Все современные копировальные аппараты, мфу и принтеры Kyocera имеют возможность диагностировать все узлы устройства в режиме запуска и во время работы аппарата. По этому, если во время включения или во время работы произошел сбой, то техника Kyocera сможет сообщить о наличии ошибки.

В большинстве случаев у аппаратов Kyocera код ошибки отображается на дисплее, в остальных случаях тип ошибки зависит от последовательности и количества миганий индикаторов.

Если Ваш копировальный аппарат, МФУ или принтер Kyocera выдал на дисплее некий код, то узнать причину, описание возникновения ошибки, а так же в каком узле аппарата стоит искать проблему, Вы можете в этом разделе выбрав интересующую модель из списка.

Но диагностика не решит проблему сбоя аппарата, для этого лучше обратиться к профессиональным и опытным сервисным специалистам компании Kyomart! Позвоните нам по телефону

8 (343) 288-23-45 или отправьте запрос на электронную почту: sales@kyomart.ru , и мы обязательно свяжемся с Вами в кратчайшие сроки.

Processing with the fax software was disabled due to a hardware problem.

Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted.

For data in which the MAC address is invalid.

Detecting engine PWB EEPROM communication error.

A checksum error is detected in the main and engine backup memories for the billing counters.

Machine number of control does not match.

The expansion memory modules (DIMM) are not correctly mounted.

The expansion memory modules (DIMM) mounted on the main PWB does not operate correctly.

The hard disk cannot be accessed.

A checksum error occurred with the program of the FAX control PWB.

The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed.

High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times.

The backup data is not retained for file system abnormality of flash memory of the FAX control PWB.

When the lift motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. After the lift motor is driven, the ON status of lift sensor cannot be detected for 8 s. The cassette installed confirmation message is displayed on the operation panel, and even if the cassette is opened and closed, the cassette installed confirmation message is displayed 5 times successively.

When the lift motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. After the lift motor is driven, the ON status of lift sensor cannot be detected for 8 s. The cassette installed confirmation message is displayed on the operation panel, and even if the cassette is opened and closed, the cassette installed confirmation message is displayed 5 times successively.

When the lift motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. After the lift motor is driven, the ON status of lift sensor cannot be detected for 8 s. The cassette installed confirmation message is displayed on the operation panel, and even if the cassette is opened and closed, the cassette installed confirmation message is displayed 5 times successively.

A temperature higher than 75C/167F is detected.

A temperature higher than 75C/167F is detected.

A temperature higher than 75aC/167F is detected.

A temperature higher than 75C/167F is detected.

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 1 is turned on.

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 2 is turned on.

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 1 is turned on.

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 2 is turned on.

Communication error between engine PWB and optional paper feeder.

The developing motor ready input is not given for 5 s during the main motor is ON.

The drum motor ready input is not given for 5 s during the drum motor is ON.

When the fuser pressure release motor is driven, the motor over-current detection signal is detected continuously for 8 times (800 ms) at 100 ms intervals.

When the fuser pressure release motor is driven, the envelope switch (EVSW) is not detectable for 6 s.

The drum motor ready input is not given for 5 s during the paper feed motor is ON.

The drum motor ready input is not given for 2 s during the PF paper feed motor is ON.

The drum motor ready input is not given for 2 s during the PF paper feed motor is ON.

When the developing release motor is driven, the motor over-current detection signal is detected continuously for 8 times (800 ms) at 100 ms intervals.

When the developing release motor is driven, the developing release switch (DEVRSW) is not detectable for 1 s.

The fuser motor ready input is not given for 5 s during the fuser motor is ON.

The home position is not correct when the power is turned on or at the start of copying using the table.

When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s.

After AGC, correct input is not obtained at CCD.

An error code is detected.

The polygon motor KM ready input is not given for 10 s during the polygon motor is ON.

The polygon motor CY ready input is not given for 10 s during the polygon motor is ON.

The pin photo signal is not output from PD PWB K for one second while laser is emitted.

The pin photo signal is not output from PD PWB C for one second while laser is emitted.

The pin photo signal is not output from PD PWB M for one second while laser is emitted.

The pin photo signal is not output from PD PWB Y for one second while laser is emitted.

When the LSU cleaning motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals.

When the cleaning lamp K is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals.

When the cleaning lamp C is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals.

When the cleaning lamp M is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals.

When the cleaning lamp Y is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals.

The detected temperature of fuser thermistor does not rise 1„aC/1.8„aF after the fuser heater has been turned on continuously for 10 s in warming up. The fuser temperature does not reach 100„aC/212„aF after the fuser heater has been turned on continuously for 30 s in warming up. The detected temperature of fuser thermistor does not reach the specified temperature (ready indication temperature) after the fuser heater has been turned on continuously for 60 s in warming up. The detected temperature of fuser thermistor does not rise 1„aC/1.8„aF after the fuser heater has been turned on continuously for 10 s during printing.

The fuser thermistor detects a temperature higher than 240C/464F. By the activation of the high temperature error detection circuit (230C/446F or more) of fuser thermistor, the illumination of fuser heater was forcibly turned off and 10 s has elapsed.

Input from fuser thermistor is 3 or less (A/D value) continuously for 1 s.

The zero-cross signal does not reach the engine PWB for more than 1 s.

When the toner motor K is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals.

When the toner motor C is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals.

When the toner motor M is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals.

When the toner motor Y is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals.

No density detection signal is output from toner sensor K in developing unit K.

No density detection signal is output from toner sensor C in developing unit C.

No density detection signal is output from toner sensor M in developing unit M.

No density detection signal is output from toner sensor Y in developing unit Y.

The EEPROM of drum PWB K does not communicate normally.

The EEPROM of drum PWB C does not communicate normally.

The EEPROM of drum PWB M does not communicate normally.

The EEPROM of drum PWB Y does not communicate normally.

…

9520

The serial number of the machine written on the EEPROM of the engine PWB differs with that is written on both the flash memory of the engine PWB and the EEPROM of the drum PWB as a backup.

- Code: 0030

- Description: FAX control PWB system error

Processing with the fax software was disabled due to a hardware problem. - Causes: Defective FAX control PWB.

- Remedy: Defective FAX control PWB. Replace the fax control PWB and check for correct operation..

- Code: 0070

- Description: FAX control PWB incompatible detection error

Abnormal detection of FAX control PWB incompatibility In the initial communication with the FAX control PWB, any normal communication command is not transmitted. - Causes: Defective FAX software.PWB. Defective FAX control PWB.

- Remedy: Defective FAX software. Install the fax software.

Defective FAX control PWB. Replace the fax control PWB and check for correct operation..

- Code: 0100

- Description: Backup memory device error

- Causes: Defective flash memory. Defective main PWB.

- Remedy: Defective flash memory. Replace the main PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0120

- Description: MAC address data error

For data in which the MAC address is invalid. - Causes: Defective flash memory. Defective engine PWB.

- Remedy: Defective flash memory. Replace the main PWB and check for correct operation.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 0130

- Description: Backup memory read/write error (main PWB)

- Causes: Defective flash memory. Defective main PWB.

- Remedy: Defective flash memory. Replace the main PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0140

- Description: Backup memory data error (main PWB)

- Causes: Defective flash memory. Defective main PWB.

- Remedy: Defective flash memory. Replace the main PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0150

- Description: Engine PWB EEPROM error

Detecting engine PWB EEPROM communication error. - Causes: Improper installation engine PWB EEPROM. Defective engine PWB. Device damage of EEPROM.

- Remedy: Improper installation engine PWB EEPROM. Check the installation of the EEPROM and remedy if necessary.

Defective engine PWB. Replace the engine PWB and check for correct operation.

Device damage of EEPROM. Contact the Service Administrative Division.

- Code: 0170

- Description: Billing counting error

A checksum error is detected in the main and engine backup memories for the billing counters. - Causes: Data damage of EEPROM. Defective PWB.

- Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

Defective PWB. Replace the main PWB or the engine PWB and check for correct operation.

- Code: 0180

- Description: Machine number mismatch

Machine number of main and engine does not match. - Causes: Data damage of EEPROM.

- Remedy: Data damage of EEPROM. Contact the Service Administrative Division.

- Code: 0600

- Description: Expanded memory (DIMM) installing error

The expansion memory modules (DIMM) are not correctly mounted. - Causes: Improper installation expanded memory (DIMM).

- Remedy: Improper installation expanded memory (DIMM). Check the installation of the expanded memory (DIMM).

- Code: 0610

- Description: Expanded memory (DIMM) error

The expansion memory modules (DIMM) mounted on the main PWB does not operate correctly. - Causes: Defective expanded memory (DIMM). Defective main PWB.

- Remedy: Defective expanded memory (DIMM). Replace the expanded memory (DIMM) and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0640

- Description: Hard disk error

The hard disk cannot be accessed. - Causes: Defective hard disk. Defective main PWB.

- Remedy: Defective hard disk. Replace the hard disk and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0830

- Description: FAX control PWB flash program area checksum error

A checksum error occurred with the program of the FAX control PWB. - Causes: Defective FAX software. Defective FAX control PWB.

- Remedy: Defective FAX software. Install the fax software.

Defective FAX control PWB. Replace the FAX control PWB.

- Code: 0840

- Description: Faults of RTC

The time is judged to go back based on the comparison of the RTC time and the current time or five years or more have passed. - Causes: The battery is disconnected from the main PWB. Defective main PWB.

- Remedy: The battery is disconnected from the main PWB. Check visually and remedy if necessary

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 0870

- Description: FAX control PWB to main PWB high capacity data transfer error

High-capacity data transfer between the FAX control PWB and the main PWB of the machine was not normally performed even if the data transfer was retried the specified times. - Causes: Improper installation FAX control PWB. Defective FAX control PWB or main PWB.

- Remedy: Improper installation FAX control PWB. Reinstall the FAX control PWB.

Defective FAX control PWB or main PWB. Replace the FAX control PWB or main PWB and check for correct operation.

- Code: 0920

- Description: Fax file system error

The backup data is not retained for file system abnormality of flash memory of the FAX control PWB. - Causes: Defective FAX control PWB.

- Remedy: Defective FAX control PWB. Replace the FAX control PWB and check for correct operation.

- Code: 0930

- Description: EEPROM bus error

- Causes: Defective drum PWB (EEPROM). Defective engine PWB (EEPROM). Defective engine PWB. Defective main PWB.

- Remedy: Defective drum PWB (EEPROM). Replace the drum unit.

Defective engine PWB (EEPROM). Replace the engine PWB and check for correct operation.

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 1010

- Description: Lift motor error

When the lift motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. After the lift motor is driven, the ON status of lift sensor cannot be detected for 8 s. The cassette installed confirmation message is displayed on the operation panel, and even if the cassette is opened and closed, the cassette installed confirmation message is displayed 5 times successively. - Causes: Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the lift motor. Defective lift motor. Defective engine PWB.

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Lift motor and engine PWB (YC27)

Defective drive transmission system of the lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective lift motor. Replace the lift motor

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 1020

- Description: PF lift motor error (paper feeder 1)

When the lift motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. After the lift motor is driven, the ON status of lift sensor cannot be detected for 8 s. The cassette installed confirmation message is displayed on the operation panel, and even if the cassette is opened and closed, the cassette installed confirmation message is displayed 5 times successively. - Causes: Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor. Defective PF lift motor. Defective PF main PWB.

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor and PF main PWB (YC7)

Defective drive transmission system of the PF lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor. Replace the PF lift motor

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1030

- Description: PF lift motor error (paper feeder 2)

When the lift motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. After the lift motor is driven, the ON status of lift sensor cannot be detected for 8 s. The cassette installed confirmation message is displayed on the operation panel, and even if the cassette is opened and closed, the cassette installed confirmation message is displayed 5 times successively. - Causes: Defective bottom plate elevation mechanism in the cassette. Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF lift motor. Defective PF lift motor. Defective PF main PWB.

- Remedy: Defective bottom plate elevation mechanism in the cassette. Check to see if the bottom plate can move smoothly and repair it if any problem is found.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF lift motor and PF main PWB (YC7)

Defective drive transmission system of the PF lift motor. Check if the gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF lift motor. Replace the PF lift motor

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1500

- Description: PF heater 1 high temperature error (paper feeder 1)

A temperature higher than 75C/167F is detected. - Causes: Defective connector cable or poor contact in the connector. Shorted PF thermistor 1. Defective PF fan motor 1. Defective PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF fan motor 1 and PF main PWB (YC111)

Shorted PF thermistor 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Defective PF fan motor 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1510

- Description: PF heater 2 high temperature error (paper feeder 1)

A temperature higher than 75C/167F is detected. - Causes: Defective connector cable or poor contact in the connector. Shorted PF thermistor 2. Defective PF fan motor 2. Defective PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF fan motor 2 and PF main PWB (YC111)

Shorted PF thermistor 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Defective PF fan motor 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1520

- Description: PF heater 1 high temperature error (paper feeder 2)

A temperature higher than 75aC/167F is detected. - Causes: Defective connector cable or poor contact in the connector. Shorted PF thermistor 1. Defective PF fan motor 1. Defective PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF fan motor 1 and PF main PWB (YC111)

Shorted PF thermistor 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Defective PF fan motor 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1530

- Description: PF heater 2 high temperature error (paper feeder 2)

A temperature higher than 75C/167F is detected. - Causes: Defective connector cable or poor contact in the connector. Shorted PF thermistor 2. Defective PF fan motor 2. Defective PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF fan motor 2 and PF main PWB (YC111)

Shorted PF thermistor 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Defective PF fan motor 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1600

- Description: PF heater 1 low temperature error (paper feeder 1)

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 1 is turned on. - Causes: Defective connector cable or poor contact in the connector. PF thermistor 1 installed incorrectly. Defective PF thermistor 1. Broken PF heater 1. Defective PF heater PWB or PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF heater 1 and PF heater PWB (YC1) PF heater PWB (YC3) and PF main PWB (YC113) PF thermistor 1 and PF main PWB (YC114)

PF thermistor 1 installed incorrectly. Check the installation of the PF thermistor 1.

Defective PF thermistor 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Broken PF heater 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Defective PF heater PWB or PF main PWB. Replace the PF heater PWB or PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1610

- Description: PF heater 2 low temperature error (paper feeder 1)

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 2 is turned on. - Causes: Defective connector cable or poor contact in the connector. PF thermistor 2 installed incorrectly. Defective PF thermistor 2. Broken PF heater 2. Defective PF heater PWB or PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF heater 2 and PF heater PWB (YC2) PF heater PWB (YC3) and PF main PWB (YC113) PF thermistor 2 and PF main PWB (YC115)

PF thermistor 2 installed incorrectly. Check the installation of the PF thermistor 2.

Defective PF thermistor 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Broken PF heater 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Defective PF heater PWB or PF main PWB. Replace the PF heater PWB or PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1620

- Description: PF heater 1 low temperature error (paper feeder 2)

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 1 is turned on. - Causes: Defective connector cable or poor contact in the connector. PF thermistor 1 installed incorrectly. Defective PF thermistor 1. Broken PF heater 1. Defective PF heater PWB or PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF heater 1 and PF heater PWB (YC1) PF heater PWB (YC3) and PF main PWB (YC113) PF thermistor 1 and PF main PWB (YC114)

PF thermistor 1 installed incorrectly. Check the installation of the PF thermistor 1.

Defective PF thermistor 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Broken PF heater 1. Replace the top heater unit (Refer to the service manual for the paper feeder).

Defective PF heater PWB or PF main PWB. Replace the PF heater PWB or PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1630

- Description: PF heater 2 low temperature error (paper feeder 2)

An external temperature higher than + 5C/+ 9F is not detected when one minute elapses after PF heater 2 is turned on. - Causes: Defective connector cable or poor contact in the connector. PF thermistor 2 installed incorrectly. Defective PF thermistor 2. Broken PF heater 2. Defective PF heater PWB or PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF heater 2 and PF heater PWB (YC2) PF heater PWB (YC3) and PF main PWB (YC113) PF thermistor 2 and PF main PWB (YC115)

PF thermistor 2 installed incorrectly. Check the installation of the PF thermistor 2.

Defective PF thermistor 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Broken PF heater 2. Replace the side heater unit (Refer to the service manual for the paper feeder).

Defective PF heater PWB or PF main PWB. Replace the PF heater PWB or PF main PWB (Refer to the service manual for the paper feeder).

- Code: 1800

- Description: Paper feeder communication error

Communication error between engine PWB and optional paper feeder. - Causes: Improper installation paper feeder. Defective connector cable or poor contact in the connector. Defective engine PWB. Defective PF main PWB.

- Remedy: Improper installation paper feeder. Follow installation instruction carefully again.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF main PWB (YC3) and engine PWB (YC33)

Defective engine PWB. Replace the engine PWB and check for correct operation.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2100

- Description: Developing motor error

The developing motor ready input is not given for 5 s during the main motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the developing motor. Defective developing motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developing motor and engine PWB (YC14)

Defective drive transmission system of the developing motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective developing motor. Replace the developing motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2200

- Description: Drum motor error

The drum motor ready input is not given for 5 s during the drum motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the drum motor. Defective drum motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum motor and engine PWB (YC13)

Defective drive transmission system of the drum motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective drum motor. Replace the drum motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2330

- Description: Fuser pressure release motor error

When the fuser pressure release motor is driven, the motor over-current detection signal is detected continuously for 8 times (800 ms) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the fuser pressure release motor. Defective fuser pressure release motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser pressure release motor and engine PWB (YC38)

Defective drive transmission system of the fuser pressure release motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective fuser pressure release motor. Replace the fuser pressure release motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2340

- Description: Fuser pressure release motor time-out error

When the fuser pressure release motor is driven, the envelope switch (EVSW) is not detectable for 6 s. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the fuser pressure release motor. Defective fuser pressure release motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser pressure release motor and engine PWB (YC38)

Defective drive transmission system of the fuser pressure release motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective fuser pressure release motor. Replace the fuser pressure release motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2500

- Description: Paper feed motor error

The drum motor ready input is not given for 5 s during the paper feed motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the paper feed motor. Defective paper feed motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Paper feed motor and engine PWB (YC3)

Defective drive transmission system of the paper feed motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective paper feed motor. Replace the paper feed motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2600

- Description: PF paper feed motor error (paper feeder 1)

The drum motor ready input is not given for 2 s during the PF paper feed motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF paper feed motor. Defective PF paper feed motor. Defective PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF paper feed motor and PF main PWB (YC6)

Defective drive transmission system of the PF paper feed motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF paper feed motor. Replace the PF paper feed motor.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2610

- Description: PF paper feed motor error (paper feeder 2)

The drum motor ready input is not given for 2 s during the PF paper feed motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the PF paper feed motor. Defective PF paper feed motor. Defective PF main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. PF paper feed motor and PF main PWB (YC6)

Defective drive transmission system of the PF paper feed motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective PF paper feed motor. Replace the PF paper feed motor.

Defective PF main PWB. Replace the PF main PWB (Refer to the service manual for the paper feeder).

- Code: 2730

- Description: Developing release motor error

When the developing release motor is driven, the motor over-current detection signal is detected continuously for 8 times (800 ms) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the developing release motor. Defective developing release motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developing release motor and engine PWB (YC35)

Defective drive transmission system of the developing release motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective developing release motor. Replace the developing release motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2740

- Description: Developing release motor time-out error

When the developing release motor is driven, the developing release switch (DEVRSW) is not detectable for 1 s. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the developing release motor. Defective developing release motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developing release motor and engine PWB (YC35)

Defective drive transmission system of the developing release motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective developing release motor. Replace the developing release motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 2820

- Description: Fuser motor error

The fuser motor ready input is not given for 5 s during the fuser motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the fuser motor. Defective fuser motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser motor and engine PWB (YC15)

Defective drive transmission system of the fuser motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective fuser motor. Replace the fuser motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 3100

- Description: ISU home position error

The home position is not correct when the power is turned on or at the start of copying using the table. - Causes: Defective connector cable or poor contact in the connector. Defective home position sensor. Defective ISU motor. Defective CCD PWB. Defective main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Home position sensor and CCD PWB (YC3) CCD PWB (YC1) and main PWB (YC8) ISU motor and main PWB (YC36)

Defective home position sensor. Replace the home position sensor.

Defective ISU motor. Replace the ISU motor.

Defective CCD PWB. Replace the scanner unit.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 3200

- Description: Exposure lamp error

When input value at the time of exposure lamp illumination does not exceed the threshold value between 5 s. - Causes: Defective connector cable or poor contact in the connector. Defective exposure lamp. Defective inverter PWB or CCD PWB. Defective main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Exposure lamp and inverter PWB (CN2) Inverter PWB (CN1) and CCD PWB (YC3) CCD PWB (YC1) and main PWB (YC8)

Defective exposure lamp. Replace the scanner unit.

Defective inverter PWB or CCD PWB. Replace the scanner unit.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 3300

- Description: AGC error

After AGC, correct input is not obtained at CCD. - Causes: Defective connector cable or poor contact in the connector. Defective exposure lamp. Defective inverter PWB or CCD PWB. Defective main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Inverter PWB (CN1) and CCD PWB (YC3) CCD PWB (YC1) and main PWB (YC8)

Defective exposure lamp. Replace the scanner unit.

Defective inverter PWB or CCD PWB. Replace the scanner unit.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 3500

- Description: Communication error between scanner and ASIC

An error code is detected. - Causes: Defective connector cable or poor contact in the connector. Defective CCD PWB. Defective main PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. CCD PWB (YC1) and main PWB (YC8)

Defective CCD PWB. Replace the scanner unit.

Defective main PWB. Replace the main PWB and check for correct operation.

- Code: 4001

- Description: Polygon motor KM error

The polygon motor KM ready input is not given for 10 s during the polygon motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective polygon motor KM. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Laser scanner unit KM and engine PWB (YC31)

Defective polygon motor KM. Replace the laser scanner unit KM.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4002

- Description: Polygon motor CY error

The polygon motor CY ready input is not given for 10 s during the polygon motor is ON. - Causes: Defective connector cable or poor contact in the connector. Defective polygon motor CY. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Laser scanner unit CY and engine PWB (YC31)

Defective polygon motor CY. Replace the laser scanner unit CY.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4201

- Description: Laser output error (black)

The pin photo signal is not output from PD PWB K for one second while laser is emitted. - Causes: Defective connector cable or poor contact in the connector. Defective APC PWB K. Defective PD PWB K. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. APC PWB K and engine PWB (YC31)

Defective APC PWB K. Replace the laser scanner unit KM.

Defective PD PWB K. Replace the laser scanner unit KM.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4202

- Description: Laser output error (cyan)

The pin photo signal is not output from PD PWB C for one second while laser is emitted. - Causes: Defective connector cable or poor contact in the connector. Defective APC PWB C. Defective PD PWB C. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. APC PWB C and engine PWB (YC32)

Defective APC PWB C. Replace the laser scanner unit CY.

Defective PD PWB C. Replace the laser scanner unit CY.

Defective engine PWB. Replace the engine PWB.

- Code: 4203

- Description: Laser output error (magenta)

The pin photo signal is not output from PD PWB M for one second while laser is emitted. - Causes: Defective connector cable or poor contact in the connector. Defective APC PWB M. Defective PD PWB M. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. APC PWB M and engine PWB (YC31)

Defective APC PWB M. Replace the laser scanner unit KM.

Defective PD PWB M. Replace the laser scanner unit KM.

Defective engine PWB. Replace the engine PWB.

- Code: 4204

- Description: Laser output error (yellow)

The pin photo signal is not output from PD PWB Y for one second while laser is emitted. - Causes: Defective connector cable or poor contact in the connector. Defective APC PWB Y. Defective PD PWB Y. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. APC PWB Y and engine PWB (YC32)

Defective APC PWB Y. Replace the laser scanner unit CY.

Defective PD PWB Y. Replace the laser scanner unit CY.

Defective engine PWB. Replace the engine PWB.

- Code: 4600

- Description: LSU cleaning motor error

When the LSU cleaning motor is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the LSU cleaning motor. Defective LSU cleaning motor. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. LSU cleaning motor and engine PWB (YC36)

Defective drive transmission system of the LSU cleaning motor. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective LSU cleaning motor. Replace the LSU cleaning motor.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 4700

- Description: VIDEO ASIC device error

- Causes: Defective connector cable or poor contact in the connector. Defective main PWB or engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Main PWB (YC39) and relay PWB (YC3) Relay PWB (YC2, 4) and engine PWB (YC8, 9)

Defective main PWB or engine PWB. Replace the main PWB or the engine PWB and check for correct operation.

- Code: 5301

- Description: Broken cleaning lamp K wire

When the cleaning lamp K is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective cleaning lamp K. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit K and Drum relay PWB (YC2) Drum relay PWB (YC1) and engine PWB (YC34)

Defective cleaning lamp K. Replace the drum unit K..

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 5302

- Description: Broken cleaning lamp C wire

When the cleaning lamp C is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective cleaning lamp C. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit C and Drum relay PWB (YC4) Drum relay PWB (YC1) and engine PWB (YC34)

Defective cleaning lamp C. Replace the drum unit C..

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 5303

- Description: Broken cleaning lamp M wire

When the cleaning lamp M is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective cleaning lamp M. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit M and Drum relay PWB (YC3) Drum relay PWB (YC1) and engine PWB (YC34)

Defective cleaning lamp M. Replace the drum unit M..

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 5304

- Description: Broken cleaning lamp Y wire

When the cleaning lamp Y is driven, the lamp over-current detection signal is detected continuously for 10 times (1 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective cleaning lamp Y. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit Y and Drum relay PWB (YC5) Drum relay PWB (YC1) and engine PWB (YC34)

Defective cleaning lamp Y. Replace the drum unit Y..

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6000

- Description: Broken fuser heater wire

The detected temperature of fuser thermistor does not rise 1„aC/1.8„aF after the fuser heater has been turned on continuously for 10 s in warming up. The fuser temperature does not reach 100„aC/212„aF after the fuser heater has been turned on continuously for 30 s in warming up. The detected temperature of fuser thermistor does not reach the specified temperature (ready indication temperature) after the fuser heater has been turned on continuously for 60 s in warming up. The detected temperature of fuser thermistor does not rise 1„aC/1.8„aF after the fuser heater has been turned on continuously for 10 s during printing. - Causes: Defective connector cable or poor contact in the connector. Fuser thermostat triggered. Broken fuser heater wire. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser heater and power source PWB (YC102) Fuser unit and eject PWB (YC3) Eject PWB (YC1) and engine PWB (YC19)

Fuser thermostat triggered. Reinsert the fuser unit.

Broken fuser heater wire. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6020

- Description: Abnormally high fuser thermistor temperature

The fuser thermistor detects a temperature higher than 240C/464F. By the activation of the high temperature error detection circuit (230C/446F or more) of fuser thermistor, the illumination of fuser heater was forcibly turned off and 10 s has elapsed. - Causes: Shorted fuser thermistor. Defective engine PWB.

- Remedy: Shorted fuser thermistor. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6030

- Description: Broken fuser thermistor wire

Input from fuser thermistor is 3 or less (A/D value) continuously for 1 s. - Causes: Defective connector cable or poor contact in the connector. Broken fuser thermistor wire. Fuser thermostat triggered. Broken fuser heater wire. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Fuser unit and eject PWB (YC3) Eject PWB (YC1) and engine PWB (YC19)

Broken fuser thermistor wire. Replace the fuser unit.

Fuser thermostat triggered. Reinsert the fuser unit.

Broken fuser heater wire. Replace the fuser unit.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 6400

- Description: Zero-cross signal error

The zero-cross signal does not reach the engine PWB for more than 1 s. - Causes: Defective connector cable or poor contact in the connector. Defective power source PWB or engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Power source PWB (YC103) and relay PWB (YC1) Relay PWB (YC4) and engine PWB (YC9)

Defective power source PWB or engine PWB. Replace the power source PWB or the engine PWB and check for correct operation.

- Code: 7001

- Description: Toner motor K error

When the toner motor K is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the toner motor K. Defective toner motor K. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Toner motor K and engine PWB (YC23)

Defective drive transmission system of the toner motor K. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective toner motor K. Replace the toner motor K.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7002

- Description: Toner motor C error

When the toner motor C is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the toner motor C. Defective toner motor C. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Toner motor C and engine PWB (YC25)

Defective drive transmission system of the toner motor C. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective toner motor C. Replace the toner motor C.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7003

- Description: Toner motor M error

When the toner motor M is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the toner motor M. Defective toner motor M. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Toner motor M and engine PWB (YC24)

Defective drive transmission system of the toner motor M. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective toner motor M. Replace the toner motor M.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7004

- Description: Toner motor Y error

When the toner motor Y is driven, the motor over-current detection signal is detected continuously for 50 times (5 s) at 100 ms intervals. - Causes: Defective connector cable or poor contact in the connector. Defective drive transmission system of the toner motor Y. Defective toner motor Y. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Toner motor Y and engine PWB (YC26)

Defective drive transmission system of the toner motor Y. Check if the rollers and gears rotate smoothly. If not, grease the bushes and gears. Check for broken gears and replace if any.

Defective toner motor Y. Replace the toner motor Y.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7401

- Description: Developing unit K noninstalling error

No density detection signal is output from toner sensor K in developing unit K. - Causes: Defective connector cable or poor contact in the connector. Defective toner sensor K. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developing unit K and Drum relay PWB (YC6) Drum relay PWB (YC1) and engine PWB (YC34)

Defective toner sensor K. Replace the developing unit K.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7402

- Description: Developing unit C noninstalling error

No density detection signal is output from toner sensor C in developing unit C. - Causes: Defective connector cable or poor contact in the connector. Defective toner sensor C. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developing unit C and Drum relay PWB (YC10) Drum relay PWB (YC1) and engine PWB (YC34)

Defective toner sensor C. Replace the developing unit C.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7403

- Description: Developing unit M noninstalling error

No density detection signal is output from toner sensor M in developing unit M. - Causes: Defective connector cable or poor contact in the connector. Defective toner sensor M. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developing unit M and Drum relay PWB (YC7) Drum relay PWB (YC1) and engine PWB (YC34)

Defective toner sensor M. Replace the developing unit M.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7404

- Description: Developing unit Y noninstalling error

No density detection signal is output from toner sensor Y in developing unit Y. - Causes: Defective connector cable or poor contact in the connector. Defective toner sensor Y. Defective engine PWB.

- Remedy: Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Developing unit Y and Drum relay PWB (YC13) Drum relay PWB (YC1) and engine PWB (YC34)

Defective toner sensor Y. Replace the developing unit Y.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7411

- Description: Drum unit K non- installing error

The EEPROM of drum PWB K does not communicate normally. - Causes: Installation of incompatible drum unit K. Defective connector cable or poor contact in the connector. Defective drum PWB K. Defective engine PWB.

- Remedy: Installation of incompatible drum unit K. Install drum unit K compatible with the specifications to the machine.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit K and Drum relay PWB (YC2) Drum relay PWB (YC1) and engine PWB (YC34)

Defective drum PWB K. Replace the drum unit K.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7412

- Description: Drum unit C non- installing error

The EEPROM of drum PWB C does not communicate normally. - Causes: Installation of incompatible drum unit C. Defective connector cable or poor contact in the connector. Defective drum PWB C. Defective engine PWB.

- Remedy: Installation of incompatible drum unit C. Install drum unit C compatible with the specifications to the machine.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit C and Drum relay PWB (YC4) Drum relay PWB (YC1) and engine PWB (YC34)

Defective drum PWB C. Replace the drum unit C.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7413

- Description: Drum unit M non- installing error

The EEPROM of drum PWB M does not communicate normally. - Causes: Installation of incompatible drum unit M. Defective connector cable or poor contact in the connector. Defective drum PWB M. Defective engine PWB.

- Remedy: Installation of incompatible drum unit M. Install drum unit M compatible with the specifications to the machine.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit M and Drum relay PWB (YC3) Drum relay PWB (YC1) and engine PWB (YC34)

Defective drum PWB M. Replace the drum unit M.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 7414

- Description: Drum unit Y non- installing error

The EEPROM of drum PWB Y does not communicate normally. - Causes: Installation of incompatible drum unit Y. Defective connector cable or poor contact in the connector. Defective drum PWB Y. Defective engine PWB.

- Remedy: Installation of incompatible drum unit Y. Install drum unit Y compatible with the specifications to the machine.

Defective connector cable or poor contact in the connector. Reinsert the connector. Also check for continuity within the connector cable. If none, replace the cable. Drum unit Y and Drum relay PWB (YC5) Drum relay PWB (YC1) and engine PWB (YC34)

Defective drum PWB Y. Replace the drum unit Y.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: 9500 … 9520

- Description: Contact the Service Administrative Division.

- Causes:

- Remedy: Contact the Service Administrative Division.

- Code: 9530

- Description: Backup data error

The serial number of the machine written on the EEPROM of the engine PWB differs with that is written on both the flash memory of the engine PWB and the EEPROM of the drum PWB as a backup. - Causes: Replacing both the engine PWB and the drum unit at the same time.

- Remedy: Check that the machine operates properly by reverting the engine controller and the drum unit to the old ones. To replace the engine PWB and the drum unit at the same time, turn on the machine after replacing either one. Check that the machine operates properly and then turn off the machine. Replace the other and turn on the machine to check that the machine operates properly. Be sure to replace one by one.

- Code: F000

- Description: Main PWB — operation panel PWB communication error

- Causes: Defective main PWB. Defective operation panel PWB.

- Remedy: Defective main PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

Defective operation panel PWB. Replace the operation panel PWB and check for correct operation.

- Code: F010

- Description: Main PWB checksum error

- Causes: Defective main PWB

- Remedy: Defective main PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

- Code: F020

- Description: Main PWB RAM checksum errors

- Causes: Defective main memory (RAM) on the main PWB. Defective expanded memory (DIMM).

- Remedy: Defective main memory (RAM) on the main PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

Defective expanded memory (DIMM). Replace the expanded memory (DIMM).

- Code: F040

- Description: Main PWB — print engine communication error

- Causes: Defective main PWB. Defective engine PWB.

- Remedy: Defective main PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: F041

- Description: Main PWB — scanner engine communication error

- Causes: Defective main PWB. Defective engine PWB.

- Remedy: Defective main PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace main PWB.

Defective engine PWB. Replace the engine PWB and check for correct operation.

- Code: F050

- Description: Print engine ROM checksum error

- Causes: Defective engine PWB.

- Remedy: Defective engine PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace engine PWB.

- Code: F051

- Description: Scanner engine ROM checksum error

- Causes: Defective engine PWB.

- Remedy: Defective engine PWB. Turn the main power switch off/on to restart the machine. If the error is not resolved, replace engine PWB.

- Code: F278

- Description: Power supply in drive system error

- Causes: Main power switch was turned off without using the power key, or a power failure has occurred.

- Remedy: Turn on power. (To switch off power, first press the power key until the main power indicator goes off, then turn the main power switch off.)

• Индикатор [Внимание] на панели управления горит или мигает.

• На дисплее сообщений панели управления аппарата появилось сообщение об ошибке.

Если индикатор [Внимание] горит или мигает и на дисплее сообщений панели управления аппарата появилось сообщение об ошибке, проверьте KYOCERA Client Tool или Монитор состояния.

ПРИМЕЧАНИЕ Если индикаторы постоянно горят и мигают не так, как описано выше, вероятно, произошла ошибка службы. Выключите питание, отсоедините шнур питания и вставьте его обратно, после чего включите питание. Это может помочь сбросить ошибку. Если ошибка не исчезает, свяжитесь со своим представителем сервисной службы (тел. в Минске +375 17 291-28-24)

Ниже описаны неполадки, которые не могут быть устранены пользователем

|

Дисплей сообщений |

Описание |

Меры устранения |

|

Бункер отраб тонера перепол. или не уст. |

Бункер для отработанного тонера установлен неправильно |

Установите Бункер для отработанного тонера должным образом |

|

Бункер для отработанного тонера заполнен |

Замените бункер отработанного тонера |

|

|

Встряхните картр. с тонером |

Тонер слежался |

Откройте переднюю крышку аппарата и вытяните контейнер с тонером. Сильно встряхните контейнер с тонером и установите его на место |

|

Вызовите сервисный персонал. |

В аппарате произошла ошибка |

Обратите внимание на код ошибки, отображаемый в дисплее сообщений, и свяжитесь с представителем сервисной службы (тел. в Минске +375 17 291-28-24) |

|

Выньте бумагу с внутреннего лотка |

Извлеките бумагу из внутреннего лотка. Нажмите клавишу [OK], чтобы возобновить печать |

|

|

Добавьте тонер |

Закончился тонер |

Замените контейнер с тонером TK-4105 |

|

Загрузите бумагу в кассету # |

↑↓ (отображается попеременно) |

Загрузите бумагу. Нажмите клавишу [OK] и перейдите к следующему шагу. • Для выбора другого устройства подачи выберите [Выберите бумагу]. • Для печати на бумаге, в настоящее время находящейся в устройстве подачи, выберите [Продолж. без изм.] |

|

Загрузите бумагу в универсальный лоток |

↑↓ (отображается попеременно) |

Загрузите бумагу. Нажмите клавишу [OK] и перейдите к следующему шагу. • Для выбора другого устройства подачи выберите [Выберите бумагу]. • Для печати на бумаге, в настоящее время находящейся в устройстве подачи, выберите [Продолж. без изм.] |

|

Закройте автоподатчик оригиналов |

Открыт автоподатчик оригиналов |

Откройте и закройте автоподатчик оригиналов |

|

Закройте крышку автопод. оригиналов |

Открыта верхняя крышка автоподатчика оригиналов |

Откройте и закройте крышку автоподатчика оригинало |

|

Закройте переднюю крышку |

Открыта передняя крышка |

Откройте и закройте переднюю крышку |

|

Закройте правую крышку # |

Открыта какая-либо крышка |

Откройте и закройте крышку, обозначенную на экране |

|

Замятие бумаги. (DP) |

В автоподатчике произошло замятие бумаги. |

См. Устранение замятия бумаги в Руководстве по эксплуатации и извлеките замятую бумагу |

|

Замените МК |

Необходимо производить замену деталей комплекта техобслуживания MK-4105 (ремкомплекта) каждые 150 000 страниц печати. |

Данная операция должна производиться специалистом. Обратитесь к представителю сервисной службы (тел. в Минске +375 17 291-28-24) |

|

Замятие |

Произошло замятие бумаги в кассете или универсальном лотке |

См. Устранение замятия бумаги и извлеките замятую бумагу |

|

Извлеките оригиналы из автоподатчика |

Для продолжения работы необходимо извлечь оригиналы из автоподатчика оригиналов |

Извлеките оригиналы из автоподатчика оригиналов |

|

Кабель USB был отключен |

Кабель USB не подключен |

Нажмите клавишу [OK] и подключите кабель USB |

|

ПК выключен |

Нажмите клавишу [OK] и включите ПК |

|

|

Не удается найти KYOCERA Client Tool |

Нажмите клавишу [OK] и откройте KYOCERA Client Tool на ПК |

|

|

Макс. к-во сканируемых страниц |

Превышен предел сканирования |

Дальнейшее сканирование невозможно. Задание отменено. Нажмите клавишу [OK] |

|

Мало тонера. (Зам., когда законч.) |

Скоро понадобится заменить контейнер с тонером |

Получите новый контейнер с тонером TK-4105. |

|

Не оригинальный тонер |

Установлен контейнер с тонером не марки Kyocera |

Производитель не несет ответственности за повреждения, вызванные использованием неоригинального тонера. Мы рекомендуем использовать исключительно оригинальные контейнеры с тонером TK-4105. . |

|

Неверный ид. уч. зап. Задание отменено |

Указан неверный идентификатор учетной записи при внешней обработке задания. Задание отменено |

Нажмите клавишу [OK] |

|

Невозможна двусторонняя печать на этой бумаге |

Не возможна печать на бумаге выбранного формата или типа |

Нажмите клавишу [OK] и перейдите к следующему шагу: |

|

Недостаточно памяти. Невозможно начать выполнение задания |

Невозможно начать выполнение задания |

Повторите попытку позже |

|

Ограничено алгоритмом учета заданий(Печать) |

Задание отменено, поскольку его выполнение ограничено функцией учета заданий |

Нажмите клавишу [OK] |

|

Ограничено алгоритмом учета заданий(Сканер) |

Задание отменено, поскольку его выполнение ограничено функцией учета заданий |

Нажмите клавишу [OK] |

|

Очистите сканер |

Произошло загрязнение сканера |

Очистите щелевое стекло с помощью чистящей салфетки, поставляемой вместе с автоподатчиком оригиналов. |

|

Ошибка. Выключить |

— |

Отключите и снова включите аппарат с помощью выключателя питания |

|

Память переполнена |

Невозможно продолжить выполнение задания из-за отсутствия свободной памяти |

Измените разрешение печати с Быстр1200 до 600 dpi. См. Printer Driver User Guide |

|

Память сканера переполнена |

Дальнейшее сканирование невозможно из-за нехватки памяти сканера. |

Для отмены задания нажмите [OK] |

|

Перезагрузка печати. Задание отменено |

Предупреждение. Недостаточно памяти принтера. Задание отменено |

Нажмите клавишу [OK] |

|

Превышено ограничение учета заданий |

Превышено число распечаток из-за ограничения алгоритмом учета заданий. Достигнут предел печати |

Это задание отменено. Нажмите клавишу [OK] |

|

Уст.другую кассету |

Выбрано «Сдвиг» |

Для использования сдвига необходимо загрузить в другой лоток бумагу такого же формата, что и в выбранном устройстве подачи, но в другой ориентации |

|

Установите все оригиналы обратно и нажмите клавишу [Старт]. |

Возникает при печати двусторонних документов в режиме ручной двусторонней печати |

Извлеките оригиналы из автоподатчика оригиналов, расположите их в первоначальном порядке и положите обратно. Нажмите клавишу [OK], чтобы возобновить печать. Для отмены задания нажмите [Стоп] |

|

Установлен неизвестный тонер. ПК |

Региональная спецификация контейнера с тонером не соответствует спецификации аппарата |

Установите оригинальный контейнер с тонером Замените контейнер с тонером TK-4105 |

Рассмотрим самые распространненные неисправности МФУ Kyocera Ecosys M3040dn, M3040idn, M3145dn, M3540dn, M3540idn, M3550idn, M3560idn, M3645dn, M3655idn, M3660idn и принтеров Kyocera Ecosys FS-2100D, FS-2100DN, FS-4100DN, FS-4200DN, FS-4300DN, P3045dn, P3050dn, P3055dn, P3060dn, P3145dn, P3150dn, P3155dn, P3260dn. Неисправности на данных аппаратах довольно типичные.

