-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

*21328994_1114*

Drive Technology Drive Automation System Integration Services

Compact Operating Instructions

Decentralized Drive Systems

MOVIMOT

®

MM..D with AS-Interface

Edition 11/2014

21328994/EN

Related Manuals for SEW-Eurodrive MOVIMOT MMxD Series

Summary of Contents for SEW-Eurodrive MOVIMOT MMxD Series

-

Page 1

*21328994_1114* Drive Technology Drive Automation System Integration Services Compact Operating Instructions Decentralized Drive Systems MOVIMOT ® MM..D with AS-Interface Edition 11/2014 21328994/EN… -

Page 2

SEW-EURODRIVE—Driving the world… -

Page 3: Table Of Contents

Contents Contents General information ……………………5 Scope of this documentation ………………5 Structure of the safety notes ………………5 Other applicable documentation ………………6 Safety notes ……………………..7 Preliminary information ………………..7 General information ………………….7 Target group ……………………7 Designated use ………………….

-

Page 4

Contents Service……………………….55 Status and error display ………………..55 Error list ……………………59 Unit replacement ………………….63 Declaration of conformity ………………….. 65 ® Compact Operating Instructions – MOVIMOT MM..D with AS-Interface… -

Page 5: General Information

General information Scope of this documentation General information Scope of this documentation This documentation comprises the general safety notes and information regarding ® MOVIMOT MM..D with AS-Interface. • Please note that this documentation does not replace the detailed operating in- structions.

-

Page 6: Other Applicable Documentation

General information Other applicable documentation Meaning of the hazard symbols The hazard symbols in the safety notes have the following meaning: Hazard symbol Meaning General hazard Warning of dangerous electrical voltage Warning of hot surfaces Warning of risk of crushing Warning of suspended load Warning of automatic restart 1.2.3…

-

Page 7: Safety Notes

Safety notes Preliminary information Safety notes The following basic safety notes must be read carefully to prevent injury to persons and damage to property. The user must ensure that the basic safety notes are read and observed. Make sure that persons responsible for the plant and its operation, as well as persons who work independently on the unit, have read through the operating instructions carefully and understood them.

-

Page 8: Designated Use

Safety notes Designated use Designated use ® MOVIMOT inverters are components intended for installation in electrical systems or machines. ® In case of installation in machines, startup of MOVIMOT inverters (i.e. start of desig- nated operation) is prohibited until it is determined that the machine meets the require- ments stipulated in the Machinery Directive 2006/42/EC.

-

Page 9: Installation

Safety notes Installation Installation The units must be installed and cooled according to the regulations and specifications contained in the corresponding documentation. ® Protect the MOVIMOT inverters from excessive strain. The following applications are prohibited unless explicitly permitted: • Use in potentially explosive areas. •…

-

Page 10: Operation

Safety notes Operation Operation ® Systems with integrated MOVIMOT inverters must be equipped with additional moni- toring and protection devices, if necessary, according to the applicable safety guide- lines, such as the law governing technical equipment, accident prevention regulations, etc. Additional preventive measures may be required for applications with increased hazard potential.

-

Page 11: Type Designations

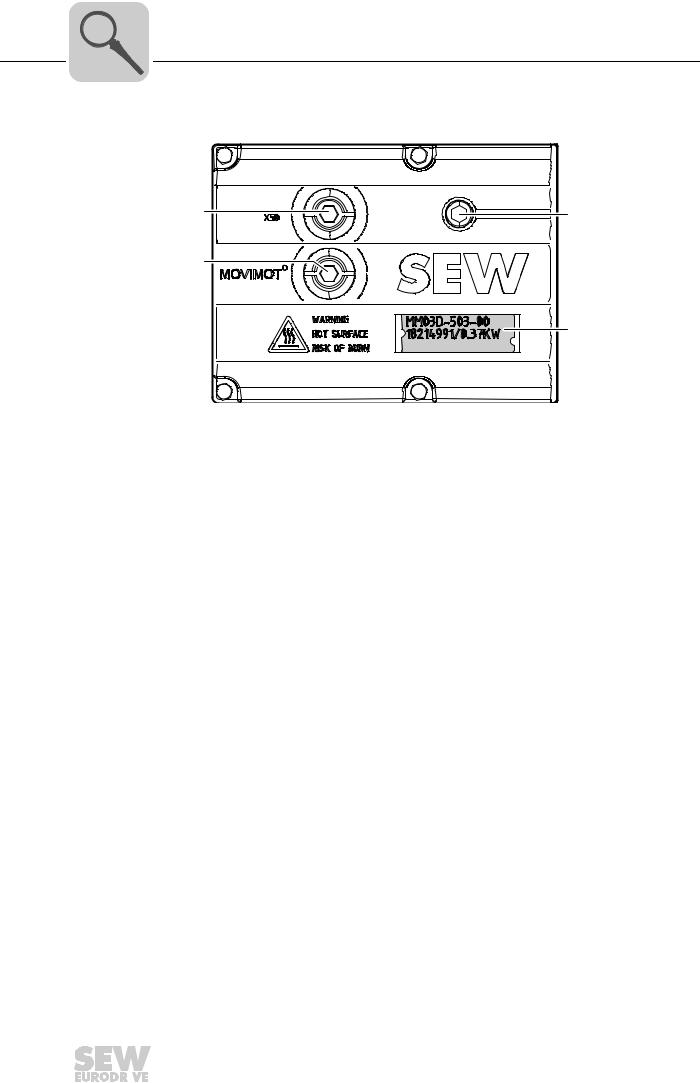

Type designations MOVIMOT® drive type designation Type designations MOVIMOT® drive type designation MOVIMOT ® drive type designation 3.1.1 Nameplate The following figure gives an example of a MOVIMOT ® drive nameplate. The name- plate is on the motor. 76646 Bruchsal/Germany R F 4 7 D R E 9 0 L 4 B E 2 / M M 1 5 / M O / A V S K 0 1 .

-

Page 12: Movimot® Inverter Type Designation

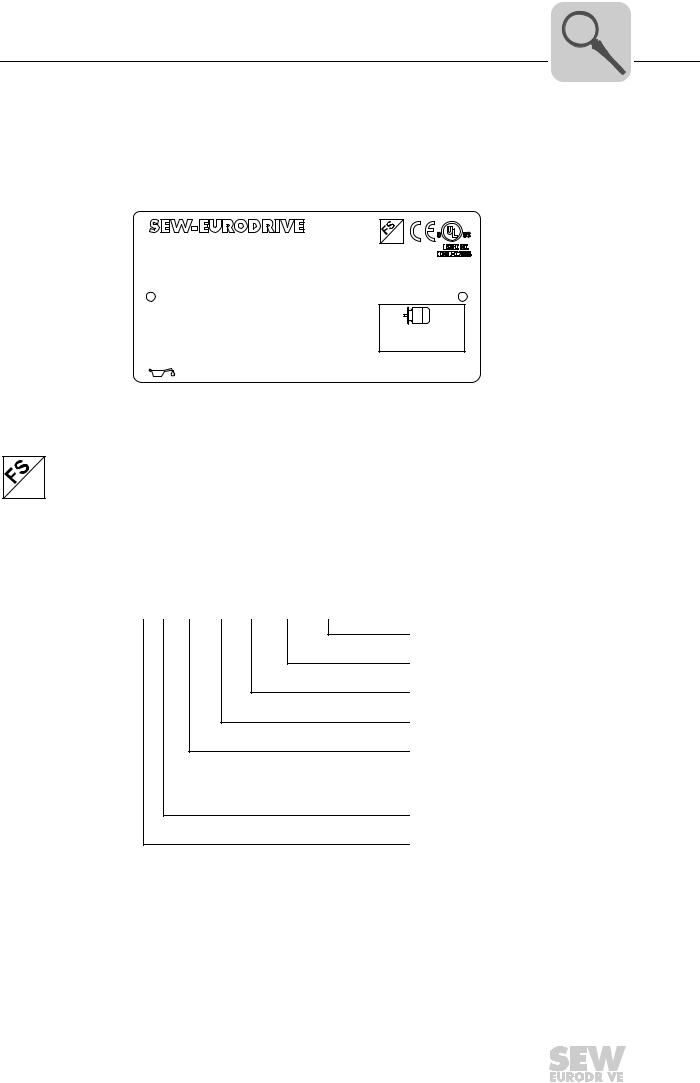

Type designations MOVIMOT® inverter type designation MOVIMOT® inverter type designation MOVIMOT ® inverter type designation 3.2.1 Nameplate ® The following figure gives an example of a MOVIMOT inverter nameplate: Status: A — — 15 10 16 08/14 829 Type : MM15D-503-00 P# : 18215033 S# : 1757110…

-

Page 13

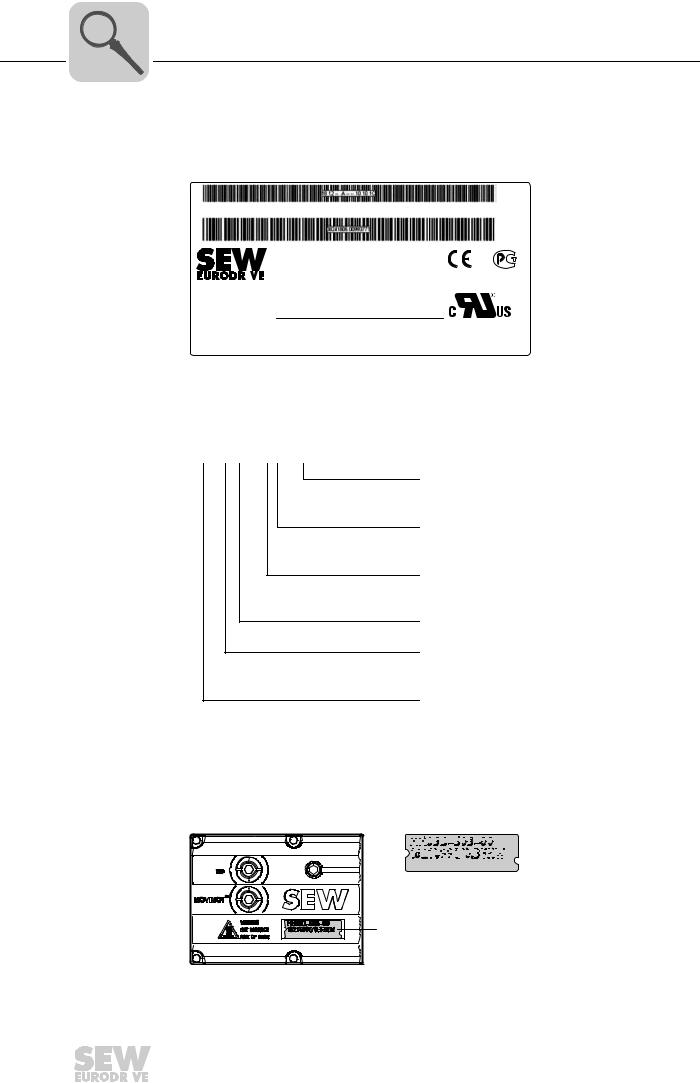

Type designations MOVIMOT® inverter type designation 3.2.3 Unit identification The unit identification [1] on the top of the MOVIMOT ® inverter provides information about the inverter type [2], inverter part number [3], unit power [4]. 1 min 9007199712657547 3.2.4 AS-Interface option nameplate The following figure shows an example of the nameplate of the AS-Interface option MLK30A: 9007201609242891… -

Page 14: Type Designation Of The Design «Mounted Close To The Motor

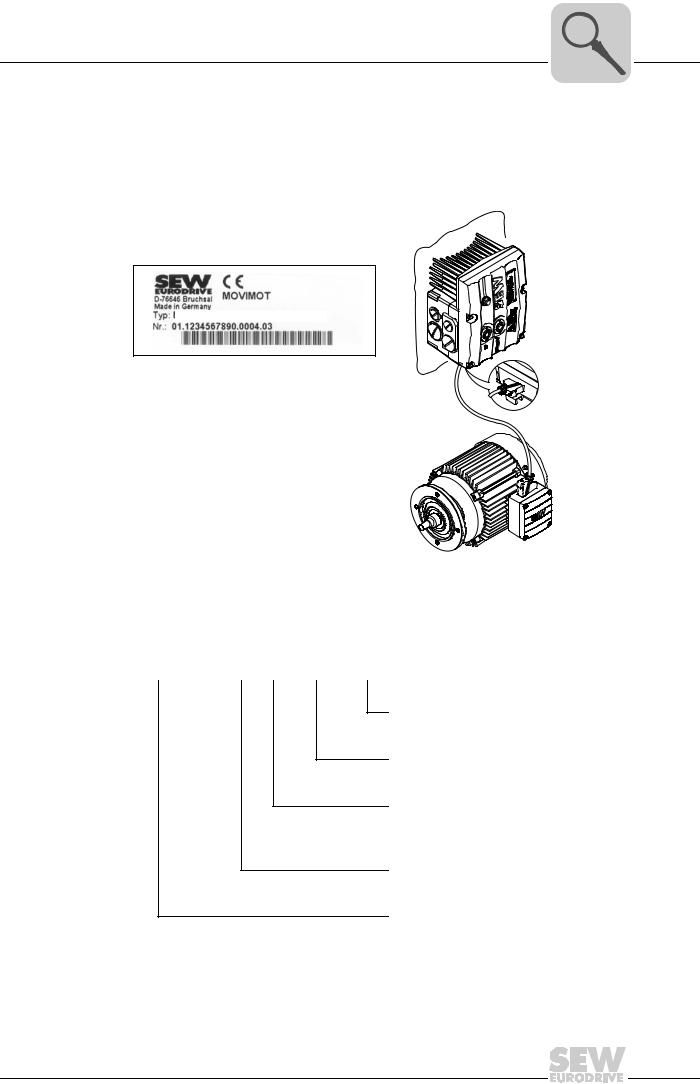

Type designations Type designation of the design «mounted close to the motor» Type designation of the design «mounted close to the motor» 3.3.1 Nameplate ® The following figure shows an example of the MOVIMOT inverter mounted close to the motor with corresponding nameplate and type designation: U = 3×380.

-

Page 15: Mechanical Installation

Mechanical installation General information Mechanical installation General information • Observe the general safety notes. • Comply with all instructions referring to the technical data and the permissible con- ditions where the unit is operated. ® • Only use the provided attachment options when mounting the MOVIMOT drive.

-

Page 16: Installation Of Movimot Gearmotor

Mechanical installation Installation of MOVIMOT® gearmotor Installation of MOVIMOT® gearmotor Installation of MOVIMOT ® gearmotor 4.4.1 Installation tolerances The following table shows the permitted tolerances of the shaft ends and flanges of the MOVIMOT ® drive. Shaft end Flange Diameter tolerance according to EN 50347 Centering shoulder tolerance in ac- cordance with EN 50347 •…

-

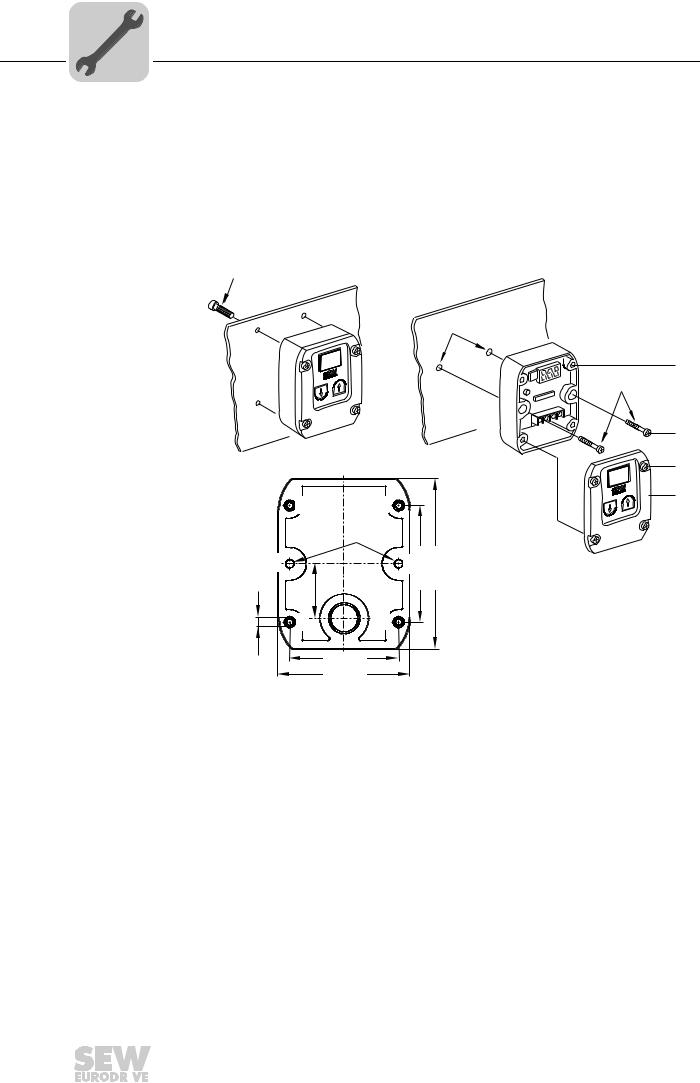

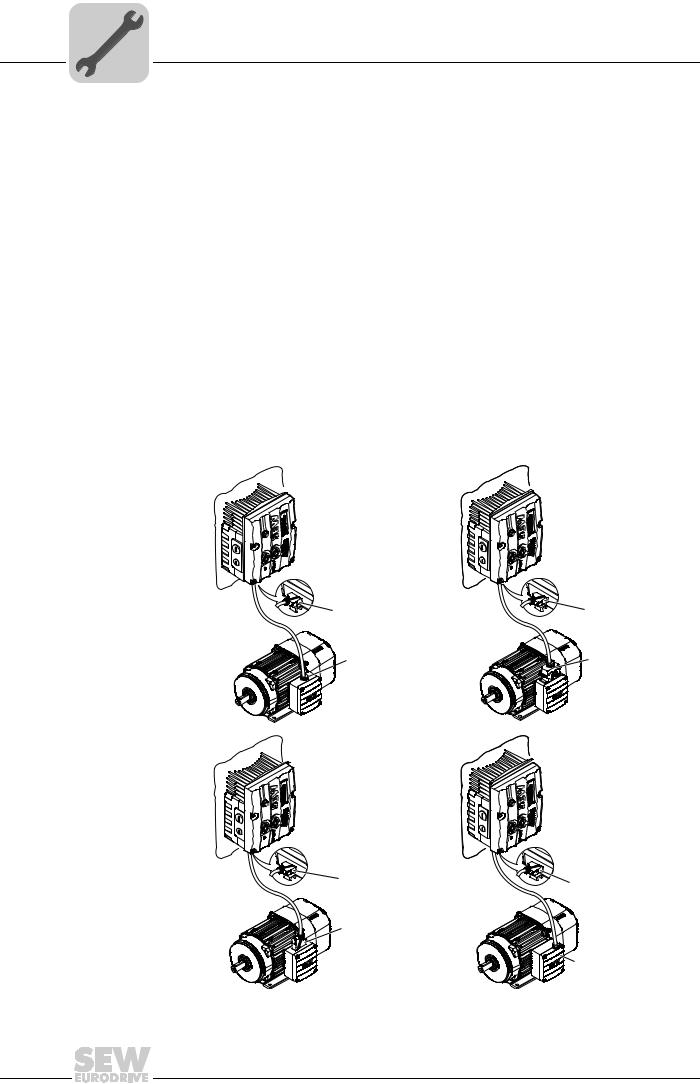

Page 17: Mounting Movimot Inverter Close To The Motor

Mechanical installation Mounting MOVIMOT® inverter close to the motor 4.4.3 Installation in damp locations or in the open Observe the following notes for mounting the MOVIMOT ® drive in damp areas or in the open: • Use suitable cable glands for the incoming cables. Use reducing adapters if neces- sary.

