cuts for a

raspberry

2015-06-03 11:14 GMT-05:00 Sonny Jeon notifications@github.com:

@beckmx https://github.com/beckmx : @ashelly

https://github.com/ashelly is right. There is an 80-ish character limit

per line in Grbl, but you should have gotten a Line overflow error to let

know something went wrong. Do you not get these?—

Reply to this email directly or view it on GitHub

#724 (comment).

@beckmx : What are the errors exactly that you are getting. That will help identify the cause.

In the console I only detected the error «T0 M6» it says, it doesn’t

support it. But beyond from that, I don’t see any errors in the console.

But what I do see are errors in the movement of the machine, It is milling

right and then it makes little pauses and kinda loses its zero coordinates

and keeps milling the right pattern in the wrong place.

2015-06-03 12:34 GMT-05:00 Sonny Jeon notifications@github.com:

@beckmx https://github.com/beckmx : What are the errors exactly that

you are getting. That will help identify the cause.—

Reply to this email directly or view it on GitHub

#724 (comment).

@beckmx : EDIT: M6 is not supported. See the supported g-code list in the Wiki.

Intermittent movement is indicative of an electrical problem, which is probably why you also had a problem with your g-code stream. It’s probably corrupting the USB data.

Error 0 – STATUS_OK

All Good, This is an error code suggesting that there is NO error

Error 1 – STATUS_EXPECTED_COMMAND_LETTER

Gcodes should start with a Letter, what ever was just sent to GRBL did not

Error 2 – STATUS_BAD_NUMBER_FORMAT

The number part of the Gcode was invalid

Error 3 – STATUS_INVALID_STATEMENT

Usualy a bad GRBL Specific $ instruction

Error 4 – STATUS_NEGATIVE_VALUE

Negative value received for an expected positive value.

Error 5 – STATUS_SETTING_DISABLED

A call to a disabled function was issued – EG you issued $H for homing but your $20 (homing enable) parameter is set to 0 (off)

Error 6 – STATUS_SETTING_STEP_PULSE_MIN

Your $0 (step pulse time) is to short, set it back to its default value, $0=10

Error 7 – STATUS_SETTING_READ_FAIL

Corrupt EEPROM values, you will need to reconfigure all your $ values as they have been reset to default – this time once you have worked them all out, make a copy! This is a rare error.

Error 8 – STATUS_IDLE_ERROR

You have issued a command only allowed when the machine active state is Idle. Example you sent $$ while the Active state was run (job was in progress)

Error 9 – STATUS_SYSTEM_GC_LOCK

machine is locked in error of some sort, and you tried to issue a movement command. Did you forget to $X the machine? Or is it sitting on a Limit Switch?

Error 10 – STATUS_SOFT_LIMIT_ERROR

You will see this if you try to enable soft limits without also enabling homing cycle. Soft limits cannot work unless you first home the machine so it knows where it is!

Error 11 – STATUS_OVERFLOW

GRBL has a max number of charactors it will accept in one command, it received on that was too long – often happens when CAM software puts long comments in file

Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

You tried to set a Step rate that was too high, look at your $110, $111,$112 values!

Error 13 – STATUS_CHECK_DOOR

You have the safety door funtion turned on and it is showing not closed…close it

Error 14 – STATUS_LINE_LENGTH_EXCEEDED

You should not see this error and if you do you should know what it means!

Error 15 – STATUS_TRAVEL_EXCEEDED

You have got soft limits turned on and configured, and the job your trying to run is larger than you have told grbl that your machine actualy is. Either fix your soft limit values and if they are correct, look at why your cam setup is trying to use more space than you actually have.

Error 16 – STATUS_INVALID_JOG_COMMAND

Jogging command issued was not valid, possibly forgot the =… part

Error 17 – STATUS_SETTING_DISABLED_LASER

Probrably happened when you turned on $32 wthout enableing PWM – We don’t know a lot about this error – email us if you work it out and we can add it to this list

Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

Unsupported or invalid g-code command found in block.

Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

Read: http://linuxcnc.org/docs/html/gcode/overview.html#_modal_groups

Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

You cannot issue a movement if no feed rate has been set – so issue something like F1000 (feed at 1000mm/min) before sending a movement command. You will likely only see this error when bashing stuff into the command prompt and not when using a gui

Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

Look into the command you sent, did it include a non integer value?

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

Two G-code commands that both require the use of the XYZ axis words were detected in the block.

Error 25 – STATUS_GCODE_WORD_REPEATED

A G-code word was repeated in the block.

Error 26 – STATUS_GCODE_NO_AXIS_WORDS

A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.

Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

N line number value is not within the valid range of 1 – 9,999,999 – why not turn off line numbers in your CAM software

Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

A G-code command was sent, but is missing some required P or L value words in the line.

Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.

Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.

Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

There are unused axis words in the block and G80 motion mode cancel is active.

Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.

Error 33 – STATUS_GCODE_INVALID_TARGET

The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.

Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.

Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.

Error 36 – STATUS_GCODE_UNUSED_WORDS

There are unused, leftover G-code words that aren’t used by any command in the block.

Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.

Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

You sent a number higher than expected, maybe for a tool change you tried to select tool 50000 or something?

ALARM 1 – EXEC_ALARM_HARD_LIMIT

Hard Limit Error, A limit switch was triggered, this always results in the end of your job. The only time a limit switch should be hit is during a homing cycle, at any other time it will stop the system. Either your machine went to far in one direction and hit a switch or you have electrical noise getting into your limit switch wiring. Do not restart your jhob without rehoming or resetting / confirming the machines position, it will unliely be correct still!

ALARM 2 – EXEC_ALARM_SOFT_LIMIT

Soft Limit Error, Either you or a Gcode file tried to send some axis past further than you have suggested it can in your $130, $131 ,$132 parameters

ALARM 3 – EXEC_ALARM_ABORT_CYCLE

The Estop was hit! Same as a hard limit, just a different button – look at details above for Alarm 1

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

Grbl was expecting your probe to be in a state other than that it is before starting a probing cycle – ie your tool is already touching the probe or similar

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

Z axis was sent down as far as it dared (instructed) and did not hit a switch. Instead of digging to china it assumes you forgot to put an aligator clip on or that something else is wrong and so stops.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

Reset was issued during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment if your estop button is connected to the Abort pin and not to the reset pin that is

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

Safety door was opened during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

Grbl tries to pull back of a switch and hit it a second time (slowly) during a homing cycle. Your Homing Pulloff value was not sufficient to enable the axis to move far enough away from the switch. Increase $27 to maybe 3 or 5mm – $27=5.000

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

When homing, grbl will not travel further than the values in parameters $130, $131 ,$132 while trying to locate a limit switch. So even if your soft limits are off, make sure these values are correct or larger than your machine. Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.”

Hold 0 – Hold complete. Ready to resume

Hold 1 – Hold in-progress. Reset will throw an alarm

Door 0 – Door closed. Ready to resume.

Door 1 – Machine stopped. Door still ajar. Can’t resume until closed.

Door 2 – Door opened. Hold (or parking retract) in-progress. Reset will throw an alarm.

Door 3 – Door closed and resuming. Restoring from park, if applicable. Reset will throw an alarm.

