Содержание

- Xerox open heat error xerox

- Обзор частых ошибок принтера Xerox и их устранение

- Ошибка температуры печки принтера

- Ошибка «Мотор»

- Ошибка Hsync

- Проблемы с принтером Xerox Phaser 3117

- Коды ошибок принтеров Xerox

- Самые распространённые ошибки фьюзеров XEROX: как решить проблемы?

- Поломки и ошибки

- Коды ошибок копировальных аппаратов Xerox

Xerox open heat error xerox

КОНФЕРЕНЦИЯ СТАРТКОПИ

Принтеры, копировальные аппараты, МФУ, факсы и другая офисная техника:

вопросы ремонта, обслуживания, заправки, выбора

0. djkondor 13.05.13 11:15

При выходе в режим готовности и попытке напечатать лист конфигураци пишет — низкая температура. Сопротивление на термисторе и термостате 1 ом . Цепь звонится.

1. Mishel01 13.05.13 11:29

djkondor (0): Сопротивление на термисторе . 1 ом

Неисправность.

2. djkondor 13.05.13 11:31

на данный момент пишет : ош: откр. фьюзер

Или Open по английски.

А в электричестве open еще имеет значение «разомкнута цепь»

То бишь печка в обрыве, я уж молчу про термистор, сопротивлением 1 Ом.

4. Mishel01 13.05.13 11:33

Так и проверяйте ВСЮ цепь нагрева, а не термистор ВМЕСТЕ с термопредом)

5. djkondor 13.05.13 11:36

когда вынимаю печку,она тёплая,значит греется,напряжение подается.Смотреть лампу?

6. Mishel01 13.05.13 11:44

djkondor (5): Смотреть лампу?

И не только. См. (4).

7. djkondor 13.05.13 11:59

сопротивление на лампе 5.6 ома ,и звонится

8. djkondor 13.05.13 12:50

Все цепи на печке прозвонил,все нормально,везде прозванивается.

9. djkondor 13.05.13 12:56

нагрева смотрю нет

10. Mishel01 13.05.13 14:14

djkondor (8): Все цепи на печке прозвонил,все нормально,везде прозванивается

И везде накоротко? Тогда см. (1).

djkondor (9): нагрева смотрю нет

djkondor (5): когда вынимаю печку,она тёплая,значит греется,напряжение подается

Определитесь уже.

11. djkondor 13.05.13 15:04

На данный момент ошибка open fuser error. Когда начинал смотреть была ошибка недостаточной температуры и удалось несколько листов напечатать,она периодически пропадала.Посмотрел термистор,он неплотно прилегал к нагревательномк валу,поправил но ошибка не исчезла. Цепи звонил от левого конца печки до правого конца контакта ,обрывов нет.Термистор звонится.

12. djkondor 13.05.13 15:05

При такой ошибке печь не нагревается

13. djkondor 13.05.13 15:06

Я понимаю что нужно менять печку ,но аппарат на гарантии, нужна конкретика от чего не работает.

14. Mishel01 13.05.13 15:11

djkondor (11): На данный момент ошибка open fuser error.

djkondor (13): аппарат на гарантии, нужна конкретика от чего не работает.

Какую вам еще конкретику??

djkondor (11): Термистор звонится.

Скока? 1 Ом?))

djkondor (11): Цепи звонил от левого конца печки до правого конца контакта

Цепи нагрева есть не только в термоузле (печке).

15. djkondor 13.05.13 15:22

В диагностике проверил component control-fuser heat-temp A выдает status 21

16. djkondor 13.05.13 15:32

Как понимаю по-вашему проблема кроется в термисторе?

17. Mishel01 13.05.13 15:46

djkondor (15): выдает status 21

Простите мою серость — а что есть «статус 21» — это хорошо или плохо?)

djkondor (16): Как понимаю по-вашему проблема кроется в термисторе?

Нет. Пока недостаточно инфы от вас, чтобы делать какие-то предположения.

18. djkondor 13.05.13 16:04

Статус 21 это температура в цельсиях на нагревательном элементе.

19. Портной Нёма 13.05.13 16:20

(18) Вот интересно, долго вы еще мучиться будете? Садо-мазо? Может уже пора взять тестер и проверить силовую часть управления фьюзером? ну и огласть сопротивление термистора не помешает в омах, если, конечно, вы не путаете, как некоторые термистор и «термостат» (он же термопред)

20. djkondor 13.05.13 16:26

10-100

10-200

Open Fuser error

Low Heat error

The Fuser did not reach a

Ready temperature during

operation.

Plug the printer directly

into the wall outlet.

page 2-46 смотрю по доке

21. Mishel01 13.05.13 16:56

Портной Нёма (19): Садо-мазо?

Судя по (20) — ему нравится))

22. djkondor 13.05.13 17:24

Проблему решил . Ответная часть фьюзера — контактная площадка отошла

23. djkondor 13.05.13 17:26

В последний момент пристально когда осмотрел все,шив что прийдется фьюзер менять, увидел что одного контакта нет на площадке ответной фьюзера.

24. Mishel01 13.05.13 17:36

(22) Молодец!

Еще 6 часов назад было сказано:

Mishel01 (4): Так и проверяйте ВСЮ цепь нагрева

😉

Источник

Обзор частых ошибок принтера Xerox и их устранение

Принтеры компании Xerox, как и других брендов, делают нашу жизнь и работу проще. Эта техника может располагаться дома, может быть на работе, в офисе, но все-таки она есть в наличии, и проблемы с ней тоже могут случиться.

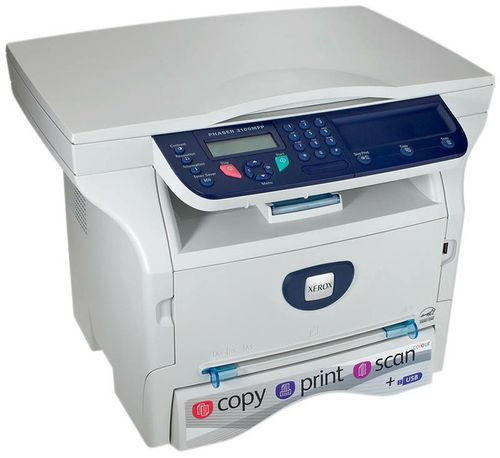

Xerox WorkCentre 5016

О чём пойдет речь:

Ошибка температуры печки принтера

Стоит подробнее разобрать ошибки принтера Xerox 3100 или Xerox WorkCentre 5016, чтобы всегда можно было решить их без проблем. Самая распространенная ошибка принтера Xerox – температура печки не может быть определена устройством, и оно выходит из строя.

Печка может перегреться, и ее температура не будет отображаться по нескольким причинам:

•термодатчик принтера вышел из строя;

•не работают мотор или отдельные части мотора;

•лампы нагрева сломались или отказали;

•инородное тело в термопредохранителе принтера.

Любые ошибки и поломки в принтере имеют свое решение.

Если дело в лампе нагрева, из-за чего возникла ошибка принтера Xerox 3100, температуру печки, естественно, не надо вычислять. При этом лампу нужно просканировать, прозвонить мультиметром. Если прибор укажет, что лампа сломана, то ее требуется заменить.

Термодатчик принтера, соответственно, тоже проверяется мультиметром. Если датчик печки грязный, его нужно почистить. Делается это с помощью тампона и ацетона.

Мультиметром проверяется и термопредохранитель печки. Чтобы он вновь заработал, можно попробовать его потрясти или постучать по нему. Если все вышеуказанные части печки исправны, то необходимо сбросить ошибку принтера, набрав определенную комбинацию кнопок и символов на клавиатуре. Эту комбинацию можно найти в инструкции.

Ошибка «Мотор»

Xerox Phaser 3100

Ошибка принтера Xerox Phaser 3100 или Xerox WorkCentre 5016 «Мотор» тоже довольно распространена. Появляется эта неисправность в тот момент, когда пользователь хочет распечатать что-то на принтере. Решается ошибка «Мотор» очень просто. Нужно несколько раз выключить и включить принтер заново, тогда ошибка «Мотор» исчезнет.

Ошибка Hsync

Ошибка Hsync – еще одна распространенная неисправность принтеров Xerox. Она подразумевает ошибку лазера. При попытке просканировать документ принтер начинает шуметь, треск длится около 30 секунд, а потом выходит чистый лист. При этом нужно проверить, замкнуты ли нормально оба контакта крышки сканера. Если замкнут только один контакт, может появиться эта ошибка. Тогда нужно замкнуть и второй контакт, и неисправность пропадет. Если все в порядке, то необходимо обратиться в сервисную службу для того, чтобы узнать, не сгорел ли сам лазер.

Проблемы с принтером Xerox Phaser 3117

Если у вас принтер Xerox Phaser 3117, то на нем могут встречаться аналогичные ошибки, которые были описаны выше. Чтобы ошибок не возникало в Xerox Phaser 3117 и другой подобной технике, необходимо регулярно чистить принтер, проводить обслуживание, проверять все контакты и подключения к сети и компьютеру, а также устанавливать новые драйвера и проверять их наличие. Это поможет избежать возникновения неисправностей в самый неудачный момент.

Коды ошибок принтеров Xerox

Коды ошибок принтеров Xerox для разных моделей могут быть разные, но основные значат одно и то же. Расшифровать коды можно с помощью инструкции по эксплуатации, где есть переводы подробное описание комбинаций для сброса ошибок и их кодов всех видов.

Будьте внимательны к вашей технике дома и в офисе, чтобы не допускать появления неисправностей. Приобретайте технику у проверенных производителей и вовремя проводите обслуживание.

Источник

Самые распространённые ошибки фьюзеров XEROX: как решить проблемы?

В лазерных устройствах печать обеспечивается с помощью специального элемента – фьюзера, который еще называют печкой, а также блоком или узлом термозакрепления. При необходимости его легко заменить, и в продаже всегда можно найти разные варианты, например, популярную модель 126k30553 от XEROX, использующуюся в распространенных устройствах этого производителя – compsch.com.

Фьюзер состоит из корпуса, в котором располагаются два валика – верхний и нижний. Верхний выполнен из алюминия и покрыт тефлоном, а внутри находится галогеновая лампа, благодаря которой тонер разогревается и закрепляется на листе бумаге. Нижний валик – прижимной, он вдавливает пигмент в поверхность.

Поломки и ошибки

Блок термозакрепления лазерных устройств XEROX, к сожалению, иногда подвергается поломкам и разнообразным ошибкам. Некоторые из них критичны – тогда элемент следует заменить новым. Но многие неполадки можно устранить, обратившись в сервисный центр или самостоятельно.