-

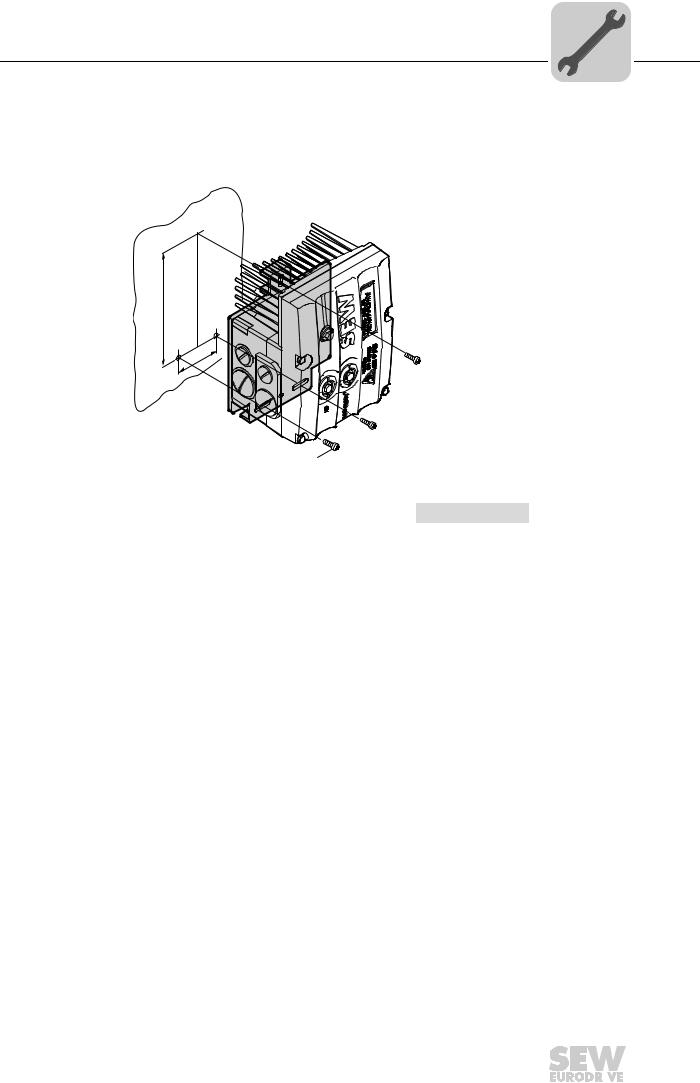

Page 18: Tightening Torques

Mechanical installation Tightening torques Tightening torques 4.6.1 MOVIMOT ® inverter ® Tighten the screws on the MOVIMOT inverter using 3.0 Nm (27 lb.in) in diametrically opposite sequence. 9007199713318923 4.6.2 Screw plugs Tighten screw plugs of potentiometer f1 and connection X50 using 2.5 Nm (22 lb.in). 9007199713311371 4.6.3 Cable glands…

-

Page 19

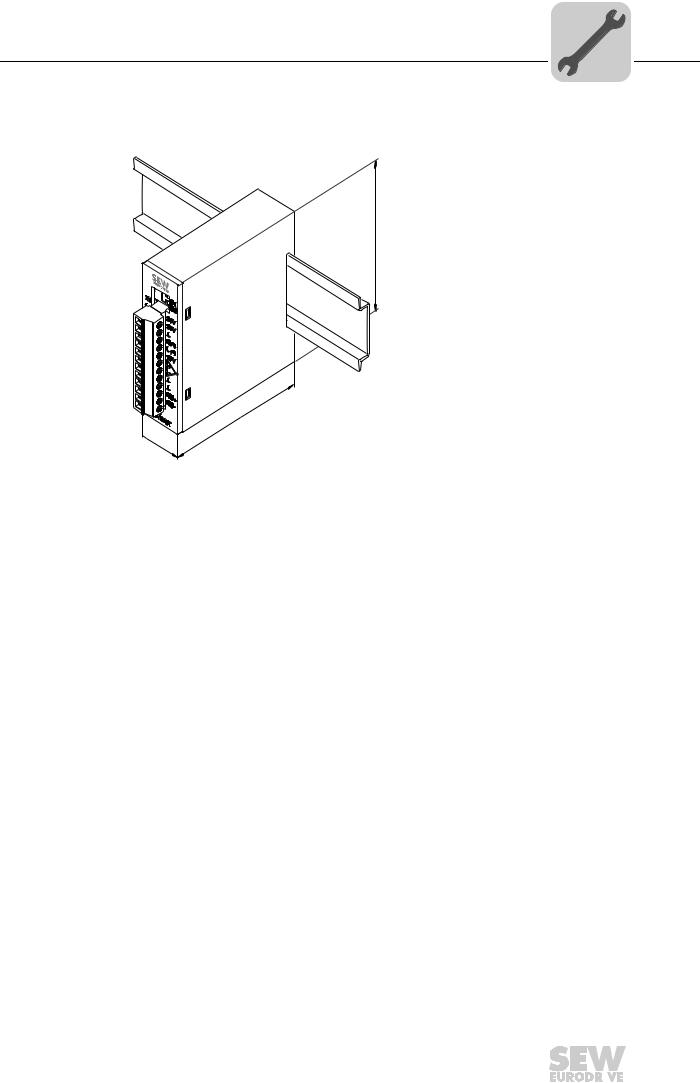

Mechanical installation Tightening torques 4.6.5 Modular connection box For fastening the connection box on the mounting plate, tighten screws using 3.3 Nm (29 lb.in). 322786187 4.6.6 Tightening torques for terminals Use the following tightening torques for terminals during installation: 1143643275 0.8 –… -

Page 20: Electrical Installation

Electrical installation General information Electrical installation General information Observe the following information on electrical installation: • Observe the general safety notes. • Comply with all instructions referring to the technical data and the permissible con- ditions where the unit is operated. •…

-

Page 21

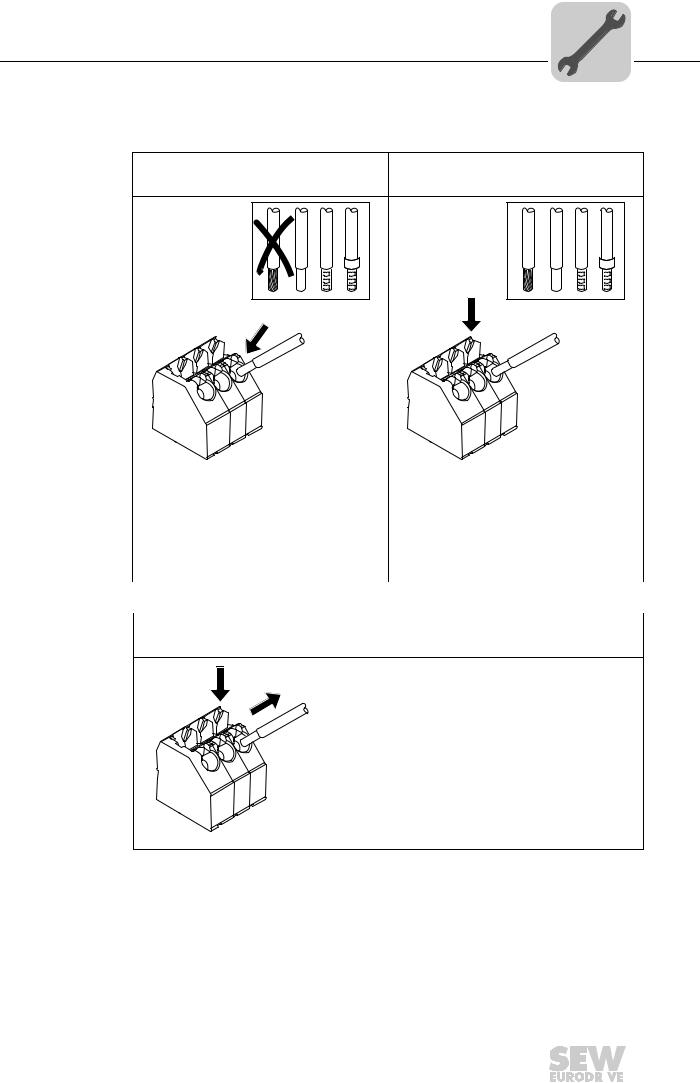

Electrical installation Installation instructions ® 5.2.2 Permitted cable cross section of the MOVIMOT terminals Power terminals Observe the permitted cable cross sections for installation: Power terminals Cable cross section 1.0 mm – 4.0 mm (2 x 4.0 mm AWG17 – AWG12 (2 x AWG12) Conductor end sleeves •… -

Page 22

Electrical installation Installation instructions 5.2.3 Residual current device WARNING Electric shock due to incorrect RCD type. Severe or fatal injuries. • The unit can cause direct current in the protective earth. In cases where an resid- ual current device (RCD) is used for protection against direct or indirect contact, only an RCD of type B on the power supply side of the frequency inverter is per- mitted. -

Page 23

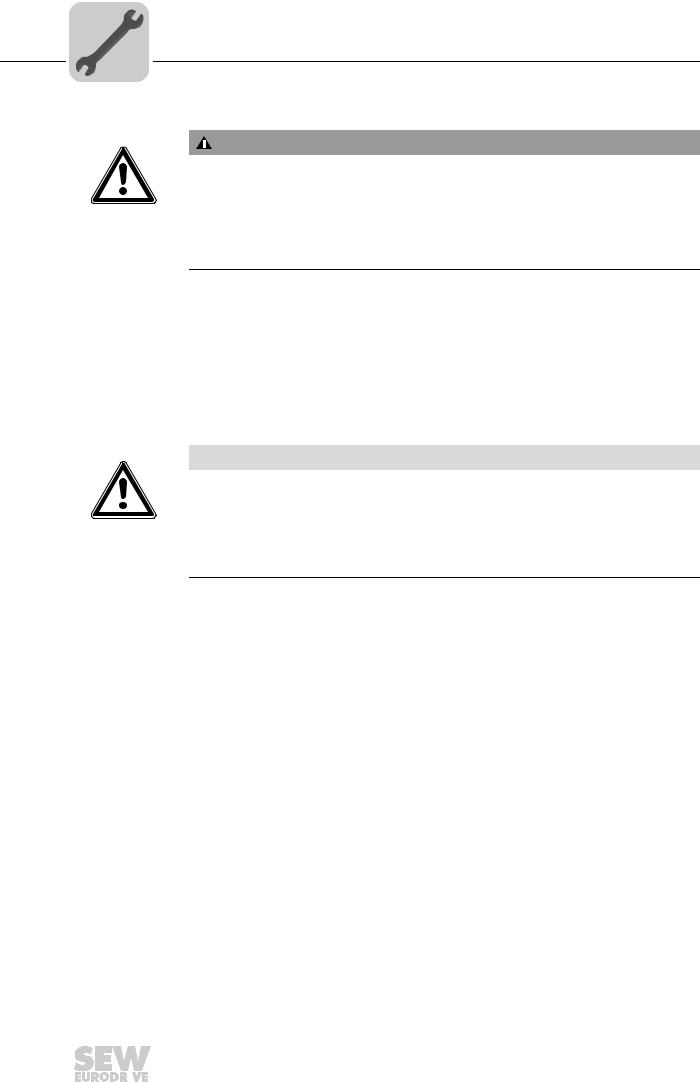

Electrical installation Installation instructions 5.2.5 Information on PE connection WARNING Electric shock due to incorrect connection of PE. Severe or fatal injuries. • The permitted tightening torque for the screw is 2.0 – 2.4 Nm (18 – 21 lb.in). • Observe the following notes regarding PE connection. -

Page 24

Electrical installation Installation instructions 5.2.6 EMC-compliant installation INFORMATION This drive system is not designed for operation on a public low voltage grid that sup- plies residential areas. This is a product with restricted availability (categories C1 to C4 according to EN 61800-3). -

Page 25

Electrical installation Installation instructions Short circuit current rating Suitable for use in current circuits with a maximum short circuit current of AC 200,000 A for the following fuses: For 240 V systems: 250 V min., 25 A max., fuse or 250 V min., 25 A max., circuit breaker For 500 V systems: 500 V min., 25 A max., fuse or 500 V min., 25 A max., circuit breaker… -

