Toyota Forklift Error Codes List pdf Download

Toyota Forklift 8FD/FG series Error Codes Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 1 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 2 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 3 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 4 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 5 Download

Toyota Forklift fault (error) codes — List Of Diagnosis Codes 6 Download

MODEL APPLICATION:

7FBCU15, 7FBCU18, 7FBCU20, 7FBCU25, 7FBCU30, 7FBCU32 7FBCU35, 7FBCU45, 7FBCU55, 7FBCHU18, 7FBCHU25 7FBEU15, 7FBEU18, 7FBEU20, 7FBEHU18, 7FGU15, 7FGU18 7FGU20, 7FGU25, 7FGU30, 7FGU32, 7FDU15,

7FDU18, 7FDU20 7FDU25, 7FDU30, 7FDU32, 8FGU15, 8FGU18, 8FGU20, 8FGU25 8FGU30, 8FGU32, 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30 8FDU32, 7FGCU15, 7FGCU18, 7FGCU20, 7FGCSU20, 7FGCU25 7FGCU30, 7FGCU32,

8FGCU18, 8FGCU20, 8FGCSU20, 8FGCU25 8FGCU30, 8FGCU32, 7FGU35, 7FDU35, 7FGKU40, 7FDKU40 7FGU45, 7FDU45, 7FGAU50, 7FDAU50, 7FGU60, 7FDU60, 7FGU70 7FDU70, 7FGU80, 7FDU80, 7FGCU35, 7FGCU45, 7FGCU55

7FGCU60, 7FGCU70

GENERAL INFORMATION:

All three error codes are for the same condition. • A5 is for sit-down electric trucks (Class I) • A5-1 is for 8-Series internal combustion trucks (Class IV & V) • 1-1 is for 7-Series

internal combustion trucks (Class IV & V) with OPSS (Operator Presence Sensing System)

Further information concerning these codes can be found in the following manuals:

7FBCU15-55 ►OPSS Manual CU335 page 3-9 7FBEU15-20 ►OPSS Manual CU341 page 1-10 7FGCU15, 18, S20 ►OPSS Manual CU042 page 1-19 7FGU15-32, 7FDU15-32, 7FGCU20-32 ►OPSS Manual CU040 page 1-18

7FGU35-80, 7FDU35-80, 7FGCU35-70 ►OPSS Manual CU041 page 1-17 8FGCU15, 18, S20 ►Service manual 00700-X8880-71 page 19.1-82 8FGU15-32, 8FDU15-32, 8FGCU20-32 ►Service manual 00700-X8880-71 page

19-111

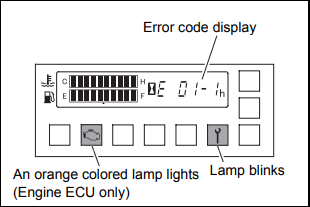

DIAGNOSIS DISPLAY METHOD

1. Diagnosis display method The diagnosis is displayed by means of an error code as shown in the illustration to the left, and by the lights turning on. When the ignition key switch is turned ON,

the lamp lights once to allow checking for the bulb, and then turns off again if the status is normal. With the ignition key switch ON, if an abnormality is detected when the vehicle is stopped,

travelling or performing meterials handling operations, an error code is displayed and the lamps turn on as a warning. When this happens, stop the vehicle immediately and check the error code.

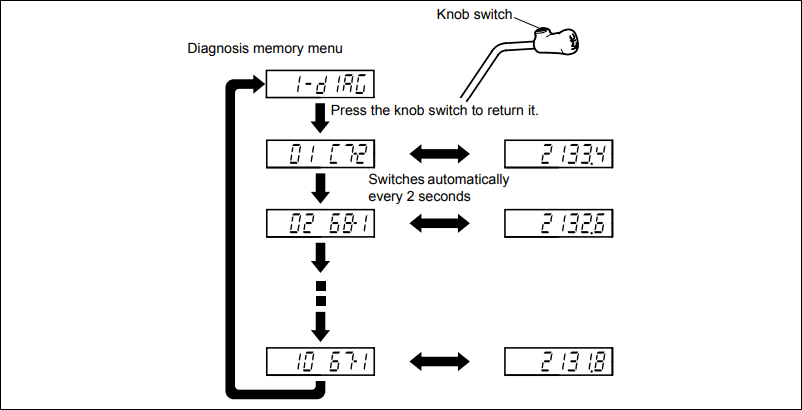

2. Diagnosis memory display method To display the diagnosis memory display, there are a method using the hour meter and tilt lever, a method using the optional display, and a method using a

plug-in analyzer. Here the display method using the hour meter and tilt lever is described. (1) From the main menu, display the diagnosis memory menu. For how to display the main menu, refer to

page 18-30. (2) A diagnosis No. and error code are displayed each time the knob switch is pressed and released. Each error code and the time at which it occurred are displayed alternately at 2

second intervals.

(3) Connect the matching connector and turn the ignition key switch OFF.

LIST OF DIAGNOSIS CODES

Translated from Indonesian!

Original text error codes Download

41-1 Matching connector abnormal Only the Connector display is faulty

Matching cable is broken

Controller is broken

51-1 Speed sensor abnormal Speed indicator keeps showing 0 km/h Connector is faulty

51-2 Rear wheel swing control Damaged connector cable

Steer knob is not in position Speed sensor is broken

Controller is broken

52-1 Yaw rate sensor abnormal Rear wheel swing control is limited. Broken connector

52-2 Connector cable is damaged

52-3 Yaw rate sensor is faulty

Controller is broken

54-1 Swing lock solenoid abnormal Rear wheel swing control is limited. Broken connector

Broken connector cable

Swing lock solenoid is broken

Controller is broken

61-1 Load sensor abnormal Rear wheel swing control is limited. Broken connector

61-2 Control mast function is partially restricted Connector cable is damaged

Drive control function is limited (MFD opt) Load sensor is faulty

Load indicator does not appear on the display (MFD) The controller is broken

Error mode Symptoms on forklift Possible causes

damaged

62-1 Tilt angle sensor abnormal Mast control function is partially restricted Connector is faulty

62-2 Connector cable is damaged

Broken tilt angle sensor

Controller is broken

63-1 Tilt lever switch abnormal Mast control function is partially restricted Connector is faulty

63-2 Forward tilt switch is broken

63-3 Backward tilt switch is broken

Broken cable

Faulty switch installation

Controller is broken

64-1 Lift lock solenoid abnormal Fork won’t come down Connector is broken

Broken connector cable

Broken lift lock solenoid

Controller is broken

65-1 Tilt control solenoid abnormal Forward tilt cannot operate, but Connector is damaged

backward tilt operable. Broken connector cable

Broken tilt control solenoid

Controller is broken

66-1 Abnormal matching measurement value The control mast function is partially restricted. The horizontal tilt angle value does not match.

Tilt forward angle value

it is not in accordance with.

Measuring value of load sensor

it is not in accordance with.

67-1 Lifting height switch abnormal Partial rearwheel swing control function Faulty connector

restricted. Broken connector cable

Mast control function is partially restricted Lifting height swt is broken

Drive control function is restricted Controller is faulty

Load indicator display changes IG fuse blown

68-1 Lift switch abnormal Fork won’t come down Connector is broken

68-2 Raising lift swt is broken

68-3 Lowering lift swt is broken

Broken connector cable

The swt elevator installation is broken

Controller is broken

Error mode Symptoms on the forklift Possible cause of failure

69-1 Backward tilt lock solenoid Backward tilt does not operate Connector is faulty

abnormal Connector cable is damaged

Backward tilt lock solenoid is faulty.

Controller is broken

71-1 Tire angle sensor abnormal Steer knob is not in position Connector is faulty

71-2 Connector cable is damaged

Broken sensor

tire angle sensor joint,

rear axle link syst. damaged

Controller is broken

72-1 Steering angle sensor abnormal Steer knob is not in position Connector is faulty

72-2 Connector cable is damaged

72-3 Sensor is faulty

72-4 Controller is faulty

73-1 Abnormal solenoid knob position Steer knob out of position Connector is faulty

Broken connector cable

Broken solenoid

Controller is broken

74-1 Measuring value of matching tire angle Steer knob is not in position Matching value

wheel alignment error no in accordance

A5-1 Seat switch abnormal Drive & hydraulic system can operate Connector is faulty

even if the operator is not sitting in the operating chair The connector cable is damaged

Broken switch

Controller is broken

A7-1 Abnormal brake switch Function of partially restricted drive control Connector is faulty

Broken brake switch

Broken connector cable

Controller is broken

AF-1

AF-2

AF-3

AF-4

AF-5

AF-6

AF-7

AF-8 CPU abnormal All control functions are unstable Controller is faulty

C7-1 Shift lever switch abnormal Cannot be positioned to neutral Connector is faulty

C7-2 Drive control function is partially restricted Forward switch is faulty

Reverse switch is broken

Broken cable

Faulty switch installation

Controller is broken

CA-1 Forward-reverse travel Torque Drive system and hydraulic system can Connector damaged

converter relay abnormal is operated even when operator is not seated Forward travel cable

the relay operator seat is broken

Forward travel relay

damaged

reverse travel cable

broken relay

Reverse travel relay

damaged

Controller is broken

EC-1 Unload solenoid abnormal Drive system and hydraulic system can Connector is faulty

operated even if the operator is not seated Connector cable is damaged

in operator seat Unload solenoid is broken

Controller is broken

F1-1 Combination meter abnormal Problem on the display Connector is damaged

F1-2 Hour meter cable is damaged

Hour meter is broken

Controller is broken

F4-1~8 CPU error CPU abnormal Multi-function board

broken display

H1-1 Lift lever potentiometer abnormal Lift cannot operate Connectro is faulty

H1-2 The potentiometer wire is damaged

H1-3 Potentiometer is broken

H1-4 Controller is broken

H1-5 Fuse blown

H2-1 Tilt lever potentiometer abnormal Tilt does not operate Connectro is faulty

H2-2 The potentiometer wire is damaged

H2-3 Potentiometer is broken

H2-4 Controller is broken

H2-5 Fuse blown

H3-1 Attachment 1 lever potentiometer Attachment 1 does not operate Connectro is faulty