Наиболее часто пользователи XEROX встречаются с такими ошибками фьюзера:

- низкая температура или перегрев;

- открыта крышка фьюзера;

- бумага мнется или вообще не выходит;

- появление дефектов при печати.

Причиной низкой температуры (ошибка 10-327) может быть использование некачественных и несовместимых с устройством печек – тогда аппарат не может нагреть их. Но если вы используете оригинальный или качественный совместимый элемент, нужно выполнить сброс ошибки из сервисного режима.

Перегрев при первом включении возникает при отхождении силового предохранителя (его нужно поправить). При частом использовании такая ошибка может выдаваться из-за налипания тонера на термисторе (что решается очисткой), а также из-за неисправности термопредохранителя (тут нужна замена детали).

Если устройство сообщает, что открытка крышка, нужно убедиться, что она закрыта, и если все в порядке – выполнить сброс. Если лист сминается на выходе или застревает – возможны проблемы с термопленкой или верхним валом печки, в таком случае нужно произвести замену дефектного элемента.

При появлении дефектов на отпечатанном изображении (от вертикальных белых полос, белых точек на черном фоне до фонового ореола), нужно убедиться в отсутствии загрязнений валиков и неисправностей блока питания. Если ничего такого нет, возможно, потребуется ремонт или замена фьюзера.

Часто справиться с ошибками помогает сброс. Он заключается в нажатии определенной комбинации кнопок, а их последовательность зависит от вида и модели устройства.

Источник

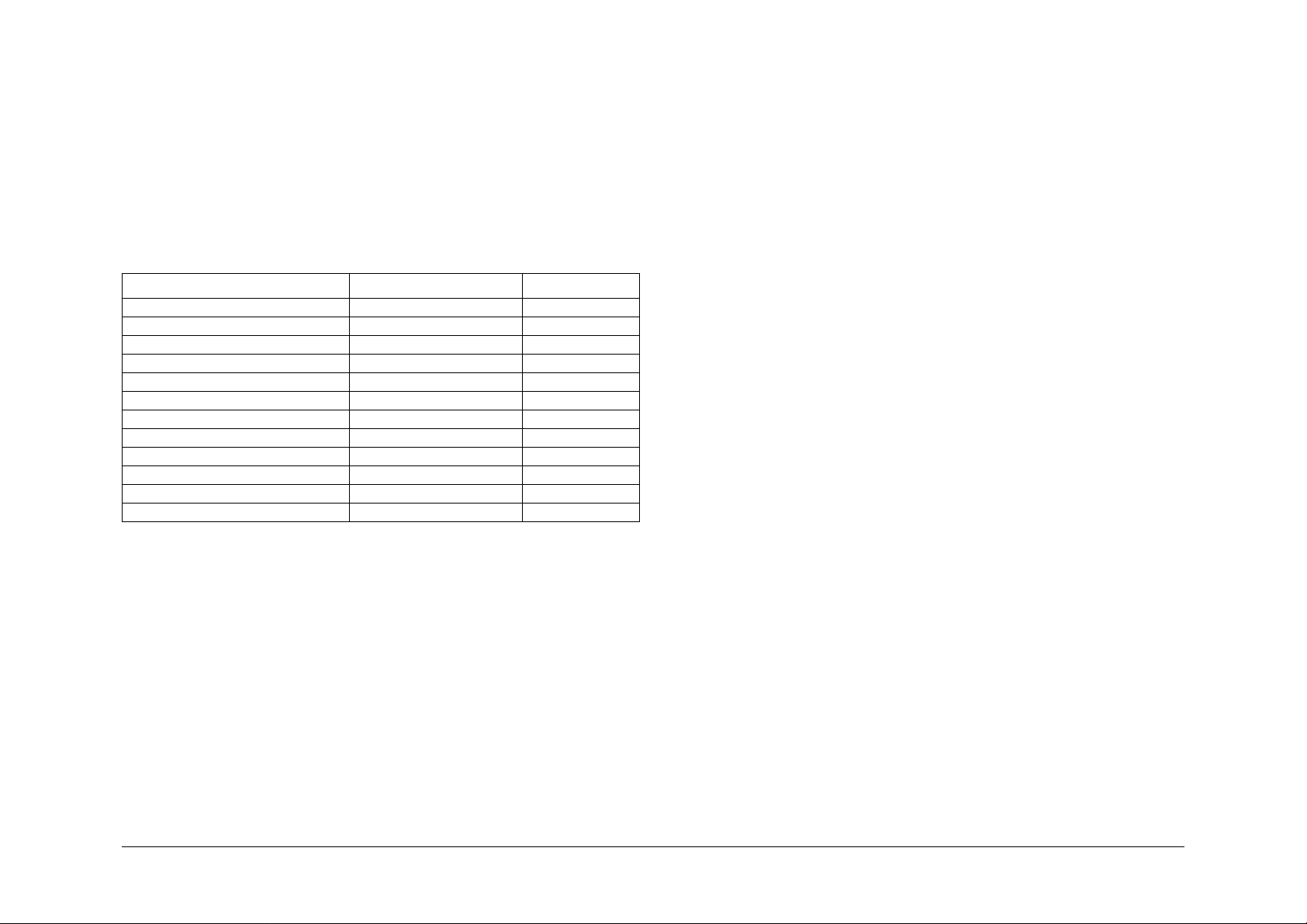

Коды ошибок

копировальных аппаратов Xerox

Если Ваш копировальный аппарат Xerox выдал на индикации некий код, то узнать причину возникновения ошибки Вы можете в этом разделе.

Но код ошибки — это лишь следствие сбоя в работе аппарата

Xerox 1012, 1012(RE)

| Код ошибки | Описание |

|---|---|

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

| E1 | Jam between paper feed and fuser |

| E3 | Jam in fuser |

| E5 | Clam shell open |

| E6 | Paper feed section cover is open |

| J1 | Toner cartridge near empty |

| J3 | Drum cartridge not seated properly |

| J7 | Waste toner full (replace drum cartridge) |

| L6 | Key counter out |

| L8 | Exposure area overheat |

| U1 | No clock pulse (drive problem) |

| U2 | Scan problem |

| U3 | Lens/mirror problem (RE model only) |

| U4 | Heat problem |

| U8 | Exposure lamp control circuit problem |

Xerox 1020

| Код ошибки | Описание |

|---|---|

| LL | Probable bad heater lamp |

Xerox 1025

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

Xerox 1035

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

Xerox 1038

| Код ошибки | Описание |

|---|---|

| A1 | DF jam |

| C1 | PF jam cass. 1 |

| C2 | PF jam cass. 2 |

| C3 | PF jam cass. 3 |

| C9 | Bypass jam |

| E1-1 | Paper jam before exit switch |

| E1-2 | Paper jam |

| E1-5 | Paper jam |

| E1-6 | Paper jam |

| E3-3 | Paper jam at exit switch |

| E3-4 | Paper jam at exit switch |

| E5 | Front door open |

| F1 | Collator jam |

| F5 | Collator interlock |

| F8 | No power to collator |

| F9 | Collator bin home switch |

| J7 | 250 copies since toner waste was full |

| L5 | Original cass. not present after clearing interrupt |

| L6 | Key counter |

| L8 | Platen glass too hot |

| U1 | Main motor clock pulse |

| U2 | Scan problem |

| U3-1 | Lens problem |

| U4-1 | Open thermistor |

| U4-2 | Low temperature |

| U4-4 | Temperature |

| U4-5 | Main PWB |

| U6-1 | Main PWB |

| U6-2 | Main PWB |

| U6-3 | Main board battery |

| U6-4 | Initialization |

| U8 | Exposure lamp |

Xerox 2830

| Код ошибки | Описание |

|---|---|

| A9 | Scanner location |

| C1 | Paper feed — upper cassette |

| C2 | Paper feed — lower cassette |

| C9 | Bypass jam |

| E5 | Clam shell is open |

| E5 | Clam shell open |

| L6 | Key counter |

| U1 | Off/On |

| U2 | Optics |

| U4 | Low fuser temperature |

Xerox 5011, 5012, 5014

| Код ошибки | Описание |

|---|---|

| C8 | Bypass jam/no paper |

| C9 | Bypass jam |

| E1 | Jam |

| E3 | Fuser jam |

| E5 | Clamshell open |

| E6 | PF section cover open |

| J1 | Toner cartridge amost empty |

| J3 | Copy cart (drum unit) missing/not seated right |

| J7 | Copy cartridge has run 18,000 copies |

| J8 | Copy cartridge. Improperly seated or possible only one of two fuses in the cartridge blew |

