-

04-11-2014

#1

Junior Member

- Rep Power

- 0

C5101. error on Ta4550ci

Have swapped Black charge roller and drum unit. Still getting error. Is it main HV. Pcb?

-

04-11-2014

#2

Re: C5101. error on Ta4550ci

There is a troubleshooting guide that Kyocera has for that model, the file size is 16 meg if you have an email I can scan you the pages that pertain to your issue.

-

11-04-2014

#3

Technician

- Rep Power

- 0

Re: C5101. error on Ta4550ci

Hi,

I have a 4550CI that gives an error C-5101

Mostly early in the morning immediatly after switching on the machine.

Sometimes the machine works normal en it gives the error during a printjob.I already replaced: Drumunit (incl. maincharger)

main HV board

engineboard

main pwb.……………………but still the same code.

What can be the solution of this problem?

thanks in advance.

Grtz.

Dikyo

Last edited by dikyo; 11-04-2014 at 08:27 PM.

-

04-28-2015

#4

Trusted Tech

50+ Posts

- Rep Power

- 29

Re: C5101. error on Ta4550ci

Originally Posted by RickyG

Have swapped Black charge roller and drum unit. Still getting error. Is it main HV. Pcb?

Hi Guys,

We had a TA4550ci with this error. It looks like we fixed it with the K main charge and resetting U930.

Our problem was we tried swapping out the K drum unit from another machine so we didnt reset U930, the error kept occurring and lead us down the HVT/Engine PWB/Drum Drive path with no results.

Its turned on this morning and worked perfectly.

The only other problem it had was faint black text on the first copy out after not being used for a few hours during the day which im guessing was tied in with the main charge issue, just not bad enough to bring up the error.

-

04-30-2015

#5

Re: C5101. error on Ta4550ci

uh…

It could be that its too cold and wet overnight. In the morning after room temperature warms up it has moisture in the system.

Idling colour developers are not healthy developers.

-

04-30-2015

#6

Trusted Tech

50+ Posts

- Rep Power

- 29

Re: C5101. error on Ta4550ci

Originally Posted by jmaister

uh…

It could be that its too cold and wet overnight. In the morning after room temperature warms up it has moisture in the system.

Our machine reproduced the same error code in our workshop, 2 other taskalfa’s next to it in the same conditions worked fine.

-

04-30-2015

#7

Re: C5101. error on Ta4550ci

ah ok.

if anyone gets random c5101/2/3/4, check environment~~~ could be.

Last edited by jmaister; 04-30-2015 at 08:27 AM.

Idling colour developers are not healthy developers.

-

04-30-2015

#8

Technician

- Rep Power

- 31

Re: C5101. error on Ta4550ci

Originally Posted by jmaister

ah ok.

if anyone gets random c5101/2/3/4, check environment~~~ could be.

the fix for this is to reset the charge roller count when it has done over life. unfortunately the majority of engineers when changing the charge roller itself do not reset the count so the machine still thinks it has done many thousands of copies so it will try and compensate for this. there comes a point when the machine says the high voltage unit cant give anymore and it throws a charge code. if in a cold enviro what I did was to fit the tray heaters from an old voyager 2525 and enabled the tray heaters -job done good luck

-

05-22-2015

#9

Re: C5101. error on Ta4550ci

Originally Posted by GUNit

the fix for this is to reset the charge roller count when it has done over life. unfortunately the majority of engineers when changing the charge roller itself do not reset the count so the machine still thinks it has done many thousands of copies so it will try and compensate for this. there comes a point when the machine says the high voltage unit cant give anymore and it throws a charge code. if in a cold enviro what I did was to fit the tray heaters from an old voyager 2525 and enabled the tray heaters -job done good luck

its uncanny how this worked right away. one color machine rebooted to this error code, replaced charge roller (but it came back few days later). The following visit u930 reset count executed, next reboot gave no problem and its been a week, no call back.

thx Kyocera engineer, another undocumented trick.

Idling colour developers are not healthy developers.

-

05-26-2015

#10

Technician

- Rep Power

- 31

Re: C5101. error on Ta4550ci

Originally Posted by jmaister

its uncanny how this worked right away. one color machine rebooted to this error code, replaced charge roller (but it came back few days later). The following visit u930 reset count executed, next reboot gave no problem and its been a week, no call back.

thx Kyocera engineer, another undocumented trick.

Think the general rule to follow is if there is a counter for it then reset it, the great thing about digital is there are so many calibrations and compensations for aging and dirty optics etc going on in the background that a lot of engineers forget this. if you think back to the analogue days when your optics got dirty then you got crappy copies, especially in dusty enviros, whereas now with digital you don’t. this is why when you clean the optics you need to do auto grey adjust just to bring back everything to base level again, just like saying ok the high voltage has adjusted enough for that 600k charge roller ill change it but I must tell the machine I have so it can once again return to base level and start recounting and compensating. hope this makes sense and glad you are up and running again.

Bookmarks

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

- Code: 0030

- Description: FAX control PWB system error

Processing with the fax software was disabled due to a software problem. - Causes: FAX control PWB

- Remedy: 1. Turn the main power swtch off and after 5 seconds, re-mount the FAX controller PWB, then turn power on. 2. Reinstall the fax software. 3. Replace the FAX control PWB.

- Code: 0060

- Description: Engine PWB mismatch

Unmatching engine and engine sub boards. Defective engine subboard. - Causes: Engine PWB

- Remedy: 1. Turn the main power swtch off and after 5 seconds, then turn power on. 2. Replace the engine PWB.

- Code: 0070

- Description: FAX control PWB incompatible detection error

Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted. - Causes: FAX control PWB (The FAX PWB installed will not be the one designed for the machine).

- Remedy: 1. Install the FAX system designed for the model. 2. Reinstall the fax software.

- Code: 0100

- Description: Backup memory device error

- Causes: EEPROM(main PWB)

- Remedy: 1. Turn the main power swtch off and after 5 seconds, then turn power on. 2. Check that the EEPROM on the main circuit PWB is peroperly installed on the main circuit PWB and, if not, re-install it. 3. Replace the main PWB.

- Code: 0120

- Description: MAC address data error

For data in which the MAC address is invalid. - Causes: EEPROM(main PWB)

- Remedy: 1. Turn the main power swtch off and after 5 seconds, then turn power on. 2. Check the MAC address on the network status page. 3. If it is blank, obtain an EEPROM with its MAC address written from the service support and install. 4. Replace the main PWB.

- Code: 0150

- Description: Backup memory read/write error (engine PWB)

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated 5 times successively. Mismatch of reading data from 2 locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. - Causes: EEPROM (engine PWB)

- Remedy: 1. Turn the main power swtch off and after 5 seconds, then turn power on. 2. Check that the EEPROM is peroperly installed on the engine PWB and reinstall it. 3. Replace the engine PWB. 4. Check the EEPROM and if the data are currupted, contact the service support.