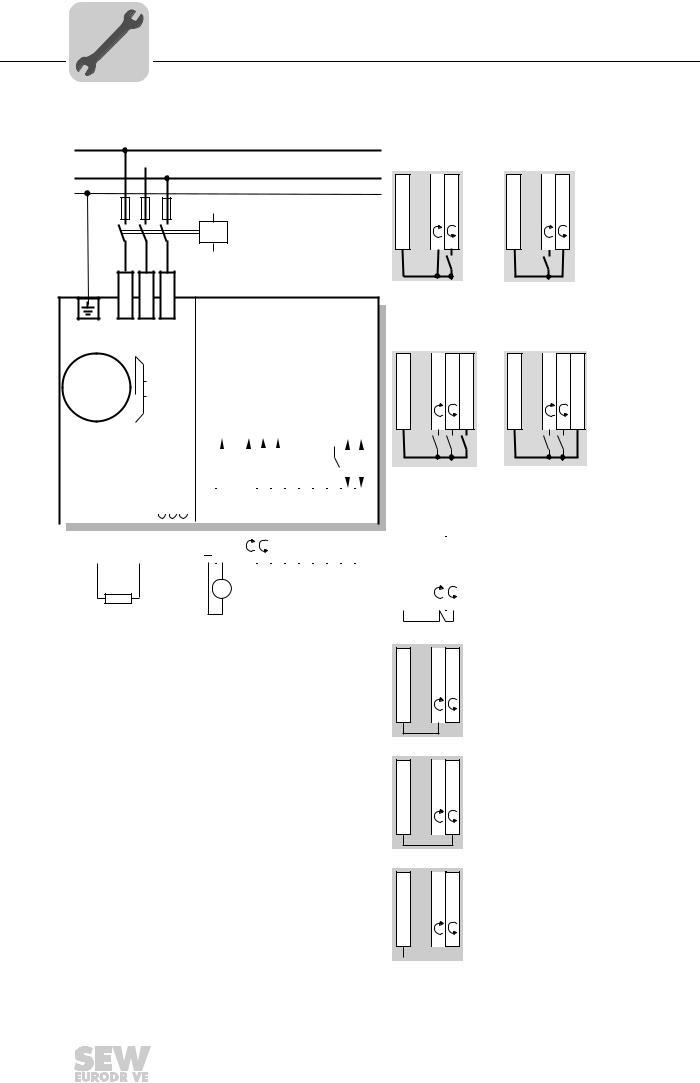

Page 26: Connection Of Movimot ® Mm

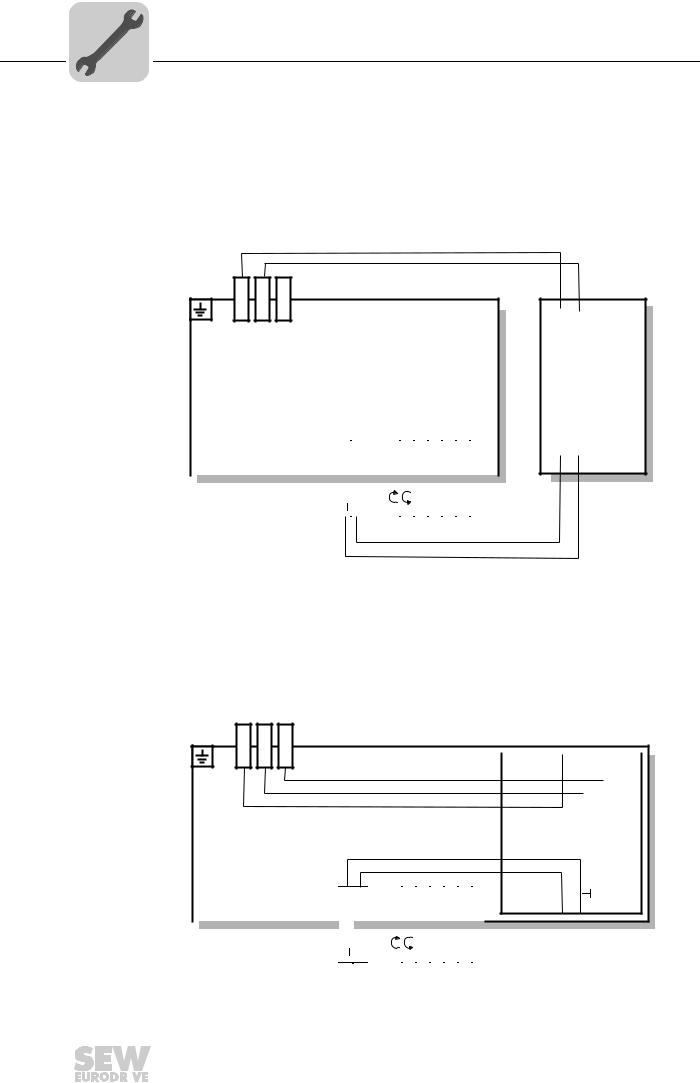

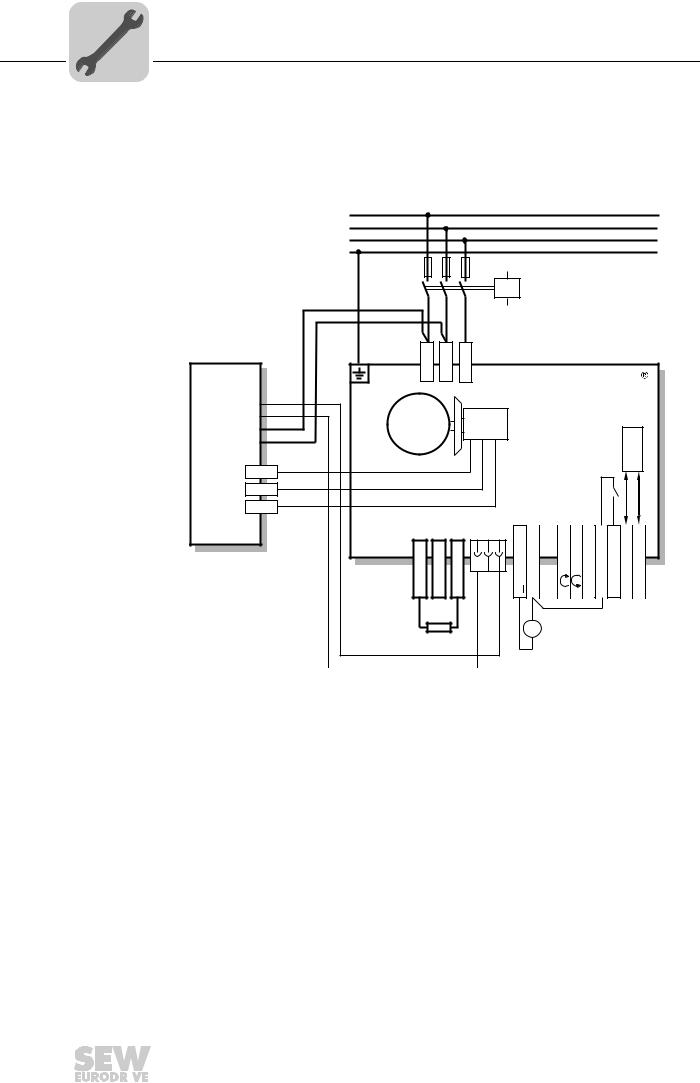

Electrical installation Connection of MOVIMOT® MM../AVSK (connection option A) Connection of MOVIMOT® MM../AVSK (connection option A) Connection of MOVIMOT ® MM../AVSK (connection option A) The following figure shows the connection in MM../AVSK design: F11/F12/F13 MM../AVSK BE/BR AS-Interface — 24 V [4][5][6][7] [8][9] BW [2]…

-

Page 27: Connection Of Movimot® Mm

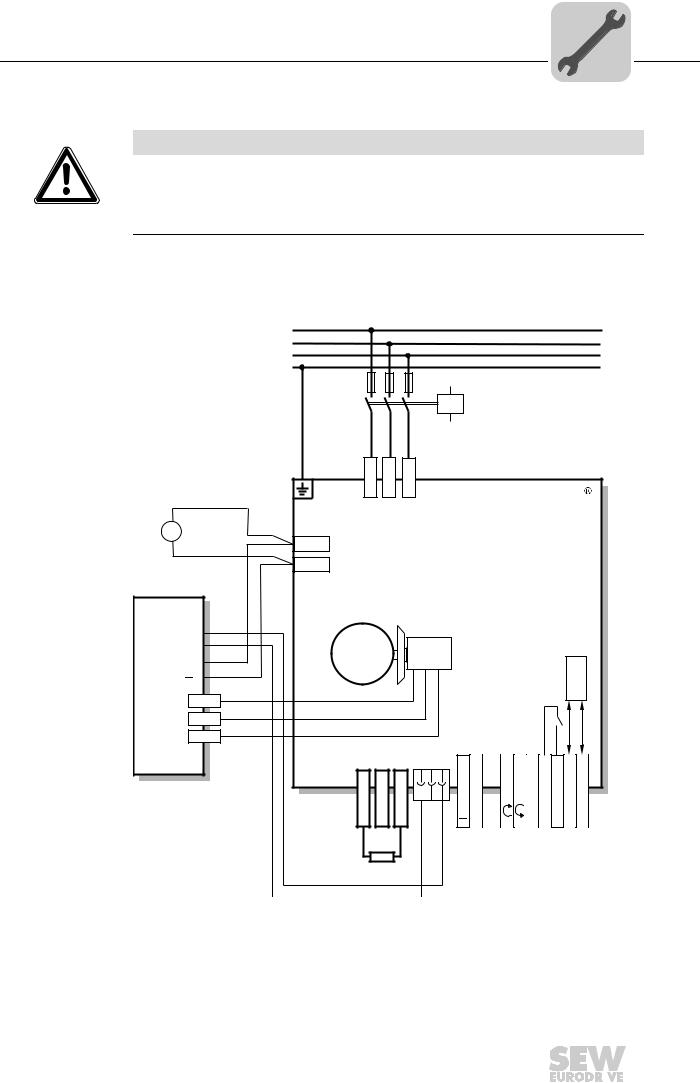

Electrical installation Connection of MOVIMOT® MM../AZSK (connection option B) Connection of MOVIMOT® MM../AZSK (connection option B) Connection of MOVIMOT ® MM../AZSK (connection option B) The following figure shows the connection in MM../AZSK design: F11/F12/F13 MM../AZSK BE/BR AS-Interface — 24 V BW [4] V024 AS-Interface +…

-

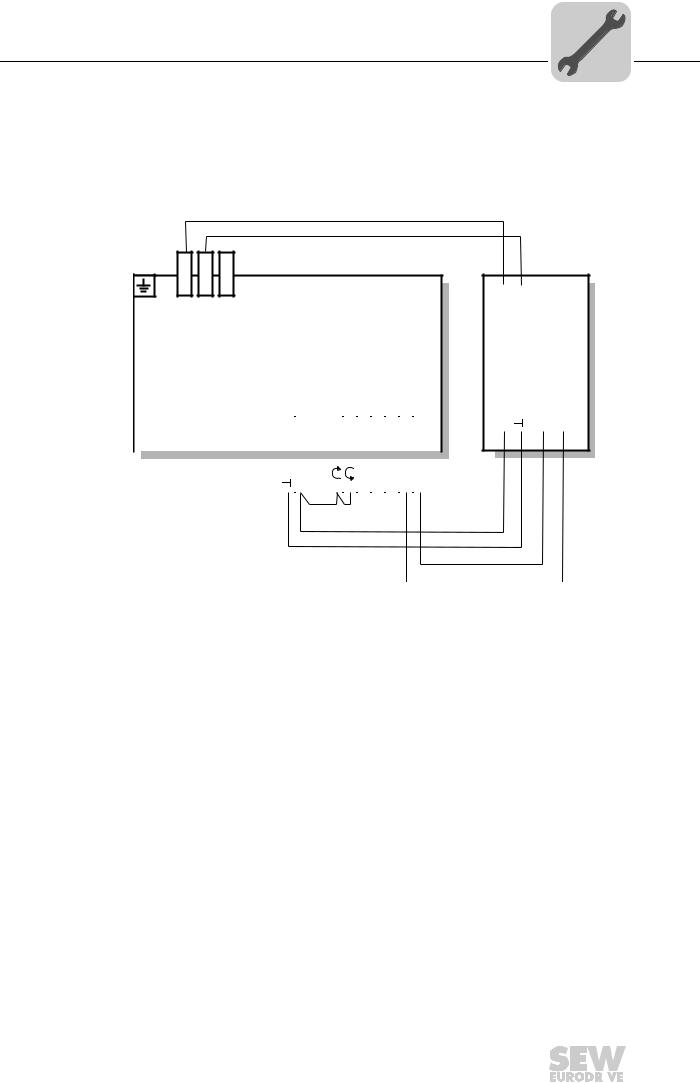

Page 28: Connection Of Movimot® Mm

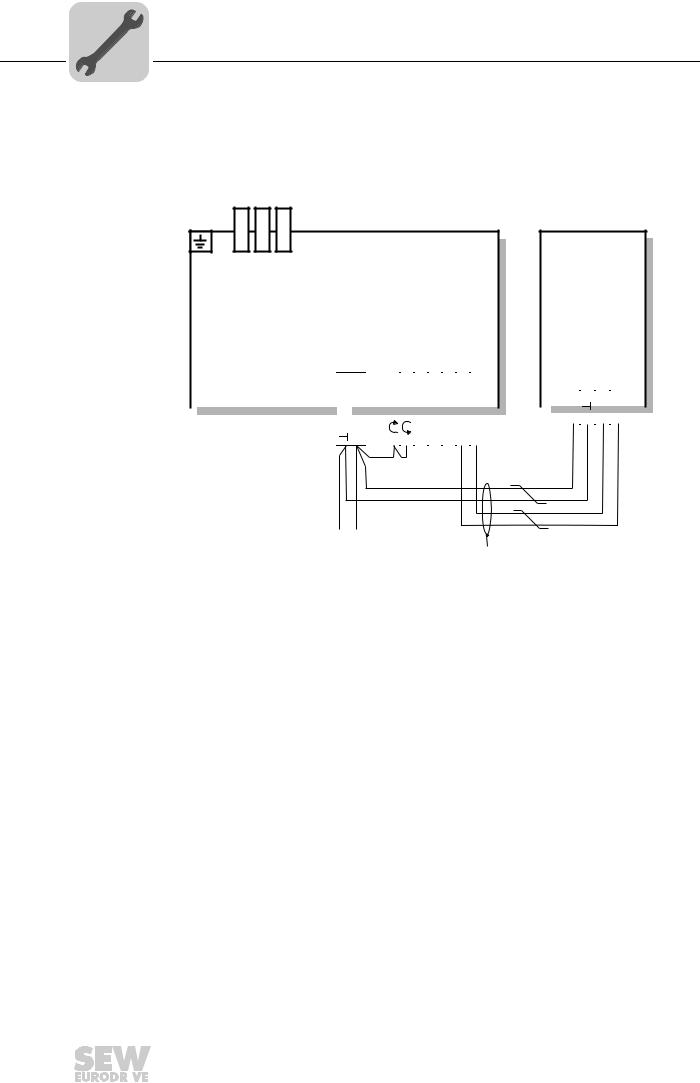

Electrical installation Connection of MOVIMOT® MM../AND3/AZSK (connection option C) Connection of MOVIMOT® MM../AND3/ AZSK (connection option C) Connection of MOVIMOT ® MM../AND3/AZSK (connection option C) The following figure shows the connection in MM../AND3/AZSK design: AS-Interface + AS-Interface — V024 N.C. N.C.

-

Page 29: Connection Of Movimot® Mm

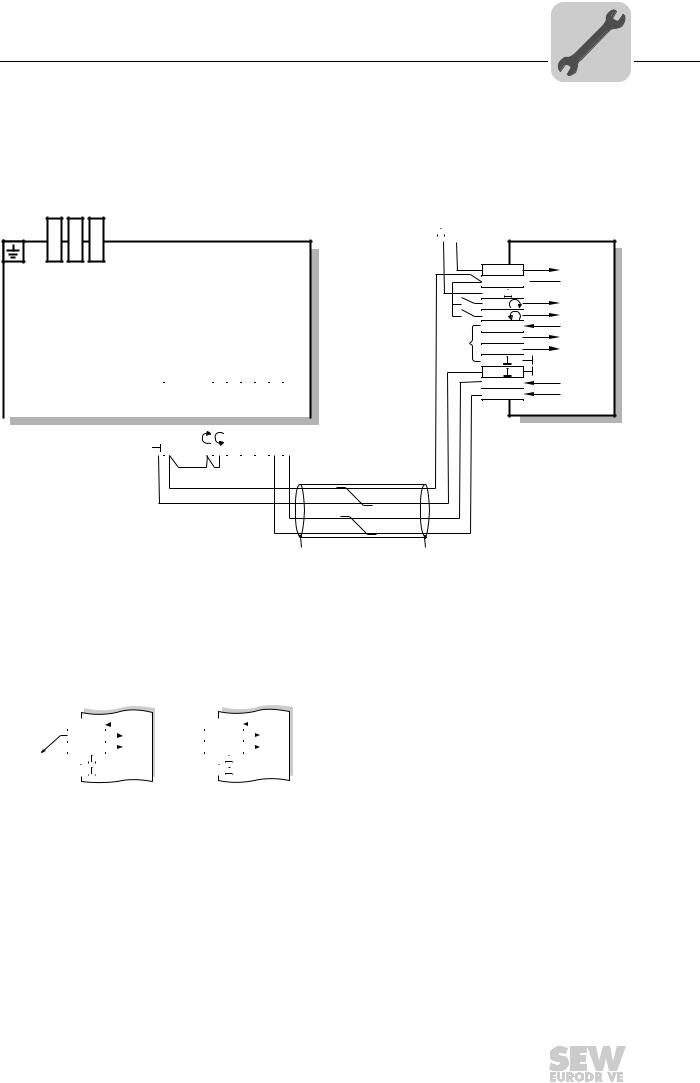

Electrical installation Connection of MOVIMOT® MM../AZZK (connection option D1/D2) Connection of MOVIMOT® MM../AZZK (connection option D1/D2) Connection of MOVIMOT ® MM../AZZK (connection option D1/D2) The following figure shows the connection in MM../AZZK design: F11/F12/F13 MM../AZZK BE/BR X03 X02 AS-Interface — 24 V [6][7] BW [4]…

-

Page 30: Connection Of Movimot® Mm

Electrical installation Connection of MOVIMOT® MM../AND3/AZZK (connection option D3/D4) Connection of MOVIMOT® MM../AND3/ AZZK (connection option D3/D4) Connection of MOVIMOT ® MM../AND3/AZZK (connection option D3/D4) The following figure shows the connection in MM../AND3/AZZK design: AS-Interface + AS-Interface — V024 V024 N.C.