| L6 | Key counter |

| L8 | Exposure glass too hot |

| U1 | Drive problem |

| U2 | Scan problem |

| U3 | Lens or mirror drive problem |

| U4 | Fuser problem. Heat lamp, thermoswitch, SSR, thermistor |

| U6 | Battery on main board |

| U8 | Exposure lamp or exposure lamp circuit |

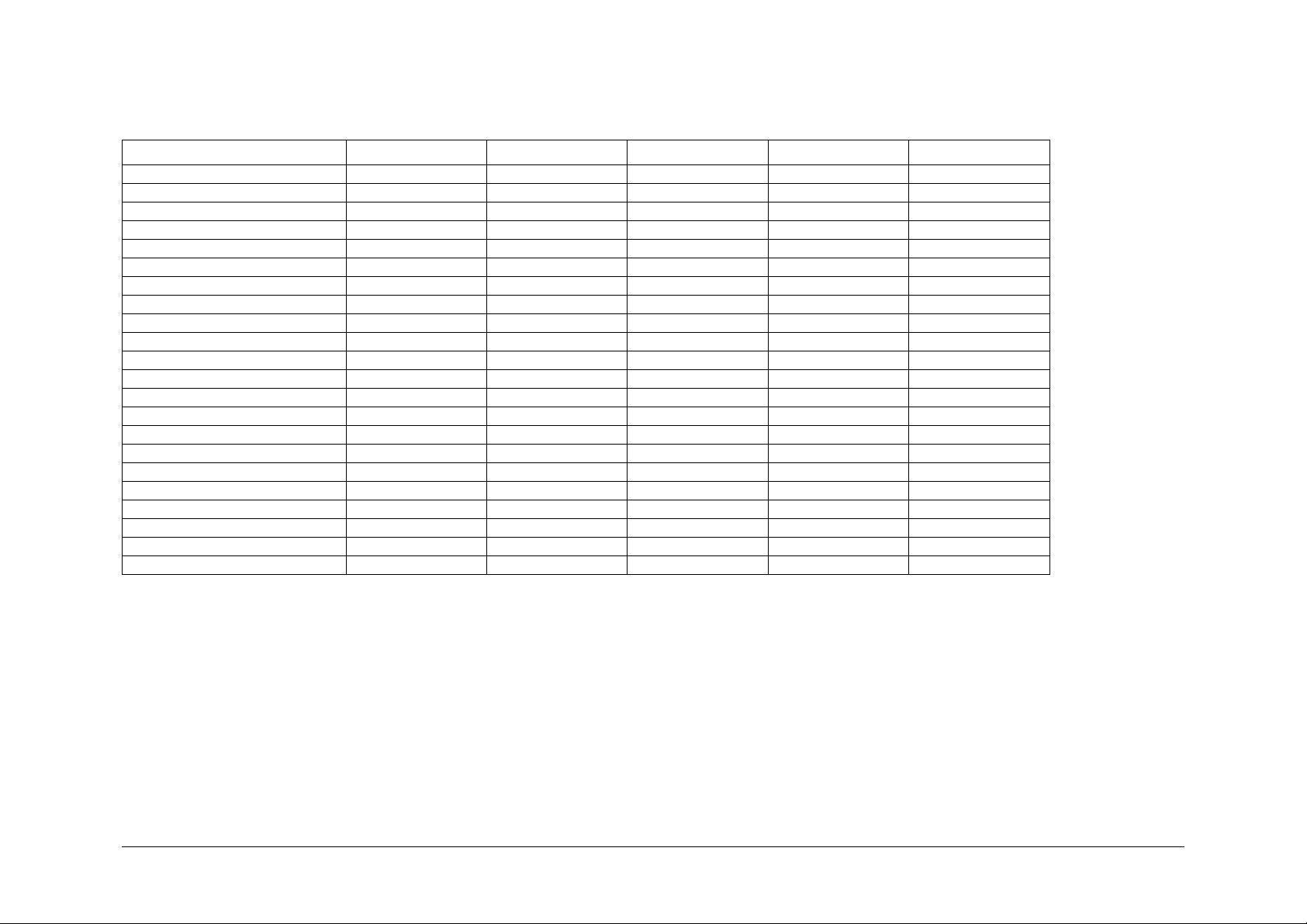

Xerox 5016, 5017, 5316, 5317

| Code | Description |

|---|---|

| A1-1 | Document feeder feed jam |

| A1-2 | Document feeder belt jam |

| A2-1 | Document feeder exit jam |

| A2-2 | Duplex jam |

| A3 | DAD interlock |

| A5 | Duplex and DAD right side interlock |

| A6 | Copier jams after |

| A9 | Document feed belt drive motor |

| C1-3 | Top cassette misfeed |

| C2-3 | Middle cassette misfeed |

| C3-3 | Bottom cassette misfeed |

| C9-3 | Bypass misfeed |

| E1-11 to E1-14 | Paper jam in machine. Did not reach exit switch soon enough |

| E1-6 | Paper path jam |

| E3-31 to E3-34 | Exit switch jam |

| E3-6 | Fuser jam |

| E5 | Front door interlock |

| E6 | Right side interlock or TTM interlock |

| F1 | Sorter jam |

| F5 | Sorter interlock |

| F8 | Sorter board to copier main board communication problem |

| F9 | Sorter bins |

Xerox 5018, 5028

| Code | Description |

|---|---|

| A1 | Document is ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6, A7 | ADF jams |

| A9 | ADF jams |

| C1 — C4 | Feed jam |

| C5-1 to C5-4 | Jams in various areas |

| C5-2 | Jams in various areas |

| C5-3 | Jams in various areas |

| C5-4 | Duplex jam |

| E0 | Machine has reset |

| E1 | Jam |

| E1-E0 | Registration jam |

| E1-E5 | Clamshell interlock |

| E1-E6 | Right side interlock |

| E1-E7 | Two tray interlock |

| E1-E8 | Sorter interlock |

| E1-E9 | Copy cartridge interlock |

| E2 | Reset signal happened |

| E3 | Jam |

| E4 | Exit jam |

| E4-10 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock. Duplex interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E7 | Duplex interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-0 | Replace copy cartridge |

| L2 | 2000 copies left on copy cartridge |

| L3 | ADF to machine communication problem |

| L4 (flashing) | 1000 copies left on fuser web |

| rr | Bad EPROM on main board |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U3-00 | Cam drive problem |

| U3-01 | Cam movement slow |

| U3-04 | Main board to duplex communication |

| U3-09 | Cam problem |

| U3-12 | Jogger problem |

| U3-19 | Cam problem |

| U3-21 | Cam problem |

| U3-23 | Cam problem |

| U3-29 | Cam problem |

| U3-32 | Cam problem |

| U3-34 | Cam problem |

| U3-39 | Cam problem |

| U3-43 | Cam problem |

| U3-45 | Cam problem |

| U3-49 | Cam problem |

| U3-54 | Cam problem |

| U3-56 | Cam problem |

| U3-59 | Cam problem |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm up |

Xerox 5312, 5313, 5314

| Код ошибки | Описание |

|---|---|

| C1 | Upper paper feed problem. Did not reach feed sensor |

| C2 | Lower paper feed problem. Did not reach feed sensor |

| E1 | Exit jam. Paper did not reach exit sensor |

| E3 | Exit jam. Paper still on exit sensor |

| J1 | Add toner |

| J3 | Copy cartridge (drum unit) not installed |

| J7 | Copy cartridge (drum unit) must be replaced |

| J8 | Copy cartridge (drum unit) problem |

| L6 | Problem with an accessory. Installed but not initialized |

| U1 | Drive problem. Main motor, gear etc. |

| U2 | Scan problem |

| U3 | Main board dip switches wrong. Lens drive problem |

| U4 | Fuser problem. Heat lamp, thermal switch, overheat, thermistor. |

| U6 | EPROM error |

| U8 | Auto exposure sensor. No exposure lamp or weak lamp |

Xerox 5318, 5320, 5322

| Code | Description |

|---|---|

| A1-11 | Original ready switch |

| A1-12 | Feed sensor |

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF |

| A1-21 | Original ready switch and document registration sensor or both the document feed sensor and document registration sensor |

| A1-22 | ADF registration sensor |

| A1-23 | Original did not reach ADF registration sensor quickly enough |

| A1-24 | ADF sensor stuck down too long |

| A1-25 | ADF sensor actuated at the wrong time during single sheet feed |

| A1-26 | ADF sensor not actuated quickly enough in sheet feed mode |

| A1-31 | In reverse, ADF sensor is not actuated soon enough |

| A1-32 | In reverse, ADF sensor is actuated too long |

| A2 | ADF exit problems |

| A2-1 | Original ready sensor and ADF exit switch are actuated or ADF feed in sensor and ADF exit switch are both actuated |

| A2-2 | ADF exit switch |

| A2-3 | ADF exit switch is not actuated on time |

| A3 | Irregular size documents |

| A3-1 | Wrong size original sensed in 1:1 mode |

| A3-2 | Wrong size original sensed in the 2:1 mode |

| A5 | ADF interlock |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A6-1 | Reset original |

| A6-2 | Reset sheet feeder |

| A7 | Document cover interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C1-2 | Paper feed problem in tray 1 |

| C1-3 | Paper does not reach registration |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C3-1 | Paper feed problem from tray 3 |

| C3-2 | Paper feed problem from tray 3 |

| C3-3 | Paper feed problem from tray 1 |

| C6-1 | Duplex paper feed problem |

| C6-2 | Duplex and/or tray 1 paper feed problem |

| C6-3 | Paper feed problem from tray 1 |

| C7-1 | Paper feed problem from HCF |

| C7-2 | Paper feed problem from HCF on tray 1 |

| C7-3 | Paper feed problem from tray 1 |

| C8 | Paper stays in tray or duplex or HCF |

| C8-1 | Paper on tray 1 feed sensor |

| C8-2 | Paper on tray 2 feed sensor |

| C8-3 | Paper on tray 3 feed sensor |

| C8-4 | Paper on HCF feed sensor |

| C8-5 | Paper in duplex section |

| C9 | Bypass feed problem |

| C9-3 | Paper from bypass did not reach registration sensor quickly enough |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-30 to E3-35 | Exit switch actuated too long |

| E3-6 | Exit jam |

| E3-6 | Paper on exit switch |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-10 to E4-45 | Paper did not reach inverter switch soon enough |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Paper on inverter switch |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2 | Duplex inverter interlock |

| E7-3 | Duplex interlock |

| E8-10 to E8-15 | Paper on duplex feed sensor is not actuated soon enough |

| E8-6 | Paper in duplex |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Paper did not reach sorter |

| F1-2 | Paper stayed on sorter feed sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| H2-1 | Communication problem between main board and duplex board |

| H2-2 | Side guard sensor problem |

| H3-1 | Communication problem between main board and HCF |

| H3-2 | Upper limit sensor problem on HCF |

| H6-1 | ADF size sensor |

| H6-2 | ADF nudgeer sensor |

| H6-3 | Belt drive motor does not have 24 volts. Black toner is empty, but 100 copies have been run without changing toner |

| J1 | Black toner is empty, but 100 copies have been run without changing toner |

| J3 | Replace copy cartridge |

| J3 | No copy cartridge (drum unit) |

| J7 | Copy cartrige must be replaced |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM must be changed |

| L6 | Auditron or other counter problem |

| L6 | Key counter not installed |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 | Scan home problem |

| U2-1 to U2-4 | Scan home sensor |

| U2-2 | Scan home problem or optics problem |

| U2-3, U2-4 | Scan home problem |

| U3-1 | Lens sensor problem |

| U4-1 | Fuser thermistor open |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 | Exposure lamp problem |