Содержание

- GRBL Error Codes

- Error 0 – STATUS_OK

- Error 1 – STATUS_EXPECTED_COMMAND_LETTER

- Error 2 – STATUS_BAD_NUMBER_FORMAT

- Error 3 – STATUS_INVALID_STATEMENT

- Error 4 – STATUS_NEGATIVE_VALUE

- Error 5 – STATUS_SETTING_DISABLED

- Error 6 – STATUS_SETTING_STEP_PULSE_MIN

- Error 7 – STATUS_SETTING_READ_FAIL

- Error 8 – STATUS_IDLE_ERROR

- Error 9 – STATUS_SYSTEM_GC_LOCK

- Error 10 – STATUS_SOFT_LIMIT_ERROR

- Error 11 – STATUS_OVERFLOW

- Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

- Error 13 – STATUS_CHECK_DOOR

- Error 14 – STATUS_LINE_LENGTH_EXCEEDED

- Error 15 – STATUS_TRAVEL_EXCEEDED

- Error 16 – STATUS_INVALID_JOG_COMMAND

- Error 17 – STATUS_SETTING_DISABLED_LASER

- Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

- Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

- Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

- Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

- Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

- Error 25 – STATUS_GCODE_WORD_REPEATED

- Error 26 – STATUS_GCODE_NO_AXIS_WORDS

- Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

- Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

- Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

- Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

- Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

- Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

- Error 33 – STATUS_GCODE_INVALID_TARGET

- Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

- Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

- Error 36 – STATUS_GCODE_UNUSED_WORDS

- Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

- Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

- ALARM 1 – EXEC_ALARM_HARD_LIMIT

- ALARM 2 – EXEC_ALARM_SOFT_LIMIT

- ALARM 3 – EXEC_ALARM_ABORT_CYCLE

- ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

- ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

- ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

- ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

- ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

- ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

- Undefined feedrate error #88

- Comments

- cnc-club.ru

- 5.5 Вт проблема с прошивкой

- 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- Re: 5.5 Вт проблема с прошивкой

- ВОПРОС Настройка щупа

- SnakeKVC

- SnakeKVC

- SnakeKVC

- SnakeKVC

- SnakeKVC

- SnakeKVC

- Вложения

- Psyx86

- Psyx86

- mixocingmail

- mixocingmail

- extrimus

- extrimus

- OlegK

- OlegK

GRBL Error Codes

Error 0 – STATUS_OK

All Good, This is an error code suggesting that there is NO error

Error 1 – STATUS_EXPECTED_COMMAND_LETTER

Gcodes should start with a Letter, what ever was just sent to GRBL did not

Error 2 – STATUS_BAD_NUMBER_FORMAT

The number part of the Gcode was invalid

Error 3 – STATUS_INVALID_STATEMENT

Usualy a bad GRBL Specific $ instruction

Error 4 – STATUS_NEGATIVE_VALUE

Negative value received for an expected positive value.

Error 5 – STATUS_SETTING_DISABLED

A call to a disabled function was issued – EG you issued $H for homing but your $20 (homing enable) parameter is set to 0 (off)

Error 6 – STATUS_SETTING_STEP_PULSE_MIN

Your $0 (step pulse time) is to short, set it back to its default value, $0=10

Error 7 – STATUS_SETTING_READ_FAIL

Corrupt EEPROM values, you will need to reconfigure all your $ values as they have been reset to default – this time once you have worked them all out, make a copy! This is a rare error.

Error 8 – STATUS_IDLE_ERROR

You have issued a command only allowed when the machine active state is Idle. Example you sent $$ while the Active state was run (job was in progress)

Error 9 – STATUS_SYSTEM_GC_LOCK

machine is locked in error of some sort, and you tried to issue a movement command. Did you forget to $X the machine? Or is it sitting on a Limit Switch?

Error 10 – STATUS_SOFT_LIMIT_ERROR

You will see this if you try to enable soft limits without also enabling homing cycle. Soft limits cannot work unless you first home the machine so it knows where it is!

Error 11 – STATUS_OVERFLOW

GRBL has a max number of charactors it will accept in one command, it received on that was too long – often happens when CAM software puts long comments in file

Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

You tried to set a Step rate that was too high, look at your $110, $111,$112 values!

Error 13 – STATUS_CHECK_DOOR

You have the safety door funtion turned on and it is showing not closed…close it

Error 14 – STATUS_LINE_LENGTH_EXCEEDED

You should not see this error and if you do you should know what it means!

Error 15 – STATUS_TRAVEL_EXCEEDED

You have got soft limits turned on and configured, and the job your trying to run is larger than you have told grbl that your machine actualy is. Either fix your soft limit values and if they are correct, look at why your cam setup is trying to use more space than you actually have.

Error 16 – STATUS_INVALID_JOG_COMMAND

Jogging command issued was not valid, possibly forgot the =… part

Error 17 – STATUS_SETTING_DISABLED_LASER

Probrably happened when you turned on $32 wthout enableing PWM – We don’t know a lot about this error – email us if you work it out and we can add it to this list

Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

Unsupported or invalid g-code command found in block.

Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

You cannot issue a movement if no feed rate has been set – so issue something like F1000 (feed at 1000mm/min) before sending a movement command. You will likely only see this error when bashing stuff into the command prompt and not when using a gui

Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

Look into the command you sent, did it include a non integer value?

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

Two G-code commands that both require the use of the XYZ axis words were detected in the block.

Error 25 – STATUS_GCODE_WORD_REPEATED

A G-code word was repeated in the block.

Error 26 – STATUS_GCODE_NO_AXIS_WORDS

A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.

Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

N line number value is not within the valid range of 1 – 9,999,999 – why not turn off line numbers in your CAM software

Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

A G-code command was sent, but is missing some required P or L value words in the line.

Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.

Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.

Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

There are unused axis words in the block and G80 motion mode cancel is active.

Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.

Error 33 – STATUS_GCODE_INVALID_TARGET

The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.

Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.

Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.

Error 36 – STATUS_GCODE_UNUSED_WORDS

There are unused, leftover G-code words that aren’t used by any command in the block.

Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.

Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

You sent a number higher than expected, maybe for a tool change you tried to select tool 50000 or something?

ALARM 1 – EXEC_ALARM_HARD_LIMIT

Hard Limit Error, A limit switch was triggered, this always results in the end of your job. The only time a limit switch should be hit is during a homing cycle, at any other time it will stop the system. Either your machine went to far in one direction and hit a switch or you have electrical noise getting into your limit switch wiring. Do not restart your jhob without rehoming or resetting / confirming the machines position, it will unliely be correct still!

ALARM 2 – EXEC_ALARM_SOFT_LIMIT

Soft Limit Error, Either you or a Gcode file tried to send some axis past further than you have suggested it can in your $130, $131 ,$132 parameters

ALARM 3 – EXEC_ALARM_ABORT_CYCLE

The Estop was hit! Same as a hard limit, just a different button – look at details above for Alarm 1

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

Grbl was expecting your probe to be in a state other than that it is before starting a probing cycle – ie your tool is already touching the probe or similar

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

Z axis was sent down as far as it dared (instructed) and did not hit a switch. Instead of digging to china it assumes you forgot to put an aligator clip on or that something else is wrong and so stops.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

Reset was issued during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment if your estop button is connected to the Abort pin and not to the reset pin that is

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

Safety door was opened during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

Grbl tries to pull back of a switch and hit it a second time (slowly) during a homing cycle. Your Homing Pulloff value was not sufficient to enable the axis to move far enough away from the switch. Increase $27 to maybe 3 or 5mm – $27=5.000

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

When homing, grbl will not travel further than the values in parameters $130, $131 ,$132 while trying to locate a limit switch. So even if your soft limits are off, make sure these values are correct or larger than your machine. Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.”

Источник

Undefined feedrate error #88

I’m getting an undefined feedrate error, but I can’t figure out what the problem is. I pasted my gcode on pastebin: http://pastebin.com/G6Ep09Ry

Can anyone help tell me where the problem is?

The text was updated successfully, but these errors were encountered:

I have had some problem like this.

I suspect that the line 20 in your code is the culprit, it has a movement command without the feedrate.

But If you encounter other problems I have found out a strange behavior:

If you have a G(0123) movement and then this movement change in another G(0123) movement something happens and it raise the error.

This code works, (I have used it with grbl 0.9i to cut some part).

Note that when i change the motion (the second line) I have to not specify the feedrate until i make a G0 move in the end and so on, but i prefer to prefix each movement with the appropriate G(0123) word, otherwise i get an error of undefined command (It strange but I’m struggling with it for almost a day prior to figure it out ) :

G1 Z-8.520 F250.000

@Scott216 when I run your code I get the same error.

However the problem is a bit before. grbl reports

error: Invalid gcode ID:33

which means that you have an arc precision problem.

When an error is faced bCNC was calling the «Stop» method

to kill the current program. From a recent change this routine to stop a running program

was issuing a soft reset and then grbl was reporting «undefined feed rate»

I’ve correct that, and should be ok, now reporting only the Id:33 error

Источник

cnc-club.ru

Статьи, обзоры, цены на станки и комплектующие.

5.5 Вт проблема с прошивкой

5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 15:21

Re: 5.5 Вт проблема с прошивкой

Сообщение arkhnchul » 14 мар 2016, 16:20

Re: 5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 17:50

сейчас залил grbl_v0.9g.hex

она поддерживает скорость 115200. родная прошивка тоже на этой скорости работала.

я так понимаю что прошивка это пол дела. там еще какие то настройки прописываются?

Re: 5.5 Вт проблема с прошивкой

Сообщение arkhnchul » 14 мар 2016, 18:19

соответствие пинов сигналам конфигурируется при компиляции прошивки в файле config.h (если глубже — в каталоге defaults), в готовом hex поменять не получится.

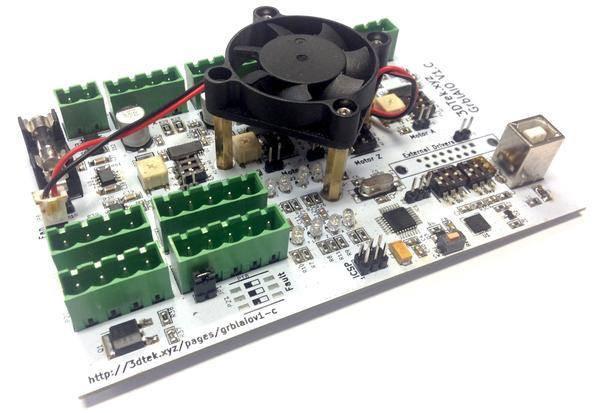

у меня есть подобный гравер, только поменьше размером — совсем игрушка, чуть меньше А4. Платка управления навскидку идентична, как доберусь дотуда сегодня-завтра — могу вытащить собранную прошивку и исходник.

Re: 5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 18:29

Re: 5.5 Вт проблема с прошивкой

Сообщение arkhnchul » 14 мар 2016, 18:44

Re: 5.5 Вт проблема с прошивкой

Сообщение selenur » 14 мар 2016, 18:50

Re: 5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 19:04

Re: 5.5 Вт проблема с прошивкой

Сообщение tvv7-7-7 » 14 мар 2016, 21:38

Скинь прошивку пжлста.

а по работе станка.

1 либо скорость не соответствует в прошивке и в управляющей программе

2 либо не верно выставлены пины в прошивке

3.

Re: 5.5 Вт проблема с прошивкой

Сообщение selenur » 14 мар 2016, 22:13

Re: 5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 23:11

Re: 5.5 Вт проблема с прошивкой

Сообщение arkhnchul » 14 мар 2016, 23:20

меняется в хедере grbl/cpu_map/cpu_map_atmega328p.h

для этого случая (ардуинские D2 = XDIR, D3 = XSTEP, D4 = YDIR, D5 = YSTEP, D8 = ENA) hex и исходник

Re: 5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 23:35

arkhnchul писал(а): меняется в хедере grbl/cpu_map/cpu_map_atmega328p.h

для этого случая (ардуинские D2 = XDIR, D3 = XSTEP, D4 = YDIR, D5 = YSTEP, D8 = ENA) hex и исходник

Re: 5.5 Вт проблема с прошивкой

Сообщение arkhnchul » 14 мар 2016, 23:48

Re: 5.5 Вт проблема с прошивкой

Сообщение selenur » 14 мар 2016, 23:50

arkhnchul писал(а): меняется в хедере grbl/cpu_map/cpu_map_atmega328p.h

для этого случая (ардуинские D2 = XDIR, D3 = XSTEP, D4 = YDIR, D5 = YSTEP, D8 = ENA) hex и исходник

Да всё верно, требуется правильно сопоставить выводы микроконтроллера и драйверов.

Что-бы подсказать на каких выводах висит TTL лазера, можешь сфоткать шилд со снятым ардуино контроллером? просто разводку платы не совсем четко видно.

Re: 5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 23:54

Re: 5.5 Вт проблема с прошивкой

Сообщение sunyun » 14 мар 2016, 23:56

arkhnchul писал(а): меняется в хедере grbl/cpu_map/cpu_map_atmega328p.h

для этого случая (ардуинские D2 = XDIR, D3 = XSTEP, D4 = YDIR, D5 = YSTEP, D8 = ENA) hex и исходник

Да всё верно, требуется правильно сопоставить выводы микроконтроллера и драйверов.

Что-бы подсказать на каких выводах висит TTL лазера, можешь сфоткать шилд со снятым ардуино контроллером? просто разводку платы не совсем четко видно.

Источник

ВОПРОС Настройка щупа

SnakeKVC

SnakeKVC

Дежурный персонал

ЗНАЕТ ЧТО ГОВОРИТ

SnakeKVC

SnakeKVC

Дежурный персонал

ЗНАЕТ ЧТО ГОВОРИТ

SnakeKVC

SnakeKVC

Дежурный персонал

ЗНАЕТ ЧТО ГОВОРИТ

- Жесть! В натуре, с глюкавыми прогами себя за идиота начинаешь держать. Не знаю от чего. У меня две разные WIN10. Одна на компе, другая на планшете. И каждая из трех Candel(ов) 1.1.8; 1.1.7: 1.2..8, по-разному себя ведет на этих девайсах.

- На компе 1.1.7 виснет при запуске, а вот на планшете работает нормально. Именно с ней удалось построить карту высот и шпиндель позиционироваться верно начал. А прежде-то и с 1.2..8 и с1.1.8 все враскосяк было! То карта высот не отражалась, то концевики переставала видеть, а то при команде «щуп» давила шпинделем стол. Кароч – полный атас! Видел я глючные проги, но что бы так они убивали устройство!

- Пойду фрезу гонять по плате, посмотрю, что в этой опции мне мозги сносить начнет.

- Спасибо, Андрей за советы, поддержку. Без настроек, которые вы порекомендовали 1.1.7 так же глючила не по децки.

ЗНАЕТ ЧТО ГОВОРИТ

- 24.06.2020

- Последнее редактирование: 24.06.2020

- Первая попытка. Гравировка не получилась .

- Указывал 0.1мм фрезу в два прохода, судя по результату,фреза как минимум 0.4мм.Чё китаец положил не знаю, на штихелях не указаны размеры.

- Но ладно, эт для другой темы.

- Карта высот удалась, наконец. В Candel поставил галку «использовать карту высот», гравернул и нате! Карта высот, я так полагаю, не включилась. Глюк? Или я её не сохранил . Выскакивало сообщение о замене старой карты, которой и не было. Я это сообщение игнорировал, а видать не нужно было?? Или как?

Вложения

МЕСТНЫЙ

- Карта высот удалась, наконец. В Candel поставил галку «использовать карту высот», гравернул и нате! Карта высот, я так полагаю, не включилась. Глюк? Или я её не сохранил . Выскакивало сообщение о замене старой карты, которой и не было. Я это сообщение игнорировал, а видать не нужно было?? Или как?

Psyx86

Psyx86

МЕСТНЫЙ

- Первая попытка. Гравировка не получилась .

- Указывал 0.1мм фрезу в два прохода, судя по результату,фреза как минимум 0.4мм.Чё китаец положил не знаю, на штихелях не указаны размеры.

- Но ладно, эт для другой темы.

- Карта высот удалась, наконец. В Candel поставил галку «использовать карту высот», гравернул и нате! Карта высот, я так полагаю, не включилась. Глюк? Или я её не сохранил . Выскакивало сообщение о замене старой карты, которой и не было. Я это сообщение игнорировал, а видать не нужно было?? Или как?

mixocingmail

mixocingmail

МЕСТНЫЙ

extrimus

extrimus

ПОЧТИ ПРОФИ

OlegK

OlegK

Младший ненаучный сотрудник

- 11.09.2020

- Последнее редактирование: 11.09.2020

Error 0 – STATUS_OK

Всё нормально, этот код ошибки указывает на то, что ошибок нет.

Error 1 – STATUS_EXPECTED_COMMAND_LETTER

Команда G-кода должна начинаться с буквы.

Error 2 – STATUS_BAD_NUMBER_FORMAT

Числовая часть G-кода некорректна

Error 3 – STATUS_INVALID_STATEMENT

Некорректная инструкция (команда), орпеделяемая через $

Error 4 – STATUS_NEGATIVE_VALUE

Получено отрицательное значение вместо ожидаемого положительного.

Error 5 – STATUS_SETTING_DISABLED

Был произведен вызов отключенной функции.

Например, вы ввели $H для возврата в «дом», но параметр $20 (активация поиска «дома») установлен в 0 (выкл.)

Error 6 – STATUS_SETTING_STEP_PULSE_MIN

Значение параметра $0 (длительность импульса шага) слишком мало, нужно вернуть его к занчению по-умолчанию, $0=10

Error 7 – STATUS_SETTING_READ_FAIL

Повреждено содержимое EEPROM, настройки сброшены в значения по-умолчанию.

Вам требуется переконфигурировать $ параметры. После конфигурации, сделайте копию настроек.

Error 8 – STATUS_IDLE_ERROR

Вы ввели команду, разрешенную только в том случае, если активным состоянием контроллера является «Неактивен».

Например, вы отправили команду $$ во время выполнения другого задания.

Error 9 – STATUS_SYSTEM_GC_LOCK

Станок был заблокирован из-за какой-то ошибки, и вы пытались подать команду движения.

Вы забыли разблокировать? Или ось упёрлась в концевой выключатель?

Error 10 – STATUS_SOFT_LIMIT_ERROR

Вы получите эту ошибку, если попытаетесь включить мягкие ограничения, не включая цикл возврата в «дом».

Мягкие ограничения не могут работать, если вы сначала не вернете машину «домой», чтобы она знала, где находится!

Error 11 – STATUS_OVERFLOW

GRBL имеет максимальное количество символов, которые он может принять в одной команде.

Т.е. команда слишком длинная. Это часто случается, CAM-софт помещает длинные комментарии в файл.

Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

Вы пытались установить слишком высокую скорость перемещения осей, проверьте значения $110, $111, $112.

Error 13 – STATUS_CHECK_DOOR

У вас включена функция контроля открытия защитной двери, и эта ошибка показывает, что дверь не закрыта… Закройте дверь — дует

Error 14 – STATUS_LINE_LENGTH_EXCEEDED

(Только для Grbl-Mega) Информация о сборке или строка запуска превысили лимит длины строки EEPROM.

Error 15 – STATUS_TRAVEL_EXCEEDED

Выход за пределы софт-лимитов.

Либо исправьте значения мягких пределов, или, если они верны, посмотрите, почему станок пытается использовать больше места, чем у вас есть на самом деле.

Error 16 – STATUS_INVALID_JOG_COMMAND

Неверная jog-команда, возможно, забыли «=» (знак равно)

Error 17 – STATUS_SETTING_DISABLED_LASER

Laser mode requires PWM output.

Предположительно выпадает, если активирован режим лазера ($32=1) и отключен ШИМ,

т.е. для лазера необх. ШИМ-управление.

Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

Обнаружена неподдерживаемая или ошибочная команда G-кода в блоке.

Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

В блоке обнаружено более одной команды g-кода из одной модальной группы.

Читать: G Code Overview

Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

Вы не можете выполнить движение, если не была задана скорость подачи, поэтому перед отправкой команды движения

введите что-то вроде F100 (подача со скоростью 100 мм/мин).

Скорее всего, вы увидите эту ошибку только при запуске команд из командной строки.

Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

Команда, которую вы отправили содержит нецелое значение.

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

В блоке были обнаружены две команды G-кода, обе из которых требуют использования букв названия оси (XYZ).

Error 25 – STATUS_GCODE_WORD_REPEATED

Повтор G-кода в блоке.

Error 26 – STATUS_GCODE_NO_AXIS_WORDS

Команда G-кода неявно или явно требует букв названия оси XYZ в блоке, что не было обнаружено.

Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

Номер строки N находится за пределами допустимого диапазона от 1 до 9 999 999.

Отключите нумерацию строк в CAM-софте.

Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

Была отправлена команда G-кода, но в строке отсутствуют некоторые требуемые слова значений P или L.

Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

Grbl поддерживаются 6 вариантов систем рабочих координат.

Это G54-G59.

G59.1, G59.2, и G59.3 — не поддерживаются.

Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

Команда G-кода G53 требует, чтобы был активен либо режим поиска G0, либо режим подачи G1.

Было другое перемещение.

Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

There are unused axis words in the block and G80 motion mode cancel is active.

Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

Для команды дуги (arc) G2 или G3, не задано плоскости, т.е. нет слов оси XYZ для трассировки дуги.

Error 33 – STATUS_GCODE_INVALID_TARGET

Команда движения имеет недопустимую цель.

G2, G3 и G38.2 генерируют эту ошибку, если невозможно создать дугу или если целью датчика (probe) является текущая позиция.

Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

Дуга G2 или G3, построенная с помощью определения радиуса, имела математическую ошибку при вычислении геометрии дуги.

Попробуйте либо разбить дугу на полукруги или квадранты, либо переопределить их с помощью определения смещения дуги.

Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

В дуге G2 или G3, отслеживаемой с помощью определения смещения, отсутствует слово смещения IJK в выбранной плоскости для трассировки дуги.

Error 36 – STATUS_GCODE_UNUSED_WORDS

Есть неиспользованные, оставшиеся слова G-кода, которые не используются ни одной командой в блоке.

Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

Команда динамической коррекции длины инструмента G43.1 не может применить коррекцию к другой оси,

кроме сконфигурированной. Ось по умолчанию Grbl — это ось Z.

Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

Вы отправили число больше, чем ожидалось, возможно, для смены инструмента вы пытались выбрать инструмент 50000 или что-то в этом роде?

СООБЩЕНИЯ ТРЕВОГИ (ALARM)

ALARM 1 – EXEC_ALARM_HARD_LIMIT

Ошибка жесткого предела, т.е. сработал концевой выключатель, это всегда приводит к окончанию работы, кроме режима поиска дома.

ALARM 2 – EXEC_ALARM_SOFT_LIMIT

Ошибка мягкого предела, вы или команда Gcode пытались отправить какую-то ось дальше, чем предполагается в параметрах $130,131,132.

ALARM 3 – EXEC_ALARM_ABORT_CYCLE

Нажат аварийный стоп! Это всегда приводит к мгновенному окончанию работы.

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

Grbl ожидал, что ваш датчик будет находиться в состоянии, отличном от того, в котором он был до начала цикла измерения, то есть ваш инструмент уже касается датчика. Или щуп касается токопроводящей заготовки.

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

Ось Z была опущена вниз, на заданную величину, но не достигла срабатывания.

Возможно, вы забыли надеть «крокодил» или что что-то еще не так, и поэтому процесс будет прерван.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

Останов был произведен во время цикла возврата в «дом» или, возможно, ложное срабатывание из-за помех.

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

Дверца безопасности была открыта во время цикла поиска «дома» или, возможно, ложно сработала из-за помех.

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

Мало значение величины отскока от концевика при поиске дома и концевик не вернулся в исходное состояние. Увеличьте $27 до 3 или 5 мм (Например $27=5.000)

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

Ошибка поиска «дома». Не удалось найти концевой выключатель на расстоянии поиска.

При перемещении в исходное положение grbl не будет перемещаться дальше значений, указанных в параметрах $130, $131, $132 при попытке найти концевой выключатель.

Поэтому, даже если мягкие пределы отключены, убедитесь, что эти значения верны или больше, чем у вашей машины.

Hold 0 – Удержание завершено. Готов продолжить.

Hold 1 – Удержание. Сброс вызовет тревогу.

Door 0 – Дверь закрыта. Готов продолжить.

Door 1 – Стоп машина! Дверь все еще приоткрыта. Не может быть продолжено до закрытия.

Door 2 – Дверь открыта. Выполняется удержание. Сброс вызовет тревогу.

Door 3 – Дверь закрыта и процесс возобновлён. Сброс вызовет тревогу.

Источник

GRBL Error Codes

Error 0 – STATUS_OK

All Good, This is an error code suggesting that there is NO error

Error 1 – STATUS_EXPECTED_COMMAND_LETTER

Gcodes should start with a Letter, what ever was just sent to GRBL did not

Error 2 – STATUS_BAD_NUMBER_FORMAT

The number part of the Gcode was invalid

Error 3 – STATUS_INVALID_STATEMENT

Usualy a bad GRBL Specific $ instruction

Error 4 – STATUS_NEGATIVE_VALUE

Negative value received for an expected positive value.

Error 5 – STATUS_SETTING_DISABLED

A call to a disabled function was issued – EG you issued $H for homing but your $20 (homing enable) parameter is set to 0 (off)

Error 6 – STATUS_SETTING_STEP_PULSE_MIN

Your $0 (step pulse time) is to short, set it back to its default value, $0=10

Error 7 – STATUS_SETTING_READ_FAIL

Corrupt EEPROM values, you will need to reconfigure all your $ values as they have been reset to default – this time once you have worked them all out, make a copy! This is a rare error.

Error 8 – STATUS_IDLE_ERROR

You have issued a command only allowed when the machine active state is Idle. Example you sent $$ while the Active state was run (job was in progress)

Error 9 – STATUS_SYSTEM_GC_LOCK

machine is locked in error of some sort, and you tried to issue a movement command. Did you forget to $X the machine? Or is it sitting on a Limit Switch?

Error 10 – STATUS_SOFT_LIMIT_ERROR

You will see this if you try to enable soft limits without also enabling homing cycle. Soft limits cannot work unless you first home the machine so it knows where it is!

Error 11 – STATUS_OVERFLOW

GRBL has a max number of charactors it will accept in one command, it received on that was too long – often happens when CAM software puts long comments in file

Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

You tried to set a Step rate that was too high, look at your $110, $111,$112 values!

Error 13 – STATUS_CHECK_DOOR

You have the safety door funtion turned on and it is showing not closed…close it

Error 14 – STATUS_LINE_LENGTH_EXCEEDED

You should not see this error and if you do you should know what it means!

Error 15 – STATUS_TRAVEL_EXCEEDED

You have got soft limits turned on and configured, and the job your trying to run is larger than you have told grbl that your machine actualy is. Either fix your soft limit values and if they are correct, look at why your cam setup is trying to use more space than you actually have.

Error 16 – STATUS_INVALID_JOG_COMMAND

Jogging command issued was not valid, possibly forgot the =… part

Error 17 – STATUS_SETTING_DISABLED_LASER

Probrably happened when you turned on $32 wthout enableing PWM – We don’t know a lot about this error – email us if you work it out and we can add it to this list

Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

Unsupported or invalid g-code command found in block.

Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

You cannot issue a movement if no feed rate has been set – so issue something like F1000 (feed at 1000mm/min) before sending a movement command. You will likely only see this error when bashing stuff into the command prompt and not when using a gui

Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

Look into the command you sent, did it include a non integer value?

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

Two G-code commands that both require the use of the XYZ axis words were detected in the block.

Error 25 – STATUS_GCODE_WORD_REPEATED

A G-code word was repeated in the block.

Error 26 – STATUS_GCODE_NO_AXIS_WORDS

A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.

Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

N line number value is not within the valid range of 1 – 9,999,999 – why not turn off line numbers in your CAM software

Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

A G-code command was sent, but is missing some required P or L value words in the line.

Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.

Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.

Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

There are unused axis words in the block and G80 motion mode cancel is active.

Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.

Error 33 – STATUS_GCODE_INVALID_TARGET

The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.

Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.

Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.

Error 36 – STATUS_GCODE_UNUSED_WORDS

There are unused, leftover G-code words that aren’t used by any command in the block.

Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.

Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

You sent a number higher than expected, maybe for a tool change you tried to select tool 50000 or something?

ALARM 1 – EXEC_ALARM_HARD_LIMIT

Hard Limit Error, A limit switch was triggered, this always results in the end of your job. The only time a limit switch should be hit is during a homing cycle, at any other time it will stop the system. Either your machine went to far in one direction and hit a switch or you have electrical noise getting into your limit switch wiring. Do not restart your jhob without rehoming or resetting / confirming the machines position, it will unliely be correct still!

ALARM 2 – EXEC_ALARM_SOFT_LIMIT

Soft Limit Error, Either you or a Gcode file tried to send some axis past further than you have suggested it can in your $130, $131 ,$132 parameters

ALARM 3 – EXEC_ALARM_ABORT_CYCLE

The Estop was hit! Same as a hard limit, just a different button – look at details above for Alarm 1

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

Grbl was expecting your probe to be in a state other than that it is before starting a probing cycle – ie your tool is already touching the probe or similar

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

Z axis was sent down as far as it dared (instructed) and did not hit a switch. Instead of digging to china it assumes you forgot to put an aligator clip on or that something else is wrong and so stops.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

Reset was issued during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment if your estop button is connected to the Abort pin and not to the reset pin that is

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

Safety door was opened during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

Grbl tries to pull back of a switch and hit it a second time (slowly) during a homing cycle. Your Homing Pulloff value was not sufficient to enable the axis to move far enough away from the switch. Increase $27 to maybe 3 or 5mm – $27=5.000

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

When homing, grbl will not travel further than the values in parameters $130, $131 ,$132 while trying to locate a limit switch. So even if your soft limits are off, make sure these values are correct or larger than your machine. Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.”

Источник

ВОПРОС Настройка щупа

SnakeKVC

SnakeKVC

Дежурный персонал

ЗНАЕТ ЧТО ГОВОРИТ

SnakeKVC

SnakeKVC

Дежурный персонал

ЗНАЕТ ЧТО ГОВОРИТ

SnakeKVC

SnakeKVC

Дежурный персонал

ЗНАЕТ ЧТО ГОВОРИТ

- Жесть! В натуре, с глюкавыми прогами себя за идиота начинаешь держать. Не знаю от чего. У меня две разные WIN10. Одна на компе, другая на планшете. И каждая из трех Candel(ов) 1.1.8; 1.1.7: 1.2..8, по-разному себя ведет на этих девайсах.

- На компе 1.1.7 виснет при запуске, а вот на планшете работает нормально. Именно с ней удалось построить карту высот и шпиндель позиционироваться верно начал. А прежде-то и с 1.2..8 и с1.1.8 все враскосяк было! То карта высот не отражалась, то концевики переставала видеть, а то при команде «щуп» давила шпинделем стол. Кароч – полный атас! Видел я глючные проги, но что бы так они убивали устройство!

- Пойду фрезу гонять по плате, посмотрю, что в этой опции мне мозги сносить начнет.

- Спасибо, Андрей за советы, поддержку. Без настроек, которые вы порекомендовали 1.1.7 так же глючила не по децки.

ЗНАЕТ ЧТО ГОВОРИТ

- 24.06.2020

- Последнее редактирование: 24.06.2020

- Первая попытка. Гравировка не получилась .

- Указывал 0.1мм фрезу в два прохода, судя по результату,фреза как минимум 0.4мм.Чё китаец положил не знаю, на штихелях не указаны размеры.

- Но ладно, эт для другой темы.

- Карта высот удалась, наконец. В Candel поставил галку «использовать карту высот», гравернул и нате! Карта высот, я так полагаю, не включилась. Глюк? Или я её не сохранил . Выскакивало сообщение о замене старой карты, которой и не было. Я это сообщение игнорировал, а видать не нужно было?? Или как?

Вложения

МЕСТНЫЙ

- Карта высот удалась, наконец. В Candel поставил галку «использовать карту высот», гравернул и нате! Карта высот, я так полагаю, не включилась. Глюк? Или я её не сохранил . Выскакивало сообщение о замене старой карты, которой и не было. Я это сообщение игнорировал, а видать не нужно было?? Или как?

Psyx86

Psyx86

МЕСТНЫЙ

- Первая попытка. Гравировка не получилась .

- Указывал 0.1мм фрезу в два прохода, судя по результату,фреза как минимум 0.4мм.Чё китаец положил не знаю, на штихелях не указаны размеры.

- Но ладно, эт для другой темы.

- Карта высот удалась, наконец. В Candel поставил галку «использовать карту высот», гравернул и нате! Карта высот, я так полагаю, не включилась. Глюк? Или я её не сохранил . Выскакивало сообщение о замене старой карты, которой и не было. Я это сообщение игнорировал, а видать не нужно было?? Или как?

mixocingmail

mixocingmail

МЕСТНЫЙ

extrimus

extrimus

ПОЧТИ ПРОФИ

OlegK

OlegK

Младший ненаучный сотрудник

- 11.09.2020

- Последнее редактирование: 11.09.2020

Error 0 – STATUS_OK

Всё нормально, этот код ошибки указывает на то, что ошибок нет.

Error 1 – STATUS_EXPECTED_COMMAND_LETTER

Команда G-кода должна начинаться с буквы.

Error 2 – STATUS_BAD_NUMBER_FORMAT

Числовая часть G-кода некорректна

Error 3 – STATUS_INVALID_STATEMENT

Некорректная инструкция (команда), орпеделяемая через $

Error 4 – STATUS_NEGATIVE_VALUE

Получено отрицательное значение вместо ожидаемого положительного.

Error 5 – STATUS_SETTING_DISABLED

Был произведен вызов отключенной функции.

Например, вы ввели $H для возврата в «дом», но параметр $20 (активация поиска «дома») установлен в 0 (выкл.)

Error 6 – STATUS_SETTING_STEP_PULSE_MIN

Значение параметра $0 (длительность импульса шага) слишком мало, нужно вернуть его к занчению по-умолчанию, $0=10

Error 7 – STATUS_SETTING_READ_FAIL

Повреждено содержимое EEPROM, настройки сброшены в значения по-умолчанию.

Вам требуется переконфигурировать $ параметры. После конфигурации, сделайте копию настроек.

Error 8 – STATUS_IDLE_ERROR

Вы ввели команду, разрешенную только в том случае, если активным состоянием контроллера является «Неактивен».

Например, вы отправили команду $$ во время выполнения другого задания.

Error 9 – STATUS_SYSTEM_GC_LOCK

Станок был заблокирован из-за какой-то ошибки, и вы пытались подать команду движения.

Вы забыли разблокировать? Или ось упёрлась в концевой выключатель?

Error 10 – STATUS_SOFT_LIMIT_ERROR

Вы получите эту ошибку, если попытаетесь включить мягкие ограничения, не включая цикл возврата в «дом».

Мягкие ограничения не могут работать, если вы сначала не вернете машину «домой», чтобы она знала, где находится!

Error 11 – STATUS_OVERFLOW

GRBL имеет максимальное количество символов, которые он может принять в одной команде.

Т.е. команда слишком длинная. Это часто случается, CAM-софт помещает длинные комментарии в файл.

Error 12 – STATUS_MAX_STEP_RATE_EXCEEDED

Вы пытались установить слишком высокую скорость перемещения осей, проверьте значения $110, $111, $112.

Error 13 – STATUS_CHECK_DOOR

У вас включена функция контроля открытия защитной двери, и эта ошибка показывает, что дверь не закрыта… Закройте дверь — дует

Error 14 – STATUS_LINE_LENGTH_EXCEEDED

(Только для Grbl-Mega) Информация о сборке или строка запуска превысили лимит длины строки EEPROM.

Error 15 – STATUS_TRAVEL_EXCEEDED

Выход за пределы софт-лимитов.

Либо исправьте значения мягких пределов, или, если они верны, посмотрите, почему станок пытается использовать больше места, чем у вас есть на самом деле.

Error 16 – STATUS_INVALID_JOG_COMMAND

Неверная jog-команда, возможно, забыли «=» (знак равно)

Error 17 – STATUS_SETTING_DISABLED_LASER

Laser mode requires PWM output.

Предположительно выпадает, если активирован режим лазера ($32=1) и отключен ШИМ,

т.е. для лазера необх. ШИМ-управление.

Error 20 – STATUS_GCODE_UNSUPPORTED_COMMAND

Обнаружена неподдерживаемая или ошибочная команда G-кода в блоке.

Error 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION

В блоке обнаружено более одной команды g-кода из одной модальной группы.

Читать: G Code Overview

Error 22 – STATUS_GCODE_UNDEFINED_FEED_RATE

Вы не можете выполнить движение, если не была задана скорость подачи, поэтому перед отправкой команды движения

введите что-то вроде F100 (подача со скоростью 100 мм/мин).

Скорее всего, вы увидите эту ошибку только при запуске команд из командной строки.

Error 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER

Команда, которую вы отправили содержит нецелое значение.

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

В блоке были обнаружены две команды G-кода, обе из которых требуют использования букв названия оси (XYZ).

Error 25 – STATUS_GCODE_WORD_REPEATED

Повтор G-кода в блоке.

Error 26 – STATUS_GCODE_NO_AXIS_WORDS

Команда G-кода неявно или явно требует букв названия оси XYZ в блоке, что не было обнаружено.

Error 27 – STATUS_GCODE_INVALID_LINE_NUMBER

Номер строки N находится за пределами допустимого диапазона от 1 до 9 999 999.

Отключите нумерацию строк в CAM-софте.

Error 28 – STATUS_GCODE_VALUE_WORD_MISSING

Была отправлена команда G-кода, но в строке отсутствуют некоторые требуемые слова значений P или L.

Error 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS

Grbl поддерживаются 6 вариантов систем рабочих координат.

Это G54-G59.

G59.1, G59.2, и G59.3 — не поддерживаются.

Error 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE

Команда G-кода G53 требует, чтобы был активен либо режим поиска G0, либо режим подачи G1.

Было другое перемещение.

Error 31 – STATUS_GCODE_AXIS_WORDS_EXIST

There are unused axis words in the block and G80 motion mode cancel is active.

Error 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE

Для команды дуги (arc) G2 или G3, не задано плоскости, т.е. нет слов оси XYZ для трассировки дуги.

Error 33 – STATUS_GCODE_INVALID_TARGET

Команда движения имеет недопустимую цель.

G2, G3 и G38.2 генерируют эту ошибку, если невозможно создать дугу или если целью датчика (probe) является текущая позиция.

Error 34 – STATUS_GCODE_ARC_RADIUS_ERROR

Дуга G2 или G3, построенная с помощью определения радиуса, имела математическую ошибку при вычислении геометрии дуги.

Попробуйте либо разбить дугу на полукруги или квадранты, либо переопределить их с помощью определения смещения дуги.

Error 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE

В дуге G2 или G3, отслеживаемой с помощью определения смещения, отсутствует слово смещения IJK в выбранной плоскости для трассировки дуги.

Error 36 – STATUS_GCODE_UNUSED_WORDS

Есть неиспользованные, оставшиеся слова G-кода, которые не используются ни одной командой в блоке.

Error 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR

Команда динамической коррекции длины инструмента G43.1 не может применить коррекцию к другой оси,

кроме сконфигурированной. Ось по умолчанию Grbl — это ось Z.

Error 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED

Вы отправили число больше, чем ожидалось, возможно, для смены инструмента вы пытались выбрать инструмент 50000 или что-то в этом роде?

СООБЩЕНИЯ ТРЕВОГИ (ALARM)

ALARM 1 – EXEC_ALARM_HARD_LIMIT

Ошибка жесткого предела, т.е. сработал концевой выключатель, это всегда приводит к окончанию работы, кроме режима поиска дома.

ALARM 2 – EXEC_ALARM_SOFT_LIMIT

Ошибка мягкого предела, вы или команда Gcode пытались отправить какую-то ось дальше, чем предполагается в параметрах $130,131,132.

ALARM 3 – EXEC_ALARM_ABORT_CYCLE

Нажат аварийный стоп! Это всегда приводит к мгновенному окончанию работы.

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL

Grbl ожидал, что ваш датчик будет находиться в состоянии, отличном от того, в котором он был до начала цикла измерения, то есть ваш инструмент уже касается датчика. Или щуп касается токопроводящей заготовки.

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT

Ось Z была опущена вниз, на заданную величину, но не достигла срабатывания.

Возможно, вы забыли надеть «крокодил» или что что-то еще не так, и поэтому процесс будет прерван.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET

Останов был произведен во время цикла возврата в «дом» или, возможно, ложное срабатывание из-за помех.

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR

Дверца безопасности была открыта во время цикла поиска «дома» или, возможно, ложно сработала из-за помех.

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF

Мало значение величины отскока от концевика при поиске дома и концевик не вернулся в исходное состояние. Увеличьте $27 до 3 или 5 мм (Например $27=5.000)

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH

Ошибка поиска «дома». Не удалось найти концевой выключатель на расстоянии поиска.

При перемещении в исходное положение grbl не будет перемещаться дальше значений, указанных в параметрах $130, $131, $132 при попытке найти концевой выключатель.

Поэтому, даже если мягкие пределы отключены, убедитесь, что эти значения верны или больше, чем у вашей машины.

Hold 0 – Удержание завершено. Готов продолжить.

Hold 1 – Удержание. Сброс вызовет тревогу.

Door 0 – Дверь закрыта. Готов продолжить.

Door 1 – Стоп машина! Дверь все еще приоткрыта. Не может быть продолжено до закрытия.

Door 2 – Дверь открыта. Выполняется удержание. Сброс вызовет тревогу.

Door 3 – Дверь закрыта и процесс возобновлён. Сброс вызовет тревогу.

Источник

- Home

- gSender

- Full Documentation

- GRBL Alarms & Errors

Page Contents

- Alarms

- Errors

The GRBL firmware has a whole list of Alarms and Error codes that you can encounter when running your CNC. gSender will always display a question mark when there’s an alarm which you can hover over for more information about why it happened and errors will appear as a hovering box in the bottom corner of the visualizer.

| Alarm Code | Message | Description | Example |

| 1 | Hard limit | Hard limit has been triggered. Machine position is likely lost due to sudden halt. Re-homing is highly recommended. | Example |

| 2 | Soft limit | Soft limit alarm. G-code motion target exceeds machine travel. Machine position retained. Alarm may be safely unlocked. | Example |

| 3 | Abort during cycle | Reset while in motion. Machine position is likely lost due to sudden halt. Re-homing is highly recommended. May be due to issuing g-code commands that exceed the limit of the machine. | |

| 4 | Probe fail | Probe fail. Probe is not in the expected initial state before starting probe cycle when G38.2 and G38.3 is not triggered and G38.4 and G38.5 is triggered. | Example |

| 5 | Probe fail | Probe fail. Probe did not contact the workpiece within the programmed travel for G38.2 and G38.4. | Example |

| 6 | Homing fail | Homing fail. The active homing cycle was reset. | |

| 7 | Homing fail | Homing fail. Safety door was opened during homing cycle. | |

| 8 | Homing fail | Homing fail. Pull off travel failed to clear limit switch. Try increasing pull-off setting or check wiring. | |

| 9 | Homing fail | Homing fail. Could not find limit switch within search distances. Try increasing max travel, decreasing pull-off distance, or check wiring. |

Errors

| Error Code | Message | Description |

| 1 | Expected command letter | G-code words consist of a letter and a value. Letter was not found. |

| 2 | Bad number format | Missing the expected G-code word value or numeric value format is not valid. |

| 3 | Invalid statement | Grbl ‘$’ system command was not recognized or supported. |

| 4 | Value < 0 | Negative value received for an expected positive value. |

| 5 | Setting disabled | Homing cycle failure. Homing is not enabled via settings. |

| 6 | Value < 3 μsec | Minimum step pulse time must be greater than 3μsec. |

| 7 | EEPROM read fail. Using defaults | An EEPROM read failed. Auto-restoring affected EEPROM to default values. |

| 8 | Not idle | Grbl ‘$’ command cannot be used unless Grbl is IDLE. Ensures smooth operation during a job. |

| 9 | G-code lock | G-code commands are locked out during alarm or jog state. |

| 10 | Homing not enabled | Soft limits cannot be enabled without homing also enabled. |

| 11 | Line overflow | Max characters per line exceeded. Received command line was not executed. |

| 12 | Step rate > 30kHz | Grbl ‘$’ setting value cause the step rate to exceed the maximum supported. |

| 13 | Check Door | Safety door detected as opened and door state initiated. |

| 14 | Line length exceeded | Build info or startup line exceeded EEPROM line length limit. Line not stored. |

| 15 | Travel exceeded | Jog target exceeds machine travel. Jog command has been ignored. |

| 16 | Invalid jog command | Jog command has no ‘=’ or contains prohibited g-code. |

| 17 | Setting disabled | Laser mode requires PWM output. |

| 20 | Unsupported command | Unsupported or invalid g-code command found in block. |

| 21 | Modal group violation | More than one g-code command from same modal group found in block. |

| 22 | Undefined feed rate | Feed rate has not yet been set or is undefined. |

| 23 | Invalid gcode ID:23 | G-code command in block requires an integer value. |

| 24 | Invalid gcode ID:24 | More than one g-code command that requires axis words found in block. |

| 25 | Invalid gcode ID:25 | Repeated g-code word found in block. |

| 26 | Invalid gcode ID:26 | No axis words found in block for g-code command or current modal state which requires them. |

| 27 | Invalid gcode ID:27 | Line number value is invalid. |

| 28 | Invalid gcode ID:28 | G-code command is missing a required value word. |

| 29 | Invalid gcode ID:29 | G59.x work coordinate systems are not supported. |

| 30 | Invalid gcode ID:30 | G53 only allowed with G0 and G1 motion modes. |

| 31 | Invalid gcode ID:31 | Axis words found in block when no command or current modal state uses them. |

| 32 | Invalid gcode ID:32 | G2 and G3 arcs require at least one in-plane axis word. |

| 33 | Invalid gcode ID:33 | Motion command target is invalid. |

| 34 | Invalid gcode ID:34 | Arc radius value is invalid. |

| 35 | Invalid gcode ID:35 | G2 and G3 arcs require at least one in-plane offset word. |

| 36 | Invalid gcode ID:36 | Unused value words found in block. |

| 37 | Invalid gcode ID:37 | G43.1 dynamic tool length offset is not assigned to configured tool length axis. |

| 38 | Invalid gcode ID:38 | Tool number greater than max supported value. |

Welcome to Our Community

Some features disabled for guests. Register Today.

-

Builder

- Joined:

- Nov 18, 2021

- Messages:

- 5

- Likes Received:

- 1

I’m testing my new machine and learning about it. I generated my toolpaths using Qcad and exported a gcode file. Then I opened the file with Open builds control software. Everything seems normal until I run job. I get an error message Grbl Error: 20 — Unsupported or invalid g-code command found in block [ N30 T1 M6 ]. It shows up on line 3. If I delete the command, the job will run. I did a test without a bit to see it’s travel. It appears to be cutting at a much reduced size scale. For example, a 2″ square is cut less than .5″.

I used the G-code (Offset) [in»]setting in my Qcad/cam. I tried other settings also. I tried a 2″ square to see if a basic shape would work. No luck. What’s the deal?

-

Staff Member

Moderator

Builder

Resident Builder- Joined:

- Mar 23, 2018

- Messages:

- 1,900

- Likes Received:

- 1,310

T (tool change) is not a valid grbl command. Find a post processor that is for grbl. (refer to the grbl wiki for valid commands: Grbl v1.1 Commands · gnea/grbl Wiki)

For the size, did your gcode have an G20 command at the beginning? If not, its cutting in mm, not inches.

-

Builder

- Joined:

- Nov 18, 2021

- Messages:

- 5

- Likes Received:

- 1

I figured it out I think. I won’t be able to use Qcad/CAM. looks like I have to use a program compatible with your controller.

-

Staff Member

Moderator

Builder

Resident Builder- Joined:

- Mar 1, 2017

- Messages:

- 11,011

- Likes Received:

- 3,490

You need a Grbl compatible CAM or Post. See the software section of docs.openbuilds.com

-

Staff Member

Moderator

Builder

Resident Builder- Joined:

- Mar 23, 2018

- Messages:

- 1,900

- Likes Received:

- 1,310

Once. That tells the controller that all coordinates are in inch mode until a G21 command is issue in which case it switches to mm mode. Does the qcad GRBL(offset)in post not work?

-

Builder

- Joined:

- Nov 18, 2021

- Messages:

- 5

- Likes Received:

- 1

I tried the GRBL(offset)in post and it still had unsupported commands

-

Staff Member

Moderator

Builder

Resident Builder- Joined:

- Aug 6, 2013

- Messages:

- 2,600

- Likes Received:

- 1,504

I have just run gcode I created in Qcad using the GRBL inch and GRBL mm posts through OpenBuilds CONTROL without errors.

What GUI are you using?

Are you SURE you selected the GRBL posts, it is easy to select the generic G-code posts instead as the Qcad interface is not very clear.

Also note everytime you change post selection you have to recreate the toolpaths. -

Builder

- Joined:

- Nov 18, 2021

- Messages:

- 5

- Likes Received:

- 1

I’m using Carvco now instead. I like it. I still prefer to draw with Qcad but I just open my drawings with carvco and spit out the job.

-

Builder

- Joined:

- Feb 5, 2022

- Messages:

- 6

- Likes Received:

- 1

Thank you So Much. I would have responded sooner but I’ve been out in the shop having a blast.

Share This Page

ERRORs

ERROR 0 – STATUS_OK All Good, This is an error code suggesting that there is NO error

ERROR 1 – STATUS_EXPECTED_COMMAND_LETTER Gcodes should start with a Letter, what ever was just sent to GRBL did not

ERROR 2 – STATUS_BAD_NUMBER_FORMAT The number part of the Gcode was invalid

ERROR 3 – STATUS_INVALID_STATEMENT Usualy a bad GRBL Specific $ instruction

ERROR 4 – STATUS_NEGATIVE_VALUE Negative value received for an expected positive value.

ERROR 5 – STATUS_SETTING_DISABLED A call to a disabled function was issued – EG you issued $H for homing but your $20 (homing enable) parameter is set to 0 (off)

ERROR 6 – STATUS_SETTING_STEP_PULSE_MIN Your $0 (step pulse time) is to short, set it back to its default value, $0=10

ERROR 7 – STATUS_SETTING_READ_FAIL Corrupt EEPROM values, you will need to reconfigure all your $ values as they have been reset to default – this time once you have worked them all out, make a copy! This is a rare error.

ERROR 8 – STATUS_IDLE_ERROR You have issued a command only allowed when the machine active state is Idle. Example you sent $$ while the Active state was run (job was in progress)

ERROR 9 – STATUS_SYSTEM_GC_LOCK machine is locked in error of some sort, and you tried to issue a movement command. Did you forget to $X the machine? Or is it sitting on a Limit Switch?

ERROR 10 – STATUS_SOFT_LIMIT_ERROR You will see this if you try to enable soft limits without also enabling homing cycle. Soft limits cannot work unless you first home the machine so it knows where it is!

ERROR 11 – STATUS_OVERFLOW GRBL has a max number of charactors it will accept in one command, it received on that was too long – often happens when CAM software puts long comments in file

ERROR 12 – STATUS_MAX_STEP_RATE_EXCEEDED You tried to set a Step rate that was too high, look at your $110, $111,$112 values! ERROR 13 – STATUS_CHECK_DOOR You have the safety door funtion turned on and it is showing not closed…close it

ERROR 14 – STATUS_LINE_LENGTH_EXCEEDED You should not see this error and if you do you should know what it means!

ERROR 15 – STATUS_TRAVEL_EXCEEDED You have got soft limits turned on and configured, and the job your trying to run is larger than you have told grbl that your machine actualy is. Either fix your soft limit values and if they are correct, look at why your cam setup is trying to use more space than you actually have.

ERROR 16 – STATUS_INVALID_JOG_COMMAND Jogging command issued was not valid, possibly forgot the =… part

ERROR 17 – STATUS_SETTING_DISABLED_LASER Probrably happened when you turned on $32 wthout enableing PWM – We don’t know a lot about this error – email us if you work it out and we can add it to this list

ERROR 20 – STATUS_GCODE_UNSUPPORTED_COMMAND Unsupported or invalid g-code command found in block.

ERROR 21 – STATUS_GCODE_MODAL_GROUP_VIOLATION Read: http://linuxcnc.org/docs/html/gcode/overview.html#_modal_groups

ERROR 22 – STATUS_GCODE_UNDEFINED_FEED_RATE You cannot issue a movement if no feed rate has been set – so issue something like F1000 (feed at 1000mm/min) before sending a movement command. You will likely only see this error when bashing stuff into the command prompt and not when using a gui

ERROR 23 – STATUS_GCODE_COMMAND_VALUE_NOT_INTEGER Look into the command you sent, did it include a non integer value?

ERROR 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT Two G-code commands that both require the use of the XYZ axis words were detected in the block.

ERROR 25 – STATUS_GCODE_WORD_REPEATED A G-code word was repeated in the block.

ERROR 26 – STATUS_GCODE_NO_AXIS_WORDS A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.

ERROR 27 – STATUS_GCODE_INVALID_LINE_NUMBER N line number value is not within the valid range of 1 – 9,999,999 – why not turn off line numbers in your CAM software

ERROR 28 – STATUS_GCODE_VALUE_WORD_MISSING A G-code command was sent, but is missing some required P or L value words in the line.

ERROR 29 – STATUS_GCODE_UNSUPPORTED_COORD_SYS Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.

ERROR 30 – STATUS_GCODE_G53_INVALID_MOTION_MODE The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.

ERROR 31 – STATUS_GCODE_AXIS_WORDS_EXIST There are unused axis words in the block and G80 motion mode cancel is active.

ERROR 32 – STATUS_GCODE_NO_AXIS_WORDS_IN_PLANE A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.

ERROR 33 – STATUS_GCODE_INVALID_TARGET The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.

ERROR 34 – STATUS_GCODE_ARC_RADIUS_ERROR A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.

ERROR 35 – STATUS_GCODE_NO_OFFSETS_IN_PLANE A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.

ERROR 36 – STATUS_GCODE_UNUSED_WORDS There are unused, leftover G-code words that aren’t used by any command in the block.

ERROR 37 – STATUS_GCODE_G43_DYNAMIC_AXIS_ERROR The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.

ERROR 38 – STATUS_GCODE_MAX_VALUE_EXCEEDED You sent a number higher than expected, maybe for a tool change you tried to select tool 50000 or something?

ALARMs

ALARM 1 – EXEC_ALARM_HARD_LIMIT Hard Limit Error, A limit switch was triggered, this always results in the end of your job. The only time a limit switch should be hit is during a homing cycle, at any other time it will stop the system. Either your machine went to far in one direction and hit a switch or you have electrical noise getting into your limit switch wiring. Do not restart your jhob without rehoming or resetting / confirming the machines position, it will unliely be correct still!

ALARM 2 – EXEC_ALARM_SOFT_LIMIT Soft Limit Error, Either you or a Gcode file tried to send some axis past further than you have suggested it can in your $130, $131 ,$132 parameters

ALARM 3 – EXEC_ALARM_ABORT_CYCLE The Estop was hit! Same as a hard limit, just a different button – look at details above for Alarm 1

ALARM 4 – EXEC_ALARM_PROBE_FAIL_INITIAL Grbl was expecting your probe to be in a state other than that it is before starting a probing cycle – ie your tool is already touching the probe or similar

ALARM 5 – EXEC_ALARM_PROBE_FAIL_CONTACT Z axis was sent down as far as it dared (instructed) and did not hit a switch. Instead of digging to china it assumes you forgot to put an aligator clip on or that something else is wrong and so stops.

ALARM 6 – EXEC_ALARM_HOMING_FAIL_RESET Reset was issued during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment if your estop button is connected to the Abort pin and not to the reset pin that is

ALARM 7 – EXEC_ALARM_HOMING_FAIL_DOOR Safety door was opened during a homing cycle, or maybe falsely triggered by electrical noise in your system/environment

ALARM 8 – EXEC_ALARM_HOMING_FAIL_PULLOFF Grbl tries to pull back of a switch and hit it a second time (slowly) during a homing cycle. Your Homing Pulloff value was not sufficient to enable the axis to move far enough away from the switch. Increase $27 to maybe 3 or 5mm – $27=5.000

ALARM 9 – EXEC_ALARM_HOMING_FAIL_APPROACH When homing, grbl will not travel further than the values in parameters $130, $131 ,$132 while trying to locate a limit switch. So even if your soft limits are off, make sure these values are correct or larger than your machine. Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.

Etc.

HOLD 0 – HOLD COMPLETE. READY TO RESUME

HOLD 1 – HOLD IN-PROGRESS. RESET WILL THROW AN ALARM

DOOR 0 – DOOR CLOSED. READY TO RESUME.

DOOR 1 – MACHINE STOPPED. DOOR STILL AJAR. CAN’T RESUME UNTIL CLOSED.

DOOR 2 – DOOR OPENED. HOLD (OR PARKING RETRACT) IN-PROGRESS. RESET WILL THROW AN ALARM.

05-13-2016, 07:17 PM

#1

Registered

GRBL 0.9j Unsupported Command

I got the following errors on a 238,000 line job. It threw off the registration, causing the router to cut off from where it was supposed to.

I don’t know enough, yet, to do anything about it.

Perhaps someone can help me to understand/correct it.