-

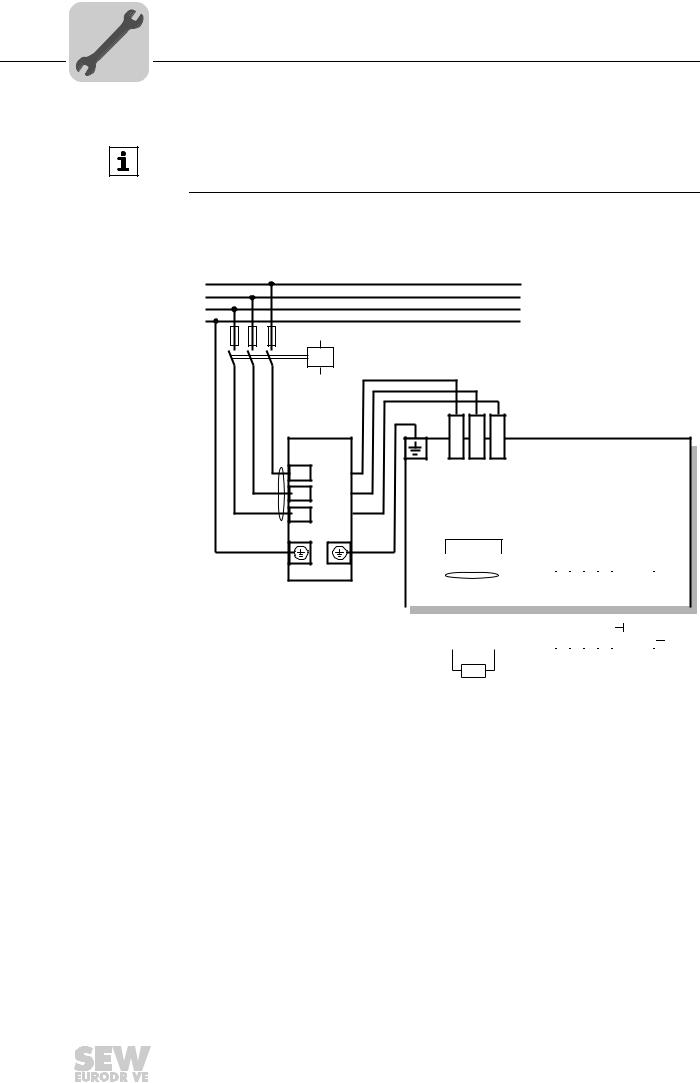

Page 31: Connection Between Movimot And Motor When Mounted Close To The Motor

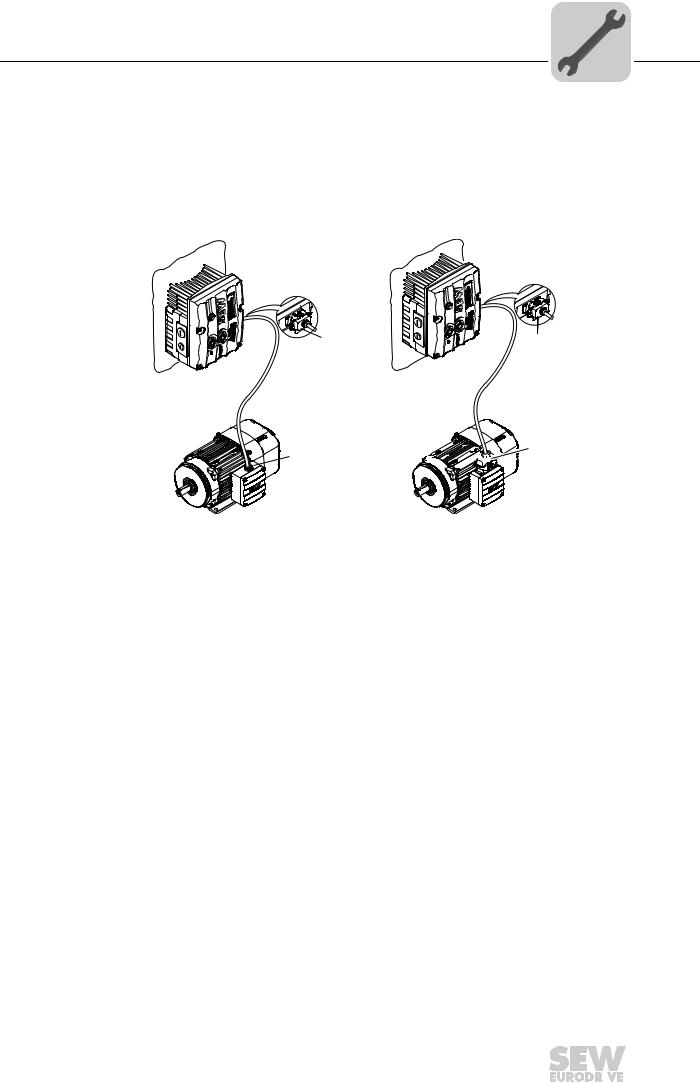

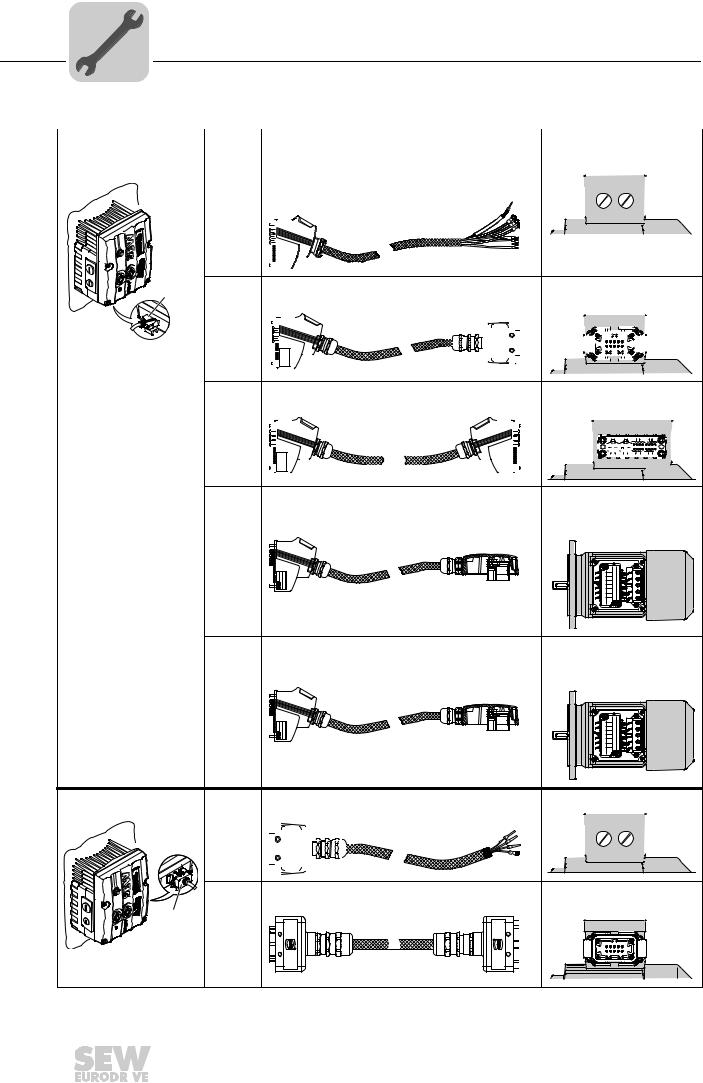

Electrical installation Connection between MOVIMOT® and motor when mounted close to the motor Connection between MOVIMOT® and motor when mounted close to the motor Connection between MOVIMOT ® and motor when mounted close to the motor If the MOVIMOT ® inverter is mounted close to the motor, the connection to the motor is realized with a pre-fabricated hybrid cable.

-

Page 32

Electrical installation Connection between MOVIMOT® and motor when mounted close to the motor ® 5.8.2 MOVIMOT with ALA4 plug connector The ALA4 design results in the following connection options to the motor, dependent upon the hybrid cable used: Design MOVIMOT ®… -

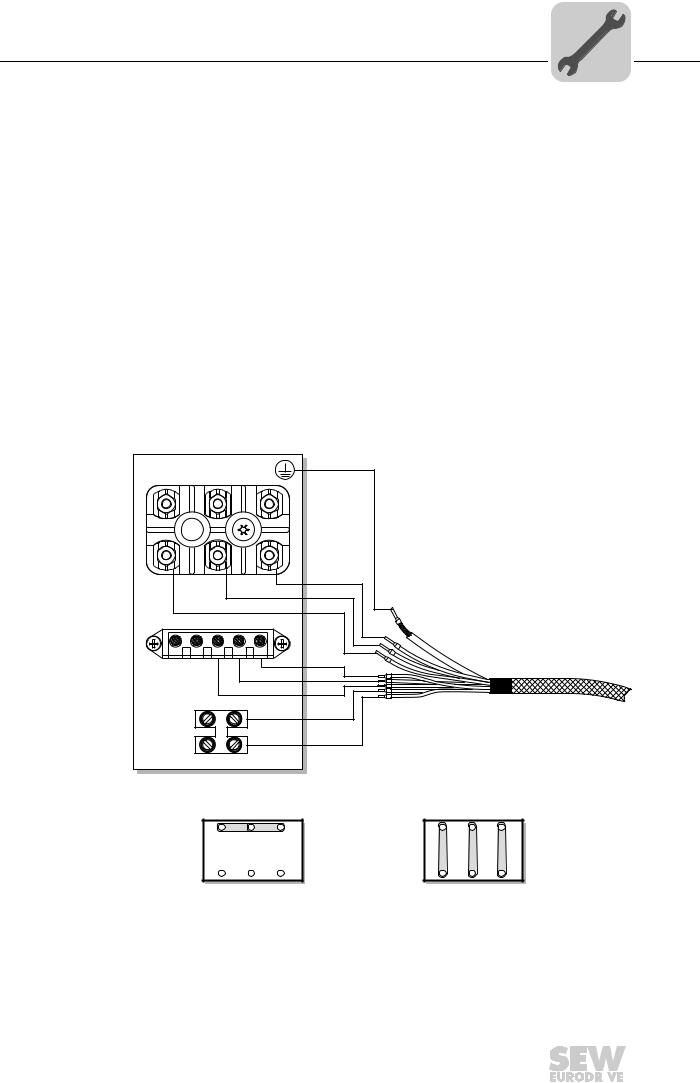

Page 33

Electrical installation Connection between MOVIMOT® and motor when mounted close to the motor 5.8.3 Hybrid cable connection The following table shows the conductor assignment of the hybrid cables with part numbers 01867423 and 08179484 and the corresponding motor terminals of the DR.. motor: Motor terminal DR.. -

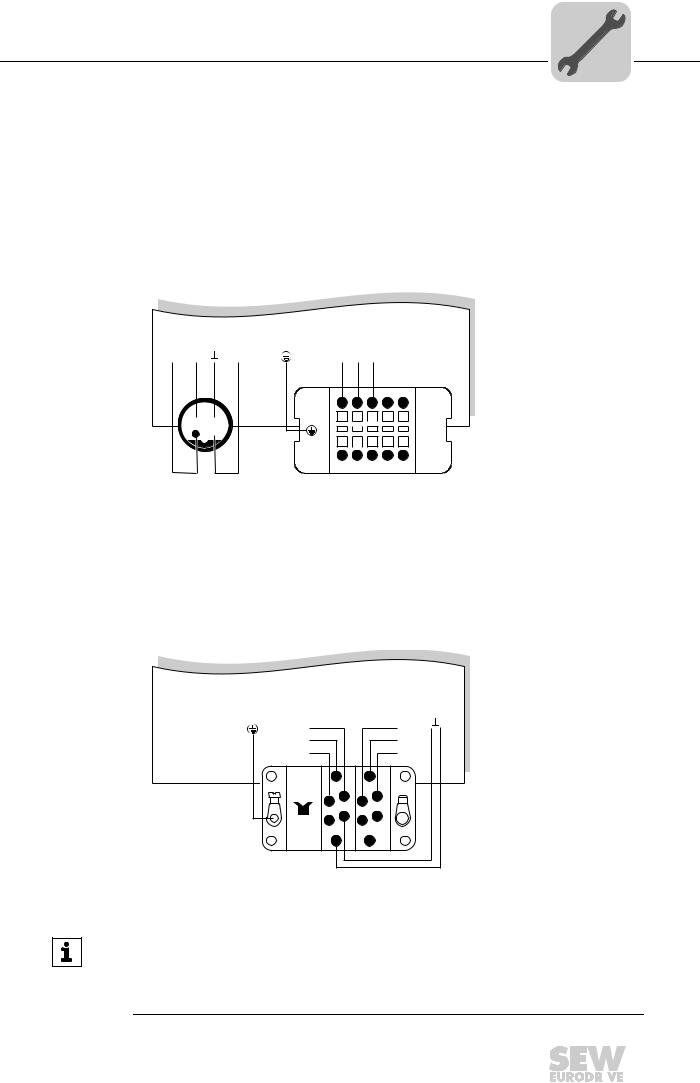

Page 34: Pc/Laptop Connection

Electrical installation PC/laptop connection PC/laptop connection ® MOVIMOT drives are equipped with an X50 diagnostic interface (RJ10 plug connec- tor) for startup, configuration and service. The diagnostic interface [1] is located underneath the screw plug on top of the MOVIMOT ®…

-

Page 35: Startup Of Movimot With Mlk30A In Easy Mode

Startup of MOVIMOT ® with MLK30A in Easy mode General information concerning startup Startup of MOVIMOT ® with MLK30A in Easy mode General information concerning startup INFORMATION You must comply with the general safety notes in the chapter «Safety notes» during startup.

-

Page 36: Description Of The Control Elements

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the control elements Description of the control elements 6.2.1 Setpoint potentiometer f1 NOTICE Loss of warranted degree of protection if the screw plugs of the f1 setpoint potenti- ometer or the X50 diagnostic interface are installed incorrectly or not at all. Damage to the MOVIMOT ®…

-

Page 37

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the control elements 6.2.4 DIP switches S1 and S2 NOTICE Damage to the DIP switches caused by unsuitable tools. Damage to the DIP switches. • To set the DIP switches, use only suitable tools, such as a slotted screwdriver with a blade width of no more than 3 mm. -

Page 38: Description Of The Dip Switches S1

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Description of the DIP switches S1 6.3.1 DIP switches S1/1 – S1/4 ® RS485 address of the MOVIMOT inverter Set the DIP switches S1/1 — S1/4 as follows for MOVIMOT ®…

-

Page 39

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Motor with operating point 400 V/50 Hz ® Applies to MOVIMOT with the following drive ID modules: Drive ID module Motor Identification ID color Part number Line voltage [V] Line frequency [Hz]… -

Page 40

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Motor with operating point 460 V/60 Hz ® Applies to MOVIMOT with the following drive ID modules: Drive ID module Motor Marking ID color Part number Line voltage [V] Line frequency [Hz]… -

Page 41

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Motor with 50/60 Hz voltage range ® Applies to MOVIMOT with the following drive ID modules: Drive ID module Motor Marking ID color Part number Line voltage [V] Line frequency [Hz]… -

Page 42

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Drive ID module Motor Identification ID color Part number Line voltage [V] Mains frequency [Hz] DRU…J/400/50 Gray 28203194 230/400 Setting DIP switch S1/6: ® Power Motor type MOVIMOT MM..D-503-00 inverter… -

Page 43: Description Of Dip Switches S2

Startup of MOVIMOT ® with MLK30A in Easy mode Description of DIP switches S2 Description of DIP switches S2 6.4.1 DIP switch S2/1 Brake type • When using the standard brake, the DIP switch S2/1 must be set to «OFF». •…

-

Page 44

Startup of MOVIMOT ® with MLK30A in Easy mode Description of DIP switches S2 Functional description You can release the brake under the following conditions by setting the AS-Interface bit DO2 «speed f2/speed f1»: Status of Enable Error Brake function AS-Interface bits status status… -

Page 45

Startup of MOVIMOT ® with MLK30A in Easy mode Description of DIP switches S2 6.4.3 DIP switch S2/3 Operating mode • DIP switch S2/3 = «OFF»: VFC operation for 4-pole motors • DIP switch S2/3 = «ON»: V/f operation reserved for special cases 6.4.4 DIP switch S2/4 Speed monitoring… -

Page 46: Startup Procedure

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure Startup procedure WARNING Electric shock from capacitors that have not been fully discharged. Severe or fatal injuries. • Disconnect the inverter from the power. Observe the minimum switch-off time af- ter disconnection from the supply system: –…

-

Page 47

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure INFORMATION The first speed is infinitely variable during operation using the setpoint potentiometer which is accessible from outside. Speeds f1 and f2 can be set independently of each other. 9. -

Page 48

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure Assigning the slave address using a hand-held programming device Hand-held AS-Interface programming devices offer the following functions: • Reading and changing an AS-Interface slave address • Reading off the AS-Interface profile •… -

Page 49

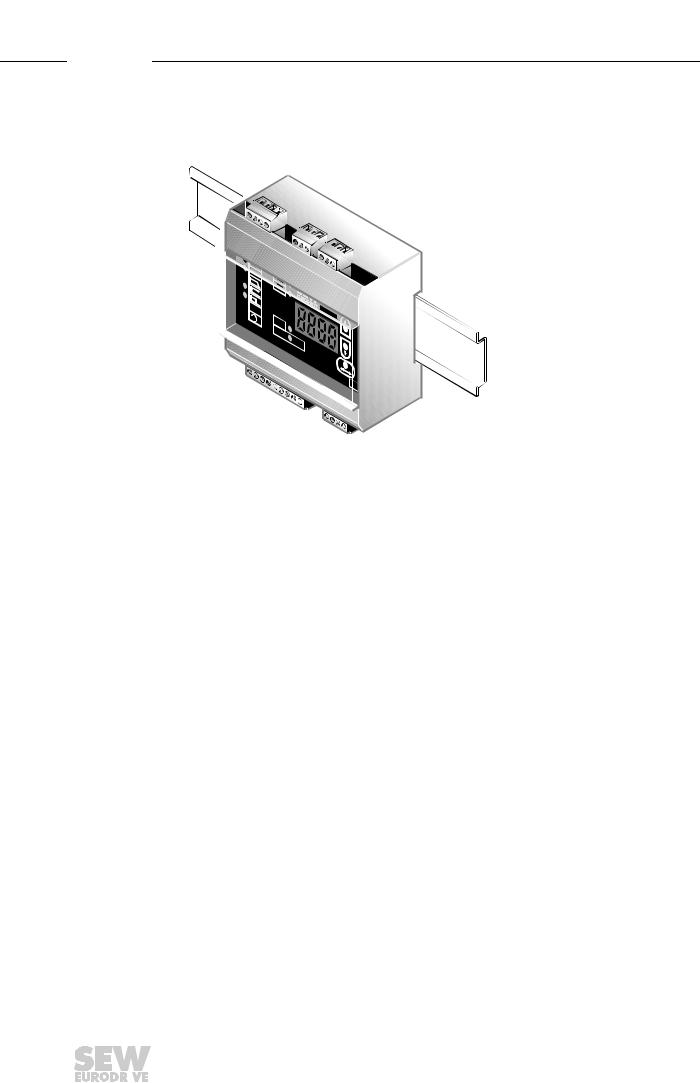

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure 6.5.2 Setting the 24 V supply via switch S5 The switch S5 [1] is located on the connection board. 18014399700786699 Size 1 Size 2 Switch S5 Use switch S5 to set the type of 24 V supply. 24 V voltage supply Switch S5 = «1»… -