| U8-2 | Communication problem main board and exposure board |

| U8-3 | Exposure lamp or exposure lamp board problem |

| U8-4 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Xerox 5328

| Code | Description |

|---|---|

| A1 | Document in ADF |

| A1-8 | Main board received reset signal |

| A2 | ADF jams |

| A6 | ADF registration jam |

| A7 | ADF interlock |

| A9 | Tray 1 jam |

| C1 | Tray 2 jam |

| C2 | Tray 3 jam |

| C3 | Bypass feed jams |

| C4 | Machine has reset |

| E1 | Jam |

| E1-5 | Clamshell interlock |

| E1-6 | Right side interlock |

| E1-7 | Two tray interlock, or duplex interlock |

| E1-8 | Sorter interlock |

| E1-9 | Copy cartridge interlock |

| E1 or E1-0 | Registration jam |

| E2 | Reset signal happened |

| E3 | Jam in transfer area |

| E4 | Exit jam |

| E4-0 | Exit jam |

| E4-5 | Clamshell interlock |

| E4-6 | Right side interlock |

| E4-7 | Two tray interlock |

| E4-8 | Sorter interlock |

| E4-9 | Copy cartridge interlock |

| E5 | Clamshell interlock |

| E6 | Right side interlock |

| E9 | Copy cartridge interlock |

| F3-1 | Sorter bin home switch |

| F3-2 | Sorter cam switch |

| F3-3 | Sorter cam switch |

| F5 | Sorter interlock |

| J1-1 | Add toner |

| J1-2 | Temporary low toner signal |

| J2-1, J2-2 | Replace copy cartridge |

| J5, J6 | ADF to machine communications problem |

| L2 | 2000 copies left on cartridge |

| L3 | ADF to machine communications problem |

| L4 | (flashing) 1000 copier left on fuser web |

| L6 | Auditron or other counter problem |

| LL | Main board. Try simulation 1.1 to initialize |

| rc | Wrong operation panel installed |

| rr | Bad EPROM on main board. Try 1.1 |

| U0 | Main board |

| U2 | Scan problem |

| U2-1 | Scan home |

| U2-2 | Scan home or scan encoder |

| U2-4 | Scan home or scan dual page sensor |

| U2-7 | Scan home |

| U4-1 | Fuser problem. Long warm up |

| U4-2 | Low fuser temperature after warm up |

| U4-3 | High fuser temperature |

| U4-4 | Open fuser thermistor |

| U4-6 | Replace fuser web. |

| U4-7 | Thermistor signal problem |

| U7-1 | Copy cartridge belt drive problem |

| U9-3 | Exposure lamp problem |

| U9-4 | Toner motor |

| U9-5 | Problem in warm-up |

Xerox 5330

| Code | Description |

|---|---|

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF. |

| A2 | ADF exit problems |

| A3 | Irregular size documents |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset. |

| A7 | Platen interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C6-1, C6-2 | Jams related to duplex |

| C6-3 | Registration sensor, re tray 1 |

| C7-1, C7-2 | HCF feed problems |

| C7-3 | Tray 1 feed problem |

| C8 | Paper stays in tray or duplex or HCF |

| C9 | Bypass feed problem |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else. |

| E3-30 to E4-14 | Exit jam |

| E3-6 | Exit jam |

| E4-10 to E4-14 | Inverter sensor not actuated. |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2, E7-3 | Duplex interlock |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Sorter entry sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| J1 | Add toner |

| J3 | Replace copy cartridge |

| J7 | Replace copy cartridge |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM |

| L6 | Auditron or other counter problem |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 to U2-4 | Scan home sensor |

| U3-1 | Lens sensor |

| U4-1 | Open fuser thermistor |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3 | Sorter bin home switch |

| U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

Xerox 5340, 5343

| Code | Description |

|---|---|

| 00-009; 030 to 033 | A door was opened while paper was being fed |

| 00-047 | Paper in duplex |

| 00-1 | Auditron |

| 00-2 | Diagnostic error |

| 00-3 | Faults error |

| 00-4 | Ric error |

| 00-5 | Job manager system error |

| 00-6 | LLM interface |

| 00-7 | Standby error |

| 00-8 | Communications error |

| 00-9 | Xerographic error |

| 01-300 | Front interlock |

| 01-310 | Right upper interlock |

| 01-315 | Left upper interlock |

| 01-320 | Left lower interlock |

| 01-325 | Fuser interlock |

| 02-910 | Key counter missing |

| 02-920 | Wrong combination of accessories |

| 03-321, 322, 326, 327 | LLM to ISIL communications problems |

| 03-328 | IOT communications problem with duplex or tray 4 |

| 03-330 | IOT communications problems with HCF |

| 03-335, 03-336 | LLM communications problems with edit |

| 03-340 | NVM memory |

| 03-341, 03-347 | Communications problems between IOT and sorter |

| 03-350, 03-354 | Communications problem with LLM and user interface |

| 03-363, 03-364 | Communications problem between LLM & optics |

| 03-370, 03-373 | Communications problem between LLM & DADF |

| 03-380, 384 | |

| 03-416, 03-422 | RAM memory problem |

| 03-424, 426 | NVM memory problem |

| 03-430, 432 | Billing problem |

| 03-439 | GRAIB communications problem |

| 03-440 | RIC communications problem |

| 03-441 | RIC NVM problem |

| 03-442 | Modem |

| 03-443, 03-458 | RIC problems |

| 03-460 | Serial communications processor problem |

| 04-300 | Main motor or drive problem |

| 05-100, 05-108 | DADF registration sensor |

| 05-110 | DADF exit sensor |

| 05-115, 120 | DADF jams |

| 05-305 | DADF document drive |

| 05-310, 312 | DADF document sensor |

| 05-316 | DADF registration sensor jam |

| 05-325 | DADF exit sensor |

| 05-335, 341, 345 | DADF interlock switches |

| 06-300, 06-310 | Scan problems |

| 06-315 | Scan drive |

| 06-320A, 320B, 320C, 325 | Scan problem |

| 06-330 | Lens drive |

| 06-340 | Exposure control problem |

| 06-342 | LLM CPU problem |

| 06-344, 06-350 | Exposure cvontrol problem |

| 06-352 | IOT CPU problem |

| 07-300, 315, 330, 345 | Tray faults |

| 07-360, 07-370 | HCF problems |

| 07-375, 380A, 380B | Duplex problems |

| 08-100, 08-110 | Feed problems. Lead edge of copy paper is late getting to feed sensor of tray 1 |

| 08-115, 08-162 | Feed problem. Lead edge of copy paper is late getting to registration sensor |

| 08-165 | Paper jam at registration sensor |

| 08-310, 08-370 | Paper at a sensor when power is turned on |

| 08-330 | DADF nudger sensor |

| 08-380 | Registration side to side problem with home position |

| 08-390 | Nip |

| 09-300 | Copy cartridge finished (drum unit) |

| 09-310 | Add black toner Add color toner |

| 09-320 | Add color toner |

| 09-330 | Wrong copy cartridge (wrong drum unit) |

| 09-340 | Drum cartridge not installed properly |

| 09-350 | Waste toner full |

| 100 | A fault has occurred |

| 10-100 | Exit jam |

| 10-105 | Exit jam |

| 10-110 | Vertical sensor jam |

| 10-120, 122, 125 | Duplex jam |

| 10-150, 155 | Too much or not enough paper in duplex tray |

| 10-300 | Fuser thermistor |

| 10-302 | Low fuser temperature |

| 10-304 | Bad fuser temp |

| 10-308 | High fuser temperature or open thermistor |

| 10-310 | High fuser temperature |

| 10-312 | Fuser not up to temperature after energy save |

| 10-314 | Fuser problem |

| 10-320 | Fuser web finished |

| 10-330, 335, 340 | Exit switch, vertical sensor switch actuated when power is turned on |

| 11-100, 11-116 | Sorter jam |

| 11-150, 11-176 | Sorter auto stapler jam |

| 11-310, 314, 316 | Sorter interlock |

| 11-325A, B, C, D, E, F, G | Sorter index |

| 11-352, 354, 356 | Sorter auto stapler interlocks |

| 11-365A, B, C, D, E | Sorter auto stapler bin |

| 11-370, 371, 372A, 373A, 373B, 374 | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 11-385A, 385B, 390A,B,C,D,E, 396A | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 301 | Fuser web must be replaced |

| 302 | Copy cartridge (drum unit) must be replaced |

| 501 | Tray 1 must be rebuilt |

| 502 | Tray 2 must be rebuilt |

| 503 | Tray 3 must be rebuilt |

| 504 | Tray 4 must be rebuilt |

| 505 | HCF must be rebuilt |

| 506 | Bypass must be rebuilt |

| 507 | Duplex unit must be rebuilt |

| 508 | Replace black developer |

| 509 | Replace red developer |

| 510 | Replace green developer |

| 512 | Replace brown developer |

| 513 | Copy cartridge (drum unit) will need replacing soon |

| 514 | Fuser web will need replacing soon |

| 515 | DADF belt should be replaced |

| 516 | DADF feed rollers should be replaced |

| 517 | Replace exposure lamp |

| 518 | Replace suction filter |

| 519 | Replace ozone filter |

| 520 | Replace optics filter |

| 521 | Replace particle filter |

| 522 | Replace upper fuser roller |

| 523 | Replace fuser pawls |

| 524 | Replace pressure roller |

| 525 | Replace pressure roller pawls |

| 900-905 | Key operator calls |

Xerox 5345

| Код ошибки | Описание |

|---|---|

| 01-01 | Frequency monitoring and zero cross problem |

| 01-02 | Interlock |

| 01-03 | AC power problem |

| 01-04 | Finisher interlock |

| 01-05 | 24v problem |

| 03-01 | Optics to main board communication problem |

| 03-02 | Software reset problem |

| 03-03 | Could be punched holes in the lead edge of the original |

| 03-04 | Software problem |

| 03-06 | Low battery |

| 03-07 | NVM not initialized or is missing or defective |

| 03-17 | Communication problem between main board and finisher board |

| 03-18 | Initializes one NVM counter to agree to others |

| 03-19 | All three NVM counter to agree with others |

| 03-20 | Main board/interface board problems |

| 03-21 | Problem with RIC NVM |

| 03-22 | RIC modem problem |

| 03-23 | RIC real time clock failure. |

| 03-25 | RIC NVM problem or not initialized |

| 03-27 | NVM problem |

| 03-28 | Watchdog software problem |

| 03-29 | Microprocessor crystal not at correct frequency |

| 03-30 | No software response from finisher after 20 seconds have elapsed |

| 06-01 | Lens did not reach 1.1 position |

| 06-02 | 1/2 rate scanner problem |

| 06-03 | Scan home problem |

| 06-04 | Scan home problem |

| 06-05 | Scan home problem |

| 06-06 | Scan encoder |

| 06-07 | Scan encoder |

| 06-08 | Scan drive boost |

| 06-09 | Scan encoder |

| 06-11 | Scan encoder pulse phases |

| 06-12 | Insufficient scan damping |

| 07-01 | Duplex tray not home during duplexing |

| 07-02 | Tray 2 not home when selected |

| 07-13 | Tray 2 height sensor problem |

| 07-15 | Tray 2 empty |

| 07-16 | Tray 1 door open |

| 07-18 | Tray 1 stack sensor |

| 07-22 | Tray 1 empty |

| 07-26 | Tray 1 bypass switch actuated too long |

| 07-27 | Tray 1 bypass switch deactuated too early |

| 07-30 | Paper in duplex |

| 07-31 | Paper in duplex |

| 07-32 | Duplex tray empty, when paper should be there |

| 08-10 | Paper did not reach tray 2 input tray sensor |

| 08-11 | Paper did not reach duplex input sensor |

| 08-12 | Paper did not reach tray 1 |

| 08-14 | Paper did not leave tray 2 input sensor quickly enough |

| 08-18 | Trail edge did not reach tray 2 input sensor quickly enough |

| 08-19 | Trail edge did not reach tray 1 input sensor quickly enough |

| 08-20 | Paper in duplex |

| 08-21 | Paper in tray 2 input |

| 08-22 | Paper in tray 2 or duplex at wrong time |

| 08-23 | Paper at tray 1 input at wrong time |

| 08-24 | Paper in tray 1 at wrong time |

| 08-28 | Upper and lower nips problem |

| 09-08 | Low toner condition |

| 09-12 | Drum signals are out of range |

| 09-13 | Unstable drum patch readings |

| 09-15 | Patch is too dark |

| 09-16 | Patch is too light |

| 09-17 | Open toner container access cover |

| 09-18 | Low toner level |

| 09-21 | Low toner sensor disconnected |

| 09-22 | Low toner condition, even after machine has been theoretically, adding toner |