H3-2 abnormal Potentiometer cable is damaged

H3-3 The potentiometer is faulty

H3-4 Controller is broken

H3-5 Fuse blown

H4-1 Attachment 2 lever potentiometer Attachment 2 does not operate Connectro is damaged

H4-2 abnormal Potentiometer cable is damaged

H4-3 The potentiometer is faulty

H4-4 Controller is broken

H4-5 Fuse blown

H5-1 Lift solenoid abnormal Elevator may not operate Faulty connector

H5-2 Elevator cable (PUSH) is damaged

Solenoid lift (PUSH) is broken

Elevator cable (PULL) is broken

Solenoid lift (PULL) is broken

Controller is broken

H6-1 Solenoid Tilt Abnormal Tilt may not operate Connector is faulty

H6-2 Faulty tilt (PUSH) cable

Solenoid tilt (PUSH) faulty

Broken tilt (PULL) cable

Solenoid tilt (PULL) faulty

Controller is broken

H7-1 Attachment 1 abnormal solenoid Attachment 1 may not work Connector is damaged

H7-2 operating Att 1 (PUSH) cable is faulty

Solenoid Att 1 (PUSH) is faulty

Att 1 (PULL) cable is damaged

Solenoid Att 1 (PULL) is faulty

Controller is broken

H8-1 Attachment 2 abnormal solenoid Attachment 2 may not work Connector is damaged

H8-2 operating Att 2 (PUSH) cable is faulty

Solenoid Att 2 (PUSH) is faulty

Att 2 (PULL) cable is damaged

Solenoid Att 2 (PULL) is faulty

Controller is broken

HA-1 3/4-way change relay abnormal Attachment transfer is not possible Connector is damaged

operating Relay cable 1 is damaged

Relay 1 is broken

Relay cable 2 is damaged

Relay 2 is broken

Controller is broken

Error mode Symptoms on forklift Possible causes

broken WARNING LIST

IF THE WRENCH LAMP IS ON AND WITH THESE SYMPTOMS BELOW ON

|

Indication |

Wrench lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

01-01 |

01-01 |

Blinking |

4Y-ECS |

Fuel feedback control error (gasoline) rich |

The engine speed is unstable and it may stop. |

|

01-02 |

01-02 |

Blinking |

4Y-ECS |

Fuel feedback control error (gasoline) lean |

|

|

01-03 |

01-03 |

Blinking |

4Y-ECS |

Fuel feedback control error (LPG/CNG) rich |

|

|

01-04 |

01-04 |

Blinking |

4Y-ECS |

Fuel feedback control error (LPG/CNG) lean |

|

|

01-05 |

01-05 |

Blinking |

4Y-ECS |

02 sensor open abnormality |

The engine speed is unstable and it may stop. |

|

01-06 |

01-06 |

Blinking |

4Y-ECS |

02 sensor heater open abnormality |

Display only |

|

02-01 |

02-01 |

Blinking |

4Y-ECS |

Intake temperature sensor open abnormality |

The engine may have a problem at low temperatures. |

|

02-02 |

02-02 |

Blinking |

4Y-ECS |

Intake temperature sensor short abnormality |

|

|

03-01 |

03-01 |

Blinking |

4Y-ECS |

Intake pipe pressure sensor open abnormality |

The engine may have a problem |

|

03-02 |

03-02 |

Blinking |

4Y-ECS |

Intake pipe pressure sensor short abnormality |

|

|

04-01 |

04-01 |

Blinking |

4Y-ECS |

Coolant temperature sensor open abnormality |

The engine may have a problem at low temperatures. |

|

04-02 |

04-02 |

Blinking |

4Y-ECS |

Coolant temperature sensor short abnormality |

|

|

05-01 |

05-01 |

Blinking |

4Y-ECS |

Throttle position sensor 1 open abnormality |

Limting speed of traveling and materials handling due to limited engine power output |

|

05-02 |

05-02 |

Blinking |

4Y-ECS |

Throttle position sensor 1 short abnormality |

|

|

05-03 |

05-03 |

Blinking |

4Y-ECS |

Throttle position sensor 2 open abnormality |

|

|

05-04 |

05-04 |

Blinking |

4Y-ECS |

Throttle position sensor 2 short abnormality |

|

|

05-05 |

05-05 |

Blinking |

4Y-ECS |

Throttle position sensor offset abnormality |

|

|

05-06 |

05-06 |

Blinking |

4Y-ECS |

Throttle position sensor out of range error |

|

|

06-01 |

06-01 |

Blinking |

4Y-ECS |

Throttle motor drive circuit open abnormality |

Limting speed of traveling and materials handling due to limited engine power output |