Page 50

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure ® 6.5.3 Data AS-Interface master → MOVIMOT The following table shows the 4 data bits that the AS-Interface master sends to the MOVIMOT ® inverter via the AS-Interface: AS-Interface Function (→… -

Page 51

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure 6.5.5 Setpoint scaling via parameter bits The following table lists the parameter bits for setpoint scaling The setpoint scaling does only affect setpoint f1 that can be set externally. Setpoint f2 and the minimum frequency are not affected by the scaling. -

Page 52

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure 6.5.6 Inverter behavior depending on the AS-Interface bits The following table shows the behavior of the MOVIMOT ® inverter depending on the status of the AS-Interface bit: Inverter AS-Interface bit Status behavior Supply… -

Page 53: Supplementary Notes For Installation Close To The Motor

Startup of MOVIMOT ® with MLK30A in Easy mode Supplementary notes for installation close to the motor Supplementary notes for installation close to the motor ® When the MOVIMOT inverter is installed close to the motor, observe the notes in the following chapters: 6.6.1 Checking the connection type of the connected motor…

-

Page 54

Startup of MOVIMOT ® with MLK30A in Easy mode Supplementary notes for installation close to the motor 6.6.3 DIP switch When the MOVIMOT ® inverter is installed close to the motor, the DIP switch S1/5 must be changed from the factory setting to «ON»: Meaning Binary coding Motor… -

Page 55: Service

Service Status and error display Service Status and error display The following figure shows the positions of the status and AS-Interface LEDs on the ® MOVIMOT drive: 9007200399453707 [1] MOVIMOT ® status LED [2] AS-Interface LED ® Compact Operating Instructions – MOVIMOT MM..D with AS-Interface…

-

Page 56

Service Status and error display 7.1.1 Meaning of the AS-Interface LED The AS-Interface LED signalizes the status of the AS-Interface slaves. MLK30A Meaning Possible cause Color Operating state State 24 V supply at AS-Interface connection ready missing. Green Ready Normal operation Steady light 24 V supply at AS-Interface connection is OK. -

Page 57

Service Status and error display 7.1.2 Meaning of the status LED The status LED is located on the top of the MOVIMOT ® inverter. The three-color status LED indicates the operating and error statuses of the MOVIMOT ® inverter. Meaning Possible cause Color Operating sta-… -

Page 58

Service Status and error display Meaning Possible cause Color Operating sta- Status tus Error code Error 08 Speed monitoring error (only when S2/4 = «ON») flashes slowly or additional function 13 is active. Error 09 Startup error Additional functions 4, 5, 12 (DIP switches S2/5 – S2/8) are not permitted. -

Page 59: Error List

Service Error list Error list The following table helps you with troubleshooting: Code Error Possible cause Measure No connection ⍊, RS+, RS- – Communication Check and establish connection, especially timeout between MOVIMOT ® earth. RS485 master (motor stops, without error code) EMC influence Check shielding of data lines and improve, if necessary.

-

Page 60

Service Error list Code Error Possible cause Measure DC link voltage too Ramp time too short. Extend the ramp time. high Reset error Faulty connection between Check the braking resistor/brake coil connec- brake coil/braking resistor tion. Correct, if necessary. Reset error Incorrect internal resist- Check internal resistance of brake coil/braking ance of brake coil/braking… -

Page 61

Service Error list Code Error Possible cause Measure EEPROM error Error when accessing Set parameter P802 to «Delivery state». EEPROM Reset error ® Re-parameterize MOVIMOT inverter. Consult the SEW Service if the error reoccurs. External terminal External signal at terminal Remove/reset external error X6: 9,10 is not present Error code 38… -

Page 62

Service Error list Code Error Possible cause Measure Thermal overload of Motor protection is active Set DIP switch S1/5 to «ON». ® motor when the MOVIMOT Reset error verter is mounted close to the motor. Incorrectly set performance Check DIP switch setting S1/6. level when MOVIMOT ®… -

Page 63: Unit Replacement

Service Unit replacement Code Error Possible cause Measure Bus module com- Timeout between fieldbus Check/establish communication link between ® ® munication timeout interface and MOVIMOT fieldbus interface and MOVIMOT inverter. – MOVIMOT ® inverter. The fieldbus interface only reports the error to the higher-level controller.

-

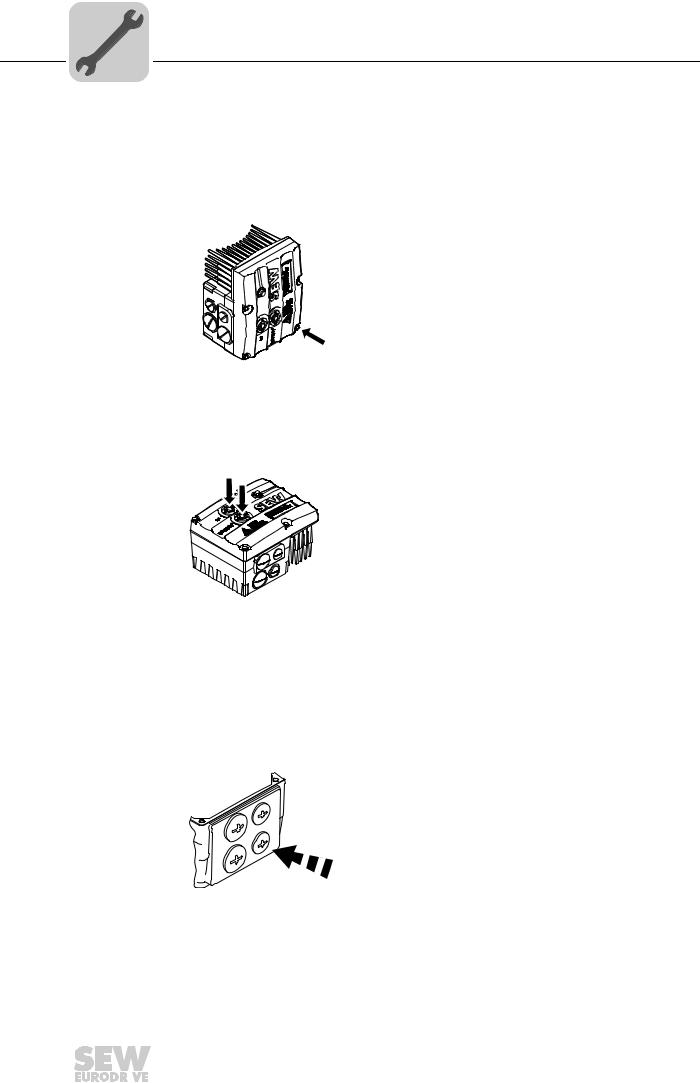

Page 64

Service Unit replacement • Switch t1 on the new MOVIMOT ® inverter analogously to the control elements of the previous MOVIMOT ® inverter. ® 4. Unlock the drive ID module of the new MOVIMOT inverter and pull it out carefully. 18014399028685579 5. -

Page 65: Declaration Of Conformity

Declaration of conformity Declaration of conformity EC Declaration of Conformity 900030110 SEW EURODRIVE GmbH & Co KG Ernst-Blickle-Straße 42, D-76646 Bruchsal declares under sole responsibility that the following products ® frequency inverters of the series MOVIMOT possibly in connection with…

-

Page 68

SEW-EURODRIVE—Driving the world SEW-EURODRIVE GmbH & Co KG P.O. Box 3023 76642 BRUCHSAL GERMANY Phone +49 7251 75-0 Fax +49 7251 75-1970 sew@sew-eurodrive.com www.sew-eurodrive.com…

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

*21328994_1114*

Drive Technology Drive Automation System Integration Services

Compact Operating Instructions

Decentralized Drive Systems

MOVIMOT

®

MM..D with AS-Interface

Edition 11/2014

21328994/EN

Related Manuals for SEW-Eurodrive MOVIMOT MMxD Series

Summary of Contents for SEW-Eurodrive MOVIMOT MMxD Series

-

Page 1

*21328994_1114* Drive Technology Drive Automation System Integration Services Compact Operating Instructions Decentralized Drive Systems MOVIMOT ® MM..D with AS-Interface Edition 11/2014 21328994/EN… -

Page 2

SEW-EURODRIVE—Driving the world… -

Page 3: Table Of Contents

Contents Contents General information ……………………5 Scope of this documentation ………………5 Structure of the safety notes ………………5 Other applicable documentation ………………6 Safety notes ……………………..7 Preliminary information ………………..7 General information ………………….7 Target group ……………………7 Designated use ………………….

-

Page 4

Contents Service……………………….55 Status and error display ………………..55 Error list ……………………59 Unit replacement ………………….63 Declaration of conformity ………………….. 65 ® Compact Operating Instructions – MOVIMOT MM..D with AS-Interface… -

Page 5: General Information

General information Scope of this documentation General information Scope of this documentation This documentation comprises the general safety notes and information regarding ® MOVIMOT MM..D with AS-Interface. • Please note that this documentation does not replace the detailed operating in- structions.

-

Page 6: Other Applicable Documentation

General information Other applicable documentation Meaning of the hazard symbols The hazard symbols in the safety notes have the following meaning: Hazard symbol Meaning General hazard Warning of dangerous electrical voltage Warning of hot surfaces Warning of risk of crushing Warning of suspended load Warning of automatic restart 1.2.3…

-

Page 7: Safety Notes

Safety notes Preliminary information Safety notes The following basic safety notes must be read carefully to prevent injury to persons and damage to property. The user must ensure that the basic safety notes are read and observed. Make sure that persons responsible for the plant and its operation, as well as persons who work independently on the unit, have read through the operating instructions carefully and understood them.

-

Page 8: Designated Use

Safety notes Designated use Designated use ® MOVIMOT inverters are components intended for installation in electrical systems or machines. ® In case of installation in machines, startup of MOVIMOT inverters (i.e. start of desig- nated operation) is prohibited until it is determined that the machine meets the require- ments stipulated in the Machinery Directive 2006/42/EC.

-

Page 9: Installation

Safety notes Installation Installation The units must be installed and cooled according to the regulations and specifications contained in the corresponding documentation. ® Protect the MOVIMOT inverters from excessive strain. The following applications are prohibited unless explicitly permitted: • Use in potentially explosive areas. •…

-

Page 10: Operation

Safety notes Operation Operation ® Systems with integrated MOVIMOT inverters must be equipped with additional moni- toring and protection devices, if necessary, according to the applicable safety guide- lines, such as the law governing technical equipment, accident prevention regulations, etc. Additional preventive measures may be required for applications with increased hazard potential.

-

Page 11: Type Designations

Type designations MOVIMOT® drive type designation Type designations MOVIMOT® drive type designation MOVIMOT ® drive type designation 3.1.1 Nameplate The following figure gives an example of a MOVIMOT ® drive nameplate. The name- plate is on the motor. 76646 Bruchsal/Germany R F 4 7 D R E 9 0 L 4 B E 2 / M M 1 5 / M O / A V S K 0 1 .

-

Page 12: Movimot® Inverter Type Designation

Type designations MOVIMOT® inverter type designation MOVIMOT® inverter type designation MOVIMOT ® inverter type designation 3.2.1 Nameplate ® The following figure gives an example of a MOVIMOT inverter nameplate: Status: A — — 15 10 16 08/14 829 Type : MM15D-503-00 P# : 18215033 S# : 1757110…

-

Page 13

Type designations MOVIMOT® inverter type designation 3.2.3 Unit identification The unit identification [1] on the top of the MOVIMOT ® inverter provides information about the inverter type [2], inverter part number [3], unit power [4]. 1 min 9007199712657547 3.2.4 AS-Interface option nameplate The following figure shows an example of the nameplate of the AS-Interface option MLK30A: 9007201609242891… -

Page 14: Type Designation Of The Design «Mounted Close To The Motor

Type designations Type designation of the design «mounted close to the motor» Type designation of the design «mounted close to the motor» 3.3.1 Nameplate ® The following figure shows an example of the MOVIMOT inverter mounted close to the motor with corresponding nameplate and type designation: U = 3×380.

-

Page 15: Mechanical Installation

Mechanical installation General information Mechanical installation General information • Observe the general safety notes. • Comply with all instructions referring to the technical data and the permissible con- ditions where the unit is operated. ® • Only use the provided attachment options when mounting the MOVIMOT drive.

-

Page 16: Installation Of Movimot Gearmotor

Mechanical installation Installation of MOVIMOT® gearmotor Installation of MOVIMOT® gearmotor Installation of MOVIMOT ® gearmotor 4.4.1 Installation tolerances The following table shows the permitted tolerances of the shaft ends and flanges of the MOVIMOT ® drive. Shaft end Flange Diameter tolerance according to EN 50347 Centering shoulder tolerance in ac- cordance with EN 50347 •…

-

Page 17: Mounting Movimot Inverter Close To The Motor

Mechanical installation Mounting MOVIMOT® inverter close to the motor 4.4.3 Installation in damp locations or in the open Observe the following notes for mounting the MOVIMOT ® drive in damp areas or in the open: • Use suitable cable glands for the incoming cables. Use reducing adapters if neces- sary.

-

Page 18: Tightening Torques

Mechanical installation Tightening torques Tightening torques 4.6.1 MOVIMOT ® inverter ® Tighten the screws on the MOVIMOT inverter using 3.0 Nm (27 lb.in) in diametrically opposite sequence. 9007199713318923 4.6.2 Screw plugs Tighten screw plugs of potentiometer f1 and connection X50 using 2.5 Nm (22 lb.in). 9007199713311371 4.6.3 Cable glands…

-

Page 19

Mechanical installation Tightening torques 4.6.5 Modular connection box For fastening the connection box on the mounting plate, tighten screws using 3.3 Nm (29 lb.in). 322786187 4.6.6 Tightening torques for terminals Use the following tightening torques for terminals during installation: 1143643275 0.8 –… -

Page 20: Electrical Installation

Electrical installation General information Electrical installation General information Observe the following information on electrical installation: • Observe the general safety notes. • Comply with all instructions referring to the technical data and the permissible con- ditions where the unit is operated. •…

-

Page 21

Electrical installation Installation instructions ® 5.2.2 Permitted cable cross section of the MOVIMOT terminals Power terminals Observe the permitted cable cross sections for installation: Power terminals Cable cross section 1.0 mm – 4.0 mm (2 x 4.0 mm AWG17 – AWG12 (2 x AWG12) Conductor end sleeves •… -

Page 22

Electrical installation Installation instructions 5.2.3 Residual current device WARNING Electric shock due to incorrect RCD type. Severe or fatal injuries. • The unit can cause direct current in the protective earth. In cases where an resid- ual current device (RCD) is used for protection against direct or indirect contact, only an RCD of type B on the power supply side of the frequency inverter is per- mitted. -

Page 23

Electrical installation Installation instructions 5.2.5 Information on PE connection WARNING Electric shock due to incorrect connection of PE. Severe or fatal injuries. • The permitted tightening torque for the screw is 2.0 – 2.4 Nm (18 – 21 lb.in). • Observe the following notes regarding PE connection. -

Page 24

Electrical installation Installation instructions 5.2.6 EMC-compliant installation INFORMATION This drive system is not designed for operation on a public low voltage grid that sup- plies residential areas. This is a product with restricted availability (categories C1 to C4 according to EN 61800-3). -

Page 25

Electrical installation Installation instructions Short circuit current rating Suitable for use in current circuits with a maximum short circuit current of AC 200,000 A for the following fuses: For 240 V systems: 250 V min., 25 A max., fuse or 250 V min., 25 A max., circuit breaker For 500 V systems: 500 V min., 25 A max., fuse or 500 V min., 25 A max., circuit breaker… -

Page 26: Connection Of Movimot ® Mm

Electrical installation Connection of MOVIMOT® MM../AVSK (connection option A) Connection of MOVIMOT® MM../AVSK (connection option A) Connection of MOVIMOT ® MM../AVSK (connection option A) The following figure shows the connection in MM../AVSK design: F11/F12/F13 MM../AVSK BE/BR AS-Interface — 24 V [4][5][6][7] [8][9] BW [2]…

-

Page 27: Connection Of Movimot® Mm

Electrical installation Connection of MOVIMOT® MM../AZSK (connection option B) Connection of MOVIMOT® MM../AZSK (connection option B) Connection of MOVIMOT ® MM../AZSK (connection option B) The following figure shows the connection in MM../AZSK design: F11/F12/F13 MM../AZSK BE/BR AS-Interface — 24 V BW [4] V024 AS-Interface +…

-

Page 28: Connection Of Movimot® Mm

Electrical installation Connection of MOVIMOT® MM../AND3/AZSK (connection option C) Connection of MOVIMOT® MM../AND3/ AZSK (connection option C) Connection of MOVIMOT ® MM../AND3/AZSK (connection option C) The following figure shows the connection in MM../AND3/AZSK design: AS-Interface + AS-Interface — V024 N.C. N.C.