| 10-02 | Low fuser temperature |

| 10-03 | High fuser temperature |

| 10-06 | Paper did not reach out put switch |

| 10-07 | Paper stayed on output switch |

| 10-10 | Paper did not reach decurler sensor |

| 10-11 | Paper did not reach decurler sensor |

| 10-12 | Paper on decurler sensor |

| 10-13 | Paper did not reach duplex entry sensor in time |

| 10-14 | Paper did not reach duplex entry sensor in time |

| 10-15 | Paper on entry sensor at wrong time |

| 10-17 | Fuser temperature is too high and fuser relay has deactuated |

| 12-01 | Paper at finisher input sensor |

| 12-02 | Paper did not reach finisher |

| 12-03 | Paper reached finisher too soon |

| 12-05 | Paper at stapler |

| 12-06 | Paper at stapler |

| 12-07 | Paper did not reach stapler |

| 12-08 | Paper did not reach stapler |

| 12-10 | Complied motor not working properly |

| 12-15 | Eject motor problem and/or eject encoder |

| 12-20 | Stacker motor problem |

| 12-21 | Stacker interlock |

| 12-22 | Stacker bottom sensor |

| 12-23 | Stacker bottom sensor |

| 12-24 | Stacker bottom sensor senses full |

| 12-25 | Stack height sensor |

| 12-26 | Stack height sensor |

| 12-27 | Stack height sensor |

| 12-30 | Offset home sensor |

| 12-31 | Offset home sensor |

| 12-32 | OCT switch |

| 12-35 | Eject nip carriage |

| 12-36 | Eject cam interlock |

| 12-37 | Eject nip carriage open timing |

| 12-38 | Eject cam interlock |

| 12-40 | Tamper motor |

| 12-41 | Tamper home problem |

| 12-42 | Tamper home sensor |

| 12-43 | Staple load sensor |

| 12-44 | Tamper home sensor |

| 12-45 | Tamper home sensor |

| 12-50 | Low on staples |

| 12-51 | Stapler home sensor |

| 12-52 | Stapler home sensor |

| 12-53 | Eject cam interlock |

| 33-37 | Too few documents |

| 55-01 | RDH interlock switch open during use |

| 55-04 | Paper on bypass sensor |

| 55-05 | Paper at vacuum timing sensor |

| 55-06 | Paper on output sensor |

| 55-10 | No paper reached S31 |

| 55-20 | Paper did not leave S31 at correct time |

| 55-24 | Set counter arm problem |

| 55-25 | Documents in input tray not detected |

| 55-27 | Lead edge did not reach S35 at correct time |

| 55-2955-30 | Trail edge did not reach S35 at correct time |

| 55-31 | S32, ADF registration sensor did not see paper at correct time |

| 55-32 | S32 did not see trail edge at correct time |

| 55-33 | S36 One too many documents |

| 55-36 | One too many documents |

| 55-39 | Hole count problem on document feeder belt |

| 55-40 | Document belt travel problem |

| 55-41 | Document belt mistracking or skewing |

| 55-45 | Paper at inverter sensor |

| 55-47 | Inverter sensor did not see paper lead edge at correct time |

| 55-49 | More than 50 sheets in input tray |

| 55-50 | Right side interlock |

| 55-51 | Left side interlock |

| 55-55 | Document on glass |

| 93-93 | NVM has to be initialized after new software installed |

Xerox 5350, 5352

| Code | Description |

|---|---|

| 00-009, 030, 031, 032, 033 | A door was opened while paper was being fed |

| 00-047 | Paper in duplex |

| 00-1 | Auditron |

| 00-2 | Diagnostic error |

| 00-3 | Faults error |

| 00-4 | Ric error |

| 00-5 | Job manager system error |

| 00-6 | LLM interface |

| 00-7 | Standby error |

| 00-8 | Communications error |

| 00-9 | Xerographic error |

| 01-300 | Front interlock |

| 01-310 | Right upper interlock |

| 01-315 | Left upper interlock |

| 01-320 | Left lower interlock |

| 01-325 | Fuser interlock |

| 02-910 | Key counter missing |

| 02-920 | Wrong combination of accessories |

| 03-321, 322, 326, 327 | LLM to ISIL communications problems |

| 03-328 | IOT communications problem with duplex or tray 4 |

| 03-330 | IOT communications problems with HCF |

| 03-335, 336 | LLM communications problems with edit |

| 03-340 | NVM memory |

| 03-341-347 | Communications problems between IOT and sorter |

| 03-350-354 | Communications problem with LLM and user interface |

| 03-363, 364 | Communications problem between LLM & optics |

| 03-370-03-373 | Communications problem between LLM & DADF |

| 03-380, 384 | |

| 03-416-422 | RAM memory problem |

| 03-424, 426 | NVM memory problem |

| 03-430, 432 | Billing problem |

| 03-439 | GRAIB communications problem |

| 03-440 | RIC communications problem |

| 03-441 | RIC NVM problem |

| 03-442 | Modem |

| 03-443-458 | RIC problems |

| 03-460 | Serial communications processor problem |

| 04-300 | Main motor or drive problem |

| 05-100-108 | DADF registration sensor |

| 05-110 | DADF exit sensor |

| 05-115, 120 | DADF jams |

| 05-305 | DADF document drive |

| 05-310, 312 | DADF document sensor |

| 05-316 | DADF registration sensor jam |

| 05-325 | DADF exit sensor |

| 05-335, 341, 345 | DADF interlock switches |

| 06-300-310 | Scan problems |

| 06-315 | Scan drive |

| 06-320A, 320B, 320C, 325 | Scan problem |

| 06-330 | Lens drive |

| 06-340 | Exposure control problem |

| 06-342 | LLM CPU problem |

| 06-344-350 | Exposure cvontrol problem |

| 06-352 | IOT CPU problem |

| 07-300, 315, 330, 345 | Tray faults |

| 07-360-370 | HCF problems |

| 07-375, 380A, 380B | Duplex problems |

| 08-100-110 | Feed problems. Lead edge of copy paper is late getting to feed sensor of tray 1 |

| 08-115-162 | Feed problem. Lead edge of copy paper is late getting to registration sensor |

| 08-165 | Paper jam at registration sensor |

| 08-310-370 | Paper at a sensor when power is turned on |

| 08-330 | DADF nudger sensor |

| 08-380 | Registration side to side problem with home position |

| 08-390 | Nip |

| 09-300 | Copy cartridge finished (drum unit) |

| 09-310 | Add black toner Add color toner |

| 09-320 | Add color toner |

| 09-330 | Wrong copy cartridge (wrong drum unit) |

| 09-340 | Drum cartridge not installed properly |

| 09-350 | Waste toner full |

| 100 | A fault has occurred |

| 10-100 | Exit jam |

| 10-105 | Exit jam |

| 10-110 | Vertical sensor jam |

| 10-120, 122, 125 | Duplex jam |

| 10-150, 155 | Too much or not enough paper in duplex tray |

| 10-300 | Fuser thermistor |

| 10-302 | Low fuser temperature |

| 10-304 | Bad fuser temp |

| 10-308 | High fuser temperature or open thermistor |

| 10-310 | High fuser temperature |

| 10-312 | Fuser not up to temperature after energy save |

| 10-314 | Fuser problem |

| 10-320 | Fuser web finished |

| 10-330, 335, 340 | Exit switch, vertical sensor switch actuated when power is turned on |

| 11-100-116 | Sorter jam |

| 11-150-176 | Sorter auto stapler jam |

| 11-310, 314, 316 | Sorter interlock |

| 11-325A,B,C,D,E,F,G | Sorter index |

| 11-352, 354, 356 | Sorter auto stapler interlocks |

| 11-365A,B,C,D,E | Sorter auto stapler bin |

| 11-370,371,372A,373A,373B,374 | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 11-385A,385B,390A,B,C,D,E,396A | Sorter auto stapler staple failure, staple home problem or tamper home problem |

| 301 | Fuser web must be replaced |

| 302 | Copy cartridge (drum unit) must be replaced |

| 501 | Tray 1 must be rebuilt |

| 502 | Tray 2 must be rebuilt |

| 503 | Tray 3 must be rebuilt |

| 504 | Tray 4 must be rebuilt |

| 505 | HCF must be rebuilt |

| 506 | Bypass must be rebuilt |

| 507 | Duplex unit must be rebuilt |

| 508 | Replace black developer |

| 509 | Replace red developer |

| 510 | Replace green developer |

| 512 | Replace brown developer |

| 513 | Copy cartridge (drum unit) will need replacing soon |

| 514 | Fuser web will need replacing soon |

| 515 | DADF belt should be replaced |

| 516 | DADF feed rollers should be replaced |

| 517 | Replace exposure lamp |

| 518 | Replace suction filter |

| 519 | Replace ozone filter |

| 520 | Replace optics filter |

| 521 | Replace particle filter |

| 522 | Replace upper fuser roller |

| 523 | Replace fuser pawls |

| 524 | Replace pressure roller |

| 525 | Replace pressure roller pawls |

| 900-905 | Key operator calls |

Xerox 5355

| Код ошибки | Описание |

|---|---|

| 01-01 | Frequency monitoring and zero cross problem |

| 01-02 | Interlock |

| 01-03 | AC power problem |

| 01-04 | Finisher interlock |

| 01-05 | 24v problem |

| 03-01 | Optics to main board communication problem |

| 03-02 | Software reset problem |

| 03-03 | Could be punched holes in the lead edge of the original |

| 03-04 | Software problem |

| 03-06 | Low battery |

| 03-07 | NVM not initialized or is missing or defective |

| 03-17 | Communication problem between main board and finisher board |

| 03-18 | Initializes one NVM counter to agree to others |

| 03-19 | All three NVM counter to agree with others |

| 03-20 | Main board/interface board problems |

| 03-21 | Problem with RIC NVM |

| 03-22 | RIC modem problem |

| 03-23 | RIC real time clock failure. |

| 03-25 | RIC NVM problem or not initialized |

| 03-27 | NVM problem |

| 03-28 | Watchdog software problem |

| 03-29 | Microprocessor crystal not at correct frequency |

| 03-30 | No software response from finisher after 20 seconds have elapsed |

| 06-01 | Lens did not reach 1.1 position |

| 06-02 | 1/2 rate scanner problem |

| 06-03 | Scan home problem |

| 06-04 | Scan home problem |

| 06-05 | Scan home problem |

| 06-06 | Scan encoder |

| 06-07 | Scan encoder |

| 06-08 | Scan drive boost |

| 06-09 | Scan encoder |

| 06-11 | Scan encoder pulse phases |

| 06-12 | Insufficient scan damping |

| 07-01 | Duplex tray not home during duplexing |

| 07-02 | Tray 2 not home when selected |

| 07-13 | Tray 2 height sensor problem |

| 07-15 | Tray 2 empty |

| 07-16 | Tray 1 door open |

| 07-18 | Tray 1 stack sensor |

| 07-22 | Tray 1 empty |

| 07-26 | Tray 1 bypass switch actuated too long |

| 07-27 | Tray 1 bypass switch deactuated too early |

| 07-30 | Paper in duplex |

| 07-31 | Paper in duplex |

| 07-32 | Duplex tray empty, when paper should be there |

| 08-10 | Paper did not reach tray 2 input tray sensor |

| 08-11 | Paper did not reach duplex input sensor |

| 08-12 | Paper did not reach tray 1 |

| 08-14 | Paper did not leave tray 2 input sensor quickly enough |

| 08-18 | Trail edge did not reach tray 2 input sensor quickly enough |

| 08-19 | Trail edge did not reach tray 1 input sensor quickly enough |

| 08-20 | Paper in duplex |

| 08-21 | Paper in tray 2 input |

| 08-22 | Paper in tray 2 or duplex at wrong time |

| 08-23 | Paper at tray 1 input at wrong time |

| 08-24 | Paper in tray 1 at wrong time |

| 08-28 | Upper and lower nips problem |

| 09-08 | Low toner condition |

| 09-12 | Drum signals are out of range |

| 09-13 | Unstable drum patch readings |

| 09-15 | Patch is too dark |

| 09-16 | Patch is too light |

| 09-17 | Open toner container access cover |

| 09-18 | Low toner level |

| 09-21 | Low toner sensor disconnected |

| 09-22 | Low toner condition, even after machine has been theoretically, adding toner |

| 10-02 | Low fuser temperature |

| 10-03 | High fuser temperature |

| 10-06 | Paper did not reach out put switch |

| 10-07 | Paper stayed on output switch |

| 10-10 | Paper did not reach decurler sensor |

| 10-11 | Paper did not reach decurler sensor |

| 10-12 | Paper on decurler sensor |

| 10-13 | Paper did not reach duplex entry sensor in time |

| 10-14 | Paper did not reach duplex entry sensor in time |

| 10-15 | Paper on entry sensor at wrong time |

| 10-17 | Fuser temperature is too high and fuser relay has deactuated |

| 12-01 | Paper at finisher input sensor |

| 12-02 | Paper did not reach finisher |

| 12-03 | Paper reached finisher too soon |

| 12-05 | Paper at stapler |

| 12-06 | Paper at stapler |

| 12-07 | Paper did not reach stapler |

| 12-08 | Paper did not reach stapler |

| 12-10 | Complied motor not working properly |

| 12-15 | Eject motor problem and/or eject encoder |

| 12-20 | Stacker motor problem |

| 12-21 | Stacker interlock |

| 12-22 | Stacker bottom sensor |

| 12-23 | Stacker bottom sensor |

| 12-24 | Stacker bottom sensor senses full |

| 12-25 | Stack height sensor |

| 12-26 | Stack height sensor |

| 12-27 | Stack height sensor |

| 12-30 | Offset home sensor |

| 12-31 | Offset home sensor |

| 12-32 | OCT switch |

| 12-35 | Eject nip carriage |

| 12-36 | Eject cam interlock |

| 12-37 | Eject nip carriage open timing |

| 12-38 | Eject cam interlock |

| 12-40 | Tamper motor |

| 12-41 | Tamper home problem |

| 12-42 | Tamper home sensor |

| 12-43 | Staple load sensor |

| 12-44 | Tamper home sensor |

| 12-45 | Tamper home sensor |

| 12-50 | Low on staples |

| 12-51 | Stapler home sensor |

| 12-52 | Stapler home sensor |

| 12-53 | Eject cam interlock |

| 33-37 | Too few documents |

| 55-01 | rdh interlock switch open during use |

| 55-04 | Paper on bypass sensor |

| 55-05 | Paper at vacuum timing sensor |

| 55-06 | Paper on output sensor |

| 55-10 | No paper reached S31 |

| 55-20 | Paper did not leave S31 at correct time |

| 55-24 | Set counter arm problem |

| 55-25 | Documents in input tray not detected |

| 55-27 | Lead edge did not reach S35 at correct time |

| 55-2955-30 | Trail edge did not reach S35 at correct time |

| 55-31 | S32, ADF registration sensor did not see paper at correct time |

| 55-32 | S32 did not see trail edge at correct time |

| 55-33 | S36 One too many documents |

| 55-36 | One too many documents |

| 55-39 | Hole count problem on document feeder belt |

| 55-40 | Document belt travel problem |

| 55-41 | Document belt mistracking or skewing |

| 55-45 | Paper at inverter sensor |

| 55-47 | Inverter sensor did not see paper lead edge at correct time |

| 55-49 | More than 50 sheets in input tray |

| 55-50 | Right side interlock |

| 55-51 | Left side interlock |

| 55-55 | Document on glass |

| 93-93 | NVM has to be initialized after new software installed |

Xerox XC520, 540, 560, 580

| Код ошибки | Описание |

|---|---|

| H2 | Fuser thermistor |

| H3 | Fuser temperature too high. Must be reset in diagnostics |

| H4 | Fuser temperature too low. Must be reset in diagnostics |

| L3 | Scan problem |

| L4 | Min motor drive problem |

| L8 | Exposure lamp not lightning or not enough light reaching auto exposure sensor |

| P | Paper did not feed |

Xerox 5622

| Code | Description |

|---|---|

| A1-1 to A1-32 | All indicate a paper path problem, etc. in the ADF |

| A2 | ADF exit problems |

| A3 | Irregular size documents |

| A5 | ADF interlock |

| A6 | ADF single sheet document reset |

| A7 | Platen interlock |

| A8 | ADF exit interlock |

| C1 | Tray 1 jam |

| C2 | Tray 2 jam |

| C3 | Tray 3 jam |

| C6-1, C6-2 | Jams related to duplex |

| C6-3 | Registration sensor, re tray 1 |

| C7-1, C7-2 | HCF feed problems |

| C7-3 | Tray 1 feed problem |

| C8 | Paper stays in tray or duplex or HCF |

| C9 | Bypass feed problem |

| E1-10 to E1-25 | Internal jam |

| E1-6 | Paper on registration sensor |

| E2 | Reset signal happened. Might read E-2 something else |

| E3-30 to E4-14 | Exit jam |

| E3-6 | Exit jam |

| E4-10 to E4-14 | Inverter sensor not actuated |

| E4-15 | Inverter sensor |

| E4-40 to E4-45 | Duplex entry sensor |

| E4-6 | Inverter sensor |

| E5 | Front door interlock |

| E6-1 | Tray 1 interlock |

| E6-2 | 2 tray or duplex interlock |

| E6-3 | HCF interlock |

| E7-2, E7-3 | Duplex interlock |

| E8-6 to E8-15 | Duplex entry sensor |

| F1-1 | Sorter entry sensor |

| F1-6 | Sorter exit sensor |

| F3 | Paper size not available for sort/stack |

| F5 | Sorter interlock |

| J1 | Add toner |

| J3 | Replace copy cartridge |

| J7 | Replace copy cartridge |

| J8-1 | Wrong copy cartridge installed |

| J8-2 | Copy cartridge EEPROM |

| L6 | Auditron or other counter problem |

| L8 | Platen glass temperature is too high |

| L9 | Communication problem between interimage erase/edge lamps and main board |

| U1-1 | Main motor drive problem |

| U2-1 to U2-4 | Scan home sensor |

| U3-1 | Lens sensor |

| U4-1 | Open fuser thermistor |

| U4-2 | Fuser did not warm up properly |

| U4-3 | Fuser temperature too high |

| U4-4 | Fuser problem. Staying on too long |

| U4-6 | High fuser temperature |

| U5-1 | Sorter bin home switch not activated |

| U5-2 | Sorter bin home switch stayed actuated |

| U5-3, U5-4 | Sorter bin home switch |

| U6-1 | ROM problem |

| U6-2 | RAM problem |

| U6-3 | Low battery |

| U6-4 | Incorrect value in NVM. Reinitialize main board with code 20-96 |

| U8-1 to U8-6 | Problem with exposure lamp, lamp sensor, lamp board |

|

||

|

||

Решение проблем с включением принтера HP LaserJet 1010 за 1010 рублей |

||

|

||

| Восстановление качества печати, в струйных принтерах EPSON, HP, CANON за 749 рублей |  |

Установка СНПЧ за 999 рублей |

|

Мы осуществляем ремонт принтеров HP следующих моделей: Мы осуществляем ремонт плоттеров HP следующих моделей: Мы осуществляем ремонт принтеров Xerox следующих моделей: Мы осуществляем ремонт принтеров Canon следующих моделей: Источник Adblock |

Фьюзер глючит.. пишет открыт нагреватель.. что можно сделать

Slavutish » 12:44 — 31.10.07

Или есть у кого нить… тех документация… на него….

Slavutish007

- Slavutish

- новичок

- Сообщения: 1

- Зарегистрирован: 12:36 — 31.10.07

- Откуда: Сочи

- Баллы репутации: 0

-

- ICQ

Andrey44_44 » 14:08 — 31.10.07

В чем глюк заглючается?

- Andrey44_44

- ученик

- Сообщения: 102

- Зарегистрирован: 10:35 — 28.06.06

- Баллы репутации: 0

Гость » 14:15 — 31.10.07

Пишет открыт нагреватель… ну я открыл … проверил нагревается … или нет .. ненагревается… питание вроде подсоединено….

- Гость

Гость » 14:16 — 31.10.07

Пишет открыт нагреватель… ну я открыл … проверил нагревается … или нет .. ненагревается… питание вроде подсоединено….