- Code: 0160

- Description: Backup memory data error (engine PWB)

Reading data from EEPROM is abnormal. - Causes: EEPROM

- Remedy: 1. Turn the main power swtch off and after 5 seconds, then turn power on. 2. Execute U021 — memory initializing.(see page 1-3-28) 3. If the EEPROM data are currupted, contact the service support.

- Code: 0170

- Description: Billing counting error

The values on the main circuit PWB and on the engine do not match for any of charging counter, life counter, and scanner counter. - Causes: EEPROM. Main PWB. Engine PWB

- Remedy: EEPROM 1. Check that the EEPROMs installed in the main PWB and the engine PWB are correct and, if not, use the correct EEPROM for the model. 2. If the EEPROM data are currupted, contact the service support.

Main PWB Replace the main PWB.

Engine PWB Replace the engine PWB.

- Code: 0180

- Description: Machine number mismatch

Machine number of main and engine does not match. - Causes: Data damage of EEPROM.

- Remedy: 1. Confirm the machine data for the main and engine units by using U004. 2. If the serial number data of different models is alternately displayed, install the correct EEPROM in the PWB of the wrong serial number data. 3. Contact the Service Support.

- Code: 0350

- Description: Panel PWB communication error (electronic volume I2C communication error) NACK is received during I2C communication — retried 5 times — rebooting command sent — retried 5 times If NACK is still received.

- Causes: Operation PWB. Main PWB

- Remedy: Operation PWB 1. Turn the main power swtch off and after 5 seconds, then turn power on. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Operation PWB (YC10) and Main PWB (YC6) 3. If the wiring is disconnected, shorted or grounded, replace the wiring.

Main PWB Replace the main PWB.

- Code: 0620

- Description: FAX image DIMM error 1.

The Fax image DIMM has not been installed. 2. Fax image DIMM access error. - Causes: FAX image DIMM. Main PWB.

- Remedy: FAX image DIMM 1. Install the FAX image DIMM supplied in the FAX system onto the main PWB. 2. Firmly install the FAX image DIMM again onto the main board. 3. Check the FAX image DIMM terminals and remove any foreign objects that may be adhered to it. 4. Replace with a new FAX image DIMM.

Main PWB. Replace the main PWB.

- Code: 0630

- Description: DMA error

DMA transmission of image data does not complete within the specified period of time. - Causes: DP CIS. DP main PWB Main PWB

- Remedy: DP CIS 1. Reconnect the CIS signal line. 2. Confirm that the CIS connector terminals are firmly connected. Insert the connector all the way in. 3. If the wiring is disconnected, shorted or grounded, replace the wiring.

DP main PWB Main PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. 2. If the wiring is disconnected, shorted or grounded, replace the wiring. Wiring that connects the CIS and the DP controller PWB. Wiring that connects the DP main PWB and the main PWB. 3. Replace the DP main PWB. 4. Replace the main PWB.

- Code: 0640

- Description: Hard disk error

The hard disk cannot be accessed. - Causes: HDD. Main PWB

- Remedy: HDD 1. If an abnormal noise is heard from the HDD, replace the HDD. 2. Check the SATA wiring between the HDD and the main circuit PWB for loose connection, disconnection and damages, and that it is connected into the correct terminal. Main PWB: YC1,YC27 3. Replace the SATA cable. 4. Execute U024 to initialize (FULL) the HDD. 5. If an error is detected after executing U024, replace the HDD.

Main PWB Replace the main PWB.

- Code: 0650

- Description: FAX image DIMM check error

A fax image DIMM which was used with another machine is installed. - Causes: FAX DIMM. Main PWB.

- Remedy: FAX DIMM. 1. Confirm that a used FAX image DIMM was used instead of the FAX image DIMM contained in the FAX system. 2. If a DIMM that was used with other unit has been installed, execute maintenance mode U671 — Recovery FAX DIMM. 3. Check whether the Fax DIMM is properly inserted into the socket on the main PWB. 4. Replace with a new FAX image DIMM.

Main PWB Replace the main PWB.

- Code: 0660

- Description: Hard disk encryption key error

- Causes: EEPROM. HDD. Main PWB

- Remedy: EEPROM 1. Execute U004 if this occurs after the EEPROM has been changed.

HDD 1. If an abnormal noise is heard from the HDD, replace the HDD. 2. Check the SATA wiring between the HDD and the main circuit PWB for loose connection, disconnection and damages, and that it is connected into the correct terminal. Main PWB: YC1,YC27 3. Replace the SATA cable. 4. Execute U024 to initialize (FULL) the HDD. 5. If an error is detected after executing U024, replace the HDD.

Main PWB Replace the main PWB.

- Code: 0670

- Description: Hard disk overwriting erasure error

- Causes: HDD. Main PWB.

- Remedy: HDD 1. If an abnormal noise is heard from the HDD, replace the HDD. 2. Check the SATA wiring between the HDD and the main circuit PWB for loose connection, disconnection and damages, and that it is connected into the correct terminal. Main PWB: YC1,YC27 3. Replace the SATA cable. 4. Execute U024 to initialize (FULL) the HDD. 5. If an error is detected after executing U024, replace the HDD.

Main PWB Replace the main PWB.

- Code: 0800

- Description: Image processing error

JAM010X is detected twice. - Causes: Main PWB

- Remedy: Replace the main PWB.

- Code: 0830

- Description: FAX control PWB flash program area checksum error

A checksum error occurred with the program of the FAX control PWB. - Causes: FAX software. FAX control PWB.

- Remedy: FAX software 1. Reinstall the fax software.

FAX control PWB 1. Execute initializing by U600.(Refer to the FAX service manual) 2. Replace the FAX control PWB.

- Code: 0840

- Description: Faults of RTC

(“Time for maintenance T” is displayed) [Check at power up] The RTC setting has reverted to a previous state. The machine has not been powered for 5 years (compared to the settings stored periodically in the EEPROM). The RTC setting is older than 00:01 on January 1, 2000. [Checked periodically (in 5- minute interval) after powered up] The RTC setting has reverted to a state older than the last time it was checked. 10 minutes have been passed since the previous check. After C840 is detected, the machine enters in disconnection mode after the main power switch has been switched on and off and indicates ‘Maintenance T.’ - Causes: Battery ( main PWB). Main PWB.

- Remedy: Battery ( main PWB) 1. Make sure that the back-up batteries on the main PWB are not short-circuited. 2. Reset Maintenance T by executing U906. 3. If the same C call is displayed when power is switched on and off, replace the back up battery. 4. If communication error (due to a noise, etc.) is present with the RTC on the main circuit PWB, check the PWB is properly grounded.

Main PWB Replace the main PWB.

- Code: 0870

- Description: PCFAX control PWB to main PWB high capacity data transfer error

High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times. - Causes: FAX control PWB. HDD. Main PWB.

- Remedy: FAX control PWB 1. Turn the main power swtch off and after 5 seconds, re-mount the FAX controller PWB, then turn power on. 2. Replace the FAX control PWB.

HDD Execute U024 to initialize the HDD.

Main PWB Replace the main PWB.

- Code: 0920

- Description: Fax file system error

The backup data is not retained for file system abnormality of flash memory of the FAX control PWB. - Causes: FAX control PWB.

- Remedy: 1. Execute initializing by U600 (Refer to the FAX service manual). 2. Replace the FAX control PWB.

- Code: 0980

- Description: 24 V power down detect

If a 24V power disconnection signal is observed and a 12V power disconnection signal is observed simultaneously for one second. - Causes: Power source PWB.

- Remedy: 1. Check the +24V output is given at YC12- 1 to 3 of the power circuit PWB. 2. Replace the power source PWB

- Code: 1000

- Description: MP lift motor error

If the MP lift sensor 1 (upper limit detect) or 2 (bottom detect) is not detectable to be turned on while the MP lift motor is ascending or descending. - Causes: Manual feed lift base elevating mechanism. MP lift motor. MP lift sensor1. MP lift sensor2. Feed PWB 2. Engine PWB.

- Remedy: Manual feed lift base elevating mechanism 1. Check that the paper lift base of the manual feed tray can smoothly ascend and descent, if not, repair or replace. 2. Check that the lift lever is located so that it can ascend or descend by the lift motor cam and that it not damaged and, if necessary, re-install or replace the manual feed table.

MP lift motor 1. Check that the paper elevator has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. MP lift motor and Relay PWB (YC3) Relay PWB (YC12) and Feed PWB1 (YC17) Feed PWB1 (YC1) and Engine PWB (YC6) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the MP lift motor.

MP lift sensor1 MP lift sensor2 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. MP lift sensor1,2 and Relay PWB (YC3) Relay PWB (YC12) and Feed PWB1(YC17) Feed PWB1 (YC1) and Engine PWB (YC6) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the MP lift sensor1 or MP lift sensor2.

Feed PWB 2 Replace the Feed PWB 2.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 1010

- Description: Lift motor 1 error

After cassette 1 is inserted, lift sensor 1 does not turn on within 12 s. This error is detected 5 times successively. The lock signal of the motor is detected continuously for 1 s. This error is detected 5 times successively. - Causes: Cassette lift base elevating mechanism. Lift motor 1. Lift sensor 1. Feed PWB 2. Engine PWB.

- Remedy: Cassette lift base elevating mechanism Check that the cassette base can be manipulated smoothly, if not, repair or replace.

Lift motor 1 1. Check that the cassette base has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Lift motor 1 and Feed PWB 2 (YC3) Feed PWB 2 (YC1) and Engine PWB (YC4) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the lift motor 1.

Lift sensor 1 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Lift sensor 1 and Feed PWB 2 (YC8) Feed PWB 2 (YC1) and Engine PWB (YC4) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the lift sensor1.

Feed PWB 2 Replace the Feed PWB 2.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 1020

- Description: Lift motor 2 error

After cassette 2 is inserted, lift sensor 2 does not turn on within 12 s. This error is detected 4 times successively. The lock signal of the motor is detected continuously for 1 s. This error is detected 4 times successively. - Causes: Cassette lift base elevating mechanism. Lift motor 2. Lift sensor 2. Feed PWB 2. Engine PWB.

- Remedy: Cassette lift base elevating mechanism Check that the cassette base can be manipulated smoothly, if not, repair or replace.

Lift motor 2 1. Check that the cassette base has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Lift motor 2 and Feed PWB 2 (YC3) Feed PWB 2 (YC1) and Engine PWB (YC4) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the lift motor 2.

Lift sensor 2 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Lift sensor 2 and Feed PWB 2 (YC8) Feed PWB 2 (YC1) and Engine PWB (YC4) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the lift sensor2.

Feed PWB 2 Replace the Feed PWB 2.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 1030

- Description: PF lift motor 1 error (paper feeder)

After cassette 3 is inserted, PF lift sensor 1 does not turn on within 12 s. This error is detected 5 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 1 s or more 5 times successively. However, the first 1 s after motor is turned on is excluded from detection. - Causes: PF Lift motor 1. PF Lift sensor 1. PF main PWB.

- Remedy: Cassette lift base elevating mechanism Check that the cassette base can be manipulated smoothly, if not, repair or replace.

PF Lift motor 1 1. Check that the cassette base has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift motor 1 and main PWB (YC7) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. PFReplace the lift motor 1.

PF Lift sensor 1 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift sensor 1 and PF main PWB (YC7) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the lift sensor 1.

PF main PWB Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1040

- Description: PF lift motor 2 error (paper feeder)

After cassette 4 is inserted, PF lift sensor 2 does not turn on within 12 s. This error is detected 5 times successively. During driving the motor, the lift overcurrent protective monitor signal is detected for 1 s or more 5 times successively. However, the first 1 s after motor is turned on is excluded from detection. - Causes: Cassette lift base elevating mechanism. PF Lift motor 2. PF Lift sensor 2. PF main PWB.

- Remedy: Cassette lift base elevating mechanism Check that the cassette base can be manipulated smoothly, if not, repair or replace.

PF Lift motor 2 1. Check that the cassette base has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift motor 2 and PF main PWB (YC7) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the PF Lift motor2.

PF Lift sensor 2 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift sensor 2 and PF main PWB (YC7) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the PF Lift sensor 2.

PF main PWB Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1100

- Description: PF lift motor 1 error (large capacity feeder)

After cassette 3 is inserted, PF lift sensor 1 does not turn on within 23 s. This error is detected 5 times successively. (Time to detect is 2 seconds at the second time and later.) During driving the motor, the lift overcurrent protective monitor signal is detected for 200 ms or more 5 times successively. However, the first 1 s after PF lift motor 1 is turned on is excluded from detection - Causes: Paper feeder lift base elevating mechanism. PF Lift motor1. PF Lift sensor1. PF main PWB.

- Remedy: Paper feeder lift base elevating mechanism Check that the cassette base can be manipulated smoothly, if not, repair or replace.

PF Lift motor1 1. Check that the cassette base has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift motor 1 and PF main PWB (YC7) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the PF lift motor1.

PF Lift sensor1 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift sensor 1 and PF main PWB (YC5) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the PF lift sensor1.

PF main PWB Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1110

- Description: PF lift motor 2 error (large capacity feeder)

After cassette 4 is inserted, PF lift sensor 2 does not turn on within 23 s. This error is detected 5 times successively. (Time to detect is 2 seconds at the second time and later.) During driving the motor, the lift overcurrent protective monitor signal is detected for 200 ms or more 5 times successively. However, the first 1 s after PF lift motor 2 is turned on is excluded from detection - Causes: Paper feeder lift base elevating mechanism. PF Lift motor 2. PF Lift sensor2. PF main PWB.

- Remedy: Paper feeder lift base elevating mechanism Check that the cassette base can be manipulated smoothly, if not, repair or replace.

PF Lift motor 2 1. Check that the cassette base has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift motor 2 and PF main PWB (YC7) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the PF Lift motor2.

PF Lift sensor2 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF Lift sensor 2 and PF main PWB (YC4) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the PF Lift sensor 2.

PF main PWB Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1140

- Description: SD lift motor error (side deck)

After cassette 5 is inserted, SD lift sensor does not turn on within 30 s. The lock signal of the motor is detected continuously for 200 ms. - Causes: Paper feeder lift base elevating mechanism. SD Lift motor. SD Lift sensor. SD main PWB.

- Remedy: Paper feeder lift base elevating mechanism Check that the cassette base can be manipulated smoothly, if not, repair or replace.

SD Lift motor 1. Check that the cassette base has been ascended. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. SD Lift motor and SD main PWB (YC8) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the SD Lift motor.

SD Lift sensor 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. SD Lift sensor and SD main PWB (YC5) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the SD Lift sensor.

SD main PWB Replace the SD main PWB (Refer to the service manual for the paper feeder).

- Code: 1400

- Description: Rotary guide motor error

The guide sensor is not detected to be on at the home position detection with the rotary guide for three times in a row. - Causes: Rotary guide motor. BR PWB.

- Remedy: Rotary guide motor 1. Check the rotary guide and drive gear can rotate or they are not unusually loaded and, if necessary, replace. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Rotary guide motor and BR PWB (YC5) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the rotary guide motor.

BR PWB Replace the BR PWB.

- Code: 1410

- Description: Rotary de-curler error

If the de-curler won’t turn On/ Off despite it has been activated for 400 steps during waiting for the de-curler sensor to be On/Off three times in a row. - Causes: Rotary de-curler motor. BR PWB.

- Remedy: Rotary de-curler motor 1. Check the rotary de-curler and drive gear can rotate or they are not unusually loaded and, if necessary, replace. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Rotary de-curler motor and BR PWB (YC5) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the rotary de-curler motor.

BR PWB Replace the BR PWB.

- Code: 1710

- Description: Side multi tray incompatible detection error

The side multi tray has been installed with a device to which it is incompatible. - Causes: The side multi tray is installed with a device to which it is incompatible.

- Remedy: Install the side multi-tray with the target model.

- Code: 1800

- Description: Paper feeder communication error

A communication error from paper feeder is detected 10 times in succession. - Causes: Paper feeder. PF main PWB. Engine PWB

- Remedy: Paper feeder Check the wiring connection status with the main unit and, if necessary, try connecting it again.

PF main PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF main PWB (YC13) and Engine PWB (YC19) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the PF main PWB (Refer to the service manual for the paper feeder).

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 1900

- Description: Paper feeder EEPROM error

When writing the data, read and write data does not match 3 times in succession. - Causes: PF main PWB (EEPROM).

- Remedy: 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. 2. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2101

- Description: Developer motor error

After developer motor is driven, the ready signal does not turn to L within 5 s. After developer motor is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Developer unit. Developer motor. Engine PWB.

- Remedy: Developer unit 1. Check that the developer waste lock has been released and, if not, release the lock. 2. Check that the gears and spiral screw of the developer unit are not damaged. 3. Confirm that the developer roller can rotate. 4. If it won’t rotate, replace the developer unit.

Developer motor 1. To check the motor operation, execute DLP(K) by U030. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer motor and Feed PWB 1 (YC8) Feed PWB 1 (YC2) and Engine PWB (YC5) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Developer motor.

Engine PWB. 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 2201

- Description: drum motor steady-state error

After drum motor is stabilized, the ready signal is at the H level for 5 s continuously. - Causes: Drum unit. Drum motor. Engine PWB

- Remedy: Drum unit 1. Confirm that the drum or the drum screw can rotate. 2. If it won’t rotate, replace the drum unit.

Drum motor 1. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. drum motor and Feed PWB 1 (YC9) Feed PWB 1 (YC2) and Engine PWB (YC5) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the drum motor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 2211

- Description: Drum motor startup error

Drum motor is not stabilized within 5 s since the motor is activated. - Causes: Drum unit. Drum motor. Engine PWB.

- Remedy: Drum unit 1. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 2. Confirm that the drum or the drum screw can rotate. 3. If it won’t rotate, replace the drum unit.

Drum motor 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. drum motor and Feed PWB 1 (YC9) Feed PWB 1 (YC2) and Engine PWB (YC5) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the drum motor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 2300

- Description: Fuser motor error

After fuser motor is driven, the ready signal does not turn to L within 2 s. After fuser motor is stabilized, the ready signal is at the H level for 1 s continuously. - Causes: Fuser motor. Engine PWB. Feed PWB 1. Fuser unit.

- Remedy: Fuser motor 1. To check the motor operation, execute U030 Fuser (Fuser motor). 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser motor and Feed PWB 1(YC18) Feed PWB 1(YC1) and Engine PWB (YC6) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the fuser motor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

Feed PWB 1 Replace the Feed PWB 1.

Fuser unit Replace the fuser unit.

- Code: 2500

- Description: Paper feed motor error

After paper feed motor is driven, the ready signal does not turn to L within 2 s. After paper feed motor is stabilized, the ready signal is at the H level for 1 s continuously. - Causes: Paper feed motor. Engine PWB.

- Remedy: Paper feed motor 1. To check the motor operation execute U030 Feed (paper feed motor). 2. Check the paper feed roller and drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Paper feed motor and Feed PWB 2(YC2) Feed PWB 2(YC1) and Engine PWB (YC4) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the paper feed motor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 2550

- Description: Transfer motor error

After Transfer motor is driven, the ready signal does not turn to L within 2 s. After Transfer motor is stabilized, the ready signal is at the H level for 1 s continuously. - Causes: Transfer motor. Engine PWB.

- Remedy: Transfer motor 1. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Transfer motor and Relay PWB(YC6) Relay PWB(YC5) and Feed PWB 1 (YC13) Feed PWB 1 (YC2) and Engine PWB (YC5) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the Transfer motor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 2600

- Description: PF paper feed motor error (large capacity feeder)

After PF paper feed motor is driven, the ready signal does not turn to L within 2 s. - Causes: PF paper feed motor. PF main PWB.

- Remedy: PF paper feed motor 1. To check the feed unit operation, execute U247 LCF- Motor ON. 2. Check the paper feed roller and drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. PF paper feed motor and PF main PWB (YC16) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the paper feed motor.

PF main PWB Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2810

- Description: Inner waste toner motor error

Initialized when an error is constantly observed for 2 seconds after the inner waste tonner motor is activated. An error is detected twice for 2.5 seconds after rebooting. The lock detect signal won’t be H level three times in a row within 200 ms at 1.25 ms cycles after the waste toner motor has been driven. - Causes: Waste toner box. Waste toner motor. Engine PWBr box

- Remedy: Waste toner box 1. Rotate the waste toner spiral by the hand and check that they are not unusually loaded. 2. If the spiral won’t rotate, replace the waste toner tank.

Waste toner motor 1. Rotate the drive gear by the hand and check that they are not unusually loaded. 2. Clean the drive gears and the axle holder. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Waste toner motor and Front PWB (YC13) Front PWB (YC3) and Engine PWB (YC7) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the waste toner motor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 3100

- Description: Scanner carriage error

The home position is not correct when the power is turned on, at the end of a reading process of the table and document processor. - Causes: The scanner mirror frame is being locked after setup. Scanner motor. Home position sensor. ISC PWB. Main PWB.

- Remedy: The scanner mirror frame is being locked after setup. Check whether the scanner mirror frame has been unlocked and unlock if necessary.

Scanner motor 1. To check the scanner motor, execute U073. 2. Move the scanner by the hand to check whether it is unusually difficult to move. 3. Check that the optical wire rope is not disengaged and engage the wire. 4. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Scanner motor and ISC PWB (YC5) ISC PWB (YC3) and Main PWB (YC11) 5. If the wiring is disconnected, shorted or grounded, replace the wiring. 6. Replace the scanner motor.

Home position sensor 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Home position sensor and ISC PWB (YC8) 3. Replace the home position sensor.

ISC PWB Replace the ISC PWB and execute U411.

Main PWB Replace the main PWB.

- Code: 3210

- Description: CIS lamp error

When input value at the time of CIS illumination does not exceed the threshold value between 5 s. - Causes: CIS. DPSHD PWB. DP relay PWB.

- Remedy: CIS 1. Execute U906 Separating Operation Release. 2. Execute CCD of U061 lamp check. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. CIS and DPSHD PWB (YC2) DPSHD PWB (YC3) and DP relay PWB (YC2) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the CIS and execute U091 and U411.

DPSHD PWB Replace the DPSHD PWB.

DP relay PWB Replace the DP relay PWB.

- Code: 3220

- Description: CCD lamp activation error

The threshold is calculated for colors at initialization and the pixel which does not exceed that value is greater than 1000. - Causes: CIS. ISC PWB. Main PWB.

- Remedy: CIS 1. Execute U906 Separating Operation Release. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. LED lamp PWB and ISC PWB (YC6) CCD PWB (YC2) and ISC PWB (YC9) ISC PWB (YC3) and Main PWB (YC11) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. If the LED lamp won’t light, replace the LED PWB and execut U411.

ISC PWB Replace the ISC PWB and execute U411.

Main PWB Replace the main PWB.

- Code: 3300

- Description: Optical system (AGC) error

One of the gains is FF or 00 during the CCD lamp AGC is being processed. - Causes: LED lamp PWB. CCD PWB. ISC PWB. Main PWB.

- Remedy: LED lamp PWB 1. To check the lamp, execute U061 CCD. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. LED lamp PWB and ISC PWB (YC6) CCD PWB (YC2) and ISC PWB (YC9) ISC PWB (YC3) and Main PWB (YC11) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. If the LED lamp won’t light, replace the LED PWB and execut U411.

CCD PWB Replace the ISU and execute U411.

ISC PWB Replace the ISC PWB and execute U411.

Main PWB Replace the main PWB.

- Code: 3310

- Description: CIS AGC error

After AGC, correct input is not obtained at CIS. - Causes: CIS. DPSHD PWB.

- Remedy: CIS 1. Execute U906 Separating Operation Release. 2. To check the lamp, execute U061 CCD. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. DP CIS and DPSHD PWB (YC2) DPSHD PWB (YC3) and DP relay PWB (YC2) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the CIS and execute U091 and U411.

DPSHD PWB Replace the DPSHD PWB.

- Code: 3500

- Description: Communication error

between scanner and ASIC An error code is detected. - Causes: ISC PWB. Main PWB.

- Remedy: ISC PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. ISC PWB (YC3) and Main PWB (YC11) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the ISC PWB and execute U411.

Main PWB Replace the main PWB.

- Code: 3600

- Description: Scanner sequence error

- Causes: ISC PWB

- Remedy: 1. Execute U021 memory initializing. 2. Replace the ISC PWB and execute U411.

- Code: 3700

- Description: Scanner device error

- Causes: CCD (ISU)

- Remedy: Since the ISU is mounted with a CCD of different type, install the ISU that matches with the model.

- Code: 3800

- Description: AFE error

When writing the data, read and write data does not match 3 times in succession. No response is received in 100 ms from AEF. - Causes: ISC PWB. CCD PWB.

- Remedy: ISC PWB 1. Confirm that the FCC wiring connector is not distorted and connect the FCC wiring all the way in. CCD PWB (YC2) and ISC PWB (YC9) 2. If the FCC wiring is disconnected, replace the FCC wiring. 3. Replace the ISC PWB and execute U411.

CCD PWB Replace the ISU and execute U411.

- Code: 3900

- Description: Backup memory read/write error (ISC PWB)

Read and write data does not match. - Causes: Backup memory (ISC PWB).

- Remedy: 1. Turn the main power switch off and after 5 seconds, turn it on. 2. Replace the ISC PWB and execute U411.

- Code: 4001

- Description: Polygon motor synchronization error

After polygon motor is driven, the ready signal does not turn to L within 30 s. The polygon motor speed won’t stabilize within 10 s. - Causes: Polygon motor (LSU). Engine PWB.

- Remedy: Polygon motor (LSU) 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Polygon motor and Engine PWB (YC15) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the laser scanner unit.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 4011

- Description: Polygon motor steady-state error

After Polygon motor is stabilized, the ready signal is at the H level for 15 s continuously. - Causes: Polygon motor (LSU). Engine PWB.

- Remedy: Polygon motor (LSU) 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Polygon motor and Engine PWB (YC15) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the laser scanner unit.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 4101

- Description: BD initialization error K

After Polygon motor is driven, the BD signal is not detected for 1 s. - Causes: PD PWB K (LSU). Engine PWB.

- Remedy: PD PWB K (LSU) 1. Confirm that the FCC wiring connector is not distorted and connect the FCC wiring all the way in. Laser scanner unit and LSU relay PWB (YC3) LSU relay PWB (YC2) and Engine PWB (YC11) 2. If the FCC wiring is disconnected, replace the FCC wiring. 3. Replace the laser scanner unit.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 4201

- Description: BD steady-state error K

The BD signal is not detected. - Causes: PD PWB K (LSU). Engine PWB.

- Remedy: PD PWB K (LSU) 1. Confirm that the FCC wiring connector is not distorted and connect the FCC wiring all the way in. Laser scanner unit and LSU relay PWB (YC3) LSU relay PWB (YC2) and Engine PWB (YC11) 2. If the FCC wiring is disconnected, shorted or grounded, replace the FCC wiring. 3. Replace the laser scanner unit.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

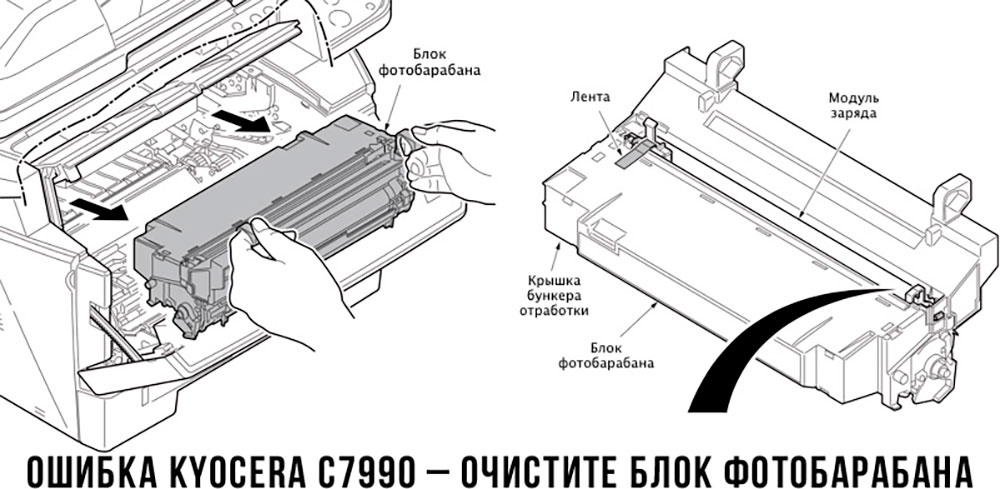

- Code: 5101

- Description: Main high-voltage error K

Measure the inflowing current when Vpp is varied in 3 steps and verify if the difference of the currents of 0 and step 2 is less than 42 (51 if lower highvoltage board). - Causes: Drum unit. Charger roller unit. High voltage PWB. Engine PWB

- Remedy: Drum unit 1. Confirm that the drum or the drum screw can rotate. 2. If it won’t rotate, replace the drum unit. 3. Check that the discharger lamp is properly connected.

Charger roller unit 1. Check that the high-voltage contacts are not distorted or adhered with foreign objects. 2. Reinstall the chrager roller unit.Or, replace the charger roller unit.

High voltage PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. High voltage PWB (YC2) and Engine PWB (YC16) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the High voltage PWB.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 6000

- Description: Broken fuser heater wire

Fuser thermistor 1 does not reach 100° C/212 °F even after 30 s during warming up. The detected temperature of fuser thermistor 1 does not reach the specified temperature (ready indication temperature) for 420 s in warming up after reached to 100° C/212 °F. - Causes: Fuser unit. Engine PWB. Power source PWB. Fuser heater.

- Remedy: Fuser unit 1. Check that no paper jam is present. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the Fuser unit and execute U167 counter clear. (Deteriorated sensitivity due to the toner adhered to the center thermistor.)

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

Power source PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Power source PWB (YC3) and fuser heater PWB (YC3) Fuser heater PWB (YC2) and feed PWB 1 (YC27) Feed PWB 1 (YC1) and Engine PWB (YC6)

Fuser heater 1. Replace the fuser unit.

- Code: 6020

- Description: Abnormally high fuser thermistor 1 temperature

Fuser thermistor 1 detects a temperature higher than 240°C/464°F for 1 s. - Causes: Fuser unit. Engine PWB.

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 6030

- Description: Broken fuser thermistor 1 wire

Fuser thermistor 1 detects a lower then 30°C/86°F when the temperature at the fuser thermistor 2 is higher than 70°C/158°F for during werming up. Fuser thermistor 2 detects a lower then 50°C/122°F for 15s during werming up. - Causes: Fuser unit. Engine PWB. Fuser thermistor 1. Fuser thermostat (triggered).

- Remedy: Fuser unit 1. Check that no paper jam is present. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the Fuser unit and execute U167 counter clear. (Deteriorated sensitivity due to the toner adhered to the center thermistor.)

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

Fuser thermistor 1 1. Replace the Fuser unit and execute U167 counter clear.

Fuser thermostat (triggered) 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and fuser heater PWB (YC1) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

- Code: 6040

- Description: Fuser heater error

Input from fuser center thermistor 1 is abnormal value continuously for 1 s. CPU port PH1 to stay in H level for one second or more in all operating modes is judged that the connector is disconnected. - Causes: Fuser unit. Engine PWB. Center thermistor 1. Fuser thermostat (triggered)

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 2. If the wiring is disconnected, shorted or grounded, replace the wiring.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

Center thermistor 1 1. Replace the Fuser unit and execute U167 counter clear.

Fuser thermostat (triggered) 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and fuser heater PWB (YC1) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

- Code: 6050

- Description: Abnormally low fuser thermistor 1 temperature

Fuser thermistor 1 detects a temperature lower than 100°C/212°F for 1 s after warming up, during ready or during print. The temperature of thermistor 1 is detected to be less than 70°C/158°F for more than one second during lowpower mode. - Causes: Power source. Fuser unit. Engine PWB. Fuser thermistor 1. Fuser thermostat (triggered).

- Remedy: Power source 1. Check that the operating voltage falls within +/-10%. 2. Check no voltage drop is caused. The heater is deactivated at 70V or lower. 3. Relocate the AC outlet that supplies power.

Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 1. Replace the engine PWB.

Fuser thermistor 1 1. Replace the fuser unit and execute U167 counter clear.

Fuser thermostat (triggered) 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and fuser heater PWB (YC1) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

- Code: 6200

- Description: Broken fuser edge heater wire

Fuser thermistor 2 does not reach 100° C/212 °F even after 30 s during warming up. The detected temperature of fuser thermistor 2 does not reach the specified temperature (ready indication temperature) for 420 s in warming up after reached to 100° C/212 °F. - Causes: Fuser unit. Engine PWB. Fuser center thermistor 1.

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

Fuser center thermistor 1 1. Replace the Fuser unit and execute U167 counter clear.

- Code: 6220

- Description: Abnormally high fuser edge thermistor temperature

Fuser thermistor 2 detects a temperature higher than 220°C/428°F for 1 s. - Causes: Fuser unit. Engine PWB.

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 6230

- Description: Broken fuser edge thermistor wire

The Input signal from the fuser thermistor 2 is 992 or more (A/D value) continuously for 1 s when the temperature at the fuser thermistor 1 is higher than 100°C/212°F. Fuser thermistor 2 detects a lower then 50°C/122°F for 15s during werming up. - Causes: Fuser unit. Engine PWB

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 6250

- Description: Abnormally low fuser edge thermistor temperature

Fuser thermistor 2 detects a temperature lower than 100°C/212°F for 1 s during ready or print. Fuser thermistor 2 detects a temperature lower than 50°C/ 122°F for 1 s during low power mode. - Causes: Fuser unit. Engine PWB.

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. 2. Fuser unit and Engine PWB (YC26) If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 6320

- Description: Abnormally high fuser middle thermistor 3 temperature

Fuser middle thermistor 3 detects a temperature higher than 205°C/401°F for 1 s. - Causes: Fuser unit. Engine PWB.

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Fuser unit and execute U167 counter clear.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 6400

- Description: Zero-cross signal error

While fuser heater ON/OFF control is performed, the zerocross signal is not input within 3 s. - Causes: Fuser unit.