-

Page 29: Connection Of Movimot® Mm

Electrical installation Connection of MOVIMOT® MM../AZZK (connection option D1/D2) Connection of MOVIMOT® MM../AZZK (connection option D1/D2) Connection of MOVIMOT ® MM../AZZK (connection option D1/D2) The following figure shows the connection in MM../AZZK design: F11/F12/F13 MM../AZZK BE/BR X03 X02 AS-Interface — 24 V [6][7] BW [4]…

-

Page 30: Connection Of Movimot® Mm

Electrical installation Connection of MOVIMOT® MM../AND3/AZZK (connection option D3/D4) Connection of MOVIMOT® MM../AND3/ AZZK (connection option D3/D4) Connection of MOVIMOT ® MM../AND3/AZZK (connection option D3/D4) The following figure shows the connection in MM../AND3/AZZK design: AS-Interface + AS-Interface — V024 V024 N.C.

-

Page 31: Connection Between Movimot And Motor When Mounted Close To The Motor

Electrical installation Connection between MOVIMOT® and motor when mounted close to the motor Connection between MOVIMOT® and motor when mounted close to the motor Connection between MOVIMOT ® and motor when mounted close to the motor If the MOVIMOT ® inverter is mounted close to the motor, the connection to the motor is realized with a pre-fabricated hybrid cable.

-

Page 32

Electrical installation Connection between MOVIMOT® and motor when mounted close to the motor ® 5.8.2 MOVIMOT with ALA4 plug connector The ALA4 design results in the following connection options to the motor, dependent upon the hybrid cable used: Design MOVIMOT ®… -

Page 33

Electrical installation Connection between MOVIMOT® and motor when mounted close to the motor 5.8.3 Hybrid cable connection The following table shows the conductor assignment of the hybrid cables with part numbers 01867423 and 08179484 and the corresponding motor terminals of the DR.. motor: Motor terminal DR.. -

Page 34: Pc/Laptop Connection

Electrical installation PC/laptop connection PC/laptop connection ® MOVIMOT drives are equipped with an X50 diagnostic interface (RJ10 plug connec- tor) for startup, configuration and service. The diagnostic interface [1] is located underneath the screw plug on top of the MOVIMOT ®…

-

Page 35: Startup Of Movimot With Mlk30A In Easy Mode

Startup of MOVIMOT ® with MLK30A in Easy mode General information concerning startup Startup of MOVIMOT ® with MLK30A in Easy mode General information concerning startup INFORMATION You must comply with the general safety notes in the chapter «Safety notes» during startup.

-

Page 36: Description Of The Control Elements

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the control elements Description of the control elements 6.2.1 Setpoint potentiometer f1 NOTICE Loss of warranted degree of protection if the screw plugs of the f1 setpoint potenti- ometer or the X50 diagnostic interface are installed incorrectly or not at all. Damage to the MOVIMOT ®…

-

Page 37

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the control elements 6.2.4 DIP switches S1 and S2 NOTICE Damage to the DIP switches caused by unsuitable tools. Damage to the DIP switches. • To set the DIP switches, use only suitable tools, such as a slotted screwdriver with a blade width of no more than 3 mm. -

Page 38: Description Of The Dip Switches S1

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Description of the DIP switches S1 6.3.1 DIP switches S1/1 – S1/4 ® RS485 address of the MOVIMOT inverter Set the DIP switches S1/1 — S1/4 as follows for MOVIMOT ®…

-

Page 39

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Motor with operating point 400 V/50 Hz ® Applies to MOVIMOT with the following drive ID modules: Drive ID module Motor Identification ID color Part number Line voltage [V] Line frequency [Hz]… -

Page 40

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Motor with operating point 460 V/60 Hz ® Applies to MOVIMOT with the following drive ID modules: Drive ID module Motor Marking ID color Part number Line voltage [V] Line frequency [Hz]… -

Page 41

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Motor with 50/60 Hz voltage range ® Applies to MOVIMOT with the following drive ID modules: Drive ID module Motor Marking ID color Part number Line voltage [V] Line frequency [Hz]… -

Page 42

Startup of MOVIMOT ® with MLK30A in Easy mode Description of the DIP switches S1 Drive ID module Motor Identification ID color Part number Line voltage [V] Mains frequency [Hz] DRU…J/400/50 Gray 28203194 230/400 Setting DIP switch S1/6: ® Power Motor type MOVIMOT MM..D-503-00 inverter… -

Page 43: Description Of Dip Switches S2

Startup of MOVIMOT ® with MLK30A in Easy mode Description of DIP switches S2 Description of DIP switches S2 6.4.1 DIP switch S2/1 Brake type • When using the standard brake, the DIP switch S2/1 must be set to «OFF». •…

-

Page 44

Startup of MOVIMOT ® with MLK30A in Easy mode Description of DIP switches S2 Functional description You can release the brake under the following conditions by setting the AS-Interface bit DO2 «speed f2/speed f1»: Status of Enable Error Brake function AS-Interface bits status status… -

Page 45

Startup of MOVIMOT ® with MLK30A in Easy mode Description of DIP switches S2 6.4.3 DIP switch S2/3 Operating mode • DIP switch S2/3 = «OFF»: VFC operation for 4-pole motors • DIP switch S2/3 = «ON»: V/f operation reserved for special cases 6.4.4 DIP switch S2/4 Speed monitoring… -

Page 46: Startup Procedure

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure Startup procedure WARNING Electric shock from capacitors that have not been fully discharged. Severe or fatal injuries. • Disconnect the inverter from the power. Observe the minimum switch-off time af- ter disconnection from the supply system: –…

-

Page 47

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure INFORMATION The first speed is infinitely variable during operation using the setpoint potentiometer which is accessible from outside. Speeds f1 and f2 can be set independently of each other. 9. -

Page 48

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure Assigning the slave address using a hand-held programming device Hand-held AS-Interface programming devices offer the following functions: • Reading and changing an AS-Interface slave address • Reading off the AS-Interface profile •… -

Page 49

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure 6.5.2 Setting the 24 V supply via switch S5 The switch S5 [1] is located on the connection board. 18014399700786699 Size 1 Size 2 Switch S5 Use switch S5 to set the type of 24 V supply. 24 V voltage supply Switch S5 = «1»… -

Page 50

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure ® 6.5.3 Data AS-Interface master → MOVIMOT The following table shows the 4 data bits that the AS-Interface master sends to the MOVIMOT ® inverter via the AS-Interface: AS-Interface Function (→… -

Page 51

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure 6.5.5 Setpoint scaling via parameter bits The following table lists the parameter bits for setpoint scaling The setpoint scaling does only affect setpoint f1 that can be set externally. Setpoint f2 and the minimum frequency are not affected by the scaling. -

Page 52

Startup of MOVIMOT ® with MLK30A in Easy mode Startup procedure 6.5.6 Inverter behavior depending on the AS-Interface bits The following table shows the behavior of the MOVIMOT ® inverter depending on the status of the AS-Interface bit: Inverter AS-Interface bit Status behavior Supply… -

Page 53: Supplementary Notes For Installation Close To The Motor

Startup of MOVIMOT ® with MLK30A in Easy mode Supplementary notes for installation close to the motor Supplementary notes for installation close to the motor ® When the MOVIMOT inverter is installed close to the motor, observe the notes in the following chapters: 6.6.1 Checking the connection type of the connected motor…

-

Page 54

Startup of MOVIMOT ® with MLK30A in Easy mode Supplementary notes for installation close to the motor 6.6.3 DIP switch When the MOVIMOT ® inverter is installed close to the motor, the DIP switch S1/5 must be changed from the factory setting to «ON»: Meaning Binary coding Motor… -

Page 55: Service

Service Status and error display Service Status and error display The following figure shows the positions of the status and AS-Interface LEDs on the ® MOVIMOT drive: 9007200399453707 [1] MOVIMOT ® status LED [2] AS-Interface LED ® Compact Operating Instructions – MOVIMOT MM..D with AS-Interface…

-

Page 56

Service Status and error display 7.1.1 Meaning of the AS-Interface LED The AS-Interface LED signalizes the status of the AS-Interface slaves. MLK30A Meaning Possible cause Color Operating state State 24 V supply at AS-Interface connection ready missing. Green Ready Normal operation Steady light 24 V supply at AS-Interface connection is OK. -

Page 57

Service Status and error display 7.1.2 Meaning of the status LED The status LED is located on the top of the MOVIMOT ® inverter. The three-color status LED indicates the operating and error statuses of the MOVIMOT ® inverter. Meaning Possible cause Color Operating sta-… -

Page 58

Service Status and error display Meaning Possible cause Color Operating sta- Status tus Error code Error 08 Speed monitoring error (only when S2/4 = «ON») flashes slowly or additional function 13 is active. Error 09 Startup error Additional functions 4, 5, 12 (DIP switches S2/5 – S2/8) are not permitted. -

Page 59: Error List

Service Error list Error list The following table helps you with troubleshooting: Code Error Possible cause Measure No connection ⍊, RS+, RS- – Communication Check and establish connection, especially timeout between MOVIMOT ® earth. RS485 master (motor stops, without error code) EMC influence Check shielding of data lines and improve, if necessary.

-

Page 60

Service Error list Code Error Possible cause Measure DC link voltage too Ramp time too short. Extend the ramp time. high Reset error Faulty connection between Check the braking resistor/brake coil connec- brake coil/braking resistor tion. Correct, if necessary. Reset error Incorrect internal resist- Check internal resistance of brake coil/braking ance of brake coil/braking… -

Page 61

Service Error list Code Error Possible cause Measure EEPROM error Error when accessing Set parameter P802 to «Delivery state». EEPROM Reset error ® Re-parameterize MOVIMOT inverter. Consult the SEW Service if the error reoccurs. External terminal External signal at terminal Remove/reset external error X6: 9,10 is not present Error code 38… -

Page 62

Service Error list Code Error Possible cause Measure Thermal overload of Motor protection is active Set DIP switch S1/5 to «ON». ® motor when the MOVIMOT Reset error verter is mounted close to the motor. Incorrectly set performance Check DIP switch setting S1/6. level when MOVIMOT ®… -

Page 63: Unit Replacement

Service Unit replacement Code Error Possible cause Measure Bus module com- Timeout between fieldbus Check/establish communication link between ® ® munication timeout interface and MOVIMOT fieldbus interface and MOVIMOT inverter. – MOVIMOT ® inverter. The fieldbus interface only reports the error to the higher-level controller.

-

Page 64

Service Unit replacement • Switch t1 on the new MOVIMOT ® inverter analogously to the control elements of the previous MOVIMOT ® inverter. ® 4. Unlock the drive ID module of the new MOVIMOT inverter and pull it out carefully. 18014399028685579 5. -

Page 65: Declaration Of Conformity

Declaration of conformity Declaration of conformity EC Declaration of Conformity 900030110 SEW EURODRIVE GmbH & Co KG Ernst-Blickle-Straße 42, D-76646 Bruchsal declares under sole responsibility that the following products ® frequency inverters of the series MOVIMOT possibly in connection with…

-

Page 68

SEW-EURODRIVE—Driving the world SEW-EURODRIVE GmbH & Co KG P.O. Box 3023 76642 BRUCHSAL GERMANY Phone +49 7251 75-0 Fax +49 7251 75-1970 sew@sew-eurodrive.com www.sew-eurodrive.com…

7

Service

7.2

Error list

Code

Error

–

Communication

timeout

(motor stops, without

error code)

–

Supply voltage not

present

(motor stops, without

error code)

–

24 V supply not

present

(motor stops, without

error code)

01

Overcurrent in out-

put stage

04

Brake chopper

06

Phase failure

(The error can only

be detected when the

drive is under load)

64

Compact Operating Instructions – MOVIMOT

The following table helps you with troubleshooting:

Possible cause

Missing connection ‘, RS

+, RS- between

®

MOVIMOT

and RS485

master

EMC influence

Incorrect type (cyclical) for

acyclical data traffic, pro-

tocol period between the

individual messages is

longer than the set timeout

interval.

DC link voltage too low,

Power off has been detec-

ted.

24 V supply voltage not

present.

AUX power supply voltage

not available (only for

®

MOVIMOT

with AS-Inter-

face).

Short circuit on inverter

output

Overcurrent in brake out-

put, resistor damaged, res-

istance too low

Short circuit in brake coil

Phase failure

®

MM..D with AS-Interface

Measure

Check and establish connection, especially

ground.

Check shielding of data lines and improve, if

necessary.

Check the number of MOVIMOT

nected to the master. If the timeout interval is

1 s, for example, you can connect a maximum

®

of 8 MOVIMOT

drives as slaves for cyclical

communication.

Reduce message cycle, increase timeout in-

terval, or select message type «acyclic».

Check power cables and line voltage for inter-

ruption.

Check 24 V supply voltage for interruption.

Check 24 V supply voltage.

Permitted voltage: DC 24 V ± 25%,

EN 61131-2, residual ripple max. 13%

Motor restarts automatically as soon as the

voltage reaches normal values.

Check AUX power supply voltage for interrup-

tion.

Check AUX power supply voltage.

Permitted voltage: DC 24 V ± 25%,

EN 61131-2, residual ripple max. 13%

Motor restarts automatically as soon as the

voltage reaches normal values.

Check the connection between the inverter

output and the motor as well as the motor

winding for short circuits.

1)

Reset error.

Check the connection of the resistor/replace it.

Replace brake.

Check the supply system cable for phase fail-

ure.

1)

Reset error

.