- Гость

Andrey44_44 » 14:17 — 31.10.07

Температура поверхности нагревательного ролика изменяется в зависимости от сопротивления термистора. Температура устанавливается с помощью преобразования значения напряжения в цифровую форму (с помощью аналого-цифрового преобразователя). Подаваемая мощность переменного тока определяется путем сравнивания заданного значения со значением от термистора. Если значение термистора находится за пределами диапазона управляющих значений, возникает состояние ошибки.

Open Heat Error — При разогреве в течение 25 с температура была ниже 68ЧС

- Andrey44_44

- ученик

- Сообщения: 102

- Зарегистрирован: 10:35 — 28.06.06

- Баллы репутации: 0

Олег Ал » 14:19 — 31.10.07

Там в печке термопредохранитель стоит,снять и шандарахнуть его об стол,не очень сильно,потом прозвонить.

Звонится,значит все путем

- Олег Ал

- Консультант

- Сообщения: 2238

- Зарегистрирован: 19:43 — 18.12.06

- Откуда: Ульяновск

- Баллы репутации: 1

-

- ICQ

Вернуться в XEROX

Кто сейчас на конференции

Сейчас этот форум просматривают: нет зарегистрированных пользователей и гости: 0

Please note the following:

This output is created from an electronic documentation (EDOC) database

and is not optimised for hard copy. Please be aware of the following:

•Text may not appear to be in the logical order when flowing around figures.

•Text may continue on a following page without indication.

•Figures may not appear on the page containing the figure reference.

•EDOC hot link references can over write text.

Transmittal Page

Product

WorkCentre M20, 4118 Family

Title

Service Manual

Part Number

708P88419

Supersedes

708P87563

Date

April 2006

Service Manual binder inserts

Front pocket insert

Spine insert

Xerox

WorkCentre

M20, 4118 Family

Service Manual

Xerox

WorkCentre M20, 4118 Family

Service Manual

April 2006

Xerox WorkCentre M20, 4118 Family

Service Manual

WorkCentre M20, 4118 Family

Service Documentation

WorkCentre M20, 4118 Service Manual

708P88419

April 2006

Prepared by:

The Document Company, Xerox

Global Knowledge & Language Services

Enterprise Centre

P.O. Box 17

Bessemer Road

Welwyn Garden City

Hertfordshire AL7 1BU

England.

© Copyright 2006 by Xerox Europe. All rights reserved.

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes

only. Xerox service documentation is intended for use by certified, product trained service per-

sonnel only. Xerox does not warrant or represent that it will notify or provide to such customer

any future change to this documentation. Customer performed service of equipment, or modules,

components or parts of such equipment may affect whether Xerox is responsible to fix machine

defects under the warranty offered by Xerox with respect to such equipment. You should consult

the applicable warranty for its terms regarding customer or third-party provided service.

While every care has been taken in the preparation of this manual, no liability will be accepted by

Xerox Europe arising out of any inaccuracies or omissions.

Xerox Europe, Xerox ® and all identifying numbers used in connection with the Xerox products

mentioned in this publication are trademarks of Xerox. Other company trademarks are also

acknowledged.

Printed in the United Kingdom.

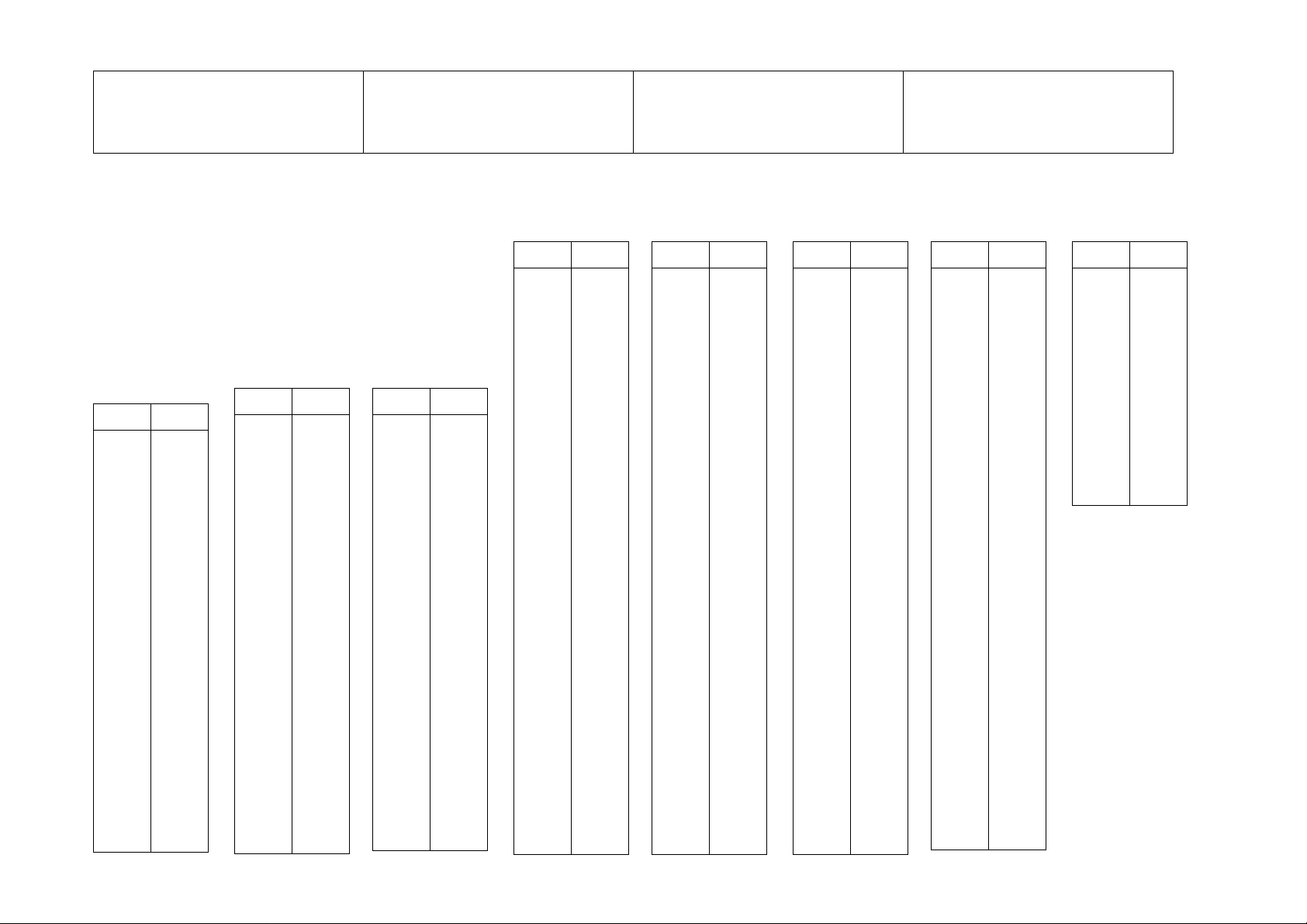

Page Rev.

i 04/06

ii 04/06

iii 04/06

iv 04/06

v 04/06

vi 04/06

vii 04/06

viii 04/06

ix 04/06

x 04/06

xi 04/06

xii 04/06

xiii 04/06

xiv 04/06

xv 04/06

xvi 04/06

xvii 04/06

xviii 04/06

xix 04/06

xx 04/06

xxi 04/06

xxii 04/06

xxiii 04/06

xxiv 04/06

xxv 04/06

xxvi 04/06

xxvii 04/06

xxviii 04/06

1-1 04/06

1-2 04/06

1-3 04/06

1-4 04/06

1-5 04/06

1-6 04/06

1-7 04/06

1-8 04/06

2-1 04/06

2-2 04/06

2-3 04/06

2-4 04/06

2-5 04/06

2-6 04/06

2-7 04/06

2-8 04/06

2-9 04/06

2-10 04/06

2-11 04/06

2-12 04/06

2-13 04/06

2-14 04/06

2-15 04/06

2-16 04/06

2-17 04/06

2-18 04/06

2-19 04/06

2-20 04/06

2-21 04/06

2-22 04/06

2-23 04/06

Page Rev.

2-24 04/06

2-25 04/06

2-26 04/06

2-27 04/06

2-28 04/06

3-1 04/06

3-2 04/06

3-3 04/06

3-4 04/06

3-5 04/06

3-6 04/06

3-7 04/06

3-8 04/06

3-9 04/06

3-10 04/06

3-11 04/06

3-12 04/06

3-13 04/06

3-14 04/06

3-15 04/06

3-16 04/06

3-17 04/06

3-18 04/06

4-1 04/06

4-2 04/06

4-3 04/06

4-4 04/06

4-5 04/06

4-6 04/06

Page Rev.

4-7 04/06

4-8 04/06

4-9 04/06

4-10 04/06

4-11 04/06

4-12 04/06

4-13 04/06

4-14 04/06

4-15 04/06

4-16 04/06

4-17 04/06

4-18 04/06

4-19 04/06

4-20 04/06

4-21 04/06

4-22 04/06

4-23 04/06

4-24 04/06

4-25 04/06

4-26 04/06

4-27 04/06

4-28 04/06

4-29 04/06

4-30 04/06

4-31 04/06

4-32 04/06

4-33 04/06

4-34 04/06

4-35 04/06

4-36 04/06

4-37 04/06

4-38 04/06

4-39 04/06

4-40 04/06

4-41 04/06

4-42 04/06

4-43 04/06

4-44 04/06

4-45 04/06

4-46 04/06

4-47 04/06

4-48 04/06

Page Rev.

4-49 04/06

4-50 04/06

4-51 04/06

4-52 04/06

4-53 04/06

4-54 04/06

5-1 04/06

5-2 04/06

5-3 04/06

5-4 04/06

5-5 04/06

5-6 04/06

5-7 04/06

5-8 04/06

5-9 04/06

5-10 04/06

5-11 04/06

5-12 04/06

5-13 04/06

5-14 04/06

5-15 04/06

5-16 04/06

5-17 04/06

5-18 04/06

5-19 04/06

5-20 04/06

5-21 04/06

5-22 04/06

5-23 04/06

5-24 04/06

5-25 04/06

5-26 04/06

5-27 04/06

5-28 04/06

5-29 04/06

5-30 04/06

5-31 04/06

5-32 04/06

5-33 04/06

5-34 04/06

5-35 04/06

Page Rev.

5-36 04/06

5-37 04/06

5-38 04/06

5-39 04/06

5-40 04/06

5-41 04/06

5-42 04/06

6-1 04/06

6-2 04/06

6-3 04/06

6-4 04/06

6-5 04/06

6-6 04/06

6-7 04/06

6-8 04/06

6-9 04/06

6-10 04/06

6-11 04/06

6-12 04/06

6-13 04/06

6-14 04/06

6-15 04/06

6-16 04/06

6-17 04/06

6-18 04/06

6-19 04/06

6-20 04/06

6-21 04/06

6-22 04/06

6-23 04/06

6-24 04/06

6-25 04/06

6-26 04/06

6-27 04/06

6-28 04/06

6-29 04/06

6-30 04/06

6-31 04/06

6-32 04/06

6-33 04/06

6-34 04/06

Page Rev.

6-35 04/06

6-36 04/06

6-37 04/06

6-38 04/06

6-39 04/06

6-40 04/06

6-41 04/06

6-42 04/06

6-43 04/06

6-44 04/06

6-45 04/06

6-46 04/06

6-47 04/06

6-48 04/06

6-49 04/06

6-50 04/06

6-51 04/06

6-52 04/06

6-53 04/06

6-54 04/06

6-55 04/06

6-56 04/06

6-57 04/06

6-58 04/06

6-59 04/06

6-60 04/06

7-1 04/06

7-2 04/06

7-3 04/06

7-4 04/06

7-5 04/06

7-6 04/06

7-7 04/06

7-8 04/06

7-9 04/06

7-10 04/06

7-11 04/06

7-12 04/06

7-13 04/06

7-14 04/06

Page Rev.

7-15 04/06

7-16 04/06

7-17 04/06

7-18 04/06

7-19 04/06

7-20 04/06

7-21 04/06

7-22 04/06

7-23 04/06

7-24 04/06

8-1 04/06

8-2 04/06

8-3 04/06

8-4 04/06

8-5 04/06

8-6 04/06

Page Rev.

Revision Control List

Product:

WorkCentre M20, 4118

Family

Title:

Service Manual

Part Number:

708P88419

Revision:

April 2006

Documentation compatible with this revision.

EDOC (Compact Disc) . . . . . . . . . . . . . . . . . . . . . . . . . . 708P88418

PDF on CD-Rom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 708P88420

EDOC Supplement (hard copy wiring diagrams) . . . . . . 708P88421

April 2006

i

WorkCentre M20, 4118 Family

Introduction

Introduction

About This Manual ……………………………………… …. …. …. ……….. …. …. …. ……… …. …. …. ….. iii

Change History ………………………………………………………………………………………………… iv

Warnings, Cautions And Notes………………….…………….……………….……………..…………. v

Safety Precautions………………..……………………………..…………….. ..…………….. ..…………. vi

Health and Safety Incident reporting……………………………………………………………………. vii

Translation of Warnings ………………….……………….……………..……………….…………….….. viii

April 2006

ii

WorkCentre M20, 4118 Family

Introduction

April 2006

iii

WorkCentre M20, 4118 Family

About This Manual

Introduction

About This Manual

This manual is part of a multinational service documentation system that is structured in the

standard Xerox service manual format.

This manual is based on a Korean original. The part names used throughout do not comply

with the standard Xerox part naming convention. Because part names have been molded on to

some plastic components and may also be embedded in the software, the part names have not

been changed.

To aid part identification, an acronym list and cross reference lists of more commonly recogn-

ised part names have been included in the manual. Refer to GP 20, Acronyms and Parts

Description List.

Organization

The service manual is the document used as the primary information source for repairing and

maintaining this family of products and is available as EDOC on a CDROM, or in printed for-

mat. The information within the manual is divided into an introduction and eight other sections.

Section 1 Service Call Procedures

This section is used to start and complete a service call. The procedures in this section will

either direct you to a Repair Analysis Procedure (RAP), or identify a faulty component or sub-

assembly.

Section 2 Status Indicator Repair Analysis Procedures

This section contains the Repair Analysis Procedures (RAPs) and checkouts necessary to

diagnose, isolate and repair faults other than image quality faults.

Section 3 Image Quality

This section contains the Image Quality Repair Analysis Procedures (IQ RAPs), checkouts and

setup procedures necessary to diagnose, isolate and repair image quality faults.

Section 4 Repairs/Adjustments

This section contains the instructions for removal, replacement, and adjus tm ent of parts within

the machine.

Section 5 Parts List

This section contains the detailed and illustrated spare parts list. Any part that is spared or that

must be removed to access a spared part is illustrated.

Section 6 General Procedures / Information

This section contains all other procedures, product specifications and general information.

Section 7 Wiring Data

This section contains the wiring diagrams.

Section 8 Accessories

This section contains details of any accessories that the machine may have.

Publication Comments Sheet

A Publication Comment Sheet is provided at the rear of the hardcopy manual.

April 2006

iv

WorkCentre M20, 4118 Family

Introduction

Change History

These are the changes made to this issue of the service documentation.

The WorkCentre 4118P and WorkCentre 4118X have been introduced. These are variations of

the WorkCentre M20. Throughout this manual, procedures and parts that are unique to either

the WorkCentre M20 family or the WorkCentre 4118 family will be designated M20F or 4118.

This issue of the service manual was updated at a time when the introduction of RoHS

(Restriction of Hazardous Substances) compliant parts was initiated. Due to these factors,

extensive changes have occurred to the part numbering within the parts lists.

The following procedures are updated

• SCP 7 Machine Configurations and Options.

• 1.1 Power Failure RAP

• 5.1 Load Document RAP

• 5.2 Document Jam RAP

• 6.1 LSU Error RAP

• 8.1 Door Open RAP

• 8.2 Bypass Lam RAP

• 8.3 Duplex Jam RAP

• 8.4 Paper Jam 0 Open/Close Door RAP

• 8.5 Paper Jam 1 Open/Close Door RAP

• 8.6 Paper Jam 2 Check Inside RAP

• 8.7 No Paper Add Paper RAP

• 9.1 Install Cartridge RAP

• 9.2 Non-Xerox Toner Cartridge RAP

• 9.4 Replace Drum RAP

• 9.5 Toner Empty RAP

• 10.1 Low Heat Error RAP

• 10.2 Open Heat Error RAP

• 10.3 Over Heat Error RAP

• 20.1 Fax Error Messages RAP

• 20.3 Fax Faults Without a Message RAP

• OF3 Use Auxiliary Access RAP

• OF4 Audible Noise RAP

• IQ1 Blank Copies RAP

• IQ2 Black Copies From the Scanner RAP

• IQ3 Blurred Image From the Scanner RAP

• IQ4 Vertical Black Lines or Bands RAP

• IQ6 Light Image RAP

• IQ7 Dark Image RAP

• IQ8 Background RAP

• IQ9 Ghost Images RAP

• IQ11 Poor Fusing RAP

• IQ14 Different Image Density (Left and Right) RAP

• IQ15 Horizontal Bands RAP

• IQ16 Periodic Printing Defects RAP

• REP 1.2 PBA Main (M20F)

• REP 2.1 ELA HOU OPE Assembly (M20F)

• REP 4.1 ELA HOU — Drive Assembly

• GP 1 Engine Test Mode Entry

• GP 2 User Mode Entry

• GP 3 Service Mode Entry

• GP 5 Memory Clear

• GP 6 Maintenance

• GP 7 Reports

• GP 11 Machine Specifications

• GP 12 Circuit Description

• GP 13 Circuit Operation

• GP 15 Host Interface

• GP 20 Acronyms and Parts Description List

• GP 21 DADF/ADF Document Feeding Specifications

• Wiring Diagram 1 (M20F)

• Wiring Diagram 2 (M20F)

• Wiring Diagram 3 (M20F)

• Wiring Diagram 4 (M20F)

• Wiring Diagram 5 (M20F)

• Wiring Diagram 6

The following procedures are new.

• IQ17 Print Damage RAP

• IQ18 DADF Lead Edge Offset RAP (M20F)

• IQ19 Poor Side Edge Registration RAP

• IQ20 Spots or Marks RAP

• REP 1.3 PBA Main (4118)

• REP 1.4 SMPS (4118)

• REP 1.5 SMPS (4118)

• REP 2.2 ELA HOU OPE Assembly (4118)

• REP 5.2 ELA HOU — ADF (4118)

• ADJ 5.1 DADF Side Edge Registration Adjustment (M20F)

• ADJ 5.2 ADF Side Edge Registration Adjustment (4118)

• GP 24 ADF Test (4118)

• Wiring Diagram 7 (4118)

• Wiring Diagram 8 (4118)

• Wiring Diagram 9 (4118)

• Wiring Diagram 10 (4118)

• Wiring Diagram 11 (4118)

• Wiring Diagram 12 (4118)

April 2006

v

WorkCentre M20, 4118 Family

Warnings, Cautions And Notes

Introduction

• PWB Connector Locations

• Change Tags

• ACC 2 Foreign Device Interface Installation

The following bulletins, ETI and TIPs are included.

• ETI 189796 C20 techmode flowchart

• ETI 208283 Faint or blank copies / DADF pause 10 sec. before feeding

• ETI 208756 Paper jam 2 message

• ETI 208972 Paper jam 0 paper does not feed from tray

• ETI 214834 Noise and toner spill

• ETI 234008 Duplex jams and grinding noise

• ETI 240382 Tray 2 module will not feed paper

• ETI 243009 Side edge registration adjustment from DADF only

• ETI 260720 DADF lead edge offset

• ETI 284873 Copy output ‘indentation’ damage

• ETI 285328 Dead machine F1 blown

• ETI 322931 Noise that is hard to pin down / noisy ROS (LSU)

• ETI 332890 Bands or streaks across copies / Internal prints OK

Warnings, Cautions And Notes

A translated version of all warnings is in Translation of Warnings.

WARNING

A warning is used whenever an operating or main tenance procedure, practice, condi-

tion or statement, if not strictly observed, could result in personal injury.

CAUTION

A caution is used whenever an operation or maintenance procedure, practice, condition or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A note is used where it is essential to highlight a procedure, practice, condition or state-

ment.

The following are examples of the symbols that are used in this m anual for an electrostatic

damage caution and laser radiation warning.

ESD caution symbol

CAUTION

Certain components in this product are susceptible to damage from electr ostatic discharge.

Observe all ESD procedures to avoid component damage.

Laser radiation warning symbol.

WARNING

Follow the service procedure exactly as written. Use of controls or adjustments other

than those specified in this manual, may result in an exposure to invisible laser radia-

tion. During servicing, the invisible laser radiation can cause eye damage if looked at

directly.

April 2006

vi

WorkCentre M20, 4118 Family

Safety Precautions

Introduction

Safety Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment

damage.

1. Ensure that all built in protective devices are in place. Restore any missing protect ive

shields.

2. Make sure there are no cabinet openings through which people, particularly children,

might insert fingers or objects and contact dangerous voltages.

3. When re-installing chassis and assemblies, be sure to restore all protective devices,

including control knobs and compartment covers.