- Remedy: Fuser unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser heater PWB (YC2) and feed PWB 1 (YC27) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the fuser heater PWB.

- Code: 6610

- Description: Fuser release sensor error

When the fuser release motor is driven, the fuser release sensor does not turn on/off for 8 s. - Causes: Fuser release motor. Fuser release sensor. Engine PWB.

- Remedy: Fuser release motor 1. To check the motor operation, execute U030 Fuser Release. 2. Check that the drive gear can be rotated and the separation is possible. 3. If the motor won’t rotate, confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Fuser unit and Engine PWB (YC26) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the fuser unit and execute U167 counter clear.

Fuser release sensor 1. Check that the sensor is correctly positioned. 2. Check that the sensor is not contaminated or damaged.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 6910

- Description: Engine software ready error

The device won’t engage in ready state in 60 minutes after warming-up has began. (A previous timeout process has not been cancelled.) - Causes: Engine PWB.

- Remedy: 1. Turn the main power switch off and after 5 seconds, turn it on. 2. Reinstall the engine software. 3. Replace the engine PWB.

- Code: 7001

- Description: Toner motor error

A state that a lock is detected 5 times in a row in 200ms cycle when the Toner motor is driven has occurred 30 times in total. - Causes: Toner container. Toner motor. Screw sensor. Engine PWB.

- Remedy: Toner container 1. Check that the spiral screw of the toner container can be rotated by the hand. 2. Check for broken gears and replace if any.

Toner motor 1. Draw out the toner container and execute U135 to check the toner motor operation. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner motor and Engine PWB (YC27) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Toner motor.

Screw sensor 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Screw sensor and Front PWB (YC5) Front PWB (YC2) and Engine PWB (YC7) 3. Replace the Screw sensor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7101

- Description: Toner sensor error

Sensor output value of 60 or less or 944 or more continued for 3 s. - Causes: Failure of locking the developer waste slot at setup. Toner sensor. Toner motor. Engine PWB.

- Remedy: Failure of locking the developer waste slot at setup. If an abnormal noise is heard, check that the developer ejection outlet is released and, if not, release the outlet.

Toner sensor 1. Check the toner sensor output by U155. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner sensor and Front PWB (YC7) Front PWB (YC2) and Engine PWB (YC8) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Check that the gears of the Developer unit are not damaged and the spiral can rotate. 5. Replace the Developer unit.

Toner motor 1. Draw out the toner container and execute U135 to check the toner motor operation. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner motor and Engine PWB (YC27) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Toner motor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7200

- Description: Broken outer temperature sensor 2 wire

The sensor input sampling is greater than 230. - Causes: Outer temperature sensor 2. Front PWB. Engine PWB.

- Remedy: Outer temperature sensor 2 1. Confirm Ext/Int is displayed by U139 temperature and humidity. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Outer temperature sensor 2 and Front PWB (YC8) Front PWB (YC2) and Engine PWB (YC8) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the outer temperature sensor 2.

Front PWB Replace the front PWB.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7210

- Description: Short-circuited outer temperature sensor 2

The sensor input sampling is less than 69. - Causes: Outer temperature sensor 2. Front PWB. Engine PWB.

- Remedy: Outer temperature sensor 2 1. Confirm Ext/Int is displayed by U139 temperature and humidity. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Outer temperature sensor 2 and Front PWB (YC8) Front PWB (YC2) and Engine PWB (YC10) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the outer temperature sensor 2.

Front PWB Replace the front PWB

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7221

- Description: Broken LSU thermistor wire

The sensor input sampling is greater than 230. - Causes: LSU thermistor. LSU relay PWB. Engine PWB.

- Remedy: LSU thermistor 1. Confirm LSU is displayed by U139 temperature and humidity. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Laser scanner unit and LSU relay PWB (YC3) LSU relay PWB (YC2) and Engine PWB (YC11) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the laser scanner unit.

LSU relay PWB REPLACE the LSU relay PWB.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7231

- Description: Short-circuited LSU thermistor K

The sensor input sampling is less than 69. - Causes: LSU thermistor. LSU relay PWB. Engine PWB.

- Remedy: LSU thermistor 1. Confirm LSU is displayed by U139 temperature and humidity. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Laser scanner unit and LSU relay PWB (YC3) LSU relay PWB (YC2) and Engine PWB (YC11) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the laser scanner unit.

LSU relay PWB Replace the LSU relay PWB.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7241

- Description: Broken Developer thermistor wire

The sensor input sampling is greater than 230. - Causes: Developer thermistor. Front PWB. Engine PWB.

- Remedy: Developer thermistor 1. Confirm Developing is displayed by U139 temperature and humidity. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer unit and Front PWB (YC7) Front PWB (YC2) and Engine PWB (YC8) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the Developer unit.

Front PWB Replace the front PWB

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7251

- Description: Short-circuited Developer thermistor

The sensor input sampling is less than 69. - Causes: Developer thermistor. Front PWB. Engine PWB.

- Remedy: Developer thermistor 1. Confirm Developing is displayed by U139 temperature and humidity. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer unit and Front PWB (YC7) Front PWB (YC2) and Engine PWB (YC8) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Replace the Developer unit.

Front PWB Replace the front PWB

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7301

- Description: Toner hopper motor error

During the toner motor is driven, an event in which a locking was detected for 5 times in 200 ms intervals has occurred in 30 sets. - Causes: Tonner hopper motor. Screw sensor. Engine PWB.

- Remedy: Tonner hopper motor 1. If the motor won’t rotate, confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Tonner hopper motor and Front PWB (YC5) Front PWB (YC3) and Engine PWB (YC7) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the tonner hopper motor .

Screw sensor 1. Check that the sensor is correctly positioned. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Screw sensor and Front PWB (YC5) Front PWB (YC2) and Engine PWB (YC7) 3. Replace the Screw sensor.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7401

- Description: Developer unit type mismatch error

Improper adaptation of the machine and developer unit is detected. - Causes: Different type of the developer unit is installed. Developer unit.

- Remedy: Different type of the developer unit is installed. Install the developer unit of the correct type.

Developer unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer unit and Front PWB (YC7) Front PWB (YC2) and Engine PWB (YC8) 2. If the wiring is disconnected, shorted or grounded, replace the wiring.

- Code: 7460

- Description: Developer shutter error

Power is turned on while the developer shutter is locked. - Causes: The developer shutter has been locked. Developer shutter sensor.

- Remedy: The developer shutter has been locked. Release the developer shutter.

Developer shutter sensor 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer shutter sensor and Front PWB (YC4) Front PWB (YC3) and Engine PWB (YC7) 2. If the wiring is disconnected, shorted or grounded, replace the wiring.

- Code: 7601

- Description: ID sensor 1 error [Front]

Dark potential error FrontDarkP and FrontDarkS are greater than 0.80V. Light potential error FrontBrightS is smaller than FrontDarkS. FrontBrightP is smaller than [FrontDarkP + 0.5V]. - Causes: ID sensor1. Feed PWB 1. Engine PWB.

- Remedy: ID sensor1 1. Execute U464 Calib for setting ID compensation operation and check the displayed values by U465 Boas Calib for ID compensation reference. 2. Clean the ID sensor on its surface. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. ID sensor 1 (front) and relay PWB (YC10) Relay PWB (YC1) and Feed PWB 1 (YC14) Feed PWB 1 (YC1) and Engine PWB (YC6) 4. If the wiring is disconnected, shorted or grounded, replace the wiring.

Feed PWB 1 Replace the Feed PWB 1.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7602

- Description: ID sensor 2 error [Rear]

Dark potential error RearDarkP and RearDarkS are greater than 0.80V. Light potential error RearBrightS is smaller than RearDarkS. RearBrightP is smaller than [RearDarkP + 0.5V]. - Causes: ID sensor 2. Feed PWB 1. Engine PWB.

- Remedy: ID sensor 2 1. Execute U464 Calib for setting ID compensation operation and check the displayed values by U465 Boas Calib for ID compensation reference. 2. Clean the ID sensor on its surface. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. ID sensor2 (rear) and relay PWB (YC10) Relay PWB (YC1) and Feed PWB 1 (YC14) Feed PWB 1 (YC1) and Engine PWB (YC6) 4. If the wiring is disconnected, shorted or grounded, replace the wiring.

Feed PWB 1 Replace the Feed PWB 1.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7800

- Description: Broken outer temperature sensor wire

The device did not respond for more than 5 ms during reading, in 5 times. - Causes: Outer temperature sensors been locked. Front PWB. Engine PWB.

- Remedy: Outer temperature sensor 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Outer temperature sensor and Front PWB (YC8) Front PWB (YC2) and Engine PWB (YC8) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Outer temperature sensor.

Front PWB Replace the front PWB

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7901

- Description: Drum EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. - Causes: DR PWB. Front PWB. Engine PWB.

- Remedy: DR PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. DR PWB and Front PWB (YC6) Front PWB (YC2) and Engine PWB (YC8) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Drum unit.

Front PWB Replace the front PWB

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7911

- Description: Developer unit EEPROM error

No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. - Causes: Developer unit. Front PWB. Engine PWB.

- Remedy: Developer unit 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer unit and Front PWB (YC7) Front PWB (YC2) and Engine PWB (YC8) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Developer unit.

Front PWB Replace the front PWB

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 7941

- Description: Laser scanner unit EEPROM error

Mismatch of reading data from two locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. - Causes: APC PWB. LSU relay PWB. Engine PWB.

- Remedy: APC PWB 1. Confirm that the FCC wiring connector is not distorted and connect the FCC wiring all the way in. APC PWB and LSU relay PWB (YC3) LSU relay PWB (YC2) and Engine PWB (YC11) 2. If the FCC wiring is disconnected, shorted or grounded, replace the FCC wiring. 3. Replace the laser scanner unit.

LSU relay PWB Replace the LSU relay PWB.

Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB.

- Code: 8010

- Description: Punch motor 1 error

When the punch motor is driven, punch home position sensor does not turn on within 200 ms. - Causes: Punch motor. Punch home position sensor. Punch PWB. DF main PWB.

- Remedy: Punch motor 1. Execute U240 Motor — Punch to check the finisher operation. 2. Manipulate the punch up and down to check it can smoothly move up and down. 3. Check that the drive from the motor reaches the punch cam. 4. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Punch motor and Punch PWB (YC4) 5. If the wiring is disconnected, shorted or grounded, replace the wiring. 6. Replace the punch motor.

Punch home position sensor 1. Execute U241 Punch — Punch HP to check the finisher switch. 2. Check that the sensor and its mounting bracket are correctly positioned. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Punch home position sensor and Punch PWB (YC8) 4. Replace the Punch home position sensor.

Punch PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Punch PWB (YC1) and DF main PWB (YC7) (4000-sheet finisher) Punch PWB (YC1) and DF main PWB (YC8) (1000-sheet finisher) 2. Replace the punch PWB.

DF main PWB Replace the DF main PWB (Refer to the service manual for the document finisher).

- Code: 8020

- Description: Punch motor 2 error

Home position is not obtained in 3 s after home position is initialized or in standby. - Causes: Punch motor. Punch PWB. DF main PWB.

- Remedy: Punch motor 1. Execute U240 Motor — Punch to check the finisher operation. 2. Manipulate the punch up and down to check it can smoothly move up and down. 3. Check that the drive from the motor reaches the punch cam. 4. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Punch motor and Punch PWB (YC4) 5. If the wiring is disconnected, shorted or grounded, replace the wiring. 6. Replace the punch motor.

Punch PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Punch PWB (YC1) and DF main PWB (YC7)(4000-sheet finisher) Punch PWB (YC1) and DF main PWB (YC8)(1000-sheet finisher) 2. Replace the punch PWB.

DF main PWB Replace the DF main PWB (Refer to the service manual for the document finisher).

- Code: 8030

- Description: Punch motor 3 error Home position does not turn from On to Off in 50 ms after home position has been initialized.

- Causes: Punch motor. Punch PWB. DF main PWB.

- Remedy: Punch motor 1. Execute U240 Motor — Punch to check the finisher operation. 2. Manipulate the punch up and down to check it can smoothly move up and down. 3. Check that the drive from the motor reaches the punch cam. 4. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Punch motor and Punch PWB (YC4) 5. If the wiring is disconnected, shorted or grounded, replace the wiring. 6. Replace the punch motor.

Punch PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Punch PWB (YC1) and DF main PWB (YC7) (4000-sheet finisher) Punch PWB (YC1) and DF main PWB (YC8) (1000-sheet finisher) 2. Replace the punch PWB.

DF main PWB Replace the DF main PWB (Refer to the service manual for the document finisher).

- Code: 8090

- Description: DF paddle motor error

When the DF paddle motor is driven, DF paddle sensor does not turn on within 1 s. - Causes: DF paddle motor. DF paddle sensor. DF main PWB.

- Remedy: DF paddle motor 1. Execute U240 Motor — Beat to check the finisher operation. 2. Check that the paddle can rotate. 3. Check that the drive from the motor reaches the paddle. 4. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. DF paddle motor and DF main PWB (YC15) (4000-sheet finisher) DF paddle motor and DF main PWB (YC11) (1000-sheet finisher) 5. If the wiring is disconnected, shorted or grounded, replace the wiring. 6. Replace the DF paddle motor.

DF paddle sensor 1. Execute U241 Finisher — Bundle Eject HP to check the finisher switch. 2. Check that the sensor and its mounting bracket are correctly positioned. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. DF paddle sensor and DF main PWB (YC22) (4000-sheet finisher) DF paddle sensor and DF main PWB (YC20) (1000-sheet finisher) 4. Replace the DF paddle sensor.

DF main PWB Replace the DF main PWB (Refer to the service manual for the document finisher).

- Code: 8100