Читайте также:

Коды ошибок функции диагностики (System Error Fxxxx) для принтеров Kyocera серии FS-2100DN/4100DN/4200DN/4300DN, а также для ECOSYS P3045dn/P3050dn/P3055dn/P3060dn.

Коды ошибок функции диагностики (Self-diagnostic function) для принтеров Kyocera серии FS-2100DN/4100DN/4200DN/4300DN, а также для ECOSYS P3045dn/P3050dn/P3055dn/P3060dn.

Электрические и механические неисправности для серии принтеров Kyocera FS-2100DN/4100DN/4200DN/4300DN, а также для ECOSYS P3045dn/P3050dn/P3055dn/P3060dn.

Принтер Kyocera не забирает бумагу с нижнего лотка (не берет бумагу, заминает бумагу, не захватывает бумагу)

Замену комплекта роликов 302F906230, 302F909171, 302HN06080 выполним на выезде за одно посещение. У мастера всегда есть с собой как оригинальный сервисный набор роликов, так и совместимый комплект. Стоимость замены 1 комплекта составляет 1200 руб без учета стоимости ЗИП. Актуальную стоимость комплекта роликов можно посмотреть в нашем каталоге

Kyocera берет по несколько листов

Если быть точным, то требуется замена ролика отделениия, НО рекомендуем заменить комплект роликов (3 шт.), а также замена площадки отделения.

Не захватывает листы с автоподатчика

Проблема с забором бумаги из ADF связана с износом роликов автоподатчика. Нужно заменить ремкомплект автоподатчика MK-3140 в сборе или можно заменить только комплект роликов ADF (без узла) и площадку отделения документов. Второй вариант наиболее экономичный.

Полосы при печати, грязная печать

Полосы при печати, грязная печать

Следующая неисправность, с которой сталкиваются большинство пользователей — неисправность связанная с качеством печати.

Скорее всего в аппарате установлены заправленные или аналоговые картриджи низкого качества.

К ремонту необходимо подойти комплексно. Рекомендуем провести полное техническое обслуживание МФУ Kyocera. С помощью специального пылесоса вычистить аппарат от старого тонера. Только после этого установить новые картриджи с качественным тонера (НЕ ЗАПРАВЛЕННЫЕ!).

Мы реализуем проверенные совместимые картриджи, качество которых не отличается от оригинальных!

Нередко происходит износ ролика заряда фотобарабана, в связи с чем аппарат начинает печатать с полосами, грязью. Решение очевидное — замена ролика заряда.

Крайне редко ремонт блока фотобарабана в сборе не поможет, т.к. это ресурсный блок на 300 000 страниц, который отслужил свой срок и пришла пора заменить Фотобарабан в сборе.

Kyocera печатает бледные листы (Бледная печать)

Причиной бледной печати принтеров Kyocera является, чаще всего, пустой картридж или картридж, тонер в котором почти закончился, заправленный или совместимый картридж низкого качетва. Попробуйте заменить картридж на новый. РЕКОМЕНДУЕМ предварительно провести техническое обслуживание аппарата Kyocera с дальнейшим его запуском с новым картриджамем. В данном случае требуется 2 картриджа, т.к. тонер с 1 картриджа практически полностью прокачается в блок проявки.

Kyocera копирует и сканирует с полосой (полосами)

Очень важный момент в том, что полоса на листке идет как при сканировании, так и при копировании. При данной неисправности Вашему аппарату требуется техническое обслуживание. Стоимость — 1500 руб.

Kyocera cкрипит во время работы.

Скрипит принтер Kyocera? Смените картридж. Скорее всего скрипит именно он. Возможно Вашему аппарату требуется обслуживание — чистка, смазка. Стоимость ТО с выездом мастера — от 1600 руб

Kyocera не сканирует, не копирует

Проверьте стол сканера на предмет механического повреждения. Осмотрите петли сканера, не сломанные ли они. Проверьте провода, которые крепят крышку сканера к МФУ, нет ли обрыва.

Может быть пора заменить Ремонтный комплект ADF Kyocera MK 3140 ? Вскрытие покажет! Обращайтесь!

Аппарат Kyocera выдает ошибку «Замените МК»

MK — это ремкоплект основных узлов принтера МФУ. В состав MK входят такие ресурсные блоки, как блок фотобарабана, термоузел в сборе, блок проявки, а также вал переноса, узел роликов подачи и ролик отделения. Заявленный ресурс MK — 300 000 ресурс. Ошибка «Замените МК» означает, что аппарат прошел данный ресурс и пора заменить ремкомплект. Если печать чистая, без явных дефектов, то можно попробовать сбросить ошибку и продолжить работу. В противном случае, без замены ремкомплекта не обойтись. После замены MK, аппарат работает как новый. Ресурс после замены МК такой же — 300 000 стр.

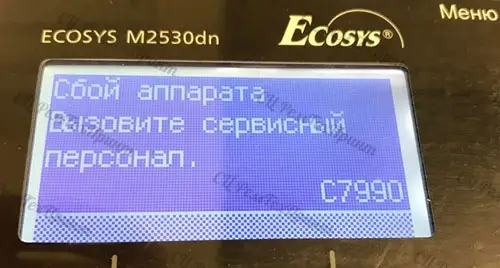

Заполнен бункер отработанного тонера Kyocera «Ошибка C7990»

Заполнен бункер отработанного тонера Kyocera «Ошибка C7990»

При печати лишний тонер попадает в бункер WT-3100. Со временем бункер заполняется и аппарат выдает сообщение «Ошибка C7990». Поможет очистка бункера или его замена бункера отработанного тонера WT-3100. Чаще всего данный бункер входит в состав картриджа. Стоимость чистки бункера от отработанного тонера на выезде — 1200-1600 руб.

Сломана петля крышки сканера МФУ Kyocera

Более подробно о данном повреждении читайте в нашей статье

Тонер не запекается на бумаге (стирается изображение или текст, не держится тонер). Полосы при печати. Кляксы на листе.

Все эти неисправности говорят о том, что пора заменить печь в сборе FK-3100

Если при работе с копировальном аппаратом у вас возникли проблемы, и система выдает код ошибки, вы можете идентифицировать ее с помощью данной таблицы.