®

drives con-

Drive Technology Drive Automation System Integration Services

Operating Instructions

MOVIMOT® MM..D

With DRS/DRE/DRP AC Motor

|

Edition 12/2010 |

17000017 / EN |

SEW-EURODRIVE—Driving the world

Contents

Contents

|

1 |

General Information ……………………………………………………………………………….. |

6 |

|

|

1.1 |

How to use this documentation…………………………………………………………. |

6 |

|

|

1.2 |

Structure of the safety notes …………………………………………………………….. |

6 |

|

|

1.3 |

Rights to claim under limited warranty ……………………………………………….. |

7 |

|

|

1.4 |

Exclusion of liability…………………………………………………………………………. |

7 |

|

|

1.5 |

Copyright……………………………………………………………………………………….. |

7 |

|

|

1.6 |

Product names and trademarks………………………………………………………… |

7 |

|

2 |

Safety Notes ………………………………………………………………………………………….. |

8 |

|

|

2.1 |

Preliminary information ……………………………………………………………………. |

8 |

|

|

2.2 |

General information ………………………………………………………………………… |

8 |

|

|

2.3 |

Target group ………………………………………………………………………………….. |

8 |

|

|

2.4 |

Designated use ………………………………………………………………………………. |

9 |

|

|

2.5 |

Other applicable documentation ……………………………………………………….. |

9 |

|

|

2.6 |

Transportation, storage………………………………………………………………….. |

10 |

|

|

2.7 |

Installation……………………………………………………………………………………. |

10 |

|

|

2.8 |

Electrical connection ……………………………………………………………………… |

10 |

|

|

2.9 |

Safe disconnection………………………………………………………………………… |

10 |

|

|

2.10 |

Operation …………………………………………………………………………………….. |

11 |

|

3 Unit Design ………………………………………………………………………………………….. |

12 |

|

|

3.1 |

MOVIMOT® drive………………………………………………………………………….. |

12 |

|

3.2 |

MOVIMOT® inverter………………………………………………………………………. |

13 |

|

3.3 |

Type designation of MOVIMOT® drive……………………………………………… |

15 |

|

3.4 |

Type designation of MOVIMOT® inverter …………………………………………. |

16 |

|

3.5 |

Type designation of the variant «mounted close to the motor»……………… |

17 |

|

4 Mechanical Installation…………………………………………………………………………. |

18 |

|

|

4.1 |

MOVIMOT® gearmotor installation ………………………………………………….. |

18 |

|

4.2 |

Installation of MOVIMOT® options …………………………………………………… |

20 |

|

4.3 |

Installation of the MOVIMOT® inverter close to the motor …………………… |

27 |

|

4.4 |

Tightening torques ………………………………………………………………………… |

28 |

|

5 Electrical Installation ……………………………………………………………………………. |

30 |

|

|

5.1 |

Installation instructions…………………………………………………………………… |

30 |

|

5.2 |

Connection of the MOVIMOT® drive………………………………………………… |

36 |

|

5.3 |

MOVIMOT® plug connectors ………………………………………………………….. |

37 |

5.4Connection between MOVIMOT® and motor

|

when mounted close to the motor……………………………………………………. |

38 |

|

|

5.5 |

Connection of the MOVIMOT® options ……………………………………………. |

42 |

|

5.6 |

Connection of RS-485 bus master…………………………………………………… |

53 |

|

5.7 |

Connecting the DBG keypad ………………………………………………………….. |

54 |

|

5.8 |

PC connection………………………………………………………………………………. |

55 |

|

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

3 |

||

Contents

|

6 |

«Easy» Startup……………………………………………………………………………………… |

56 |

|

|

6.1 |

Overview ……………………………………………………………………………………… |

56 |

|

|

6.2 |

Important notes on startup ……………………………………………………………… |

57 |

|

|

6.3 |

Requirements……………………………………………………………………………….. |

58 |

|

|

6.4 |

Description of control elements……………………………………………………….. |

58 |

|

|

6.5 |

Description of the DIP switches S1………………………………………………….. |

61 |

|

|

6.6 |

Description of DIP switches S2……………………………………………………….. |

63 |

|

|

6.7 |

Selectable additional functions MM..D-503-00 ………………………………….. |

67 |

|

|

6.8 |

Startup with binary control ……………………………………………………………… |

91 |

|

|

6.9 |

Startup with options MBG11A or MLG..A …………………………………………. |

93 |

|

|

6.10 |

Startup with MWA21A option ………………………………………………………….. |

95 |

|

|

6.11 |

Startup with MWF11A option ………………………………………………………….. |

98 |

|

|

6.12 |

Supplementary notes for installation close to the motor …………………… |

100 |

|

7 |

«Easy» Startup with RS-485 Interface/Fieldbus…………………………………….. |

103 |

|

|

7.1 |

Important notes on startup ……………………………………………………………. |

103 |

|

|

7.2 |

Requirements……………………………………………………………………………… |

104 |

|

|

7.3 |

Startup procedure ……………………………………………………………………….. |

104 |

|

|

7.4 |

Coding of process data ………………………………………………………………… |

106 |

|

|

7.5 |

Function with RS-485 master………………………………………………………… |

111 |

|

8 |

«Expert» Startup with Parameter Function …………………………………………… |

116 |

|

|

8.1 |

Important notes on startup ……………………………………………………………. |

116 |

|

|

8.2 |

Requirements……………………………………………………………………………… |

117 |

|

|

8.3 |

MOVITOOLS® MotionStudio…………………………………………………………. |

117 |

|

|

8.4 |

Startup and function expansion with individual parameters……………….. |

119 |

|

|

8.5 |

Startup and configuration with a central controller and MQP……………… |

122 |

|

|

8.6 |

Startup by transferring the set of parameters ………………………………….. |

123 |

|

|

8.7 |

Parameter list……………………………………………………………………………… |

125 |

|

|

8.8 |

Parameter description………………………………………………………………….. |

131 |

|

9 Operation …………………………………………………………………………………………… |

151 |

|

|

9.1 |

Operating display ………………………………………………………………………… |

151 |

|

9.2 |

Drive ID module ………………………………………………………………………….. |

152 |

|

9.3 |

Keypads …………………………………………………………………………………….. |

153 |

|

9.4 |

MWA21A setpoint converter …………………………………………………………. |

154 |

|

9.5 |

MWF11A setpoint converter …………………………………………………………. |

155 |

|

9.6 |

MOVIMOT® manual operation with MOVITOOLS® MotionStudio ………. |

160 |

|

9.7 |

DBG keypad……………………………………………………………………………….. |

164 |

|

4 |

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

||

Contents

|

10 Service ………………………………………………………………………………………………. |

172 |

|

|

10.1 |

Status and error display ……………………………………………………………….. |

172 |

|

10.2 |

Inspection/maintenance ……………………………………………………………….. |

176 |

|

10.3 |

Diagnostics with MWF11A option ………………………………………………….. |

177 |

|

10.4 |

Unit replacement…………………………………………………………………………. |

178 |

|

10.5 |

Rotating the connection box …………………………………………………………. |

180 |

|

10.6 |

SEW Service………………………………………………………………………………. |

182 |

|

10.7 |

Shut down ………………………………………………………………………………….. |

182 |

|

10.8 |

Storage ……………………………………………………………………………………… |

183 |

|

10.9 |

Extended storage………………………………………………………………………… |

183 |

|

10.10 |

Disposal …………………………………………………………………………………….. |

183 |

|

11 |

Technical Data……………………………………………………………………………………. |

184 |

|

|

11.1 |

Motor with operating point 400 V / 50 Hz or 400 V / 100 Hz………………. |

184 |

|

|

11.2 |

Motor with operating point 460 V / 60 Hz………………………………………… |

186 |

|

|

11.3 |

Motor with operating point 230 V / 60 Hz………………………………………… |

188 |

|

|

11.4 |

Technical data of options & accessories…………………………………………. |

190 |

|

|

11.5 |

Work done, working air gap and braking torque of the brake …………….. |

195 |

|

|

11.6 |

Braking torque assignment …………………………………………………………… |

195 |

|

|

11.7 |

Integrated RS-485 interface………………………………………………………….. |

196 |

|

|

11.8 |

Diagnostics interface……………………………………………………………………. |

196 |

|

|

11.9 |

Assignment of internal braking resistors …………………………………………. |

196 |

|

|

11.10 |

Assignment of external braking resistors ………………………………………… |

197 |

|

|

11.11 |

Resistance and assignment of the brake coil ………………………………….. |

197 |

|

|

11.12 |

Assignment of the Drive-ID module ……………………………………………….. |

198 |

|

|

12 |

Declaration of Conformity …………………………………………………………………… |

199 |

|

|

13 |

Address List ………………………………………………………………………………………. |

200 |

|

|

Index |

………………………………………………………………………………………………….. |

210 |

|

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

5 |

||

General Information

How to use this documentation

1 General Information

1.1How to use this documentation

The documentation is an integral part of the product and contains important information on operation and service. The documentation is written for all employees who assemble, install, startup, and service this product.

The documentation must be accessible and legible. Make sure that persons responsible for the system and its operation, as well as persons who work independently on the unit, have read through the documentation carefully and understood it. If you are unclear about any of the information in this documentation, or if you require further information, contact SEW-EURODRIVE.

1.2Structure of the safety notes

1.2.1Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes, notes on potential risks of damage to property, and other notes.

|

Signal word |

Meaning |

Consequences if disregarded |

|

DANGER |

Imminent danger |

Severe or fatal injuries |

|

WARNING |

Possible dangerous situation |

Severe or fatal injuries |

|

CAUTION |

Possible dangerous situation |

Minor injuries |

|

NOTICE |

Possible damage to property |

Damage to the drive system or its envi- |

|

ronment |

||

|

INFORMATION |

Useful information or tip: Simpli- |

|

|

fies the handling of the drive |

||

|

system. |

||

1.2.2Structure of the section-related safety notes

Section safety notes do not apply to a specific action, but to several actions pertaining to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section safety note:

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

•Measure(s) to prevent the danger.

1.2.3Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

•

– Measure(s) to prevent the danger.

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor

|

General Information |

1 |

|

Rights to claim under limited warranty |

||

1.3Rights to claim under limited warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited warranty is that you adhere to the information in the documentation. Read the documentation before you start working with the unit!

1.4Exclusion of liability

You must comply with the information contained in this documentation to ensure safe operation of MOVIMOT® and to achieve the specified product characteristics and performance features. SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions. In such cases, any liability for defects is excluded.

1.5Copyright

© 2010 – SEW-EURODRIVE. All rights reserved.

Unauthorized duplication, modification, distribution or any other use of the whole or any part of this documentation is strictly prohibited.

1.6Product names and trademarks

All brands and product names in this documentation are trademarks or registered trademarks of their respective titleholders.

|

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

7 |

||

|

2 |

Safety Notes |

|

Preliminary information |

||

2 Safety Notes

The following basic safety notes must be read carefully to prevent injury to persons and damage to property. The operator must ensure that the basic safety notes are read and adhered to. Make sure that persons responsible for the plant and its operation, as well as persons who work independently on the unit, have read through the operating instructions carefully and understood them. If you are unclear about any of the information in this documentation or if you require further information, please contact SEWEURODRIVE.

2.1Preliminary information

The following safety notes are primarily concerned with the use of MOVIMOT® drives. If you use other SEW components, also refer to the safety notes for the respective components in the corresponding documentation.

Please also observe the supplementary safety notes in the individual chapters of this documentation.

2.2General information

Never install or start up damaged products. Submit a complaint to the shipping company immediately in the event of damage.

During operation, MOVIMOT® drives can have live, bare and movable or rotating parts as well as hot surfaces, depending on their enclosure.

Removing covers without authorization, improper use as well as incorrect installation or operation may result in severe injuries to persons or damage to property. Refer to the documentation for additional information.

2.3Target group

Only qualified personnel is authorized to install, startup or service the units or correct unit faults (observing IEC 60364 and/or CENELEC HD 384 or DIN VDE 0100 and IEC 60664 or DIN VDE 0110 as well as national accident prevention guidelines).

Qualified personnel in the context of these basic safety notes are persons familiar with installation, assembly, startup and operation of the product who possess the necessary qualifications.

Any activities regarding transportation, storage, operation, and disposal must be carried out by persons who have been instructed appropriately.

|

8 |

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

||

|

Safety Notes |

2 |

|

Designated use |

||

2.4Designated use

MOVIMOT® inverters are components intended for installation in electrical systems or machines.

In case of installation in machines, startup of MOVIMOT® inverters (i.e. start of designated operation) is prohibited until it is determined that the machine meets the requirements stipulated in the Machinery Directive 2006/42/EC.

Startup (i.e. the start of designated use) is only permitted under observance of the EMC directive 2004/108/EC.

MOVIMOT® inverters comply with the regulations of the Low Voltage Directive 2006/95/ EC. The standards given in the declaration of conformity are used for the MOVIMOT® inverter.

You must observe the technical data and information on the connection requirements as provided on the nameplate and in the documentation.

2.4.1Safety functions

The MOVIMOT® inverter may not perform safety functions unless these functions are described and expressly permitted.

2.4.2Hoist applications

MOVIMOT® inverters are suitable for hoist applications to a limited degree only, see sec. «Additional function 9» (page 78).

MOVIMOT® inverters are not designed for use as a safety device in hoist applications.

2.5Other applicable documentation

Note also the following documentation:

•«MOVIMOT® Gearmotors» catalog

•«DR.71-225, 315 AC Motors» operating instructions

•Operating instructions for the gear unit (only for MOVIMOT® gearmotors)

You can download or order these publications on the Internet (http://www.sew-euro- drive.de, under the heading «Documentation»).

|

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

9 |

||

|

2 |

Safety Notes |

|

Transportation, storage |

||

2.6Transportation, storage

You must observe the notes on transportation, storage and proper handling. Comply with the requirements for climatic conditions stated in chapter «Technical Data». Tighten installed eyebolts securely. They are designed for the weight of the MOVIMOT® drive. Do not attach any additional loads. Use suitable, sufficiently rated handling equipment (e.g. rope guides) if required.

2.7Installation

The units must be installed and cooled according to the regulations and specifications in the corresponding documentation.

Protect the MOVIMOT® inverters from improper strain.

The following applications are prohibited unless the unit is explicitly designed for such use:

•Use in potentially explosive atmospheres.

•Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

•Use in non-stationary applications with strong mechanical oscillation and impact loads; see chapter «Technical Data».

2.8Electrical connection

Observe the applicable national accident prevention guidelines when working on live MOVIMOT® drive inverters (e.g. BGV A3).

Perform electrical installation according to the pertinent regulations (e.g. cable cross sections, fusing, protective conductor connection). For any additional information, refer to the applicable documentation.

For notes on EMC compliant installation, such as shielding, grounding, arrangement of filters and routing of lines, refer to chapter «Installation instructions». The manufacturer of the system or machine is responsible for maintaining the limits established by EMC legislation.

Protective measures and protection devices must comply with the regulations in force (e.g. EN 60204 or EN 61800-5-1).

A voltage test according to EN 61800-5-1:2007 chapter 5.2.3.2 is required for the MOVIMOT® drives prior to startup in order to ensure the insulation.

2.9Safe disconnection

MOVIMOT® inverters meet all requirements for safe disconnection of power and electronic connections in accordance with EN 61800-5-1. All connected circuits must also satisfy the requirements for safe disconnection.

|

10 |

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

||

Safety Notes

Operation

2.10Operation

Systems with integrated MOVIMOT® inverters must be equipped with additional monitoring and protection devices according to the applicable safety guidelines, such as the law governing technical equipment, accident prevention regulations, etc. Additional protective measures may be necessary for applications with increased potential risk.

Do not touch live components and power connections immediately after separation of the MOVIMOT® inverter from the supply voltage because there may still be some charged capacitors. Wait at least for 1 minute after having switched off the supply voltage.

As soon as supply voltages are present at the MOVIMOT® inverter, the connection box must be closed (i.e. the MOVIMOT® inverter and, if applicable, the connector of the hybrid cable must be connected).

The fact that the status LED and other display elements are no longer illuminated does not indicate that the unit has been disconnected from the supply system and no longer carries any voltage.

Mechanical blocking or internal safety functions of the unit can cause a motor standstill. Eliminating the cause of the problem or performing a reset may result in the drive restarting automatically. If, for safety reasons, this is not permitted for the driven machine, disconnect the unit from the supply system before correcting the error.

Caution: Danger of burns: The surface temperature of the MOVIMOT® drive and of external options, e.g. the heat sink of the braking resistor, can exceed 60 °C during operation!

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor

|

3 |

Unit Design |

MOVIMOT® drive |

3 Unit Design

3.1MOVIMOT® drive

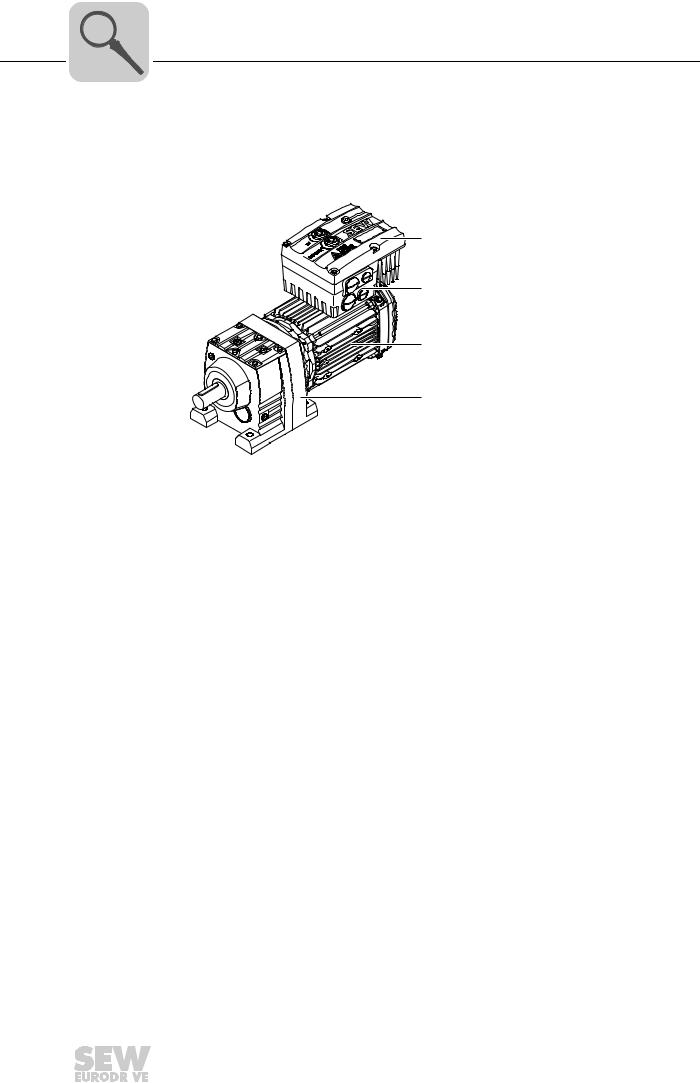

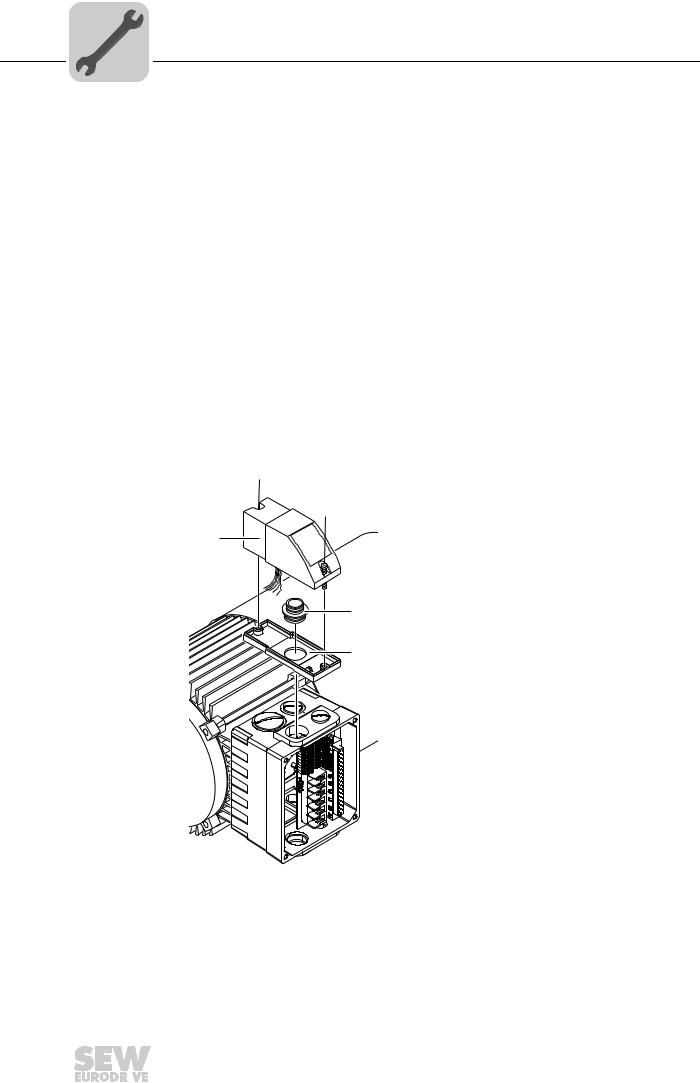

The following figure shows a MOVIMOT® drive with helical gear unit:

[1]

[2]

[3]

[4]

3531634827

[1]MOVIMOT® inverter

[2]Connection box

[3]Motor

[4]Helical gear unit

A MOVIMOT® drive is a combination of:

•MOVIMOT® inverter

–Mounted on the motor (see example above)

–or mounted close to the motor

•Motor (see motor operating instructions)

•Gear unit (optional, see gear unit operating instructions)

|

12 |

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

||

|

Unit Design |

3 |

MOVIMOT® inverter |

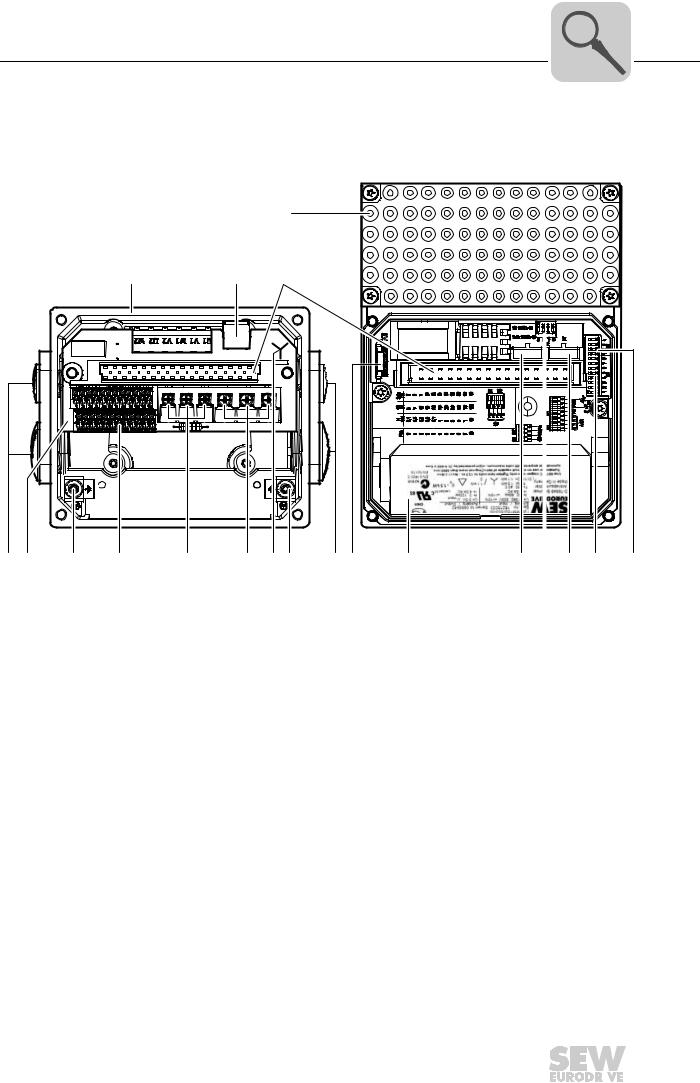

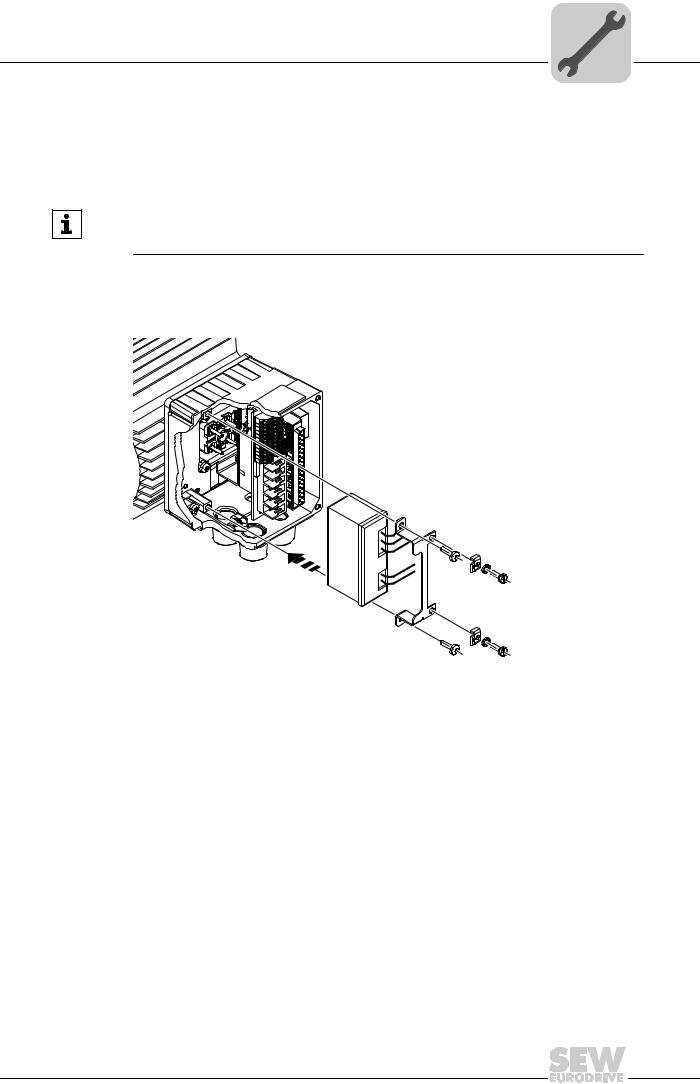

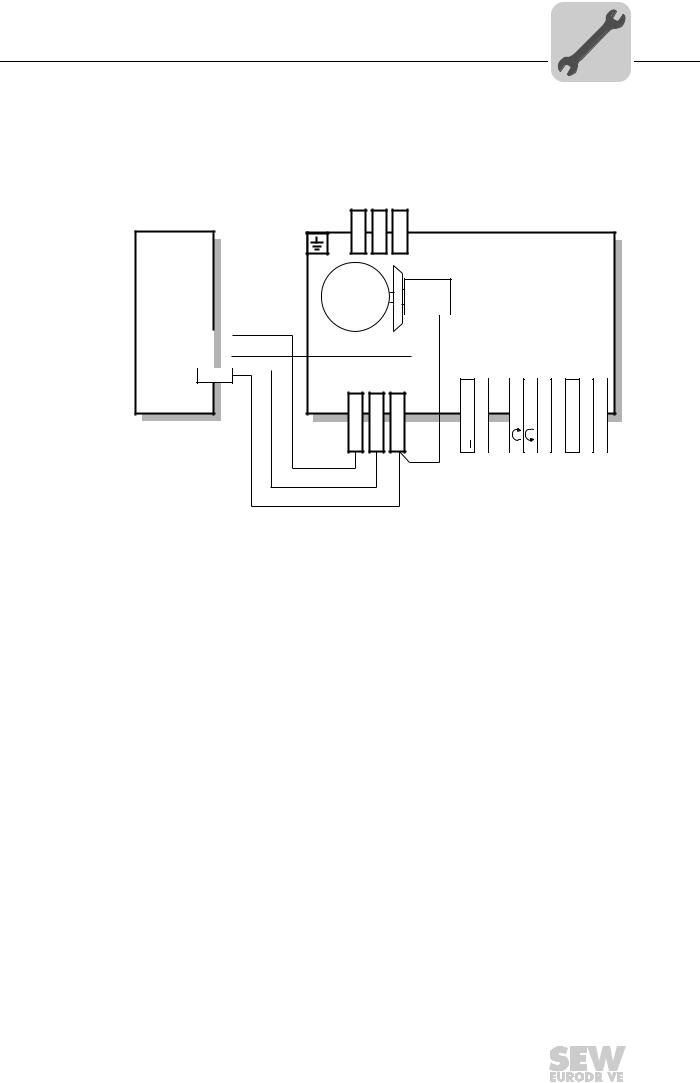

3.2MOVIMOT® inverter

The following figure shows the connection box and the MOVIMOT® inverter:

|

[5] |

[6] |

[7] |

[8] |

[9] |

[10] |

[11] [7] |

|

0 1 2 |

0 1 2 |

|||||

|

[5] [12] |

[13] |

[14] |

[15] |

[16] |

[17] |

[18] |

|

615683595 |

[1]Connection box

[2]X10: Plug connector for BEM option

[3]Plug connector for MOVIMOT® inverter

[4]MOVIMOT® inverter with heat sink

[5]Cable glands

[6]Connection unit with terminals

[7]Screw for PE connection

[8]X5, X6: Electronics terminal strips

[9]X1: Connection for brake coil (motors with brake) or braking resistor (motors without brake)

[10]X1: Supply system connection L1, L2, L3

[11]Connection type identification

[12]Drive-ID module

[13]Nameplate of the MOVIMOT® inverter

[14]Setpoint switch f2 (green)

[15]DIP switches S2/5 – S2/8

[16]Switch t1 for integrator ramp (white)

[17]DIP switches S1/1 – S1/8

[18]DIP switches S2/1 – S2/4

|

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

13 |

||

|

3 |

Unit Design |

|

MOVIMOT® inverter |

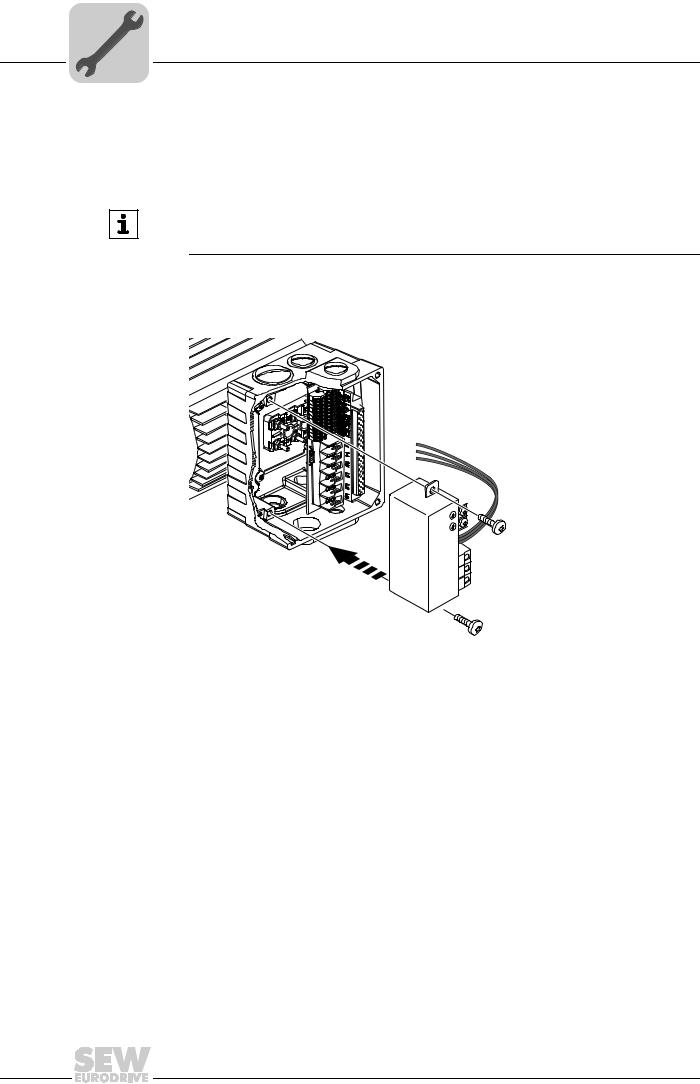

The following figure shows the top of the MOVIMOT® inverter:

[1]X50: Diagnostics interface with screw plug

[2]Setpoint potentiometer f1 with screw plug

[3]Status LED

[4]Unit identification

|

14 |

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

||

|

Unit Design |

3 |

Type designation of MOVIMOT® drive |

3.3Type designation of MOVIMOT® drive

3.3.1Nameplate

The following figure gives an example of a nameplate of a MOVIMOT® drive. The nameplate is attached to the motor.

|

76646 Bruchsal/Germany |

01 |

|||||||||

|

RF47DRE90L4BE2/MM15/MO |

||||||||||

|

01.300123457.0002.06 |

°C |

-20…40 |

||||||||

|

V |

380-500 |

Hz 50-60 |

A |

3.5 |

Iso.Kl. |

155(F) |

||||

|

kW |

1.5 |

Hz |

50 |

r/min |

1400/86 |

CT |

1:5 |

TEFC |

||

|

I |

16.22 |

Nm |

166 |

IP |

54 |

M.L. |

02 |

3~ |

||

|

IM |

M1 |

kg |

31 |

|||||||

|

V BR |

220..240 |

Nm |

13 |

kW |

1.5 |

Hz 50 |

||||

|

eff % |

85.2 |

|||||||||

|

1883410 |

||||||||||

|

CLP CC VGB220 0.65I |

Made in Germany |

9007199774918155

The logos at the top of the nameplate are only there if:

•the motor is manufactured accordingly,

•and contains at least one safety-rated component.

The FS logo on the nameplate is based on the combination of safety-related components that is installed.

3.3.2Type designation

The following table shows the type designation of the MOVIMOT® drive:

RF 47 DRE 90L4 BE/MM15/MO

Additional feature: inverter 1)

MOVIMOT® inverter

Optional design motor (brake)

Size, number of poles on motor

Motor series

DRS = DRS motor

DRE = DRE motor

DRP = DRP motor

Gear unit size

Gear unit series

1) The nameplate only displays options installed at the factory.

The available variants are listed in the «MOVIMOT® Gearmotors» catalog.

|

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

15 |

||

|

3 |

Unit Design |

Type designation of MOVIMOT® inverter |

3.4Type designation of MOVIMOT® inverter

3.4.1Nameplate

The following figure gives an example of a nameplate of a MOVIMOT® inverter:

|

Status: |

10 |

12 |

— A — — |

10 |

10 |

12 |

02 / 08 444 |

|||||||

|

Type : MM15D-503-00 |

||||||||||||||

|

P# : |

18215033 |

S# : 0886946 |

||||||||||||

|

Eingang / |

Input |

Ausgang / Output |

CH01 |

|||||||||||

|

U = |

3×380 . . . 500V AC |

U = |

3x0V . . . Uin |

|||||||||||

|

D-76646 Bruchsal |

I |

= |

3.5A AC |

I |

= |

4.0A AC |

N2936 |

|||||||

|

Made in Germany |

f |

= |

50 … 60Hz |

f |

= |

2 … 120Hz |

||||||||

|

MOVIMOT |

T = |

-30 . . . +40°C |

||||||||||||

|

Antriebsumrichter |

P-Motor |

1.5kW / 2.0HP |

||||||||||||

|

Drive Inverter |

Use 60/75°C copper wire only. Tighten terminals to 13.3 in.– ibs. (1.5 Nm). Suitable for use on a circuit capable of delivering not more than 200,000 rms symmetrical amperes, 500 volts maximum. Integral solid state short crcuit protection does not provide BCP. BCP must be provided in

accordance with the NEC and any additional local codes.

9007201212668299

3.4.2Type designation

The following table shows the type designation of the MOVIMOT® inverter:

MM 15 D – 503 – 00

Variant

00 = Standard

Connection type

3 = 3-phase

Supply voltage

50 = AC 380 – 500 V

23 = AC 200 – 240 V

Version D

Motor power

15 = 1.5 kW

Unit series

MM = MOVIMOT®

The available variants are listed in the «MOVIMOT® Gearmotors» catalog.

3.4.3Unit identification

The unit identification [1] on the top of the MOVIMOT® inverter provides information about the inverter type [2], inverter part number [3], unit power [4].

[2]

[1]

457916555

|

16 |

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor |

||

Unit Design

Type designation of the variant «mounted close to the motor»

3.5Type designation of the variant «mounted close to the motor»

3.5.1Nameplate

The following illustration shows an example of the MOVIMOT® inverter mounted close to the motor with corresponding nameplate:

MM15D-503-00/0/P21A/RO1A/APG4

457921547

3.5.2Type designation

The following table shows the type designation of a MOVIMOT® inverter mounted close to the motor:

MM15D-503-00/0/P21A/RO1A/APG4

Plug connector

For the connection to the motor

Connection box design

Adapter for mounting close to the motor

21 = Size 1

22 = Size 2

Connection type

MOVIMOT® inverter

Operating Instructions – MOVIMOT® MM..D with DRS/DRE/DRP AC Motor

|

4 |

Mechanical Installation |

MOVIMOT® gearmotor installation |

4 Mechanical Installation

4.1MOVIMOT® gearmotor installation

4.1.1General information

•Observe the general safety notes.

•Strictly observe all instructions as to the technical data and the permissible conditions regarding the place of installation.

•Only use the provided attachment options when mounting the MOVIMOT® drive.

•Only use mounting and locking elements that fit into the existing bores, threads and countersinks.

4.1.2Installation requirements

Make sure that the following requirements are met before you start installing the unit: