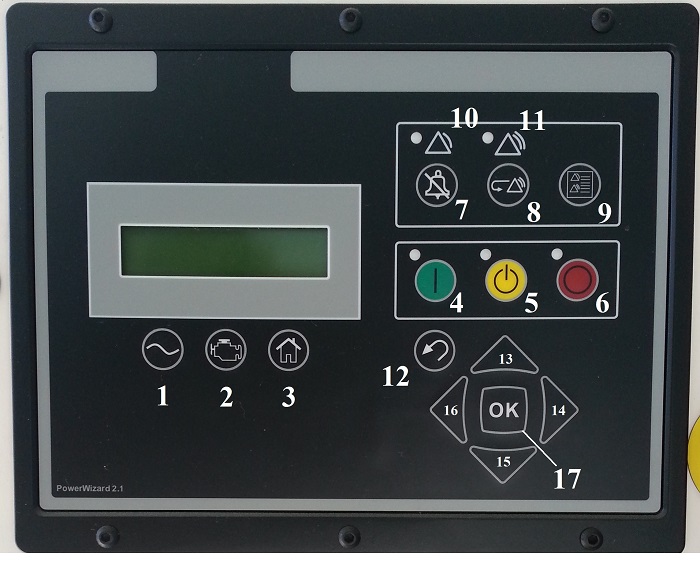

Описание кнопок:

1 – информация по вырабатываемому электрическому току;

2 – информация по работе двигателя;

3 – вход в главное меню;

4 – ручной запуск ДГУ «RUN»;

5 – ввод ДГУ в автоматический режим «AUTO»;

6 – останов ДГУ «STOP»;

7 – кнопка подтверждения аварийного сигнала;

8 – кнопка сброса событий;

9 – кнопка входа в журнал событий;

10 – предупреждающий индикатор желтого цвета;

11 – аварийный индикатор красного цвета;

12 – кнопка возврата в предыдущее меню;

13, 14, 15, 16 – курсоры для передвижения по меню (вверх,вниз,вправо,влево);

17 – кнопка «ENTER» или «ОК» для входа в меню и подтверждения действия

Чтобы запустить дизельный генератор в ручном режиме необходимо:

- Убедиться что отводящий кабель подсоединен к нагрузке или к АВР;

- Если отводящий кабель не подсоединен к нагрузке или АВР, то необходимо отключить выходной автомат

- Нажать зеленую кнопку «RUN» №4 на панели управления (над ней загорится индикатор), после этого ДГУ должна завестись.

Для перевода ДГУ в автоматический режим необходимо:

- Убедиться, что АВР находится в автоматическом режиме, а выходной автомат в положении включено.

- Нажать на желтую кнопку «AUTO» №5 на панели управления (над ней загорится индикатор) – ДГУ переведена в режим ожидания, после пропадания внешней электроэнергии она заведется автоматически.

Для сброса аварии на ДГУ необходимо:

- Нажать кнопку останова ДГУ «STOP» №6, при этом мигающий индикатор красного цвета №11 должен загореться в постоянном режиме.

- Нажать кнопку №9 для входа в «ГЛАВНОЕ МЕНЮ», затем войти в «ЗАПИСИ СОБЫТИЙ» и найти при помощи кнопок №13 и №15 событие со статусом «АКТИВНЫЙ».

- Устранить, если это необходимо, удалить причины, вызвавшие аварийный останов ДГУ.

- Далее, нажать кнопку «ENTER» или «ОК» №17, на дисплее появится надпись «СБРОС», повторно нажать кнопку «ОК», ошибка удалится, а красный индикатор №11 должен погаснуть.

- Если красный индикатор не погас, необходимо повторить процедуру входа в «ЗАПИСИ СОБЫТИЙ» для поиска «АКТИВНЫХ» событий и сбросить их, как описано в п.4.

- После того как все аварии сброшены и не горит красный индикатор №11, нажать желтую кнопку «AUTO» №5 для перевода генератора в автоматический режим или зеленую кнопку «RUN» №4 для запуска генератора в ручном режиме.

Если же по какой- либо причине авария на ДГУ не сбрасывается, то необходимо связаться с сервисным инженером ТОО «Вильсон Казахстан». Сервисная служба: +7(727)245 81 75, +7777 2737370

Table of Contents:

-

Manual DCP — 10 Genset Controller

-

DCP-10 I The interpretation of the Symbol: WARNING: A WARNING indicates a potentially hazardous situation which, if not avoided, could result in death, serious personal injury or property damage. CAUTION: A CAUTION indicates a potentially hazardous situation which, if not a

-

DCP-10 II WARNING: Read this entire manual pertaining to the work to be performed before installing, operating, or servicing this controller. Practice all plant and safety instructions and p

-

DCP-10 III Contents 1. Description…………………………………………………………………………………………………… 2. Outline Dimension Drawings and Controller Wiring………………………………………�

-

DCP-10 Page 1/27 1. Description The DCP-10 is an Automatic Controller for generator. When running in “AUTO” mode, it starts the Genset after receiving remote start signal and on failure automatically stops the Genset. The generator’s controlling

-

DCP-10 Page 2/27 2. Outline Dimension Drawings and Controller Wiring 2.1 Following Details: Module Dimensions W120mm×H102mm Panel Cutout W110mm×H92mm Thickness D48mm (without connection)

Download Operation & user’s manual of FG Wilson DCP-10 Controller for Free or View it Online on All-Guides.com.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Manual

DCP

-

10

Genset Controller

DCP-10

I

The interpretation of the Symbol:

WARNING:

A WARNING indicates a potentially hazardous situation which, if not

avoided, could result in death, serious personal injury or property

damage.

CAUTION:

A CAUTION indicates a potentially hazardous situation which, if not

avoided, could result in damage to equipment or property.

NOTE:

A NOTE provides other helpful information that does not fall under the

warning or caution categories.

DCP-10

II

WARNING:

Read this entire manual pertaining to the work to be performed before

installing, operating, or servicing this controller. Practice all plant and

safety instructions and precautions. Failure to follow instructions can

cause personal injury and/or property damage.

The engine or other type of prime mover should be equipped with an

overspeed shutdown device to protect against runaway or damage to

the prime mover with possible personal injury, loss of life, or property

damage.

The overspeed shutdown device must be totally independent of the

prime mover control system. An over temperature or low pressure

shutdown device may also be needed for safety, as appropriate.

CAUTION—BATTERY CHARGING

To prevent damage to a controller that uses an alternator or battery-

charging device, make sure the charging device is turned off before

disconnecting the battery from the system.

Controllers contain static-sensitive parts. Observe the following

precautions to prevent damage to these parts:

Do not disassemble the rear back of controller or touch the

components and conductors on a printed circuit board.

DCP-10

III

Contents

1. Description……………………………………………………………………………………………………

2. Outline Dimension Drawings and Controller Wiring…………………………………………………

3. Panel Operation……………………………………………………………………………………………

4. Installation Guide…………………………………………………………………………………………

5. Control and Operation Instruction………………………………………………………………………

6. Measure and Display Data………………………………………………………………………………

7. Pre-alarm and Shutdown Alarm…………………………………………………………………………

8. Parameter Settings………………………………………………………………………………………

9. LCD Display and Menu System…………………………………………………………………………

10. Preparation before Starting the Controller……………………………………………………………

11. Technical Specification…………………………………………………………………………………

1

2

5

6

7

12

13

17

23

28

27

DCP-10

Page 1/27

1. Description

The DCP-10 is an Automatic Controller for generator. When running in “AUTO” mode, it starts the

Genset after receiving remote start signal and on failure automatically stops the Genset. The

generator’s controlling procedure and protection parameters can be modified, which fully meets the

Genset’s requirements of automatic start, stop control and basic protection.

The module displays fault conditions, operational status and related metering data on panel LCD.

LCD has a backlight function so that the operator can read running parameters clearly even in the

shadow.

The controller has 2 modes: AUTO and MANUAL. Either can be chosen through the panel push

button.

Measures and displays generator’s output voltage, current, oil pressure, coolant temperature,

frequency, DC source voltage, etc.

True RMS measure of voltage and current, which ensures the data more accurate.

Control the close/open of generator output switch.

Equipped with built-in communication interface to configure parameters by PC.

All connections of controller are by secure plug and socket, for ease and convenience to connect,

move, maintain and replace the device.

This manual is only suitable for DCP-10 Automatic control module, user must carefully read

this manual first.

DCP-10

Page 2/27

2. Outline Dimension Drawings and Controller Wiring

2.1 Following Details:

Module Dimensions W120mm×H102mm

Panel Cutout W110mm×H92mm

Thickness D48mm (without connection)

DCP-10

Page 3/27

2.2 Terminal Connections:

Pin no.

Function Description Signal Dim

1

GEN. V

L1-N

input 0-300Vac

1mm²

2

GEN. V

L2-N

input 0-300Vac

1mm²

3

GEN. V

L3-N

input 0-300Vac

1mm²

4

GEN. Neutral

1mm²

5

Not used

6 Not used

7 I1 Gen current input 0-5A

2.5mm²

8 I2 Gen current input 0-5A

2.5mm²

9 I3 Gen current input 0-5A

2.5mm²

10 Common port for current input 0-5A

2.5mm²

11 LOP sensor or switch signal LOP sensor (<2KΩ)

1mm²

12 HET sensor or switch signal HET sensor (<2KΩ)

1mm²

13 Configurable digital input signal 1 low level is active

1mm²

14 Configurable digital input signal 2 low level is active

1mm²

15 Configurable digital input signal 3 low level is active

1mm²

16

Charge excitation power output if not used, do not connect to negative

1mm²

17

Configurable relay output 1 N.O. contact, 3A/30Vdc

1mm²

18

Configurable relay output 2 N.O. contact, 3A/30Vdc

1mm²

19

Configurable relay output 3 N.O. contact, 3A/30Vdc

1mm²

20

+5V supply Max 100mA,

1mm²

21

Start (Crank) relay output N.O. contact, 3A/30Vdc

1mm²

22

Fuel solenoid relay output N.O. contact, 3A/30Vdc

1mm²

23

Battery supply (+B)

1mm²

24

Battery supply (-B)

12V/24V (8-35Vdc continuous)

1mm²

DCP-10

Page 4/27

2.3 Typical Wiring Diagram

(12/24V)

DC POWER

CRANKFUEL

CONFIG.OUTPUT

LOAD

M

CONFIG. INPUT

REMOTE START

COOLANT TEMP.

(OR TEMP. SWITCH)

OIL PRESSURE

(OR OIL SWITCH)

DCP-10

Fuse protection with a rating of 0.5A must be provided externally to the Controller.

DCP-10

Page 5/27

3. Panel Operation

The operation panel consists of 3 sections: LCD display indicating measurement parameters, LED

indicator for common failure, and push buttons for Genset and selection of control modes.

The LCD circularly displays different measuring parameters. When failure occurs, LCD displays the

corresponding fault icon. LCD also has a backlight so that the operator can clearly read information day

or night. After pressing any button the backlight will automatically turn off in a certain time.

The LCD display and its control push buttons provide a friendly operation interface for the operator to

conveniently read information and parameter setting.

3.1 Control buttons and LEDs

Function Description

Tag

Scroll Button

Enter into submenu / Modify / confirm modification / scroll menu to

display.

MUTE / LAMP TEST Button

When failure occurs, alarm buzzer sounds. Pressing mute button will

mute the sound. LCD displays mute icon. Press and hold mute button

for 2sec, all LEDs illuminate simultaneously.

AUTO Mode Button / LED

The push button is used for selecting “AUTO mode”. When the

controller is running in AUTO mode, the LED above the push button

illuminated. The activation and deactivation of the “remote start signal

input” controls the starting and stopping of the Genset.

MAN Mode Button / LED

The push button is used for selecting “manual mode”. When the

controller is running in MANUAL mode, the LED above the push button

illuminated. The Start and Stop push buttons control the starting and

stopping of the Genset..

START / VALUE INCREASE “+” Push Button

The push button is used for manually start the Genset .When the

controller is in MANUAL mode, press this push button to start the

generator.

When in parameter setting mode, this push button is used to increase

values.

STOP / RESET / VALUE DECREASE “-” Push Button

The push button is used for MANUALLY stops the Genset. When the

controller is in MAN mode, press and hold this button more than 2sec

to stop the Genset.

If failure occurs, press this button, the shutdown alarm lockout can be

cleared.

When in parameter setting mode, this push button is used to decrease

values.

COMMEN FAILURE LED

LED will flash when pre-alarm (Warning) occurs.

LED will illuminate permanently when shutdown alarm occurs.

DCP-10

Page 6/27

4. Installation Guide

4.1 The cutout dimensional drawing installed on panel as above attached.

The controller is fixed by 2 special fittings. The shock-proof equipment must be mounted if the

enclosure is mounted on Genset or other heavy vibrant device. A readily accessible disconnect

device shall be incorporated external to the equipment.

4.2 Please refer to the above Typical Wiring Diagram 2.3 for connection.

4.3 Installation of engine LOP and HET sensors:

1211

Terminal

12

Battery negative (Genset enclosure)

11

Description

Sensor Com. Port

HET sensor/ temp switch

LOP sensor/ LOP switch

DCP-10

CAUTION:

Pin no. “11” and “12” is for “LOP sensor or switch signal” and “HET

sensor or switch signal” input respectively. Either switch or sensor can be

chosen. When sensor is used, according to the actual situation, increase

the cross section area of cable to reduce the cable resistance from

controller to engine, which ensures the accuracy of measured values for

both oil pressure and engine temperature.

If both switches and sensors are required for oil pressure and engine

temperature, connect Pin no. “11” and “12” as above, and connect 2

configurable inputs to the switches of oil pressure and temperature, then

configure parameters by setting.

DCP-10

Page 7/27

5. Control and Operation Instruction

5.1 Operation Mode Setting:

The controller has 2 modes: AUTO and MANUAL.

Operation Description

Press and hold the “AUTO” button for 2sec, the LED above the button

is illuminated; the controller is running in “AUTO” mode.

Press and hold the “MAN” button for 2sec, the LED above the button is

illuminated; the controller is running in “MAN” mode.

NOTE: Only 1 mode can be selected from above 2 modes.

5.2 AUTO control Sequence:

Controller is running in “AUTO” mode.

First of all, one of configurable inputs must be defined as Remote Start Signal.

When the remote start signal is active, the controller implements following procedure:

The Start delay timer is activated, when it times out the Preheat relay output is energized (if preheat

function selected), the timer starts. When it times out, the fuel relay output is energized, and operates the

fuel solenoid of the engine. After 300ms delay, the start (crank) relay output is energized; the start motor

engages and begins to crank. When the engine speed reaches the crank cutout RPM, the start relay

output is de-energized and the safety-on delay starts. When the safety-on times out, if the controller

detects that the parameters of the Genset such as voltage, frequency, oil pressure, coolant temperature

are normal, and no other failure is detected this indicates the Genset has successfully started and running

normally. The LCD displays the Genset Measuremen parameters.

When the voltage and frequency of Generator is normal, Gen. Normal LED illuminates, the timer for

Gen. On delay is activated, when it times out, GCB close/open relay closes,the transfer switch switches

on Gen. The Gen Aux. Switch’s contact feeds back a signal to a configurable input on our controller.

GCB closed LED illuminates.

NOTE:

When remote signal is active, the start-delay timer is activated. During

this period, if remote start signal is inactive, the start delay timer

terminates immediately; the controller will recovers to the original standby

status.

During cranking or idle period, if remote start signal is inactive, controller

stops the start procedure and recovers to original standby status.

DCP-10

Page 8/27

NOTE:

While cranking, engine ignites. The start motor will power off when the

output frequency of generator reaches the preset value (configurable

crank cutout value), or if there are one of the following conditions occur:

A. Generator’s voltage reaches 80% of rated voltage;

B. Cranking time’s up,

C. LOP switch is opened and the delay time’s up.

D. Oil pressure switch is opened or oil pressure is higher than crank

cutout value.

E. Cutout P-delay time’s up.

Controller can not implement crank procedure if the frequency of

generator reaches the preset value (configurable cranking cutout value)

or LOP switch is opened.

CAUTION:

To avoid damage to the start motor please make sure the generator’s

voltage is higher than the measurable value of controller while cranking,

since the crank cutout signal is sensed from the generator voltage and

frequency.

NOTE:

Above control procedure, assumes that one of configurable inputs has

been configured as Gen Aux. Switch Closed and connects the switch’s

N.O. Aux. contact signal to this port. If you do not configure an input as

Gen Aux. Switch Closed, then the GCB closed LED illuminates is only

an indication that the GCB close/open relay should have been closed.

If you have selected idle function, the idle relay will be closed at the same time as the crank relay is

closed. The timers of idle and safety-on delay will begin counting down at the same time, and in priority

to display the shorter one on the LCD, and the following procedure is the same as above.

During the crank period, if the engine can not ignite and controller will not output start signal during crank

rest, Fail to Start icon on LCD flashes at this time. Once crank rest timer times out the start relay

energizes once again and will attempt to start engine again.

The above procedure will be repeated until engine successfully ignites or reaches the preset number of

crank attempt. However, if any shutdown alarm occurs during crank, controller will stop cranking

immediately and only can be restarted after clearing failure and reset.

Fail to Start: when the above procedure repeats again and again and reaches the preset number of

crank attempt, the crank relay output is then de-energized. The failure LED illuminates and the LCD

displays Fail to Start.

CAUTION:

If Fail to Start occurs, operator must check the whole Genset system to

find out failure reason, only after clearing the failure can press

“STOP/RESET” button to relieve fault lock out status, and restart the

Genset.

Generator shutdown sequence:

When the remote start signal is deactivated, the timer for cool down is activated, When it times out, the

fuel relay de-energizes, the timer for cool down is activated,

DCP-10

Page 9/27

Stop Failure: When cool down times out, the fuel relay opens and the timer for Stop delay begins.

When it times out, if controller detects that the voltage and frequency of generator or oil pressure of

engine are greater than the preset values, the Fail to stop LED illuminates and the LCD displays Fail to

stop.

NOTE:

After stop failure, the controller will not energize the crank relay output if

the failure has not been removed and the controller reset.

5.3 MAN control sequence:

Controller is in “MANUAL” mode.

Generator starting sequence:

Pressing “START” button the fuel relay energises, and operates the fuel solenoid of engine.After 300ms

delay, the start relay output is energized, the start motor engages and begins to crank. When the engine

speed reaches the crank cutout RPM, the start relay output is de-energized and the safety-on delay starts.

When the safety-on times out, if the controller detects that the parameters of the Genset such as voltage,

frequency, oil pressure and coolant temperature are normal, and no other failure is detected this indicates

the Genset has successfully started and running normally. The LCD displays the Genset Measurement

parameters.

When generator is running normally, GCB close/open relay will not close automatically. Manually close

the Gen switch, Gen is on load, the Gen Aux. Switch’s contact feeds back the signal to a configurable

input on our controller, Gen. Normal LED illuminates.

5.4 The start and stop sequence of engine whose fuel solenoid is N. O. type:

Start control sequence:

During the starting sequence, the fuel relay of controller will not energize, fuel solenoid is no power, so

no signal is required for fuel solenoid to activate.

Stop control sequence:

During the stopping sequence, the fuel relay energizes, fuel solenoid is on power and energizes, and

the engine begins to stop. After a delay (same as stop delay) fuel relay de-energizes, disconnecting the

supply for the fuel solenoid.

Other control sequence is same as engine whose fuel solenoid is N. C. type.

NOTE:

When the controller is in “MANUAL” mode and Gen. Normal LED

illuminates, you must define one configurable input as Gen Aux. Switch

Closed and connect the switch’s N.O. Aux. contact signal to this port,

otherwise the GCB closed LED will not illuminate.

DCP-10

Page 10/27

5.5 Idle function:

For idle function configure one of the configurable outputs as idle.

Refer to the flow chart 5.7 for start and stop for idle control flows.

5.6 Preheat function:

For Preheat function, configure one of the configurable outputs as Preheat. The controller has 3

selectable preheat control modes as below:

Mode 1 — during preheat time, preheat relay output energizes.

Mode 2 — during preheat time, preheat relay output energizes until the successful ignition.

Mode 3 — during preheat time, preheat relay output energizes until safety-on delay times out.

During crank period, the Preheat relay output will not energize in any of above modes.

Refer to the flow chart 5.7 for start and stop for Preheat control flows.

When the Preheat relay output energizes, LCD displays the icon of preheat operating status:

DCP-10

Page 11/27

5.7 Flow chart for start and stop

T1- start delay

T2- crank time

T3- pre-heat time

T4- safety-on delay

T5- idle time

T6- stop delay

NOTE:

If T4 is longer than T5, low oil pressure protection is ignored during T5.

If T4 is shorter than T5, low oil pressure protection becomes effective

after T4 in T5.

DCP-10

Page 12/27

6. Measure and Display Data

Gen phase voltage L1-N L2-N L3-N

Gen line voltage L1-L2 L2-L3 L3-L1

Generator current I1 I2 I3

Generator frequency Hz

Engine speed RPM (signal derived from generator frequency)

Engine oil pressure BAR / PSI (signal from engine LOP sensor)

Engine coolant temperature ℃/℉ (signal from engine HET sensor)

Battery voltage Vdc

Genset Running hour Hour

DCP-10

Page 13/27

7. Pre-alarm and Shutdown Alarm

7.1 Pre-alarm (Warning)

NOTE: (Pre-alarms are non-critical failure conditions and do not affect the operation of the generator

system, they serve for drawing the operators’ attention to an undesirable condition so they can remove

it to ensure continuous running of the system. When Pre-alarms occur, the LED indicator flashes, but

failure will not be locked out and the unit will not shutdown. Once the Pre-alarm failure is removed the

Pre-alarm LED will automatically turn off.)

Pre-alarm / Description

LCD Display

CHARGE FAILURE: After safety-on times up, if the charging voltage

from the excitation contact of alternator is lower than the “charge V

Pre-alarm”, the common failure LED indicator ( ) flashes, the LCD

displays Charge failure icon:

BATT. UNDER VOLT: if controller detects that battery voltage has

fallen below the “Batt. Under volt”, common failure LED indicator

flashes. For example, “Batt. Under volt” preset as: 23.6V, when battery

voltage falls below this value, LCD flashing low value icon:

BATT. OVER VOLT: if controller detects that battery voltage has

exceeded the “Batt. Over volt”, common failure LED indicator flashes.

For example, “Batt. Over volt” preset as preset as: 28.2V, when battery

voltage exceeds this value, LCD flashing high value icon:

LOW OIL PRESS: if controller detects that the engine oil pressure has

fallen below the “Oil-P low preALM” after the safety-on timer expired,

common failure LED indicator flashes. For example, “Oil-P low preALM”

preset as: 2.2BAR, when engine oil pressure falls below this value,

LCD flashing low value icon:

HIGH TEMP: if controller detects that engine coolant temperature has

exceeded the “high temp pre-alarm”, common failure LED indicator

flashes. For example, “high temp pre-alarm” preset as: 95℃

℃℃

℃, when

engine coolant temperature exceeds this value, LCD flashing high

value icon:

OVER SPEED: if engine speed exceeds the “Over SP preALM”,

common failure LED indicator flashes. For example, “Over SP

preALM” preset as: 1600RPM, when engine speed exceeds this value,

LCD flashing high value icon:

UNDER SPEED: if engine speed falls below the “Under SP preALM”

after the safety-on timer has expired, common failure LED indicator

flashes. For example, “Under SP preALM” preset as: 1440RPM, when

engine speed falls below this value, LCD flashing low value icon:

DCP-10

Page 14/27

OVER CURRENT: if any phase output current of generator exceeds the

“over current pre-alarm” after the safety-on timer has expired, common

failure LED indicator flashes. For example, “over current pre-alarm”

preset as: 850A, when any phase output current of generator exceeds

this value, LCD flashing high value icon for corresponding phase:

GEN. OVER VOLT: if controller detects that any phase output voltage

of generator has exceeded the “GEN-V over preALM”after the safety-

on timer has expired, common failure LED indicator flashes. For

example, “Rated ph-voltage” preset as: 220V, “GEN-V over preALM”

preset as: 115%, when any phase output voltage of generator exceeds

this value, LCD flashing high value icon for corresponding phase:

GEN. UNDER VOLT: if controller detects that any phase output voltage

of generator has fallen below the “GEN-V under preALM”after the

safety-on timer has expired, common failure LED indicator flashes. For

example, “Rated ph-voltage” preset as: 220V, “GEN-V under

preALM”preset as: 90%, when any phase output voltage of generator

falls below this value, LCD flashing low value icon for corresponding

phase:

LOW FUEL LEVEL: If a configurable input has been defined as low

fuel level, when the input signal is active, common failure LED

indicator flashes, LCD displaying low fuel level icon:

AUXILIARY PRE-ALARM: if a configurable input is defined as pre-alarm,

when the input signal is active, common failure LED indicator flashes.

LCD displaying Aux. pre-alarm icon:

NOTE:

To make “low oil pressure” and “high temperature” pre-alarm active, you

must use LOP sensor and HET sensor, if you only use LOP and HET

switches, both pre-alarms are inactive.

NOTE:

Controller continuously detects battery voltage during standby and

Battery Low/High Voltage pre-alarms are active.

Battery Low Voltage pre-alarm is inactive during cranking.

CAUTION:

Under the period of safety-on delay, some pre-alarms (e.g.: under speed,

low voltage and low oil pressure) are inactive, the safety-on delay must

be carefully and properly set to make Genset have full protection.

DCP-10

Page 15/27

7.2 Shutdown Alarm

NOTE: (shutdown alarm failures immediately lock out the system and stop the Genset. The failure must

be removed and the controller reset before restarting the Genset.)

Shutdown Alarm / Description LCD Display

START FAILURE: if engine does not fire after the preset number of

crank attempt has been made, the Shutdown alarm LED illuminates.

LCD displays “start failure” icon:

STOP FAILURE: if engine does not stop after the stop delay expired,

the Shutdown alarm LED illuminates. LCD displays stop failure icon:

EMERGENCY STOP: Configure a configurable input as emergency stop,

when the input signal is active, controller immediately stops all relay

control outputs except alarm,Genset is shut down, the Shutdown alarm

LED illuminates, LCD displays emergency stop icon:

LOW OIL PRESS: if controller detects that the oil pressure level still falls

below “Oil-P low Alarm” or LOP switch closes after the safety-on timer

has expired, engine stops immediately, the Shutdown alarm LED

illuminates. LCD displays low oil pressure icon:

ENGINE HIGH TEMP: if controller detects that engine coolant

temperature has exceeded the “Coolant Alarm” or HET switch closes,

engine stops immediately, the Shutdown alarm LED illuminates. LCD

displays high temperature icon:

OVER SPEED: if controller detects that engine speed exceeds “Over SP

Alarm”, engine stops immediately, the Shutdown alarm LED illuminates.

LCD displays over speed icon:

OVER CURRENT: After safety-on delay time out, if controller detects

that any phase output current of generator exceeds the “over current

alarm”, the Genset will be shut down immediately, the Shutdown

alarm LED illuminates.

GEN. OVER VOLT: After safety-on delay times out, if controller detects

that one of the phase voltage exceeds the“GEN-V over Alarm”, the

engine will be shut down immediately, the Shutdown alarm LED

illuminates.

GEN. UNDER VOLT: After safety-on delay times up, if controller

detects that any phase output voltage is lower than the “Vac low

alarm”, the engine will be shut down immediately, common failure LED

illuminates.

AUXILIARY FAILURE: If a configurable input has been defined as

Shutdown Alarm, when the input signal is active, common failure LED

illuminates. LCD displays Aux. shutdown alarm icon:

DCP-10

Page 16/27

Code Table for Failure:

Name Code Name Code

CHARGE FAILURE

ENGINE HIGH TEMP

BATT. UNDER VOLT

OVER SPEED

BATT. OVER VOLT

UNDER SPEED

START FAILURE

OVER CURRENT

STOP FAILURE

GEN. OVER VOLT

EMERGENCY STOP

GEN. UNDER VOLT

LOW OIL PRESS

P-SENSOR OPEN

NOTE:

Engine speed signal is derived from the frequency of generator output

voltage, it is used for control and failure protection parameters, for the

convenience of user, some data is expressed by RPM, RPM = Hz * 60 /

pair of poles.

While the Genset is running, if there are high coolant temperature, low oil

pressure or over speed failure occurs, the controller will shutdown it

immediately without delay. During the cool down period, if there is low oil

pressure failure, the alarm will be active no matter if there is idle function.

CAUTION:

During the period of safety-on delay, low oil pressure protection is

inactive. To avoid starting an engine with no oil, you must make sure the

oil levels are normal and the safety-on delay shall be carefully and

properly set for the first commissioning.

DCP-10

Page 17/27

8. Parameters Setting

8.1 System Parameters:

NO. Items Preset Value Range

1.1 CT ratio

100 1-2000

1.2 VT ratio

1.0 1.0-100.0

1.3 Rated ph-voltage

220 45-9999Vac

1.4 AC voltage

2

1,3 (3 for 3 phase 4 wire, 1 for signal

phase 2 wire)

1.5 Startup mode

0 0-1 / 0 (MAN) / 1 (AUTO)

1.6 Oil pressure unit

0 0-1 (0-BAR,1-PSI)

1.7 Temperature unit

0

0-1 (0-℃,1-℉)

1.8 Comm. Address

1 1-247

1.9 Default settings

1.10 On-line update

1.11 Scroll time

0S 0-10 S / 0 (not used)

NOTE:

For 1.5 Startup Mode, When parameter is configured as “1”, the controller

will be in AUTO mode when it is powered on; When parameter is

configured as “0”, the controller will be in Manual mode when it is powered

on.

After the oil pressure and temperature units changed, the corresponding

failure alarm value must be reset according to actual situation.

Engine speed is calculated by the number of “pair of poles”. RPM=Hz * 60

/ pair of poles, when rated frequency is 50 Hz, if pair of poles set as “2”,

then running speed is 1500 RPM, if pair of poles set as “1” , then running

speed is 3000 RPM.

8.2 Generator Parameters:

NO. Items Preset Value Range

2.1 V under Alarm

0 20-200% / 0 (not set)

2.2 V under preALM

90% 20-200% / 0 (not set)

2.3 V over preALM

115% 20-200% / 9999 (not set)

2.4 V over Alarm

9999 20-200% / 9999 (not set)

2.5 Hz low alarm

45.0Hz 10.0-100.0Hz / 0 (not set)

2.6 Hz high alarm

57.0Hz 10.0-100.0Hz / 999.9 (not set)

2.7 Over current pre-alarm

100% 0-200%

2.8 Over current alarm

150% 0-200%

2.9 Over current action

0

0-1 (0- electrical tripping,

1-shutdown alarm)

2.10 Alarm delay

10S 0-600 S

2.11 Gen. On delay

5S 1-9999 S

2.12 GCB opening delay

5S 1-9999 S

DCP-10

Page 18/27

8.3 Engine Parameters:

NO. Items Preset Value Range

3.1 Pair of poles

2 1-4

3.2 Fuel mode

0 0-1 / 0(NC) / 1 (NO)

3.3 T-sensor type

12 0-15 / 0 (not used)

3.4 P-sensor type

11 0-15 / 0 (not used)

3.5 Start delay

10S 0-300 S

3.6 Crank attempt

3 times 1-10 times

3.7 Crank time

5S 0-30 S

3.8 Crank rest

10S 0-300 S

3.9 Crank cutout RPM

300RPM 1-9999 RPM

3.10 Crank cutout Oil-P

1.0BAR

0.1-150.0BAR/999.9(not set)

3.11 cutout P-delay

0 1-60 S / 0(not set)

3.12 Idle delay

0 0-9999 S

3.13 Preheat delay

3S 0-300 S

3.14 Preheat mode

1 1-3

3.15 Safety-on delay

10S 0-600 S

3.16 Cool down delay

300S 0-600 S

3.17 Stop delay

20S 0-60 S

3.18 Under SP Alarm

0RPM 0-9999 RPM / 0 (not set)

3.19 Under SP preALM

1440RPM 0-9999 RPM / 0 (not set)

3.20 Over SP preALM

1600RPM 1-9999 RPM / 9999 (not set)

3.21 Over SP Alarm

1710RPM 1-9999 RPM / 9999 (not set)

3.22 Oil-P low Alarm

1.1BAR 0-45.0 BAR

3.23 Oil-P low preALM

1.4BAR 0-45.0 BAR

3.24 Coolant preALM

92℃ 70-320℃ / 9999 (not set)

3.25 Coolant Alarm

100℃ 70-320℃ / 9999 (not set)

3.26 Batt. Undervolt.

8.0V 1.0-25.0V / 0 (not set)

3.27 Batt. overvolt.

28.0V 1.0-35.0V / 99.9 (not set)

3.28 charge V Pre-alarm

8.0V 1.0-25.0V / 0 (not set)

8.4 Configurable Inputs and Outputs:

NO. Items Preset Value Range

4.1 Configurable input 1

8 0-12 (define code as 8.7)

4.2 Configurable input 2

7 0-12 (define code as 8.7)

4.3 Configurable input 3

12 0-12 (define code as 8.7)

4.4 Input 1 delay

2S 0-60 S

4.5 Input 2 delay

2S 0-60 S

4.6 Input 3 delay

2S 0-60 S

4.7 Configurable relay 1

2 0-80 (define code as 8.8)

4.8 Configurable relay 2

3 0-80 (define code as 8.8)

4.9 Configurable relay 3

5 0-80 (define code as 8.8)

NOTE: D-Input Delay is only for 1 to 4 codes in 8.7.

DCP-10

Page 19/27

8.5 Calibration Menu:

NO. Items Preset Value Range

5.1 GEN. V1 offset

±10.0%

5.2 GEN. V2 offset

±10.0%

5.3 GEN. V3 offset

±10.0%

5.4 Current I1 offset

±10.0%

5.5 Current I2 offset

±10.0%

5.6 Current I3 offset

±10.0%

5.7 Pressure offset

±10.0%

5.8 Temperature offset

±10.0%

5.9 Batt. V offset

±10.0%

8.6 The optional items for P/T-sensor:

Code The brand model of LOP sensor The brand model of HET sensor

0 not used not used

1 close for low oil pressure close for high temperature

2 open for low oil pressure open for high temperature

3 VDO 5 bar

VDO 120 ℃

4 VDO 10 bar

VDO 150 ℃

5 Datcon 7 bar Datcon

6 Murphy 7 bar Murphy

7 Pre-set 1 PT100

8 Pre-set 2 Pre-set 1

9 Pre-set 3 Pre-set 2

10 Pre-set 4 Pre-set 3

11 configured by user Pre-set 4

12 configured by user

NOTE:

When the controller leaves factory, the optional types and functions of

LOP sensor and HET sensor have been preset as the above table. If the

using sensor is not listed in this table, the user can select “configurable”,

and write sensor parameters to controller via software.

LOP sensor parameter addendum:

VDO 5 bar:

VDO 10 bar:

P(Bar)

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5

P(PSI)

0 7.3

14.5

21.8

29.0

36.3

43.5

50.8

58.0

65.3

72.5

R(Ω)

11 29 47 65 82 100 117 134 151 167 184

P(Bar)

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

P(PSI)

0 14.5

29.0

43.5

58.0

72.5

87.0

101.5

116.0

130.5

145.0

R(Ω)

10 31 52 71 90 106 124 140 155 170 184

DCP-10

Page 20/27

Datcon 7 bar:

Murphy 7 bar:

Pre-set 1:

Pre-set 2:

Pre-set 3:

Pre-set 4:

Type 11:

::

:

HET sensor parameter addendum:

VDO 120℃

℃℃

℃:

VDO 150℃

℃℃

℃:

P(Bar)

0.0 0.7 1.4 2.1 2.8 3.4 4.1 4.8 5.5 6.2 6.9

P(PSI)

0 10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

R(Ω)

240 200 165 135 115 95 78 63 48 35 25

P(Bar)

0.0 0.7 1.4 2.1 2.8 3.4 4.1 4.8 5.5 6.2 6.9

P(PSI)

0 10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

R(Ω)

240 205 171 143 123 103 88 74 60 47 33

P(Bar)

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

P(PSI)

0 14.5

29.0

43.5

58.0

72.5

87.0

101.5

116.0

130.5

145.0

R(Ω)

15 31 49 66 85 101 117 132 149 164 178

P(Bar)

0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0

P(PSI)

0 14.5

29.0

43.5

58.0

72.5

87.0

101.5

116.0

130.5

145.0

R(Ω)

30 41 65 88 110 115 145 150 172 185 190

P(Bar)

0.0 1.7 3.4 5.2 6.9 8.6 10.3

P(PSI)

0 25 50 75 100 125 150

R(Ω)

21 36 52 72 84 100 120

P(Bar)

0.0 1.0 2.0 3.0 4.0 5.0 6.0 6.5 7.0 8.0 9.0

P(PSI)

0 14.5 29.0 43.5 58.0 72.5 87.0 94.3 101.5

116.0

130.5

R(Ω)

251 195 155 127 107 88 72 65 61 54 48

P(Bar) 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

R(Ω)

21.5

25 27.6

30.2

33.5

36.8

40.3

43.2

46.9

50.6

V 0.48 0.55 0.6 0.65 0.71 0.77 0.83 0.88 0.94 1.0

T(℃)

40 50 60 70 80 90 100 110 120 130 140

T(℉)

104 122 140 158 176 194 212 230 248 266 284

R(Ω)

291 197 134 97 70 51 38 29 22 18 15

T(℃)

50 60 70 80 90 100 110 120 130 140 150

T(℉)

122 140 158 176 194 212 230 248 266 284 302

R(Ω)

322 221 155 112 93 62 47 37 29 23 19

DCP-10

Page 21/27

Datcon:

Murphy:

PT100:

Pre-set 1:

Pre-set 2:

Pre-set 3:

Pre-set 4:

Type 12:

::

:

8.7 The optional items for configurable input:

Code Optional Function NOTE

0 not used

1 Pre-alarm (active immediately) low level is active

2 Shutdown Alarm(active immediately) low level is active

3 Pre-alarm (active after safety-on delay) low level is active

4 Shutdown Alarm(active after safety-on delay) low level is active

T(℃)

40 50 60 70 80 90 100 110 120 130 140

T(℉)

104 122 140 158 176 194 212 230

248 266 284

R(Ω)

900 600 400 278 200 141 104 74 50 27 4

T(℃) 40 50 60 70 80 90 100 110 120 130 140

T(℉)

104 122 140 158 176 194 212 230 248 266 284

R(Ω)

1029 680 460 321 227 164 120 89 74 52 40

T(℃)

-100

-50 0 20 40 60 80 100 150 200 300

T(℉)

-148

-58 32 68 104 140 176 212 302 392 572

R(Ω)

60 81 100 108 116 123 131 139 157 176 212

T(℃) 20 30 40 50 60 70 80 90 100 110 120

T(℉) 68 86 104 122 140 158 176 194 212 230 248

R(Ω)

900 600 420 282 152 113 86 62 48 40 30

T(℃) 30 50 60 70 80 90 100 110 120

T(℉) 86 122 140 158 176 194 212 230 248

R(Ω)

980 400 265 180 125 90 65 50 38

T(℃) 20 30 40 50 60 70 80 90 100 110 120

T(℉) 68 86 104 122 140 158 176 194 212 230 248

R(Ω)

805 540 380 260 175 118 83 58 42 30 21

T(℃) 28 35 40 50 60 70 80 90 95 98

T(℉) 82 95 104 122 140 158 176 194 203 208

R(Ω)

579 404 342 250 179 136 103 77 67 63

T(℃) 150 130 110 90 80 70 50 25 0 0

R(Ω) 6.9 10.8 17.7 30.6 41.1 56.3 111.8

300 964.4

964.4

DCP-10

Page 22/27

5 LOP switch low level is active

6 HET switch low level is active

7 Emergency stop low level is active

8 Remote start signal low level is active

9 Reserved low level is active

10 Gen Aux. Switch closed low level is active

11 Low fuel level low level is active

12 Lamp test low level is active

8.8 The optional items for configurable output:

Code Failure Type Define Code Failure Type Define

0 Not used 1 Over current tripping

2 Alarm 3 Pre-alarm

4 Idle 0 (N.C.) 5 Preheat

6 Speed up 7 Reserved

8 Fuel pump control 9 Running

10 System in AUTO mode 11 Reserved

12 System in MAN mode 13 Reserved

14 Idle 1 (N.O.) 15 Reserved

16 GCB failure (within 5s) 17 Fail to start

NOTE:

If define one configurable relay as Speed up, the relay will close after the

engine has successfully started. If there is idle function, the relay will

close after idle timer times out.

DCP-10

Page 23/27

9. LCD Display and Menu System

Using a backlit TN type LCD to display data and information. After pressing any push button the

backlight will automatically turn off in a preset time. In normal operating status, you can set the page

scroll time to circularly display each page of measuring data. Press “ ” manually scrolls to view each

measuring data. When failure occurs, LCD displays the corresponding failure icon.

Press and hold “ ” button 2sec to enter into parameters setting menu, then use “ ” or “ ” to scroll

page, press “ ” again to select the required modify item, press “ ” or “ ”, LCD displays 0 0 0 0 when

prompted to enter password, then use “ ” or “ ” to modify the first digital value, press “ ” move to

modify the next one, after this, the first digital value will be displayed as “H”. Press “ ” to confirm after

the password is set as 2213, then you can modify parameters. Otherwise it will prompt to key in

password again. Press and hold “ ” for more than 2sec to quit parameters setting mode after finishing

configuration.

9.1 Static LCD displays

Controller is in standby status, circularly displays each measuring data:

→

→→

→

Controller is normally running, circularly displays each measuring data:

→

→→

→

→

→→

→

→

→→

→

→

→→

→

NOTE:

When T-sensor or P-sensor is set as “not used”, LCD will not display related

measuring data.

DCP-10

Page 24/27

9.2 Setting running parameters

For example: (setting CT ratio at 1000/5, then CT should be configured as 200)

Operation Description

Press and hold “ ” 2sec, enter into parameters setting menu, then LCD

displays:

press “ ”, then LCD displays:

Press “ ”, prompted enter password, then LCD displays:

Press “ ” or “ ” prompted enter password: (2213), then press “ ”

again, press “ ” or “ ” to change parameter, change at 200, then LCD

displays:

Press “ ” to confirm,then press “ ”, then LCD displays:

Press “ ” again to quit, or press and hold “ ” more than 2s also can

quit, then LCD displays:

For example: (setting controller crank attempt at 2)

Operation Description

Press and hold “ ” 2sec, enter into parameters settings menu, then

LCD displays:

Press “ ” 28 times and then press “ ”, then LCD displays:

press “ ” prompted enter password, then LCD displays:

Key in password: (2213), press “ ”, then LCD displays:

Press “ ” or “ ” change parameter, change at 2, Press “ ” to confirm

change, and then press and hold “

” for more than 2sec will quit

parameter settings menu.

DCP-10

Page 25/27

For example: (resume parameters of controller to factory default)

Operation Description

Press and hold “ ” 2sec, enter into parameter settings menu, then LCD

displays:

Press “ ” 8 times, then LCD displays:

press “ ” prompted enter password, then key in password: (2213)

Press “ ” to recover default, press and hold “ ” for more than 2sec will

quit parameters setting menu.

For example: (configure controller as online program mode)

Operation Description

Press and hold “ ” 2sec, enter into parameter settings menu, then LCD

displays:

Press “ ” 9 times and then LCD displays:

press “ ” prompted enter password, then key in password: (3132)

Press “ ” again to enter into online program mode, use the

communication cable and the software to program, please make sure

the power supply is normal during programming, the controller will

reset automatically after programming. If you have entered into this

mode already, but you do not program, you need to turn the controller

off to exit this mode.

DCP-10

Page 26/27

10. Preparation before Starting the Controller

10.1 Make sure the controller is correctly installed to meet the ambient requirements.

10.2 Confirm all wiring connections of the controller meet the correct electric specification and

corresponding to “2.3 typical wiring diagram”. Ensure the correct polarity of the DC supply source

and that it has been protected by an external fuse. Otherwise damage to the controller may occur.

10.3 We recommend mounting an “Emergency Stop” button externally. The emergency stop input could

be connected to N.O. contact of emergency stop push button, and the other contactor point be

connected to the battery negative.

10.4 Switch on DC working power, make sure the preset parameters meet practical operating conditions,

such as P-sensor mode, T-sensor mode, etc.

DCP-10

Page 27/27

11. Technical Specification

DC working power

Voltage range: 12V/24V (8-35V continuous)

Cranking drop outs: 0V for 100mS, assuming dc supply was at least 10V before dropout and recovers

to 5V

Max. operating current: @12V 180mA, @24V 90mA

Standby current: TBA

AC input voltage: phase voltage15-300Vac RMS (AC frequency≥40 Hz)

AC input frequency: 3-70Hz (voltage ≥15V)

Accuracy: 1%

Aux Control relay output: 3A/30Vdc

Start relay output: 3A/30Vdc

Fuel relay output: 3A/30Vdc

Protection: IP65 (when correctly installed)

Operating ambient temperature: -20 to 70℃

Storage ambient temperature: -30 to 80℃