|

06-02 |

06-02 |

Blinking |

4Y-ECS |

Throttle motor drive circuit short abnormality |

|

|

06-03 |

06-03 |

Blinking |

4Y-ECS |

Throttle motor power supply circuit open abnormality |

|

|

06-04 |

06-04 |

Blinking |

4Y-ECS |

Throttle motor power supply circuit short abnormality |

|

|

06-05 |

06-05 |

Blinking |

4Y-ECS |

Throttle motor seizing abnormality |

|

|

06-06 |

06-06 |

Blinking |

4Y-ECS |

Electronic throttle system error |

|

|

07-01 |

07-01 |

Blinking |

4Y-ECS |

Air-fuel ratio motor open abnormality |

The engine speed is unstable and it may stop. |

|

08-01 |

08-01 |

Blinking |

4Y-ECS |

Low voltage (battery line open) error |

Display only |

|

09-01 |

09-01 |

Blinking |

4Y-ECS |

Ignition signal error |

The engine speed is unstable and it may stop. |

|

OA-1 |

OA-1 |

Blinking |

4Y-ECS |

Fuel specification determination signal error |

Display only |

|

OA-2 |

OA-2 |

Blinking |

4Y-ECS |

Fuel specification changeover switch error |

Display only |

|

OA-3 |

OA-3 |

Blinking |

4Y-ECS |

Fuel specification type unmatch |

Engine may stop |

|

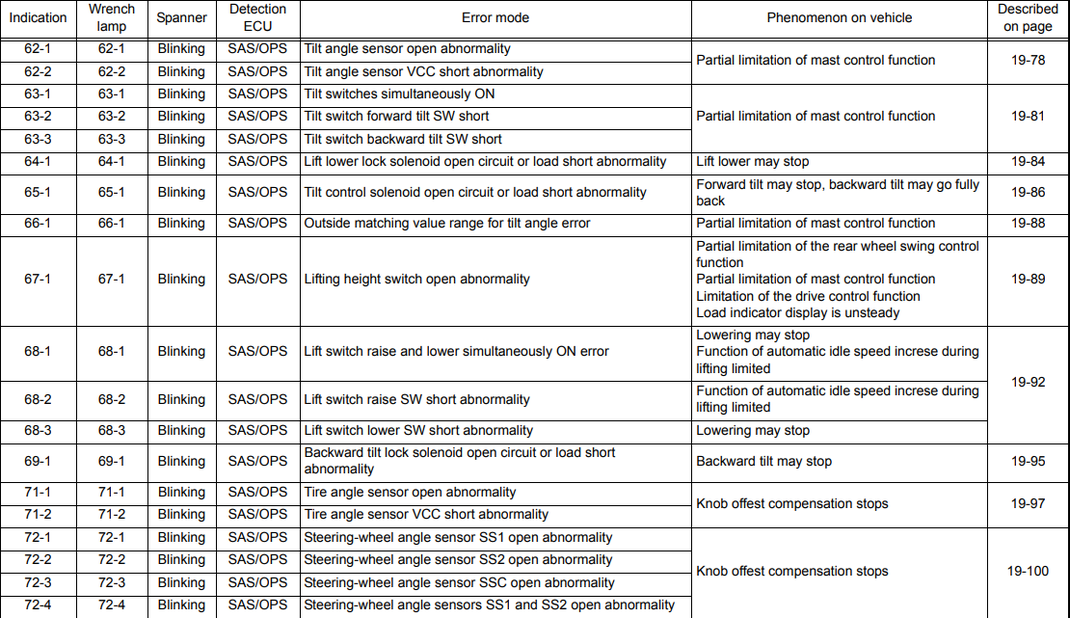

62-1 |

62-1 |

Blinking |

SAS/OPS |

Tilt angle sensor open abnormality |

Partial limitation of mast control function |

|

62-2 |

62-2 |

Blinking |

SAS/OPS |

Tilt angle sensor VCC short abnormality |

|

|

63-1 |

63-1 |

Blinking |

SAS/OPS |

Tilt switches simultaneously ON |

Partial limitation of mast control function |

|

63-2 |

63-2 |

Blinking |

SAS/OPS |

Tilt switch forward tilt SW short |

|

|

63-3 |

63-3 |

Blinking |

SAS/OPS |

Tilt switch backward tilt SW short |

|

|

64-1 |

64-1 |

Blinking |

SAS/OPS |

Lift lower lock solenoid open circuit or load short abnormality |

Lift lower may stop |

|

65-1 |

65-1 |

Blinking |

SAS/OPS |

Tilt control solenoid open circuit or load short abnormality |

Forward tilt may stop, backward tilt may go fully back |

|

66-1 |

66-1 |

Blinking |

SAS/OPS |

Outside matching value range for tilt angle error |

Partial limitation of mast control function |

|

67-1 |

67-1 |

Blinking |

SAS/OPS |

Lifting height switch open abnormality |

Partial limitation of the rear wheel swing control function |

|

68-1 |

68-1 |

Blinking |

SAS/OPS |

Lift switch raise and lower simultaneously ON error |

Lowering may stop |

|

68-2 |

68-2 |

Blinking |

SAS/OPS |

Lift switch raise SW short abnormality |

Function of automatic idle speed increse during lifting limited |

|

68-3 |

68-3 |

Blinking |

SAS/OPS |

Lift switch lower SW short abnormality |

Lowering may stop |

|

69-1 |

69-1 |

Blinking |

SAS/OPS |

Backward tilt lock solenoid open circuit or load short abnormality |

Backward tilt may stop |

|

71-1 |

71-1 |

Blinking |

SAS/OPS |

Tire angle sensor open abnormality |

Knob offest compensation stops |

|

71-2 |

71-2 |

Blinking |

SAS/OPS |

Tire angle sensor VCC short abnormality |

|

|

72-1 |

72-1 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SS1 open abnormality |

Knob offest compensation stops |

|

72-2 |

72-2 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SS2 open abnormality |

|

|

72-3 |

72-3 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SSC open abnormality |

|

|

72-4 |

72-4 |

Blinking |

SAS/OPS |

Steering-wheel angle sensors S51 and SS2 open abnormality |

|

Indication |

Wrench lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

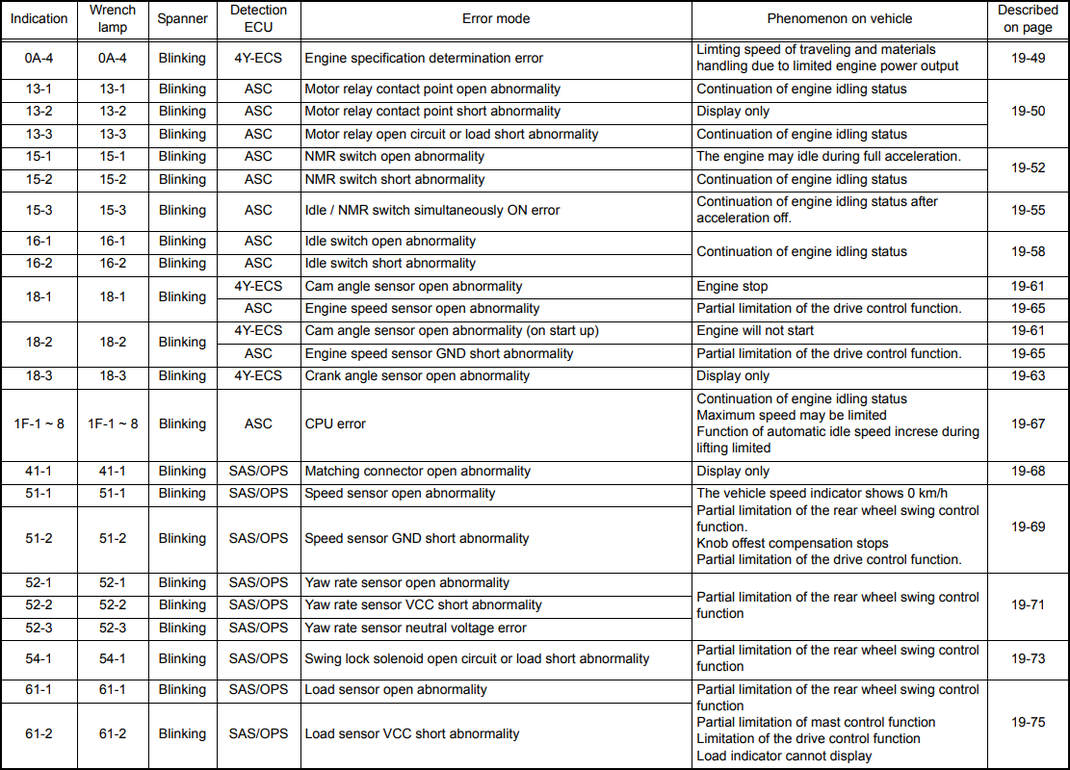

OA-4 |

OA-4 |

Blinking |

4Y-ECS |

Engine specification determination error |

Limting speed of traveling and materials handling due to limited engine power output |

|

13-1 |

13-1 |

Blinking |

ASC |

Motor relay contact point open abnormality |

Continuation of engine idling status |

|

13-2 |

13-2 |

Blinking |

ASC |

Motor relay contact point short abnormality |

Display only |

|

13-3 |

13-3 |

Blinking |

ASC |

Motor relay open circuit or load short abnormality |

Continuation of engine idling status |

|

15-1 |

15-1 |

Blinking |

ASC |

NMR switch open abnormality |

The engine may idle during full acceleration. |

|

15-2 |

15-2 |

Blinking |

ASC |

NMR switch short abnormality |

Continuation of engine idling status |

|

15-3 |

15-3 |

Blinking |

ASC |

Idle / NMR switch simultaneously ON error |

Continuation of engine idling status after acceleration off. |

|

16-1 |

16-1 |

Blinking |

ASC |

Idle switch open abnormality |

Continuation of engine idling status |

|

16-2 |

16-2 |

Blinking |

ASC |

Idle switch short abnormality |

|

|

18-1 |

18-1 |

Blinking |

4Y-ECS |

Cam angle sensor open abnormality |

Engine stop |

|

ASC |

Engine speed sensor open abnormality |

Partial limitation of the drive control function. |

|||

|

18-2 |

18-2 |

Blinking |

4Y-ECS |

Cam angle sensor open abnormality (on start up) |

Engine will not start |

|

ASC |

Engine speed sensor GND short abnormality |

Partial limitation of the drive control function. |

|||

|

18-3 |

18-3 |

Blinking |

4Y-ECS |

Crank angle sensor open abnormality |

Display only |

|

1 F-1 — 8 |

1 F-1 — 8 |

Blinking |

ASC |

CPU error |

Continuation of engine idling status |

|

41-1 |

41-1 |

Blinking |

SAS/OPS |

Matching connector open abnormality |

Display only |

|

51-1 |

51-1 |

Blinking |

SAS/OPS |

Speed sensor open abnormality |

The vehicle speed indicator shows 0 km/h Partial limitation of the rear wheel swing control function. |

|

51-2 |

51-2 |

Blinking |

SAS/OPS |

Speed sensor GND short abnormality |

|

|

52-1 |

52-1 |

Blinking |

SAS/OPS |

Yaw rate sensor open abnormality |

Partial limitation of the rear wheel swing control function |

|

52-2 |

52-2 |

Blinking |

SAS/OPS |

Yaw rate sensor VCC short abnormality |

|

|

52-3 |

52-3 |

Blinking |

SAS/OPS |

Yaw rate sensor neutral voltage error |

|

|

54-1 |

54-1 |

Blinking |

SAS/OPS |

Swing lock solenoid open circuit or load short abnormality |

Partial limitation of the rear wheel swing control function |

|

61-1 |

61-1 |

Blinking |

SAS/OPS |

Load sensor open abnormality |

Partial limitation of the rear wheel swing control function |

|

61-2 |

61-2 |

Blinking |

SAS/OPS |

Load sensor VCC short abnormality |

|

Indication |

lamp lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

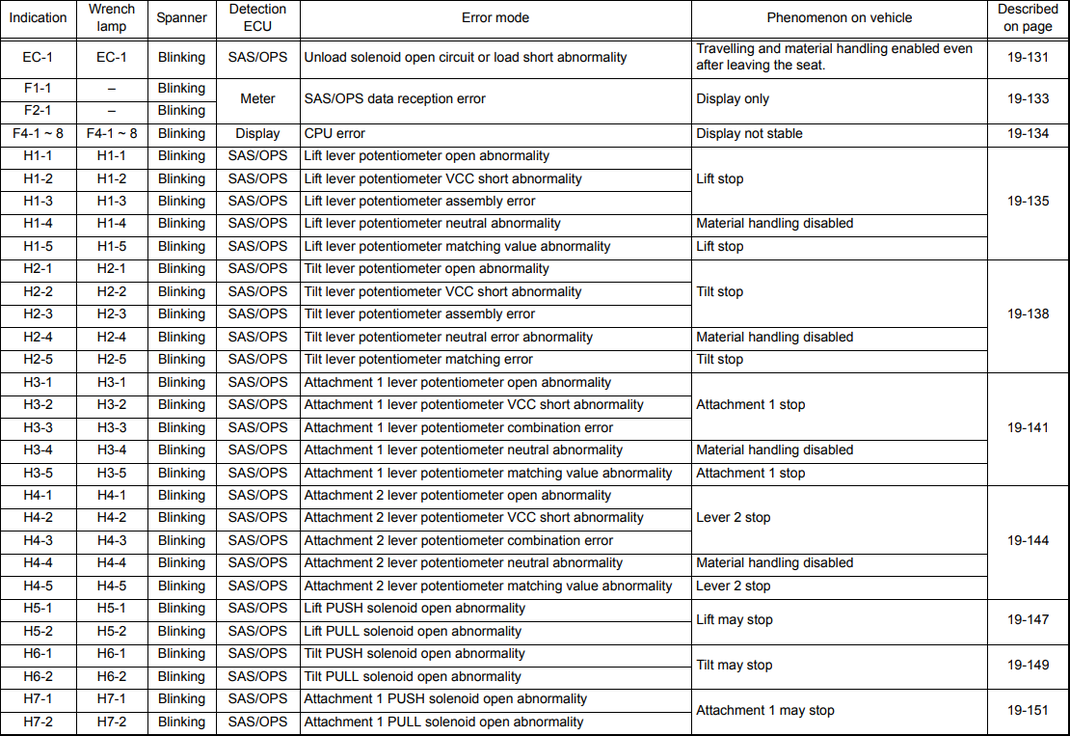

EC-1 |

EC-1 |

Blinking |

SAS/OPS |

Unload solenoid open circuit or load short abnormality |

Travelling and material handling enabled even after leaving the seat. |

|

F1-1 |

— |

Blinking |

Meter |

SAS/OPS data reception error |

Display only |

|

F2-1 |

— |

Blinking |

|||

|

F4-1 — 8 |

F4-1 — 8 |

Blinking |

Display |

CPU error |

Display not stable |

|

H1-1 |

H1-1 |

Blinking |

SAS/OPS |

Lift lever potentiometer open abnormality |

Lift stop |

|

H1-2 |

H1-2 |

Blinking |

SAS/OPS |

Lift lever potentiometer VCC short abnormality |

|

|

H1-3 |

H1-3 |

Blinking |

SAS/OPS |

Lift lever potentiometer assembly error |

|

|

H1-4 |

H1-4 |

Blinking |

SAS/OPS |

Lift lever potentiometer neutral abnormality |

Material handling disabled |

|

H1-5 |

H1-5 |

Blinking |

SAS/OPS |

Lift lever potentiometer matching value abnormality |

Lift stop |

|

H2-1 |

H2-1 |

Blinking |

SAS/OPS |

Tilt lever potentiometer open abnormality |

Tilt stop |

|

H2-2 |

H2-2 |

Blinking |

SAS/OPS |

Tilt lever potentiometer VCC short abnormality |

|

|

H2-3 |

H2-3 |

Blinking |

SAS/OPS |

Tilt lever potentiometer assembly error |

|

|

H2-4 |

H2-4 |

Blinking |

SAS/OPS |

Tilt lever potentiometer neutral error abnormality |

Material handling disabled |

|

H2-5 |

H2-5 |

Blinking |

SAS/OPS |

Tilt lever potentiometer matching error |

Tilt stop |

|

H3-1 |

H3-1 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer open abnormality |

Attachment 1 stop |

|

H3-2 |

I-13-2 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer VCC short abnormality |

|

|

H3-3 |

H3-3 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer combination error |

|

|

H3-4 |

H3-4 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer neutral abnormality |

Material handling disabled |

|

H3-5 |

H3-5 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer matching value abnormality |

Attachment 1 stop |

|

H4-1 |

H4-1 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer open abnormality |

Lever 2 stop |

|

H4-2 |

H4-2 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer VCC short abnormality |

|

|

H4-3 |

H4-3 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer combination error |

|

|

H4-4 |

H4-4 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer neutral abnormality |

Material handling disabled |

|

H4-5 |

H4-5 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer matching value abnormality |

Lever 2 stop |

|

H5-1 |

H5-1 |

Blinking |

SAS/OPS |

Lift PUSH solenoid open abnormality |

Lift may stop |

|

H5-2 |

H5-2 |

Blinking |

SAS/OPS |

Lift PULL solenoid open abnormality |

|

|

H6-1 |

H6-1 |

Blinking |

SAS/OPS |

Tilt PUSH solenoid open abnormality |

Tilt may stop |

|

H6-2 |

H6-2 |

Blinking |

SAS/OPS |

Tilt PULL solenoid open abnormality |

|

|

H7-1 |

H7-1 |

Blinking |

SAS/OPS |

Attachment 1 PUSH solenoid open abnormality |

Attachment 1 may stop |

|

H7-2 |

H7-2 |

Blinking |

SAS/OPS |

Attachment 1 PULL solenoid open abnormality |

|

Indication |

Wrench lamp |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

|

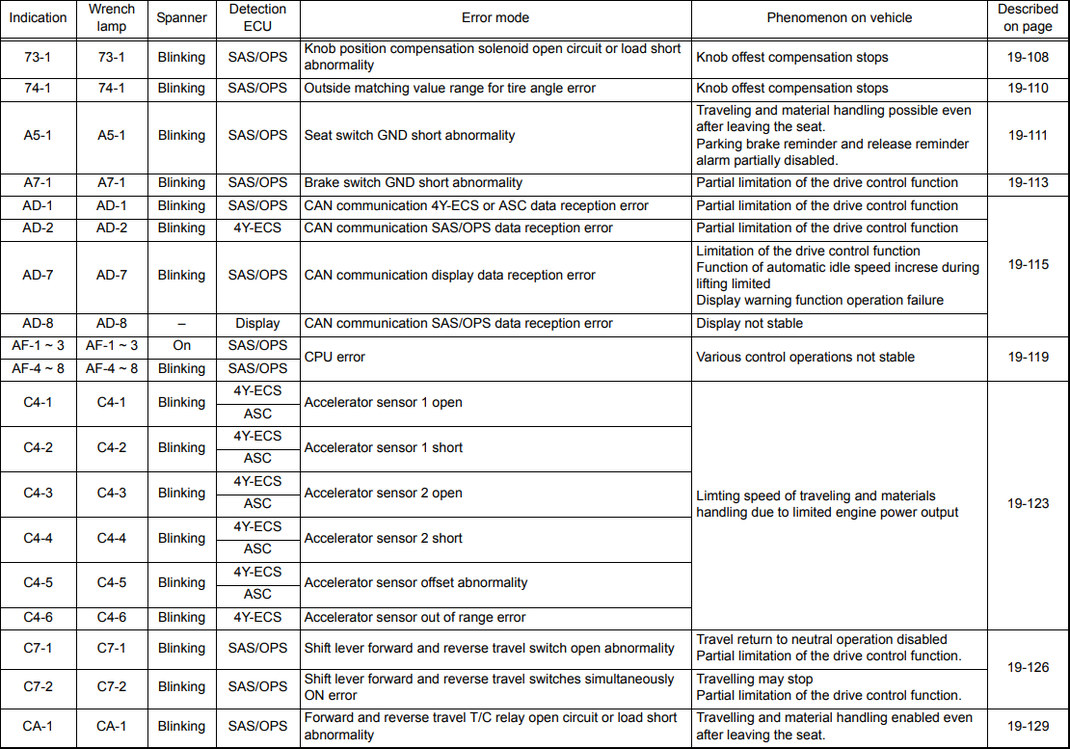

73-1 |

73-1 |

Blinking |

SAS/OPS |

Knob position compensation solenoid open circuit or load short abnormality |

Knob offest compensation stops |

|

74-1 |

74-1 |

Blinking |

SAS/OPS |

Outside matching value range for tire angle error |

Knob offest compensation stops |

|

A5-1 |

A5-1 |

Blinking |

SAS/OPS |

Seat switch GND short abnormality |

Traveling and material handling possible even after leaving the seat. |

|

A7-1 |

A7-1 |

Blinking |

SAS/OPS |

Brake switch GND short abnormality |

Partial limitation of the drive control function |

|

AD-1 |

AD-1 |

Blinking |

SAS/OPS |

CAN communication 4Y-ECS or ASC data reception error |

Partial limitation of the drive control function |

|

AD-2 |

AD-2 |

Blinking |

4Y-ECS |

CAN communication SAS/OPS data reception error |

Partial limitation of the drive control function |

|

AD-7 |

AD-7 |

Blinking |

SAS/OPS |

CAN communication display data reception error |

Limitation of the drive control function |

|

AD-8 |

AD-8 |

Display |

CAN communication SAS/OPS data reception error |

Display not stable |

|

|

AF-1 — 3 |

AF-1 — 3 |

On |

SAS/OPS |

CPU error |

Various control operations not stable |

|

AF-4 — 8 |

AF-4 — 8 |

Blinking |

SAS/OPS |

||

|

C4-1 |

C4-1 |

Blinking |

4Y-ECS |

Accelerator sensor 1 open |

Limting speed of traveling and materials handling due to limited engine power output |

|

ASC |

|||||

|

C4-2 |

C4-2 |

Blinking |

4Y-ECS |

Accelerator sensor 1 short |

|

|

ASC |

|||||

|

C4-3 |

C4-3 |

Blinking |

4Y-ECS |

Accelerator sensor 2 open |

|

|

ASC |

|||||

|

C4-4 |

C4-4 |

Blinking |

4Y-ECS |

Accelerator sensor 2 short |

|

|

ASC |

|||||

|

C4-5 |

C4-5 |

Blinking |

4Y-ECS |

Accelerator sensor offset abnormality |

|

|

ASC |

|||||

|

C4-6 |

C4-6 |

Blinking |

4Y-ECS |

Accelerator sensor out of range error |

|

|

C7-1 |

C7-1 |

Blinking |

SAS/OPS |

Shift lever forward and reverse travel switch open abnormality |

Travel return to neutral operation disabled Partial limitation of the drive control function. |

|

C7-2 |

C7-2 |

Blinking |

SAS/OPS |

Shift lever forward and reverse travel switches simultaneously ON error |

Travelling may stop |

|

CA-1 |

CA-1 |

Blinking |

SAS/OPS |

Forward and reverse travel T/C relay open circuit or load short abnormality |

Travelling and material handling enabled even after leaving the seat. |

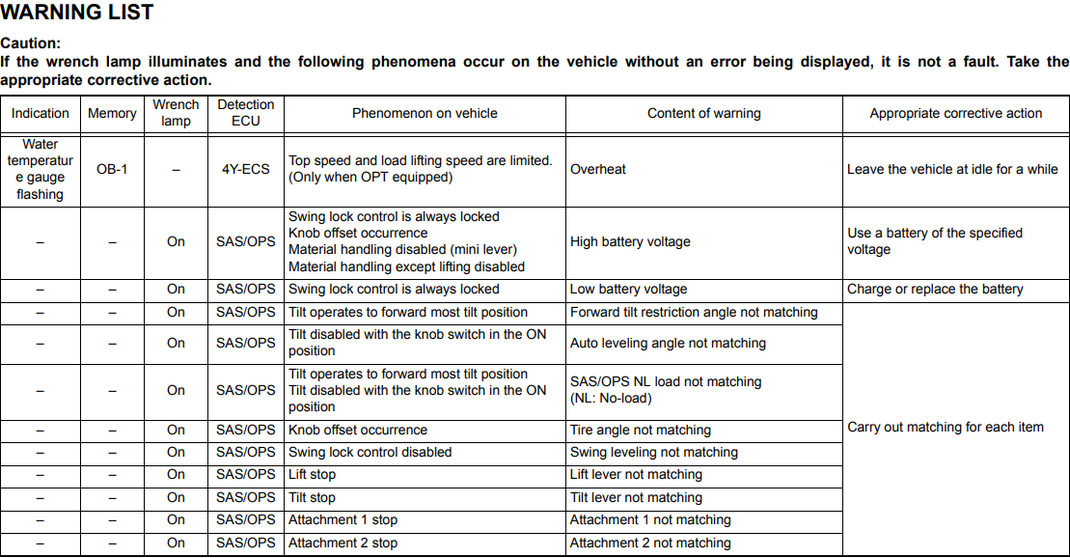

Caution:

If the wrench lamp illuminates and the following phenomena occur on the vehicle without an error being displayed, it is not a fault. Take the appropriate corrective action.

|

Indication |

Memory |

Wrench lamp |

Detection ECU |

Phenomenon on vehicle |

Content of warning |

Appropriate corrective action |

|

Water temperatur e gauge flashing |

OB-1 |

— |

4Y-ECS |

Top speed and load lifting speed are limited. (Only when OPT equipped) |

Overheat |

Leave the vehicle at idle for a while |

|

— |

— |

On |

SAS/OPS |

Swing lock control is always locked Knob offset occurrence |

High battery voltage |

Use a battery of the specified voltage |

|

— |

— |

On |

SAS/OPS |

Swing lock control is always locked |

Low battery voltage |

Charge or replace the battery |

|

— |

— |

On |

SAS/OPS |

Tilt operates to forward most tilt position |

Forward tilt restriction angle not matching |

Carry out matching for each item |

|

— |

— |

On |

SAS/OPS |

Tilt disabled with the knob switch in the ON position |

Auto leveling angle not matching |

|

|

— |

— |

On |

SAS/OPS |

Tilt operates to forward most tilt position Tilt disabled with the knob switch in the ON position |

SAS/OPS NIL load not matching (NL: No-load) |

|

|

— |

— |

On |

SAS/OPS |

Knob offset occurrence |

Tire angle not matching |

|

|

— |

— |

On |

SAS/OPS |

Swing lock control disabled |

Swing leveling not matching |

|

|

— |

— |

On |

SAS/OPS |

Lift stop |

Lift lever not matching |

|

|

— |

— |

On |

SAS/OPS |

Tilt stop |

Tilt lever not matching |

|

|

— |

— |

On |

SAS/OPS |

Attachment 1 stop |

Attachment 1 not matching |

|

|

— |

— |

On |

SAS/OPS |

Attachment 2 stop |

Attachment 2 not matching |

DIAGNOSIS DISPLAY METHOD

1. Diagnosis display method

The diagnosis is displayed by means of an error code as

shown in the illustration to the left, and by the lights turning on.

When the ignition key switch is turned ON, the lamp lights

once to allow checking for the bulb, and then turns off again if

the status is normal.

With the ignition key switch ON, if an abnormality is detected

when the vehicle is stopped, travelling or performing meterials

handling operations, an error code is displayed and the lamps

turn on as a warning.

When this happens, stop the vehicle immediately and check

the error code.

2. Diagnosis memory display method

To display the diagnosis memory display, there are a method using the hour meter and tilt lever, a method using

the optional display, and a method using a plug-in analyzer.

Here the display method using the hour meter and tilt lever is described.

(1) From the main menu, display the diagnosis memory menu. For how to display the main menu, refer to page

18-30.

(2) A diagnosis No. and error code are displayed each time the knob switch is pressed and released. Each

error code and the time at which it occurred are displayed alternately at 2 second intervals.

Note:

• The maximum number of error codes that can be stored is 10. The smaller the diagnosis No., the more

recent the error is.

• The stored time of an error code appearing just when the ignition key switch is turned ON may be stored

as 0.0.

(3) Connect the matching connector and turn the ignition key switch OFF.

|

Indication |

Wrench |

Spanner |

Detection ECU |

Error mode |

Phenomenon on vehicle |

Described on page |

|

01-1 |

01-1 |

Blinking |

4Y-ECS |

Fuel feedback control error |

The engine speed is unstable |

19-14 |

|

01-1 |

01-1 |

Blinking |

4Y-ECS |

Fuel feedback control error (gasoline) rich |

The engine speed is unstable and it may stop. |

19-14 |

|

01-2 |

01-2 |

Blinking |

4Y-ECS |

Fuel feedback control error (gasoline) lean |

||

|

01-3 |

01-3 |

Blinking |

4Y-ECS |

Fuel feedback control error (LPG/CNG) rich |

19-18 |

|

|

01-4 |

01-4 |

Blinking |

4Y-ECS |

Fuel feedback control error (LPG/CNG) lean |

||

|

01-5 |

01-5 |

Blinking |

4Y-ECS |

O2 sensor open abnormality |

The engine speed is unstable and it may stop. |

19-23 |

|

01-6 |

01-6 |

Blinking |

4Y-ECS |

O2 sensor heater open abnormality |

Display only |

19-25 |

|

02-1 |

02-1 |

Blinking |

4Y-ECS |

Intake temperature sensor open abnormality |

The engine may have a problem at low |

19-27 |

|

02-2 |

02-2 |

Blinking |

4Y-ECS |

Intake temperature sensor short abnormality |

||

|

03-1 |

03-1 |

Blinking |

4Y-ECS |

Intake pipe pressure sensor open abnormality |

The engine may have a problem |

19-29 |

|

03-2 |

03-2 |

Blinking |

4Y-ECS |

Intake pipe pressure sensor short abnormality |

||

|

04-1 |

04-1 |

Blinking |

4Y-ECS |

Coolant temperature sensor open abnormality |

The engine may have a problem at low |

19-31 |

|

04-2 |

04-2 |

Blinking |

4Y-ECS |

Coolant temperature sensor short abnormality |

||

|

05-1 |

05-1 |

Blinking |

4Y-ECS |

Throttle position sensor 1 open abnormality |

Limting speed of traveling and materials |

19-33 |

|

05-2 |

05-2 |

Blinking |

4Y-ECS |

Throttle position sensor 1 short abnormality |

||

|

05-3 |

05-3 |

Blinking |

4Y-ECS |

Throttle position sensor 2 open abnormality |

||

|

05-4 |

05-4 |

Blinking |

4Y-ECS |

Throttle position sensor 2 short abnormality |

||

|

05-5 |

05-5 |

Blinking |

4Y-ECS |

Throttle position sensor offset abnormality |

|

05-6 |

05-6 |

Blinking |

4Y-ECS |

Throttle position sensor out of range error |

||

|

06-1 |

06-1 |

Blinking |

4Y-ECS |

Throttle motor drive circuit open abnormality |

Limting speed of traveling and materials |

19-35 |

|

06-2 |

06-2 |

Blinking |

4Y-ECS |

Throttle motor drive circuit short abnormality |

||

|

06-3 |

06-3 |

Blinking |

4Y-ECS |

Throttle motor power supply circuit open abnormality |

19-37 |

|

|

06-4 |

06-4 |

Blinking |

4Y-ECS |

Throttle motor power supply circuit short abnormality |

||

|

06-5 |

06-5 |

Blinking |

4Y-ECS |

Throttle motor seizing abnormality |

19-38 |

|

|

06-6 |

06-6 |

Blinking |

4Y-ECS |

Electronic throttle system error |

19-40 |

|

|

07-1 |

07-1 |

Blinking |

4Y-ECS |

Air-fuel ratio motor open abnormality |

The engine speed is unstable and it may stop. |

19-41 |

|

08-1 |

08-1 |

Blinking |

4Y-ECS |

Low voltage (battery line open) error |

Display only |

19-43 |

|

09-1 |

09-1 |

Blinking |

4Y-ECS |

Ignition signal error |

The engine speed is unstable and it may stop. |

19-44 |

|

0A-1 |

0A-1 |

Blinking |

4Y-ECS |

Fuel specification determination signal error |

Display only |

19-47 |

|

0A-2 |

0A-2 |

Blinking |

4Y-ECS |

Fuel specification changeover switch error |

Display only |

|

|

0A-3 |

0A-3 |

Blinking |

4Y-ECS |

Fuel specification type unmatch |

Engine may sto |

|

0A-4 |

0A-4 |

Blinking |

4Y-ECS |

Engine specification |

Limting speed of traveling and materials |

19-49 |

|

13-1 |

13-1 |

Blinking |

ASC |

Motor relay contact point open abnormality |

Continuation of engine idling status |

19-50 |

|

13-2 |

13-2 |

Blinking |

ASC |

Motor relay contact point short abnormality |

Display only |

|

|

13-3 |

13-3 |

Blinking |

ASC |

Motor relay open circuit or load short abnormality |

Continuation of engine idling status |

|

|

15-1 |

15-1 |

Blinking |

ASC |

NMR switch open |

The engine may idle during full acceleration. |

19-52 |

|

15-2 |

15-2 |

Blinking |

ASC |

NMR switch short |

Continuation of engine idling status |

|

|

15-3 |

15-3 |

Blinking |

ASC |

Idle / NMR switch simultaneously ON error |

Continuation of engine idling status after |

19-55 |

|

16-1 |

16-1 |

Blinking |

ASC |

Idle switch open |

Continuation of engine idling status |

19-58 |

|

16-2 |

16-2 |

Blinking |

ASC |

Idle switch short |

||

|

18-1 |

18-1 |

Blinking |

4Y-ECS |

Cam angle sensor open abnormality |

Engine stop |

19-61 |

|

ASC |

Engine speed sensor open abnormality |

Partial limitation of the drive control function. |

19-65 |

|||

|

18-2 |

18-2 |

Blinking |

4Y-ECS |

Cam angle sensor open abnormality (on start up) |

Engine will not start |

19-61 |

|

ASC |

Engine speed sensor GND short abnormality |

Partial limitation of the drive control function. |

19-65 |

|||

|

18-3 |

18-3 |

Blinking |

4Y-ECS |

Crank angle sensor open abnormality |

Display only |

19-63 |

|

1F-1 ~ 8 |

1F-1 ~ 8 |

Blinking |

ASC |

CPU error |

Continuation of engine idling status |

19-67 |

|

41-1 |

41-1 |

Blinking |

SAS/OPS |

Matching connector open |

Display only |

19-68 |

|

51-1 |

51-1 |

Blinking |

SAS/OPS |

Speed sensor open |

The vehicle speed indicator shows 0 km/h |

19-69 |

|

51-2 |

51-2 |

Blinking |

SAS/OPS |

Speed sensor GND short abnormality |

||

|

52-1 |

52-1 |

Blinking |

SAS/OPS |

Yaw rate sensor open abnormality |

Partial limitation of the rear wheel swing control |

19-71 |

|

52-2 |

52-2 |

Blinking |

SAS/OPS |

Yaw rate sensor VCC short abnormality |

||

|

52-3 |

52-3 |

Blinking |

SAS/OPS |

Yaw rate sensor neutral voltage error |

||

|

54-1 |

54-1 |

Blinking |

SAS/OPS |

Swing lock solenoid open circuit or load short abnormality |

Partial limitation of the rear wheel swing control |

19-73 |

|

61-1 |

61-1 |

Blinking |

SAS/OPS |

Load sensor open |

Partial limitation of the rear wheel swing control |

19-75 |

|

61-2 |

61-2 |

Blinking |

SAS/OPS |

Load sensor VCC short |

|

62-1 |

62-1 |

Blinking |

SAS/OPS |

Tilt angle sensor open abnormality |

Partial limitation of mast control function |

19-78 |

|

62-2 |

62-2 |

Blinking |

SAS/OPS |

Tilt angle sensor VCC short abnormality |

||

|

63-1 |

63-1 |

Blinking |

SAS/OPS |

Tilt switches simultaneously |

Partial limitation of mast control function |

19-81 |

|

63-2 |

63-2 |

Blinking |

SAS/OPS |

Tilt switch forward tilt SW short |

||

|

63-3 |

63-3 |

Blinking |

SAS/OPS |

Tilt switch backward tilt SW short |

||

|

64-1 |

64-1 |

Blinking |

SAS/OPS |

Lift lower lock solenoid open circuit or load short abnormality |

Lift lower may stop |

19-84 |

|

65-1 |

65-1 |

Blinking |

SAS/OPS |

Tilt control solenoid open circuit or load short abnormality |

Forward tilt may stop, backward tilt may go fully |

19-86 |

|

66-1 |

66-1 |

Blinking |

SAS/OPS |

Outside matching value range for tilt angle error |

Partial limitation of mast control function |

19-88 |

|

67-1 |

67-1 |

Blinking |

SAS/OPS |

Lifting height switch open abnormality |

Partial limitation of the rear wheel swing control |

19-89 |

|

68-1 |

68-1 |

Blinking |

SAS/OPS |

Lift switch raise and lower simultaneously ON error |

Lowering may stop |

19-92 |

|

68-2 |

68-2 |

Blinking |

SAS/OPS |

Lift switch raise SW short abnormality |

Function of automatic idle speed increse during |

|

|

68-3 |

68-3 |

Blinking |

SAS/OPS |

Lift switch lower SW short abnormality |

Lowering may stop |

|

|

69-1 |

69-1 |

Blinking |

SAS/OPS |

Backward tilt lock solenoid open circuit or load short |

Backward tilt may stop |

19-95 |

|

71-1 |

71-1 |

Blinking |

SAS/OPS |

Tire angle sensor open abnormality |

Knob offest compensation |

19-97 |

|

71-2 |

71-2 |

Blinking |

SAS/OPS |

Tire angle sensor VCC short abnormality |

||

|

72-1 |

72-1 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SS1 open abnormality |

Knob offest compensation |

19-100 |

|

72-2 |

72-2 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SS2 open abnormality |

||

|

72-3 |

72-3 |

Blinking |

SAS/OPS |

Steering-wheel angle sensor SSC open abnormality |

||

|

72-4 |

72-4 |

Blinking |

SAS/OPS |

Steering-wheel angle sensors SS1 and SS2 open abnormali |

|

73-1 |

73-1 |

Blinking |

SAS/OPS |

Knob position compensation solenoid open circuit or load short |

Knob offest compensation |

19-108 |

|

74-1 |

74-1 |

Blinking |

SAS/OPS |

Outside matching value range for tire angle error |

Knob offest compensation |

19-110 |

|

A5-1 |

A5-1 |

Blinking |

SAS/OPS |

Seat switch GND short abnormality |

Traveling and material handling possible even |

19-111 |

|

A7-1 |

A7-1 |

Blinking |

SAS/OPS |

Brake switch GND short abnormality |

Partial limitation of the drive control function |

19-113 |

|

AD-1 |

AD-1 |

Blinking |

SAS/OPS |

CAN communication 4Y-ECS or ASC data reception error |

Partial limitation of the drive control function |

19-115 |

|

AD-2 |

AD-2 |

Blinking |

4Y-ECS |

CAN communication SAS/OPS data reception error |

Partial limitation of the drive control function |

|

|

AD-7 |

AD-7 |

Blinking |

SAS/OPS |

CAN communication display data reception error |

Limitation of the drive control function |

|

|

AD-8 |

AD-8 |

– |

Display |

CAN communication SAS/OPS data reception error |

Display not stable |

|

|

AF-1 3 |

AF-1 ~ 3 |

On |

SAS/OPS |

CPU error |

Various control operations not stable |

19-119 |

|

AF-4 8 |

AF-4 ~ 8 |

Blinking |

SAS/OPS |

|||

|

C4-1 |

C4-1 |

Blinking |

4Y-ECS |

Accelerator sensor 1 |

Limting speed of traveling and materials |

19-123 |

|

ASC |

||||||

|

C4-2 |

C4-2 |

Blinking |

4Y-ECS |

Accelerator sensor 1 |

||

|

ASC |

||||||

|

C4-3 |

C4-3 |

Blinking |

4Y-ECS |

Accelerator sensor 2 |

||

|

ASC |

||||||

|

C4-4 |

C4-4 |

Blinking |

4Y-ECS |

Accelerator sensor 2 |

||

|

ASC |

||||||

|

C4-5 |

C4-5 |

Blinking |

4Y-ECS |

Accelerator sensor offset |

||

|

ASC |

||||||

|

C4-6 |

C4-6 |

Blinking |

4Y-ECS |

Accelerator sensor out of range error |

||

|

C7-1 |

C7-1 |

Blinking |

SAS/OPS |

Shift lever forward and reverse travel switch open abnormality |

Travel return to neutral operation disabled |

19-126 |

|

C7-2 |

C7-2 |

Blinking |

SAS/OPS |

Shift lever forward and reverse travel switches simultaneously |

Travelling may stop |

|

|

CA-1 |

CA-1 |

Blinking |

SAS/OPS |

Forward and reverse travel T/C relay open circuit or load short |

Travelling and material handling enabled even |

19-129 |

|

Indic ation |

Wrench |

Spanner |

Detection ECU |

Error mode |

Phenomen |

|

EC-1 |

EC-1 |

Blinking |

SAS/OPS |

Unload solenoid open circuit or load short abnormality |

Travelling and material handling enabled even |

19-131 |

|

F1-1 |

– |

Blinking |

Meter |

SAS/OPS data reception error |

Display only |

19-133 |

|

F2-1 |

– |

Blinking |

||||

|

F4-1 ~ 8 |

F4-1 ~ 8 |

Blinking |

Display |

CPU error |

Display not stable |

19-134 |

|

H1-1 |

H1-1 |

Blinking |

SAS/OPS |

Lift lever potentiometer open abnormality |

Lift stop |

19-135 |

|

H1-2 |

H1-2 |

Blinking |

SAS/OPS |

Lift lever potentiometer VCC short abnormality |

||

|

H1-3 |

H1-3 |

Blinking |

SAS/OPS |

Lift lever potentiometer assembly error |

||

|

H1-4 |

H1-4 |

Blinking |

SAS/OPS |

Lift lever potentiometer neutral abnormality |

Material handling |

|

|

H1-5 |

H1-5 |

Blinking |

SAS/OPS |

Lift lever potentiometer matching value abnormality |

Lift stop |

|

|

H2-1 |

H2-1 |

Blinking |

SAS/OPS |

Tilt lever potentiometer open abnormality |

Tilt stop |

19-138 |

|

H2-2 |

H2-2 |

Blinking |

SAS/OPS |

Tilt lever potentiometer VCC short abnormality |

||

|

H2-3 |

H2-3 |

Blinking |

SAS/OPS |

Tilt lever potentiometer assembly error |

||

|

H2-4 |

H2-4 |

Blinking |

SAS/OPS |

Tilt lever potentiometer neutral error abnormality |

Material handling |

|

|

H2-5 |

H2-5 |

Blinking |

SAS/OPS |

Tilt lever potentiometer matching error |

Tilt stop |

|

|

H3-1 |

H3-1 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer open abnormality |

Attachment 1 stop |

19-141 |

|

H3-2 |

H3-2 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer VCC short abnormality |

||

|

H3-3 |

H3-3 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer combination error |

||

|

H3-4 |

H3-4 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer neutral abnormality |

Material handling |

|

|

H3-5 |

H3-5 |

Blinking |

SAS/OPS |

Attachment 1 lever potentiometer matching value abnormality |

Attachment 1 stop |

|

|

H4-1 |

H4-1 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer open abnormality |

Lever 2 stop |

19-144 |

|

H4-2 |

H4-2 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer VCC short abnormality |

||

|

H4-3 |

H4-3 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer combination error |

||

|

H4-4 |

H4-4 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer neutral abnormality |

Material handling |

|

|

H4-5 |

H4-5 |

Blinking |

SAS/OPS |

Attachment 2 lever potentiometer matching value abnormality |

Lever 2 stop |

|

|

H5-1 |

H5-1 |

Blinking |

SAS/OPS |

Lift PUSH solenoid open abnormality |

Lift may stop |

19-147 |

|

H5-2 |

H5-2 |

Blinking |

SAS/OPS |

Lift PULL solenoid open abnormality |

||

|

H6-1 |

H6-1 |

Blinking |

SAS/OPS |

Tilt PUSH solenoid open abnormality |

Tilt may stop |

19-149 |

|

H6-2 |

H6-2 |

Blinking |

SAS/OPS |

Tilt PULL solenoid open abnormality |

||

|

H7-1 |

H7-1 |

Blinking |

SAS/OPS |

Attachment 1 PUSH solenoid open abnormality |

Attachment 1 may stop |

19-151 |

|

H7-2 |

H7-2 |

Blinking |

SAS/OPS |

Attachment 1 PULL solenoid open abnormal |

||

|

H8-1 |

H8-1 |

Blinking |

SAS/OPS |

Attachment 2 PUSH solenoid open abnormality |

Attachment 2 may stop |

19-153 |

|

H8-2 |

H8-2 |

Blinking |

SAS/OPS |

Attachment 2 PULL solenoid open abnormality |

||

|

HA-1 |

HA-1 |

Blinking |

SAS/OPS |

3/4 way change relay GND short abnormality |

Attachmen |

🏠

Home

Subjects

➗

Math

🧪

Science

🏛️

History

📺

Arts & Humanities

🤝

Social Studies

💻

Engineering & Technology

💰

Business

📚

Other

Resources

📓

Study Guides

🏆

Leaderboard

💯

All Tags

❓

Unanswered

🔀

Random

Tags

🚗

Toyota

Forklifts

0

Wiki User

∙ 6y ago

Want this question answered?

Be notified when an answer is posted

Study guides

📓

See all Study Guides

✍️

Create a Study Guide

Add your answer:

Earn +

20

pts

Q: What is error code a5-1 on Toyota forklift?

Write your answer…

Submit

Still have questions?

Related questions

People also asked

Study Guides

DNA

Created By

Olivia Brown

4.0

★★★

747 Reviews

Music Theory

Created By

Zi Xuan WANG

3.4

★★★

☆ ☆

154 Reviews

Partes de la casa

Created By

Giyuu tomioka

3.6

★★★

☆

98 Reviews

American History

Created By

Lillian Woods

3.1

★★★

☆ ☆

100 Reviews

Trending Questions

How do you get 1000000 robux for free?

Asked By

Wiki User

Who would you swap lives with for a day?

Asked By

Fletcher Altenwerth

How many miles are between the 2 super bowl champion cities?

Asked By

Wiki User

Physical learners account for approximately what percentage of learners?

Asked By

Wiki User

What’s something you’ve always wanted to learn?

Asked By

Leland Grant

What instrument measures mass?

Asked By

Wiki User

What is speed of a jet plane that travels 3000 meters in 10 seconds?

Asked By

Wiki User

as a marketer of what relevance is consumer behaviour to you and what buying decisions can you expect from your target market?

Asked By

cynthiakate67

Still have questions?

Previously Viewed

What is error code a5-1 on Toyota forklift?

Asked By

Wiki User

Unanswered Questions

Reasons why religion disapproves sexuality focused art?

Asked By

Wiki User

Why is there a lack of unity among umbrella organizations?

Asked By

Wiki User

What is the date of hsc result of maharashtra MARCH 1999?

Asked By

Wiki User

What is ketchup freezing point?

Asked By

Wiki User

In what way must the pilot be adept during the return to earth?

Asked By

Wiki User

Which city is at 5 s and 30 e?

Asked By

Wiki User

Who is the actress in the otezla commercial?

Asked By

Wiki User

What does this settler woman suggest to Colt about her own future?

Asked By

Wiki User

Subjects

Math

Science

History

Business

Arts & Humanities

Social Studies

Engineering & Technology

Other

Arts & Entertainment

Sciences

Humanities

Sports

Auto

Hobbies

Books and Literature

Electronics

Food & Drink

Jobs & Education

Law & Government

Travel & Places

People & Society

Beauty & Health

Animals & Plants

All Subjects

Top Categories

Algebra

Chemistry

Biology

World History

English Language Arts

Psychology

Computer Science

Economics

Product

Community Guidelines

Honor Code

Flashcard Maker

Study Guides

Math Solver

FAQ

Company

Contact Us

Terms of Use

Privacy Policy

Disclaimer

Cookie Policy

IP Issues

Made with 💙 in St. Louis

Copyright ©2023 Infospace Holdings LLC, A System1 Company. All Rights Reserved. The material on this site can not be reproduced, distributed, transmitted, cached or otherwise used, except with prior written permission of Answers.

Skip to content

How to clear forklift error codes

How to clear forklift error codes?

In all new generation of forklift and also some old models of forklift sometimes when you are using the forklift will see some error code on the monitor(dashboard) of the forklift.

In different forklift, each Error code means different things.

On Yale and Hyster forklift the error code can be showed or can be in the system.

Yale and Hyster Forklift Fault Codes List

for going inside the system you need the password that the company using or can be changed by the dealer before they ship it to the customer.

When you go inside the system you are able to see the error code and you will see how many time this error code showed in your forklift and also when (In witch hours of using the forklift), from the error code list that the company gives for each forklift to the dealers and forklift technician you will understand what is the problem and you can solve the issue with any headache.

In some other trucks same as Raymond, Toyota, and Nissan you will see the error code directly in the forklift and you can solve the issue and use the forklift easy.

How to detect and figure out forklift error codes?

In all forklift when the technician connect with computer to forklift all the issue and error will show up and he can fix for you, your forklift

Sometimes you see the error code in your forklift but you see your forklift work well, But it can be a point and you have to solve it because it is same as alarm and if you don’t ask the forklift technician for this issue in future you will be stuck with the bigger problem and big charge to repair your forklift.

Our suggestion is when you do your daily checklist please look and see your forklift doesn’t have any error code.

If you find any error code, don’t use the forklift to solve the issue.

How you can figure out forklift error codes?

Please leave the error code below this article then We and other specialists will answer you as soon as possible.

Our technician at Forklift Plus can detect and figure out your forklift problems as soon as possible.

Share This Story, Choose Your Platform!

Related Posts

Page load link

Go to Top

Коды неисправностей бензиновых двигателей (Toyota)

———————————————————————————

Коды самодиагностики считываются по числу вспышек индикатора «CHECK ENGINE» при замкнутых выводах «TE1»-«E1» разъема DLC1 под капотом или «TC»-«CG» разъема DLC3 под приборной панелью и включенном зажигании.

12 — Датчик положения коленчатого вала (P0335)

13 — Датчик положения коленчатого вала (P0335, P1335)

14 — Система зажигания, катушка №1 (P1300) и №4 (P1315)

15 — Система зажигания, катушка №2 (P1305) и №3 (P1310)

16 — Система управления АКПП

18 — Система VVT-i — фазы (P1346)

19 — Датчик положения педали акселератора (P1120)

19 — Датчик положения педали акселератора (P1121)

21 — Кислородный датчик (P0135)

22 — Датчик температуры охлаждающей жидкости (P0115)

24 — Датчик температуры воздуха на впуске (P0110)

25 — Кислородный датчик — сигнал бедной смеси (P0171)

27 — Кислородный датчик №2

31 — Датчик абсолютного давления (P0105, P0106)

34 — Система турбонаддува

35 — Датчик давления турбонаддува

36 — Датчик CPS (P1105)

39 — Система VVT-i (P1656)

41 — Датчик положения дроссельной заслонки (P0120, P0121)

42 — Датчик скорости автомобиля (P0500)

43 — Сигнал стартера

47 — Датчик положения дополнительной дроссельной заслонки

49 — Датчик давления топлива (D-4) (P0190, P0191)

51 — Состояние выключателей

52 — Датчик детонации (P0325)

53 — Сигнал детонации

55 — Датчик детонации №2

58 — Привод SCV (D-4) (P1415, P1416, P1653)

59 — Сигнал VVT-i (P1349)

71 — Система EGR (P0401, P0403)

78 — ТНВД (D-4)

89 — Привод ETCS (P1125, P1126, P1127, P1128, P1129, P1633)

92 — Форсунка холодного пуска (D-4) (P1210)

97 — Форсунки (D-4) (P1215)

Коды неисправностей дизельных двигателей (Toyota)

———————————————————————————

12 — Датчик положения коленчатого вала

13 — Датчик частоты вращения

14 — Клапан регулировки угла опережения впрыска

15 — Сервопривод дроссельной заслонки

17 — Сигнал блока управления

18 — Электромагнитный перепускной клапан

19 — Датчик положения педали акселератора

22 — Датчик температуры охлаждающей жидкости

24 — Датчик температуры воздуха на впуске

32 — Корректирующие резисторы

35 — Датчик давления наддува

39 — Датчик температуры топлива

42 — Датчик скорости автомобиля

96 — Датчик положения клапана EGR

Коды неисправностей АКПП (Toyota)

———————————————————————————

Коды самодиагностики считываются по числу вспышек индикатора «O/D OFF» при замкнутых выводах «TE1»-«E1» разъема DLC1 под капотом или «TC»-«CG» разъема DLC3 под приборной панелью и включенном зажигании (при этом должно быть разрешено включение повышающей передачи — «O/D OFF» не горит).

11 — Норма

37 — Датчик частоты вращения входного вала АКПП (Р1705)

38 — Датчик температуры рабочей жидкости АКПП

42 — Датчик скорости (или датчик частоты вращения выходного вала) (Р0500)

44 — Датчик скорости (или датчик частоты вращения заднего выходного вала)

46 — Соленоид управления давлением гидроаккумулятора (Р1765)

61 — Датчик скорости (или датчик частоты вращения переднего выходного вала)

62 — Соленоид №1 (Р0753)

63 — Соленоид №2 (Р0758)

64 — Соленоид муфты блокировки гидротрансформатора (Р0773)

67 — Датчик частоты вращения входного вала АКПП

68 — Соленоид управления муфтой блокировки гидротрансформатора

73 — Соленоид муфты блокировки межосевого дифференциала

Коды неисправностей ABS (Toyota)

———————————————————————————

Считывание кодов (модели с разъемом DLC1)

— Включите зажигание.

— Перемкните выводы «ТС» и «E1» разъема DLC1.

— Снимите перемычку с выводов «WA» и «WB» разъема DLC1.

— Через 4 секунды считайте код по количеству вспышек индикатора.

— Снимите перемычку с выводов «TC» и «E1».

— Установите перемычку на выводы «WA» и «WB».

Сброс кодов (модели с разъемом DLC1)

— Включите зажигание.

— Перемкните выводы «ТС» и «E1» разъема DLC1 (автомобиль неподвижен).

— Нажмите на педаль тормоза восемь или более раз в интервале трех секунд.

— Индикатор должен выводить код нормы (мигать 2 раза в секунду).

— Выключите зажигание.

— Снимите перемычку с выводов «TC» и «E1».

— Убедитесь, что индикатор ABS погас.

Считывание кодов (модели с разъемом DLC3)

— Перемкните выводы «ТС» и «CG» разъема DLC3.

— Включите зажигание.

— Через 4 секунды считайте код по количеству вспышек индикатора.

— Снимите перемычку с выводов «TC» и «CG».

Сброс кодов (модели с разъемом DLC3)

— Перемкните выводы «ТС» и «CG» разъема DLC3.

— Включите зажигание.

— Нажмите на педаль тормоза восемь или более раз в интервале трех секунд.

— Индикатор должен выводить код нормы (мигать 2 раза в секунду).

— Снимите перемычку с выводов «TC» и «CG».

Код Система

11 Обрыв цепи реле электромагнитного клапана

12 Короткое замыкание в цепи реле э/м клапана

13 Обрыв в цепи реле электронасоса

14 Короткое замыкание в цепи реле электронасоса

21 Обрыв или короткое замыкание в э/м клапане переднего правого колеса

22 Обрыв или короткое замыкание в э/м клапане переднего левого колеса

23 Обрыв или короткое замыкание в э/м клапане заднего правого (левого) колеса

24 Обрыв или короткое замыкание в э/м клапане заднего левого (правого) колеса

31 Неисправность датчика частоты вращения переднего правого колеса

32 Неисправность датчика частоты вращения переднего левого колеса

33 Неисправность датчика частоты вращения заднего правого колеса

34 Неисправность датчика частоты вращения заднего левого колеса

41 Слишком высокое или слишком низкое напряжение аккумуляторной батареи

43 Неисправность в цепи датчика замедления

44 Обрыв или короткое замыкание в цепи датчика замедления

49 Обрыв в цепи выключателя стоп-сигналов

51 Короткое замыкание или обрыв цепи питания электронасоса

71 Низкий уровень сигнала от датчика частоты вращения переднего правого колеса

72 Низкий уровень сигнала от датчика частоты вращения переднего левого колеса

73 Низкий уровень сигнала от датчика частоты вращения заднего правого колеса

74 Низкий уровень сигнала от датчика частоты вращения заднего левого колеса

75 Неправильное изменение сигнала от датчика частоты вращения переднего правого колеса

76 Неправильное изменение сигнала от датчика частоты вращения переднего левого колеса

77 Неправильное изменение сигнала от датчика частоты вращения заднего правого колеса

78 Неправильное изменение сигнала от датчика частоты вращения заднего левого колеса

79 Неисправность датчика замедления

98 — Датчик разрежения в вакуумном усилителе тормозов (C1200

Коды неисправностей SRS (Toyota)

———————————————————————————

Коды самодиагностики считываются аналогично прочим, по числу вспышек индикатора «SRS» при замкнутых выводах «TC»-«E1» разъема DLC1 под капотом или «TC»-«CG» разъема DLC3 под приборной панелью и включенном зажигании.

Стирание кодов должно происходить при выключении зажигание. Если коды сохраняются, необходимо провести процедуру очистки:

— подсоединть два провода к выводам «TC» и «AB»

— включить зажигание и подождать не менее 6 секунд

— поочередно, раз в секунду, замыкать на массу выводы «TC» и «AB» (пауза между замыканием — менее 0,2 секунды)

— после третьего замыкания вывода «TC» индикатор должен замигать с высокой частотой — значит коды стерты.

11 — Воспламенитель ПБ водителя (замыкание на массу)

12 — Воспламенитель ПБ водителя (замыкание на питание)

13 — Воспламенитель ПБ водителя (замыкание в цепи)

14 — Воспламенитель ПБ водителя (разрыв в цепи)

15 — Передний правый датчик SRS (замыкание или разрыв в цепи)

15 — Передний правый датчик SRS (замыкание на массу или питание)

16 — Передний левый датчик SRS (замыкание или разрыв в цепи)

16 — Передний левый датчик SRS (замыкание на массу или питание)

31 — Неисправность блока управления SRS

51 — Воспламенитель ПБ пассажира (замыкание на массу)

52 — Воспламенитель ПБ пассажира (замыкание на питание)

53 — Воспламенитель ПБ пассажира (замыкание в цепи)

54 — Воспламенитель ПБ пассажира (разрыв в цепи)

61 — Воспламенитель преднатяжителя ремня водителя (замыкание на массу)

62 — Воспламенитель преднатяжителя ремня водителя (замыкание на питание)

63 — Воспламенитель преднатяжителя ремня водителя (замыкание в цепи)

64 — Воспламенитель преднатяжителя ремня водителя (разрыв в цепи)

71 — Воспламенитель преднатяжителя ремня пассажира (замыкание на массу)

72 — Воспламенитель преднатяжителя ремня пассажира (замыкание на питание)

73 — Воспламенитель преднатяжителя ремня пассажира (замыкание в цепи)

74 — Воспламенитель преднатяжителя ремня пассажира (разрыв в цепи)

Коды неисправностей системы 4WS (Toyota)

———————————————————————————

Коды самодиагностики считываются по числу вспышек индикатора «4WS» при замкнутых выводах «TC»-«E1» разъема DLC1 под капотом и включенном зажигании.

Код Система

— —

11 Электронный блок управления 4WS

12 Неисправность главного электродвигателя заднего рулевого механизма

13 Неисправность привода управления рулевым механизмом

21 Короткое замыкание в системе главного электродвигателя

22 Разрыв цепи в системе главного электродвигателя

23 Блокировка главного электродвигателя

24 Неисправность в работе главного электродвигателя

31 Разрыв в системе электродвигателя заднего хода

32 Неисправность в работе электродвигателя заднего хода

41 Неисправность датчика частоты вращения левого переднего колеса

42 Неисправность датчика системы 4WS

43 Неверная работа датчика системы 4WS