Содержание

- Hose error ошибка tokheim

- Tokheim

- На рынке представлены следующие серии оборудования Токхайм:

- Потребители ТРК Токхайм отмечают целый ряд его преимуществ:

Hose error ошибка tokheim

Подключение ТРК Tokheim к системе СНК-АЗС

Подключение сигнального кабеля к колонке осуществляется к разъему X2 интерфейсной платы WWC 0EL 021.0 COMM TOKHEIM INTERFACE .

Для подключения ТРК к СОМ порту персонального компьютера мы применяем специализированный преобразователь интерфейсов RS232-Tokheim

Настройка системы управления СНК-АЗС

Настройка в программе HWServerConfig :

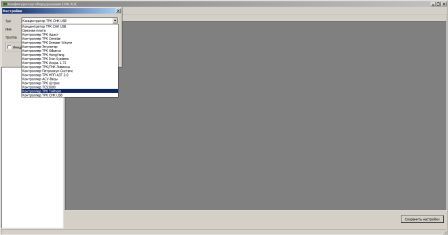

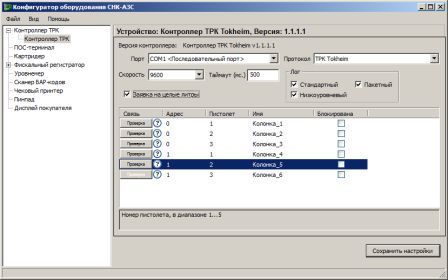

Запустите программу HWServerConfig . exe , во вкладке Контроллеры создайте Контроллер Tokheim

- Выберите COM-порт, к которому подключен преобразователь интерфейсов.

- Добавьте необходимое количество шлангов.

- При необходимости измените значение полей «Адрес» и «Пистолет».

- Для отпуска топлива на СУММУ установите галочку параметра «Заявка на целые литры».

- Нажмите кнопку «Сохранить».

Настройка в программе «Управление конфигурацией»:

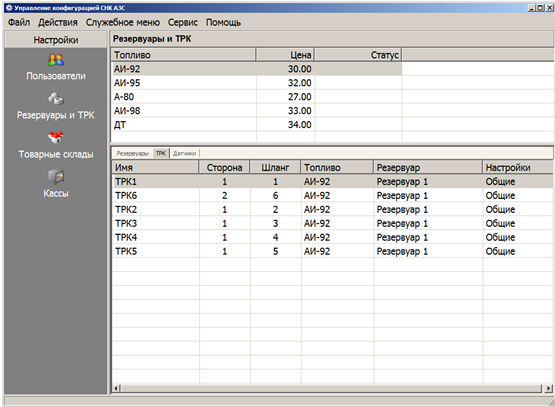

- Откройте приложение «Управление конфигурацией».

- Выберите вкладку «Резервуары и ТРК», экран ТРК.

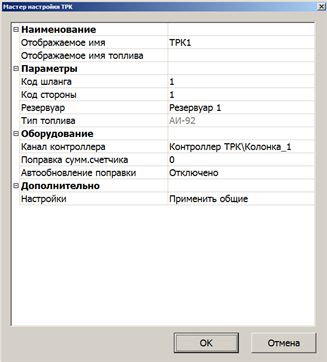

- Создайте новую ТРК или отредактируйте существующую.

- Выберите канал контроллера.

- При необходимости примените индивидуальные параметры.

Настройка ТРК Tokheim

Подготовка электроники ТРК

ТРК Tokheim имеет три типа запуска:

- Холодный пуск.

- Горячий пуск.

- Запуск для обслуживания.

Холодный пуск (COLD RESTART)

Для программирования всех параметров калькулятора ТРК требуется выполнить процедуру холодного пуска. Данный тип пуска может потребоваться при первом пуске ТРК, а также в случае появления сообщений об ошибках во время выполнения горячего пуска или запуска для обслуживания.

Внимание: Перед проведением процедуры COLD RESTART (Холодный пуск) необходимо отключить электропитание электроники ТРК. После выполнения процедуры холодного пуска потребуется полностью настроить конфигурацию ТРК.

Для выполнения сброса (обнуления) требуется:

1. Отключить электропитание электроники ТРК.

2. Проверить наличие интерфейсной платы WWC COMM TOKHEIM INTERFACE.

3. Снять джамперы W201 и W202, расположенные на центральной плате (Main Board v.4) электроники TOKHEIM.

4. Включить электропитание электроники ТРК.

ТРК перейдет в режим настроек и на дисплее отобразится мигающее сообщение «SEtUP PIncd». Для перехода к дальнейшим пунктам настройки потребуется ввод PIN-кода.

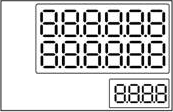

После ввода PIN-кода нажать клавишу «7». При вводе действительного PIN-кода ТРК выполнит процедуру самотестирования (мигающие 8-ки на дисплее) и перейдет к первому пункту меню настроек «cntrY code».

Вид дисплея при самотестировании:

Пункт меню cntrY code:

Программирование параметров работы ТРК TOKHEIM

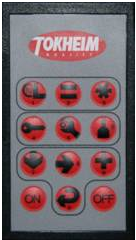

Внимание: Для изменения параметров ТРК TOKHEIM необходима клавишная панель дистанционного управления (IRM) или внутренняя конфигурационная клавишная панель. Инфракрасный контроллер дистанционного управления является опцией.

В зависимости от версии ядра некоторые пункты меню могут отличаться от описанных далее.

Вид дистанционной клавишной панели (IRM):

Необходимо установить следующие параметры:

Код страны (обязательный параметр)

Необходимо установить параметр 0007, соответствующий «РОССИЯ». Для выбора параметра (кода) используется клавиша «9». Для возврата к значению «0000» необходимо нажать «0». Для подтверждения выбора и перехода к следующему меню нажать «7».

Если код страны не выбран, появится сообщение об ошибке.

Положение десятичной запятой Euro YES/NO

Необходимо установить значение «NO». Данный параметр определяет положение десятичной запятой, заданное по настройке (коду) для страны.

Для выбора параметра используется клавиша «9». Для подтверждения выбора и перехода к следующему меню нажать «7».

Положение десятичной запятой при отображении цены ScalE

Необходимое значение «0». В данном меню можно изменить положение десятичной запятой для цены за единицу.

Значение «Х» можно увеличить с помощью клавиши «9», пока не будет достигнуто нужное значение. Для подтверждения выбора и перехода к следующему меню нажать «7».

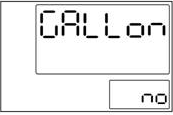

Единица измерения GALLON/LITER

Требуемое значение «no» для измерений в литрах. Это параметр задает единицы измерения продукта.

Для выбора параметра используется клавиша «9». Для подтверждения выбора и перехода к следующему меню нажать «7».

Код настройки diSP SEtUP (обязательный параметр)

Значение должно соответствовать гидравлической схеме.

Для выбора параметра используется клавиша «9». Для подтверждения выбора и перехода к следующему меню нажать «7».

Максимальное количество рукавов для сторон ТРК

Максимальное значение зависит от кода настройки, но не может быть больше 6.

Установить значение для правой стороны. Справа мигает значение «X». Значение «X» можно увеличить с помощью клавиши «9», пока не будет достигнуто нужное значение. Для переключения между сторонами нажать клавишу «8».

Установить значение для левой стороны. Слева мигает значение «X». Значение «X» можно увеличить с помощью клавиши «9», пока не будет достигнуто нужное значение. Для подтверждения выбора и перехода к следующему меню нажать клавишу «7».

Обнаружение утечки паров

После выполнения этого пункта меню необходимо установить перемычку W201 .

Это последний пункт начальных настроек.

Внимание: На этом этапе выполнения начальных настроек необходимо вставить перемычку W201 во избежание повторного холодного пуска.

При этом происходит автоматический перезапуск калькулятора. В память EEPROM будут записаны новые конфигурационные данные.

Если в процессе автоматического перезапуска будут обнаружены несоответствия оборудования и заданных параметров, появится сообщение об ошибке.

Сообщение содержит код возникшей ошибки. Пояснения кодов содержатся в документации производителя.

Сообщения об ошибках мигают в течение нескольких секунд, после чего электроника переходит к первому пункту меню начальных установок.

Настройка WWC T1

Все дальнейшие настройки производятся на уровне техника АЗС.

Для перехода в режим конфигурации (сервисный) необходимо нажать клавишу «ON» на конфигурационной клавишной панели. Колонка перейдет в режим конфигурирования. На дисплее ТРК будет отображено текущее состояние ТРК – «conF».

Вид дисплея при переходе в режим настроек:

Важно: При проведении операций программирования все пистолеты на обеих сторонах ТРК должны быть повешены.

Дальнейший порядок действий:

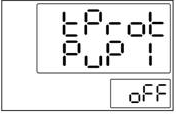

1. Нажать клавишу «5» для перехода в меню технических настроек ТРК. На дисплее колонки будет отображен мигающий пункт входа в техническое меню «tEcH».

Вход в меню осуществляется по нажатию клавиши «7». Далее по запросу системы на ввод PIN-кода нужно еще раз нажать «7». На дисплее ТРК будет отображено сообщение с приглашением ввести четырехзначный PIN-код техника АЗС (мигает левый символ «-«).

На этом этапе необходимо ввести PIN-код техника АЗС. При вводе недействительного PIN-кода на дисплее будет мигать сообщение «Error» в течение нескольких секунд, а затем калькулятор ТРК перейдет в предыдущее меню для ввода PIN-кода.

При вводе правильного PIN-кода ТРК перейдет к первому пункту меню технических настроек «diAG LoG» (журнал диагностики).

2. Переустановка термозащиты. Эта функция служит для управления термозащитой двигателя. Для перехода к соответствующему пункту меню используется клавиша «7» панели клавишного управления.

Если термозащита двигателя отключена, калькулятор не будет включать двигатель. Для выбора номера двигателя используется клавиша «8». Для переключения между «on» (Вкл) и «off» (Выкл) нажимать «9». Номер двигателя зависит от установок гидравлической системы ТРК. Для подтверждения выбора и перехода к следующему меню нажать «7».

Адрес узла (обязательный параметр)

Для программирования адреса правой стороны ТРК необходимо выбрать пункт меню «node Addr r», для левой – «node Addr L».

Адреса должны быть различными в пределах одного контроллера. Сначала задается адрес для правой стороны ТРК, а затем для левой.

Для увеличения значения используется клавиша «9». Для подтверждения выбора и перехода к следующему меню нажать «7».

Выход из режима обслуживания

Выйти из режима обслуживания можно на любом этапе программирования. Для выхода из режима необходимо нажимать клавишу «0».

Важно: Перед выходом из режима обслуживания необходимо, чтобы все пистолеты на обеих сторонах ТРК были повешены.

Для выхода из режима обслуживания нажать клавишу «OFF» дистанционной клавишной панели. Появится запрос о сохранении произведенных изменений в памяти ТРК:

При выходе из режима обслуживания и подтверждении запроса на сохранение параметров будет произведена проверка конфигурации (самотестирование).

В случае обнаружения критической ошибки в конфигурации на индикаторах ТРК появится сообщение «Error» и электроника перейдет к начальному меню настроек.

Источник

Tokheim

Tokheim («Токхайм») — торговая марка, которая имеет мировую известность, более чем вековую историю и принадлежит компании Tokheim Group. Под брендом Tokheim производятся топливораздаточные колонки (ТРК), а также технологические системы для обслуживания автозаправочных станций. Оборудование Токхейм работает в 120 странах мира на более чем 40 тысячах АЗС.

Tokheim — уникальность предлагаемых продуктов и синергетический эффект от их комплексного использования.

Сегодня головной офис производителя трк токхейм находится недалеко от Парижа. Но начиналась история бренда в США, когда в 1890 году купец из штата Айова Джон Токхайм изобрел и запатентовал первую систему перекачивания топлива. Этот прообраз современной топливораздаточной колонки стал настоящим прорывом в технологии быстрой и дозированной доставки потребителям различных видов топлива.

Сейчас под брендом Tokheim производятся одно- и двухпродуктовые ТРК, а также многофункциональные мультипродуктовые топливораздаточные комплексы для подачи бензина, дизельного топлива, метана и жидкого реагента AdBlue, очищающего выхлопные газы от дизельных двигателей.

На рынке представлены следующие серии оборудования Токхайм:

Потребители ТРК Токхайм отмечают целый ряд его преимуществ:

- идеальный баланс между ценой и качеством;

- выбор опций ТРК по желанию заказчика;

- возможность выбрать цвет колонки и нанести на нее логотип;

- устойчивая работа электроники;

- низкая восприимчивость к перепадам напряжения;

- антикоррозионная выносливость;

- наличие многоразовых фильтров, снижающих затраты на обслуживание ТРК;

- удобная система автоматического сматывания шлангов;

- безопасность.

Основная идея бренда Tokheim — комплексность обслуживания АЗС с достижением синергетического эффекта. Колонки Токхейм комплектуются платежными терминалами и мультимедийными системами для продвижения топливных продуктов. Владелец АЗС имеет возможность приобрести не просто оборудование, а готовый бизнес, в котором предусмотрены все технические и технологические решения – от строительства АЗС и их оснащения до рекламы продукции и постоянной технической поддержки станций.

Купить топливораздаточное оборудование Tokheim по цене завода-производителя можно в компании «Венго», оформив заявку и указав желаемую серию ТРК. Заявку можно оставить на сайте или позвонив по телефонам 8 800 222 44 52, +7 495 240 52 52.

Источник

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

WWC T1

Calculator

Set Up & Maintenance

Manual

Document Ref 905675-001

Rev — 2

01/2006

Related Manuals for Tokheim WWC T1

Summary of Contents for Tokheim WWC T1

-

Page 1

WWC T1 Calculator Set Up & Maintenance Manual Document Ref 905675-001 Rev — 2 01/2006… -

Page 2: Document Ref

Tokheim shall not be liable for damage to the product, nor for personal or third party injury, caused by incorrect use of the product or by attempts to maintain or to repair the product by parties other than those fully trained by Tokheim or by its accredited third party representatives.

-

Page 3

WWC T1 Set Up & Maintenance Manual Revision Record REVISION RECORD Date Revision Page Issue Reason 01/07/2004 Original Issue 19/01/2006 3 to 6 Main Contents revised 19/01/2006 2-16,2-17 Updated Functionalities 19/01/2006 2-21 to 2-23 New info added (Input Type, Master PIN Code, Gallon Type, Cent Overshoot Hide, 4 position product indicator, Heavy Lei);… -

Page 4

Revision Record WWC T1 Set Up & Maintenance Manual This page is intentionally blank Document Ref 905675-001 Rev 2… -

Page 5: Table Of Contents

WWC T1 Set Up & Maintenance Manual Contents CONTENTS INTRODUCTION ………………….1-2 How to Use this Manual ………………1-2 Product Scope ………………… 1-3 Authorised Technicians ………………1-3 Contact Information ……………….. 1-3 Health & Safety ………………..1-3 1.5.1 Safety Checklist ……………… 1-3 1.5.2…

-

Page 6

Contents WWC T1 Set Up & Maintenance Manual LPG SET UP / Timing with Deadmans Button only & Motor Off Delay ≠ ≠ ≠ ≠ ≠ 0 …. 3-7 3.3.3 3.3.4 Timing with Deadmans Button only & Motor Off Delay = 0 …. 3-7 SERVICE KEYPAD …………………. -

Page 7

WWC T1 Set Up & Maintenance Manual Contents MAINTENANCE MODE / 6.20 Node Address ………………..6-18 6.21 Test Delivery ………………… 6-19 6.22 Emergency Manual Pumping Device (EMPD) ……….6-21 6.23 Product Relation ………………..6-21 6.23.1 Product Name by Character Input ………… 6-22 6.23.2… -

Page 8

Contents WWC T1 Set Up & Maintenance Manual INSPECTION FUNCTIONS / 11.7 Release Management ………………11-4 11.8 Maximum Time for a Filling …………….11-4 11.9 Time Between Two Fillings …………….11-4 11.10 Maximum Time of No Flow …………….11-4 11.11 Maximum Time a Filling can be Suspended …………. 11-5 11.12 Timer for Display TImeout ……………. -

Page 9

WWC T1 Set Up & Maintenance Manual Introduction CONTENTS INTRODUCTION ………………….1-2 How to Use this Manual ………………1-2 Product Scope …………………. 1-3 Authorised Technicians ………………1-3 Contact Information ………………… 1-3 Health & Safety ………………..1-3 1.5.1 Safety Checklist ………………. 1-3 1.5.2… -

Page 10: Introduction

Section 2 — Product Information This section contains the system description and operating principles of the WWC T1 Calculator. It also describes the main components, their configurations and functions including the service keypads.

-

Page 11: Product Scope

WWC T1 Set Up & Maintenance Manual Introduction Product Scope This manual is designed to cover the Quantium T range of dispensers including LPG. As functionality is equivalent to the Coca 1.1 functionality, reference is frequently made to the existing Coca Manuals.

-

Page 12: Duties Of The Employees

Introduction WWC T1 Set Up & Maintenance Manual 1.5.2 DUTIES OF THE EMPLOYEES • To ensure optimal accident prevention in our company, in addition to general rules applying to worker’s protection, it is necessary to take into account all the national protection of workers legislation and to actively support all measures which enhance safety standards.

-

Page 13: Warning Signs

WWC T1 Set Up & Maintenance Manual Introduction At unattended service stations, every end-user should be able to read the User Instructions. They should be visible on a notice board or integrated into the DIT and should be sufficiently well lit so that they can be read at night.

-

Page 14: Personal Protective Equipment (Ppe)

Introduction WWC T1 Set Up & Maintenance Manual 1.5.5 PERSONAL PROTECTIVE EQUIPMENT (PPE) PROTECTIVE CLOTHING The following clothing should be worn at all times during installation and maintenance procedures:- • Protective helmet. • Protective shoes (conductive). • Protective gloves and/or protective hand cream.

-

Page 15: Nomenclature

WWC T1 Set Up & Maintenance Manual Introduction Nomenclature The various abbreviations used in thie manual are described as follows:- CoCa Today’s Common Calculator and base of the WWC CSD-F Common Sales Display — Ferranti CSD-L Common Sales Display — LCD…

-

Page 16

Introduction WWC T1 Set Up & Maintenance Manual This page is intentionally blank Page 1-8 Document Ref 905675-001 Rev 2… -

Page 17

WWC T1 Set Up & Maintenance Manual Product Information CONTENTS PRODUCT INFORMATION ………………2-2 System Description ………………..2-2 2.1.1 Operating Principles…………….2-2 Main Components of the WWC …………….2-2 2.2.1 External Power Supply ……………. 2-3 2.2.2 Mainboard ……………….. 2-3 2.2.3 I/O Board (version 3++) ………….. -

Page 18: Product Information

The WWC (World Wide Calculator) is a ‘measuring system’ built to conform to the international recommendations specified in the document OIML R117 Edition 1995. The WWC is also a peripheral within the different Tokheim filling station systems. As such, the WWC software and hardware can be configured without modifying the characteristics of the measuring system.

-

Page 19: External Power Supply

WWC T1 Set Up & Maintenance Manual Product Information ARCHITECTURAL OVERVIEW Valves, motors and sensors Displays CSD-L CSD-L CSD-F CSD-F Communication Mains Calculator Module Interfaces Battery I/O extensions Mainboard MB251 Nozzle Bus Dispenser light, Interface Electr totaliser Dipnet Low End Hydraulic…

-

Page 20: I/O Board (Version 3++)

Product Information WWC T1 Set Up & Maintenance Manual Since the release of Version 3 of the mainboard, the NBB board has been eliminated and the serial nozzle bus is directly controlled by the mainboard. Two optional modules can be directly connected to the mainboard (piggy-back):- •…

-

Page 21: Standard Dispensers With Up To Four Single Products

WWC T1 Set Up & Maintenance Manual Product Information 2.3.1 STANDARD DISPENSERS WITH UP TO FOUR SINGLE PRODUCTS Valves, motors and sensors Displays CSD-L CSD-L CSD-F CSD-F Communication Mains Calculator Module Interfaces Battery I/O extensions Mainboard MB251 Nozzle Bus Dispenser light,…

-

Page 22: Vapour Recovery Controller Board (Vrc)

Product Information WWC T1 Set Up & Maintenance Manual 2.3.3 VAPOUR RECOVERY CONTROLLER BOARD (VRC) The VRC is an independent module which communicates with the calculator module. After the VRC is initialised at each delivery start, it performs the open or closed loop vapour recovery process by controlling its own motors and valves.

-

Page 23: Functionalities Per Hose

WWC T1 Set Up & Maintenance Manual Product Information 2.5.1 FUNCTIONALITIES PER HOSE 40 (45) litres per minute — Petrol or Diesel Standard speed flow rate is achieved using one pump and one meter. 40 (45) litres per minute for two filling positions — Petrol or Diesel Standard speed flow rate is achieved using one pump and two meters.

-

Page 24

Product Information WWC T1 Set Up & Maintenance Manual The choice is made by push button selection with product indication. There are two principles:- • 2 grades in, 3 grades out, 2 hoses • 2 grades in, 3 grades out, 1 hose Refer to section 6.18 for programming information. -

Page 25

WWC T1 Set Up & Maintenance Manual Product Information If detected, the leak error is forwarded to the system and will immediately block the complete dispenser. The calculator keeps track of the leak status. Parameter: — hose expansion volume :… -

Page 26: Functionalities Per Side

Product Information WWC T1 Set Up & Maintenance Manual If the nozzle is replaced with volume = 0 before the time out expires, the leak sequence counter is neither incremented nor reset i.e. this will not increase the volume lost if it is a real leak.

-

Page 27

WWC T1 Set Up & Maintenance Manual Product Information Push Button Methods — Push buttons connected to the sensor bus or direct connections — Push buttons connected to the IEB Up to four buttons (three amount or volume and one reset button) are available and can be connected to the sensor bus, direct connections or via IEB at each filling position. -

Page 28

Product Information WWC T1 Set Up & Maintenance Manual Keypad Methods — Keypad connected to the IEB — Keypad connected to the OCB preset clear CREDIT preset amount preset CASH volume When Local Preset is connected using a keypad method, a 4×4 keypad is available at each filling position to allow the entry of a preset amount or preset volume. -

Page 29

WWC T1 Set Up & Maintenance Manual Product Information displays last delivery filling is cashed and the volume and amount display show “0” filling is cashed and all displays show “0” 3 to 9 reserved for future implementations Satellite Nozzle Control Menu A high speed diesel dispenser can have a satellite nozzle on each side. -

Page 30

Product Information WWC T1 Set Up & Maintenance Manual Parameters:- • function is disabled 0000 • max. time 0959 (= 9 minutes and 59 seconds) • default value 0100 (certain applications may overrule this) Time Between Two Fillings Menu (Inter delivery time out) This is the minimum time to elapse between two successive fillings. -

Page 31

WWC T1 Set Up & Maintenance Manual Product Information Note: The request to program EMT positions for left-hand dispensers (PMR297) means that the EMT connector must always be used for 4/5 products on the Optional Peripheral Board (OPB). OCB Functionality When an OCB board is connected, the following functions can be selected:- •… -

Page 32: Functionalities Per Dispenser

Product Information WWC T1 Set Up & Maintenance Manual — volume unit (number of cl/pulse) 1 to 10 (default = 1) — volume period (value * 0.25 ms) 5 to 40 (default = 5) — amount unit (number of units/pulse currency unit)

-

Page 33

WWC T1 Set Up & Maintenance Manual Product Information Kernel Hydr Additional No of Sided Flow Rates/Products Drawing No Version Setup No Description Products 130 l/min/SAT and 4×40 l/min 5 right 9235110584 (right); > 01.09 Asymmetric 4 left 4 x 40 l/min (left) -

Page 34

Product Information WWC T1 Set Up & Maintenance Manual Backlight for LCD The backlight is standard with LCD displays. Switch Dispenser Lighting If defined in the application, the switch for the dispenser or calculator lighting is via a command from the forecourt controller system. -

Page 35

WWC T1 Set Up & Maintenance Manual Product Information Node Address Menu This function is required for multi drop communication links (e.g. IFSF) to select the address of the calculator on the network. Refer to section 6.20 for programming information. -

Page 36

Product Information WWC T1 Set Up & Maintenance Manual Kernel version >= 02.xx Option Controller Board Hydraulic Controller Module CS1R CSD 1 Right CS2R CSD 2 Right CS1L CSD 1 Left CS2L CSD 2 Left Sound Option Module VRC Module… -

Page 37: Weights & Measures Related Functionality

WWC T1 Set Up & Maintenance Manual Product Information Nozzle Input Type This function allows the selection between two different types of nozzle input:- • Value “no” — normal nozzle switch position i.e. always OPEN in idle and CLOSED when nozzle lifted — for all dispensers except Q500T1.

-

Page 38

Product Information WWC T1 Set Up & Maintenance Manual Pulser Test Time Before starting a delivery, the pulser is tested during a specified ‘pulser test time’. During this test, the valves remain closed and the pulser is checked on consistent high/low values of both channels and there should be no pulses generated during this period. -

Page 39

WWC T1 Set Up & Maintenance Manual Product Information Note : For European Community countries, selection of the Euro is only possible up to kernel version 03.12. In later kernel versions, the Euro selection is fixed. Heavy Lei This function is designed to enable the conversion to Heavy Lei currency in Romania by simple (software) switch. -

Page 40

Product Information WWC T1 Set Up & Maintenance Manual Two EMT options are available for selection following a cold start:- • Value “d” = double-sided EMT (each nozzle of a product has an individual EMT total) • Value “s” = single-sided EMT (the left and right totals of the same product are… -

Page 41

WWC T1 Set Up & Maintenance Manual LPG Set Up CONTENTS LPG SET UP ……………………3-2 LPG Functionality ………………..3-2 3.1.1 LPG Pulse Menu …………….. 3-2 3.1.2 LPG Nozzle Flag Menu …………… 3-2 3.1.3 LPG Delay Timer Menu …………..3-3 3.1.4… -

Page 42: Lpg Set Up

LPG Set Up WWC T1 Set Up & Maintenance Manual LPG SET UP This section will cover the the hydraulic situation and the functional operation for LPG dispensers:- • LPG Functionality (refer to section 3.1) • LPG Hydraulic Functions (refer to section 3.2) •…

-

Page 43: Lpg Delay Timer Menu

WWC T1 Set Up & Maintenance Manual LPG Set Up • N = No nozzle switch present. The dispenser is activated by pressing the Deadmans Button. A delay timer is fitted (refer to section 3.1.3) to allow the customer to temporarily release the Deadmans Button without ending the delivery.

-

Page 44: Lpg Hydraulic Functions

LPG Set Up WWC T1 Set Up & Maintenance Manual LPG Hydraulic Functions In the LPG Hydraulic section, the basic flow is regulated by a valve in the liquid line, positioned before the break-away coupling and hose. For additional safety, the Hydraulic Chair option is available. The Chair hydraulic block may contain additional valves in the liquid line and vapour return line.

-

Page 45: Hydraulic Schematic

WWC T1 Set Up & Maintenance Manual LPG Set Up 3.2.2 HYDRAULIC SCHEMATIC RBU1 RNO1 RSV1 CHAIR RRV1 vapour liquid liquid WWC SET vapour LSV1 CHAIR LRV1 LNO1 LBU1 Note : The Hydraulic Chair block is an option. Where applicable, the additional valve in the vapour line (V…

-

Page 46: Functionality With Nozzle Switch

LPG Set Up WWC T1 Set Up & Maintenance Manual Functionality with Nozzle Switch TIMING WITH NOZZLE SWITCH & MOTOR OFF DELAY ≠ ≠ ≠ ≠ ≠ 0 3.3.1 nozzle button motor valve Start LPG Delay (Deadmans No action button)

-

Page 47: Functionality Without Nozzle Switch

WWC T1 Set Up & Maintenance Manual LPG Set Up Functionality without Nozzle Switch TIMING WITH DEADMANS BUTTON ONLY & MOTOR OFF DELAY ≠ ≠ ≠ ≠ ≠ 0 3.4.1 button motor valve Start LPG Delay (Deadmans button) Terminate Motor Off…

-

Page 48

LPG Set Up WWC T1 Set Up & Maintenance Manual This page is intentionally blank Page 3-8 Document Ref 905675-001 Rev 2… -

Page 49

WWC T1 Set Up & Maintenance Manual Set Up Modes CONTENTS SERVICE KEYPAD ………………… 4-2 User Access Keypad (UAK) …………….4-2 Infra Red (IR) Remote Control Keypad ………….. 4-4 Internal Configuration Keypad …………….4-4 Page 4-1 Document Ref 905675-001 Rev 2… -

Page 50: Service Keypad

Set Up Modes WWC T1 Set Up & Maintenance Manual SERVICE KEYPAD There are three types of keypads used in conjunction with the WWC:- • User Access Keypad (standard) — refer to section 4.1 • Inra-Red Remote Control (equal to CoCa) — refer to section 4.2 •…

-

Page 51

WWC T1 Set Up & Maintenance Manual Set Up Modes Symbol Calculator Function VRC Function Set unit price Start calibration Show totals Parameters keyboarding Application Set up Cancel current operation Set pincode Enter password Maintenance Functions Start maintenance Inspection Functions… -

Page 52: Infra Red (Ir) Remote Control Keypad

Set Up Modes WWC T1 Set Up & Maintenance Manual Infra Red (IR) Remote Control Keypad The IR Remote Control is available as an option for Station Managers to access the management functions of the calculator. Note: The IR option incurs an additional cost and is not suitable for VRC configuration or calibration.

-

Page 53

WWC T1 Set Up & Maintenance Manual Set Up Modes CONTENTS SET UP MODE ………………….5-2 General …………………… 5-2 Start Ups ………………….5-2 5.2.1 Cold Start ……………….. 5-2 5.2.2 Warm Start ………………5-3 5.2.3 Service Start ………………5-3 Initial Set Up Menu ………………… 5-3 5.3.1… -

Page 54: Set Up Mode

Set Up Modes WWC T1 Set Up & Maintenance Manual SET UP MODE General The set up of the calculator is a set of procedures which initialise the system according to the requirements of the dispenser itself and also individual customer requests. There are two main sequences to be followed:- •…

-

Page 55: Warm Start

WWC T1 Set Up & Maintenance Manual Set Up Modes After the 7 key is pressed, the initial setup will be mandatory (see section 5.3). Note : Remember to insert the jumper W201 after start up. 5.2.2 WARM START When jumper W201 is ON and W202 is OFF, the calculator performs a normal start up and all data from previous sessions is restored.

-

Page 56: Set Up Function Overview

5.3.1 SET UP FUNCTION OVERVIEW Function Kernel IFSF M3000 Dres K ER3 K S&B Country code Euro (always visible) > 01.12 Euro (European countries only) > 02.06 Scaling > 02.11 Gallon (always visible) > 01.12 Gallon (except country 001) > 02.06 Gallon type (if Gallon = yes only) >…

-

Page 57: Set Up Menu

WWC T1 Set Up & Maintenance Manual Set Up Modes 5.3.2 SET UP MENU The Set Up menu is executed when:- • A cold start is performed • Errors are detected with the set up during a warm start or a service start…

-

Page 58

Set Up Modes WWC T1 Set Up & Maintenance Manual Display Explanations/comments G A L L o n Gallon menu. Default no is flashing. Press 9 to toggle to yes to change the volume measurement to gallons. Press 7 to save and continue. -

Page 59

WWC T1 Set Up & Maintenance Manual Set Up Modes Display Explanations/comments Satellite/Slave Display menu. d I S P L The option for satellite/slave displays per dispenser side is defined within the set up code. Set satellite/slave display for the right side (side A):- The right 1 is flashing. -

Page 60

Set Up Modes WWC T1 Set Up & Maintenance Manual Display Explanations/comments EMT menu. e n n t Default d is flashing (double-sided). Press 9 to toggle to s for sigle-sided. Press 7 to save and continue. Combined Hose Product Preselection menu. -

Page 61

WWC T1 Set Up & Maintenance Manual Set Up Modes Display Explanations/comments Cent Overshoot Hide menu. n n A S Set the masking type:- t Y P E Use 9 to toggle between 1 (xxxx,x0 [default]) and 2 (xxxx,00) Note : France only (country code 33) Press 7 to save and continue. -

Page 62: Afm Set Up Menu

Set Up Modes WWC T1 Set Up & Maintenance Manual AFM Set Up Menu Display Explanations/comments AFM Set Up menu. Press 7 to skip AFM set up — this will disable any AFMs. S e t U P If AFM is not set, any attempt to start a delivery will generate error message 4 3 (pulser not connected).

-

Page 63

WWC T1 Set Up & Maintenance Manual Set Up Modes Y IS BLANK (INVALID OR MISSING AFM ADDRESS) Display Explanations/comments If the AFM address is invalid or not detected, y is blank. H o S E Check the following:- L E F t… -

Page 64

Set Up Modes WWC T1 Set Up & Maintenance Manual Y IS VALID ADDRESS Display Explanations/comments AFM Address menu. H o S E A valid address is displayed i.e. y is within the range 1 to 12. r I G H t Each AFM must be programmed according to the following procedures. -

Page 65

WWC T1 Set Up & Maintenance Manual Set Up Modes Display Explanations/comments Conversion: round 32768 K-factor Press 7 to save and continue. Close Seal menu. c L o S E Close the seal to save the new settings. S E A L Press 7 to save and continue. -

Page 66: Address Conflict

Set Up Modes WWC T1 Set Up & Maintenance Manual 5.4.2 ADDRESS CONFLICT Address Conflict If an address conflict is detected, the display will flash error in the volume line for approx. 3 seconds. e r r o r AFM Address menu.

-

Page 67

WWC T1 Set Up & Maintenance Manual Set Up Modes Address Conflict Change Address menu(only if seal is open). c H A n G E The address will correspond to the previously selected set up and A d d r number of hoses — refer to section 5.4.3. -

Page 68: Afm Addresses

Set Up Modes WWC T1 Set Up & Maintenance Manual 5.4.3 AFM ADDRESSES SINGLE METER/PRODUCT DEFINITIONS (SET UPS 50 AND 58) Product Hose number Comments number number address Right 1 Right 2 Right 3 Right 4 Reserved Reserved Reserved Reserved…

-

Page 69

WWC T1 Set Up & Maintenance Manual Maintenance Modes CONTENTS MAINTENANCE MODE ………………… 6-2 General …………………… 6-2 Maintenance Function Overview ……………. 6-2 Access the Maintenance Functions …………..6-4 Exit Maintenance Mode ………………6-5 Diagnostic Information (Error Log) …………..6-6 6.5.1 Kernel versions >… -

Page 70: Maintenance Mode

MAINTENANCE MODE General Within the initial set up mode, the parameters for several functions are given a default value. To prevent fraud, selected Weights & Measures related parameters defined during set up cannot be changed e.g. pulser hide, hose expansion, rounding type etc. — refer to Appendix B for further information.

-

Page 71

Issue B Function Kernel IFSF ZSR EPS Dun M3000 Tat Aut Dres K ER3 K S&B Tok Log EINF Combined Hose (set up = 90) > 03.07 EMT Mode > 03.09 > 03.24 Cent Overshoot Hide > 04.02 Q500T1 4 Position Product Indicator >… -

Page 72: Access The Maintenance Functions

Maintenance Modes WWC T1 Set Up & Maintenance Manual Access the Maintenance Functions Display Explanations/comments Press ON to enter Configuration. c o n F Press 5 to continue. Technicians menu. t E c H Tech is flashing. Press 7 to continue.

-

Page 73: Exit Maintenance Mode

WWC T1 Set Up & Maintenance Manual Maintenance Modes Exit Maintenance Mode If any Maintenance functions have been changed, the calculator automatically prompts for the storage of these modifications in Eeprom before exiting the Maintenance Functions menu. Display Explanations/comments Press 0 to return to Diagnostic Log (first menu).

-

Page 74: Diagnostic Information (Error Log)

Maintenance Modes WWC T1 Set Up & Maintenance Manual Diagnostic Information (Error Log) This menu provides access to the calculator’s error log where the error codes for each error database can be viewed. The database stores the last 100 errors/events since the last reset of the error log.

-

Page 75: Kernel Versions <= 01.07

WWC T1 Set Up & Maintenance Manual Maintenance Modes With kernel versions equal or less than 01.07 the diagnostic information is displayed in a different layout. For a detailed description, refer to Appendix C. 6.5.2 KERNEL VERSIONS <= 01.07 Display…

-

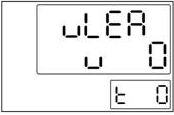

Page 76: Leak Tests

Maintenance Modes WWC T1 Set Up & Maintenance Manual Leak Tests Display Explanations/comments L E A French Leak Test menu (only if French Leak Test is activated). A c t v t E Press 7 to save and continue. L E A Esso Leak Test menu (only if the Esso Leak Test is activated).

-

Page 77

WWC T1 Set Up & Maintenance Manual Maintenance Modes Display Explanations/comments c n t r Y Country Code (as defined in initial Set Up). c o d E Note : This value is read-only and cannot be changed in this menu. -

Page 78: Lpg Functionality

Maintenance Modes WWC T1 Set Up & Maintenance Manual LPG Functionality This function enables the selection of a nozzle switch or Deadmans button and the ability to set a delay timer for stopping the motor after the LPG button is released accidentally.

-

Page 79: Thermal Protection Reset

WWC T1 Set Up & Maintenance Manual Maintenance Modes Thermal Protection Reset When the thermal protection of a motor is tripped, the calculator will not allow the motor to re-start without user intervention either via this menu or via an optional button.

-

Page 80: Leak Detection Functionality

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.10 Leak Detection Functionality This menu is displayed when the hose is activated and ready for use. Display Explanations/comments L E A Fuel Leak menu. The first product is displayed. Press 8 to increase the product number (right then left).

-

Page 81: Fraud Detection Functionality

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.10.3 ESSO LEAK DETECTION When Esso Leak Detection is activated and a leak is detected, the calculator will disable the associated dispenser which must be reset by user intervention via this menu. The Flow Leak menu changes into:-…

-

Page 82: Combined Hose Pre-Selection And Display Timeout

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.12 Combined Hose Pre-selection and Display Timeout The Combined Hose Pre-selection Menu is read-only and cannot be changed in this menu (set up 90 and Tatsuno application only). Display Explanations/comments P r o…

-

Page 83: Cent Overshoot Hide Functionality

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.14 Cent Overshoot Hide Functionality The Cent Overshoot Hide function is read-only and can only be changed in Set Up Mode. Note : This menu is only available with country code 33 (France).

-

Page 84: Stop/Off Switch

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.16 Stop/Off Switch This function allows the back-up battery to be switched off to enable Maintenance to be carried out in the event of a power failure. It is only available with kernel versions <=01.08.

-

Page 85: Blend Ratio

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.17.1 SET UP PIN CODE (FUEL LEAK DETECTION ONLY) A special Personal Identification Number (PIN) code is required to store any changes to the Fuel Leak Detection settings. Display Explanations/comments Set Up PIN Code menu.

-

Page 86: Local Preset Values

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.19 Local Preset Values Preset values are predefined (selected from a pick list) and are dependent upon the comma position as defined in Appendix A. For more information, refer to section 2.5.2.

-

Page 87: Test Delivery

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.21 Test Delivery During a test delivery, certain calculator functions can be tested and/or calibrated. If enabled, a test delivery message will appear on the unit price display. The exact message will depend on which test is enabled.

-

Page 88

Maintenance Modes WWC T1 Set Up & Maintenance Manual Display Explanations/comments The unit price display will alternate between Test and 0. The display reading setting allows meter information to be displayed on the volume/amount display. Depending on the test type, the following information will be displayed during a delivery:- 0 = normal readings i.e. -

Page 89: Emergency Manual Pumping Device (Empd)

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.22 Emergency Manual Pumping Device (EMPD) This special function of the WWC enables fuel to be dispensed manually (using handle on the pump) in the event of a power failure (using a back-up battery) by bypassing the motor/valves and recording the delivery on the pulser.

-

Page 90: Product Name By Character Input

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.23.1 PRODUCT NAME BY CHARACTER INPUT Display Explanations/comments o U t Product Name selection character by character. The first — is flashing. r I n 1 Press 9 to scroll through the character list to select the first character of the product name.

-

Page 91: Product Name From Pick List

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.23.2 PRODUCT NAME FROM PICK LIST Display Explanations/comments o U t Product Name from a Pick List. The first — is flashing. Press 3 to scroll through the pick list. r I n 1 Press 3 to select from a pick list.

-

Page 92: Vapour Recovery

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.24 Vapour Recovery The Vapour Recovery function is controlled via a separate Vapour Recovery Controller (VRC) or third party controlling module i.e. Fafnir, GRVP etc. This menu will indicate whether vapour recovery is applicable for a selected product. This menu is only visible if the system detects a VRC board.

-

Page 93: Vapour Delay

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.25 Vapour Delay This function (implemented since kernel version 3.03) enables extended vapour recovery error checking and reporting if the parameter >0. If the VRC system is running in SCG (self calibrating gas) mode and detects a problem in a hose then the error will be reported to the kiosk.

-

Page 94: Optional Preset Valve

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.27 Optional Preset Valve This function allows the use of a low flow valve (reduction valve) in parallel with the normal flow valve (stop valve) so that during a delivery, both valves are opened. It is designed to support the use of different preset valve mechanisms.

-

Page 95: Afm Menu

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.29 AFM Menu This menu will allow the configuration of Axial Flow volume meters. Display Explanations/comments At the Maintenance menu, press 7 to scroll through the options c o n F until the AFM Configuration menu is displayed.

-

Page 96

Maintenance Modes WWC T1 Set Up & Maintenance Manual Display Explanations/comments y y y y w w Serial Number menu (only if AFM is connected and initialised). n n n n n n information displayed:- yyyy = year ww = week nnnnnn = serial number Press 7 to continue. -

Page 97: Product Position

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.30 Product Position This function assigns the position of Product Indicators, Electro-mechanical Totalisers (EMT) and Unit Price Displays (UPD) to calculator internal product codes. For more information, refer to section 2.5.2. Also refer to kernel versions according to section 6.2 Maintenance Function Overview.

-

Page 98: Option Selection

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.31 Option Selection Option selection is by means of one of the following ways:- • I/O Extention Board (IEB ) — refer to section 6.29.1 • Option Controller Board (OCB) — refer to section 6.29.2 6.31.1…

-

Page 99: Ocb (Option Controller Board) Options

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.31.2 OCB (OPTION CONTROLLER BOARD) OPTIONS The parameter values are 0 to 9 for all options:- option disabled (default) controlled by application (selected applications can overrule the kernel functionality). Note : few applications use different functionality than the standard functionality.

-

Page 100

Maintenance Modes WWC T1 Set Up & Maintenance Manual For all other applications, the menu appears as follows:- Display Explanations/comments o c b OCB menu. Press 8 to enter OCB menu. Traffic Lights menu. L I G H t S Default off is flashing. -

Page 101

WWC T1 Set Up & Maintenance Manual Maintenance Modes Display Explanations/comments Volume/Amount Pulse menu. v o L A U Press 8 to enter submenu. Press 0 to exit OCB menu. v o L U Volume Pulse submenu (number of pulses per cl). -

Page 102

Maintenance Modes WWC T1 Set Up & Maintenance Manual Kernel versions 01.12 – 01.16 Display Explanations/comments o c b OCB menu. Press 8 to enter OCB menu. Traffic Lights menu. L I G H t S Default 0 is flashing. Press 9 to change value to:-… -

Page 103

WWC T1 Set Up & Maintenance Manual Maintenance Modes Kernel versions 01.08 – 01.11 Display Explanations/comments o c b OCB menu. Press 8 to enter OCB menu. Traffic Lights menu. L I G H t S Default 0 is flashing. Press 9 to change value to:-… -

Page 104

Maintenance Modes WWC T1 Set Up & Maintenance Manual Kernel versions <= 01.07 Display Explanations/comments o c b OCB menu. Press 8 to enter OCB menu. t r A F F Traffic Lights menu (dispenser status — green = on) L I G H t Default 0 is flashing. -

Page 105: Nozzle Sensor Definition

WWC T1 Set Up & Maintenance Manual Maintenance Modes 6.32 Nozzle Sensor Definition This menu allows sensor numbers to be changed in order to match the pre-installed sensors with the correct functions. e.g. For replacing of a faulty sensor with a new one with a different address.

-

Page 106

Maintenance Modes WWC T1 Set Up & Maintenance Manual Display Explanations/comments S E n S o r Sensor Activate submenu. t E S t The current activated sensor will be displayed with its function as described above. Press 7 to go to next submenu (Change Sensor). -

Page 107

WWC T1 Set Up & Maintenance Manual Maintenance Modes Display Explanations/comments Press 8 to enter this submenu. Press 0 to return to nbus menu. Press 7 to skip and go to next menu (Program Sensor). E r A S E All connected sensors are erased. -

Page 108: Kernel Version >= 02.12

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.32.3 KERNEL VERSION >= 02.12 Display Explanations/comments n b b Nozzle Sensor Definition menu. Press 8 to enter this menu. d I S P L Display Sensor submenu. S E n S o r All installed sensors are displayed with their specific functions.

-

Page 109

WWC T1 Set Up & Maintenance Manual Maintenance Modes Display Explanations/comments S E n Store changes setting. Press 9 to toggle between yes (store changes) and no (exit without storing changes). Y E S Press 0 to save and continue. -

Page 110: Kernel Version < 02.12

Maintenance Modes WWC T1 Set Up & Maintenance Manual 6.32.4 KERNEL VERSION < 02.12 Display Explanations/comments n b b Nozzle Sensor Definition menu. Press 8 to enter this menu. o L d Replace old sensor number with new sensor number.

-

Page 111

WWC T1 Set Up & Maintenance Manual Application Mode CONTENTS APPLICATION MODE ………………..7-2 All Applications ………………..7-2 EPS ……………………7-3 IFSF ……………………7-4 ZSR ……………………7-5 Dunclare ………………….7-6 Tokheim ………………….7-7 Page 7-1 Document Ref 905675-001 Rev 2… -

Page 112: Application Mode

Application Mode WWC T1 Set Up & Maintenance Manual APPLICATION MODE All Applications Display Explanations/comments Press ON to enter Configuration. c o n F Press 3 to enter Application Mode. APPLIc is flashing. A P P L I c Press 7 to continue.

-

Page 113: Eps

WWC T1 Set Up & Maintenance Manual Application Mode Display Explanations/comments EPS 3 is flashing. E P S Press 9 to toggle between 3 and 5. Note : EPS 5 functionality will enable sending of EPS/5 messages to the k iosk ; send totals when connected to k iosk ;…

-

Page 114: Ifsf

Application Mode WWC T1 Set Up & Maintenance Manual IFSF Display Explanations/comments v o L L I Volume Limit menu (UK only). Press 9 to set the volume limit. Press 7 to save and continue. 8 8 8 8 8 8 Display Test menu (UK only).

-

Page 115: Zsr

WWC T1 Set Up & Maintenance Manual Application Mode Display Explanations/comments d o S DOS Task Interface Timing menu. t I m Note : SC30 specific timing delays are excluded and the release process made quick er. Default no is flashing. Press 9 to to ggle to yes (select DOS/ Schenk interface).

-

Page 116: Dunclare

Application Mode WWC T1 Set Up & Maintenance Manual Dunclare Display Explanations/comments v o L L I Volume Limit menu. 0 1 0 0 0 0 Default 1000 is flashing. Press 9 to change the value. Press 8 to change another digit.

-

Page 117: Tokheim

WWC T1 Set Up & Maintenance Manual Application Mode Tokheim Display Explanations/comments Delivery Volume x10 menu. v o L — 1 0 For use with old MEMs systems in order to shift the incoming and outgoing delivery volumes. Press 9 to toggle between yes (enable) and no (disable).

-

Page 118

Application Mode WWC T1 Set Up & Maintenance Manual This page is intentionally blank Page 7-8 Document Ref 905675-001 Rev 2… -

Page 119

WWC T1 Set Up & Maintenance Manual PIN Codes CONTENTS PIN CODES ……………………8-2 First PIN code ………………….8-2 Change PIN code ………………..8-3 Page 8-1 Document Ref 905675-001 Rev 2… -

Page 120: Pin Codes

PIN Codes WWC T1 Set Up & Maintenance Manual PIN CODES The PIN Code functionality is equal to Coca 1.1 with the following exceptions:- • The Station Manager PIN code is replaced by a keylock (local regulation). • With the Calculator Housing CLOSED, the Station Manager PIN code allows read-only access.

-

Page 121: Change Pin Code

WWC T1 Set Up & Maintenance Manual PIN Codes Change PIN code Display Explanations/comments X X X X X X All displays show X . X X X X X X X X X X Select ON c o n F Configure PIN code menu.

-

Page 122

PIN Codes WWC T1 Set Up & Maintenance Manual Display Explanations/comments E E P r o Memory Store menu. S t o r E Press 9 to toggle yes (save) and no (exit without save). Y E S Press 7 to continue. -

Page 123

WWC T1 Set Up & Maintenance Manual Totals CONTENTS TOTALS ……………………. 9-2 Reading the Totals (Amount, Volume & Number of Deliveries) ……. 9-2 Page 9-1 Document Ref 905675-001 Rev 2… -

Page 124: Totals

Totals WWC T1 Set Up & Maintenance Manual TOTALS Reading the Totals (Amount, Volume & Number of Deliveries) In the Read Totals menu, the total amount, total volume and total number of deliveries per product are displayed by lifting the relevant nozzle. It is also possible to see the total volume per volume meter and the total volume per nozzle.

-

Page 125

WWC T1 Set Up & Maintenance Manual Totals Display Explanations/comments At the Unit Price line, the t nr (total number of deliveries) and p 1 (product 1) are flashing. Replace the nozzle to continue reading the totals. Press 0 to return to Totals menu. -

Page 126

Totals WWC T1 Set Up & Maintenance Manual Display Explanations/comments — — — — — — The display will return to dashes. — — — — — — Lift a nozzle to read the sub-totals for that product. — — — — Press 0 to return to Sub-Totals menu. -

Page 127

WWC T1 Set Up & Maintenance Manual Totals Display Explanations/comments d I S P Dispenser Totals menu. t o t A L Press 7 to select another type of total. Press 0 to return to CONF menu. Press 8 to enter this menu. -

Page 128

Totals WWC T1 Set Up & Maintenance Manual Display Explanations/comments Total amount of false flow for prod 2 on right side (side A) is 1 2 3 4 displayed. r 2 A u Press 7 for the next hose. Press 8 to go to total volume for this hose. -

Page 129

WWC T1 Set Up & Maintenance Manual Unit Prices CONTENTS UNIT PRICES ………………….10-2 10.1 Set/Change Unit Prices ………………10-2 Page 10-1 Document Ref 905675-001 Rev 2… -

Page 130: Unit Prices

Unit Prices WWC T1 Set Up & Maintenance Manual UNIT PRICES Functionality equal to Coca 1.1. 10.1 Set/Change Unit Prices Display Explanations/comments X X X X X X All displays show X . X X X X X X X X X X Select ON .

-

Page 131

WWC T1 Set Up & Maintenance Manual Unit Prices Display Explanations/comments P r o d Enter Unit Price for Product 1 on the left side (side B):- L E F t Repeat for each product on the left side (side B) up to max of X X X X 6 fuel grades. -

Page 132

Unit Prices WWC T1 Set Up & Maintenance Manual This page is intentionally blank Page 10-4 Document Ref 905675-001 Rev 2… -

Page 133: Inspection Functions

WWC T1 Set Up & Maintenance Manual Inspection Functions CONTENTS INSPECTION FUNCTIONS ………………11-2 11.1 Inspection Function Overview …………….11-2 11.2 General ………………….. 11-3 11.3 Delivery Mode ………………..11-3 11.4 Traffic Lights ………………… 11-3 11.5 Idle Display Control ………………. 11-3 11.6…

-

Page 134: Inspection Function Overview

INSPECTION FUNCTIONS Functionality equal to Coca 1.1 with the exception of the version numbers menu. 11.1 Inspection Function Overview K ER3 — Kienzle ER3, K S&B — Kienzle S&B Function IFSF M3000 Dres K ER3 K S&B Kernel Delivery Mode Traffic Light <…

-

Page 135: General

WWC T1 Set Up & Maintenance Manual Inspection Functions 11.2 General In the Inspection Functions menu, the parameters for certain functions have default values or are disabled. Applications can overrule the default settings — refer to the appropriate Release Notes for further information.

-

Page 136: Release Management

Inspection Functions WWC T1 Set Up & Maintenance Manual 11.7 Release Management Release a dispenser for the next filling:- r E L E A r E L E A S E L c t S E L c t 0 = Release via system only — no manual release possible…

-

Page 137: 11.11 Maximum Time A Filling Can Be Suspended

WWC T1 Set Up & Maintenance Manual Inspection Functions 11.11 Maximum Time a Filling can be Suspended Within this set time, a filling must be started (released via Payment Terminal) or continued at a slave/satellite dispenser. If this time is exceeded, the filling is ended and the dispenser must be released before it can be used again.

-

Page 138

Inspection Functions WWC T1 Set Up & Maintenance Manual Display Explanations/comments 8 8 8 8 8 8 All displays show 8 . 8 8 8 8 8 8 The calculator is checking for connected peripherals. 8 8 8 8 Press 7 to go to next peripheral. -

Page 139

WWC T1 Set Up & Maintenance Manual Inspection Functions Display Explanations/comments The UAM software version is displayed. Press 0 to return to Software Version menu. 0 1 0 2 Press 7 to go to next peripheral. The HOM X software version is displayed (X = 1,2,3,4). -

Page 140: 11.15 Pulser Hide

Inspection Functions WWC T1 Set Up & Maintenance Manual 11.15 Pulser Hide If the Pulser Hide function is activated, the first X pulses dispensed do not appear on the display i.e. the display remains 0. When next pulse (X+1) is received, the display will show the total (X+1).

-

Page 141: Appendix

WWC T1 Set Up & Maintenance Manual Appendix CONTENTS APPENDIX ……………………12-2 12.1 Appendix A — Product Option Matrix …………… 12-2 12.2 Appendix B — Country Codes …………….12-4 12.3 Appendix C — Error Codes …………….12-6 12.3.1 Startup Error Situations …………..12-6 12.3.2…

-

Page 142: Appendix A — Product Option Matrix

APPENDIX 12.1 Appendix A — Product Option Matrix K ER3 — Kienzle ER3, K S&B — Kienzle S&B Option description IFSF M3000 Dres K ER3 K S&B Application dependent Blender Combined Hose Manual release Car Detection X (CH) Voice synthesizer (SOM) Programming Switch (writing data with remote if head open) Indication light (red or white)

-

Page 143

Issue B Option description IFSF M3000 Dres K ER3 K S&B MPD with sat hose (80 or 130) on 1 side Satellite connection 80 l/min Satellite connection 130 l/min Continuous filling button for satellite 130 l/min as single product on 1 side (MPD) Oil mixer Unit price display… -

Page 144: Appendix B — Country Codes

Appendix WWC T1 Set Up & Maintenance Manual 12.2 Appendix B — Country Codes Key:- In USA the pulser resolution is 0,0005 Gallons. Therefore these values are expressed in this unit. Comma Position , The position of the comma on the displays for amount/volume/unit price is counted from the RIGHT side.

-

Page 145

WWC T1 Set Up & Maintenance Manual Appendix Hose Expansion Position in Rounding Pulse Hide Code Country Euro Software time/value Type One Meter Two Meters 0001 2/3/3 Fixed: 30/21(*) 5(*) 5(*) 0007 Russia 2/2/2 Fixed: 30/8 0020 Egypt 2/2/2 Fixed: 30/8… -

Page 146: Appendix C — Error Codes

Appendix WWC T1 Set Up & Maintenance Manual 12.3 Appendix C — Error Codes 12.3.1 STARTUP ERROR SITUATIONS “LRC ERROR” flashing on display The system will not start. EPROM has been patched or is invalid and must be replaced. Calculator does not start and “CAM251_RUN_LED” is flashing on display RAM error — exchange the Mainboard.

-

Page 147: Diagnostic Database

WWC T1 Set Up & Maintenance Manual Appendix LIST OF PERIPHERAL TYPES Component indication Application Kernel Customer Sales display Sound Option Module User Access Module Option Controller Board Subcategory of peripheral HCM 0 General HCM error e.g. totaliser, dispenser light, high speed valve…

-

Page 148

Appendix WWC T1 Set Up & Maintenance Manual HCM/HOM ERRORS Main event code Sub event code 1 DIPNET DRIVER ERROR 1 MAX NR OF REQUESTS (HM DRIVER MAIN) 2 DIPNET TIMEOUT 3 DIPNET ERROR 4 STATE TRANSITION ERROR 2 GENERAL HCM/HOM ERROR… -

Page 149

WWC T1 Set Up & Maintenance Manual Appendix CUSTOMER SALES DISPLAY ERRORS Main event code Sub event code 1 COMMUNICATION LOST SOUND OPTION MODULE ERRORS Main event code Sub event code 1 GENERAL ERROR USER ACCESS MODULE ERRORS Main event code… -

Page 150: Appendix D — Jumper Positions

Appendix WWC T1 Set Up & Maintenance Manual 12.4 Appendix D — Jumper Positions 12.4.1 MAINBOARD For the latest board revisions, please refer to the appropriate Product Specification Sheet. Bus to/from I/O Nozzles & Buttons from Nozzles & Pulsers Board X117…

-

Page 151: Vrc Board

WWC T1 Set Up & Maintenance Manual Appendix 12.4.2 VRC BOARD Valve Left DIPNET Valve Right EPM7064 28F010 OL / CL 80C251 CL type Motor Left Motor Right ERROR LED’s ERZ barrier Right-product 3 Left-product 1 Left-product 2 Right-product 2…

-

Page 152: User Access Module

Appendix WWC T1 Set Up & Maintenance Manual 12.4.3 USER ACCESS MODULE ECVR METER 87C52 DIPNET sensor keyboard 87C52 DIPNET sensor LED’s: • LED_1 (H4 = RED) Normal operation • LED_2 (H5 = GREEN) Key activated Jumpers: • IR remote sensor for IR remote control •…

-

Page 153: Ocb Board

WWC T1 Set Up & Maintenance Manual Appendix 12.4.4 OCB BOARD UPD_L UPD_R DIPNET KEY_L W202 KEY_R W201 OUT_SPARE OUT_YELLOW OUT_RED OUT_GREEN 87C52 POWER LCD_L W501 OPTO_INPUT H201 GROUND AMOUNT_2 H202 AMOUNT_1 LCD_R VOLUME_2 VOLUME_1 W502 POWER LED’s: •LED_1 (H201 = YELLOW) Normal operation •…

-

Page 154: I/O Extension Board (Ieb)

Appendix WWC T1 Set Up & Maintenance Manual 12.4.5 I/O EXTENSION BOARD (IEB) • W300 OFF Preset Keypad • W300 ON Preset Buttons • W301 Not used • W302 Not used 12.4.6 HYDRAULIC OPTION MODULE (HOM) W201 Not used W202…

-

Page 155: Appendix E — General Purpose Inputs

WWC T1 Set Up & Maintenance Manual Appendix 12.5 Appendix E — General Purpose Inputs Application GPI 1 GPI 2 GPI 3 GPI 4 IFSF enable standalone switch configuration read only tank level input left tank level input right configuration read only…

-

Page 156: Appendix F- Ieb General Purpose Outputs

Appendix WWC T1 Set Up & Maintenance Manual 12.6 Appendix F- IEB General Purpose Outputs The functions in the table below are the application controlled functions. GPO menu parameter = 1 (refer to section 6.29.1) Application GPO 1 GPO 2…

-

Page 157

WWC T1 Set Up & Maintenance Manual This page is intentionally blank Document Ref 905675-001 Rev 2… -

Page 158

1762 Givisiez +49 (0) 89 189 533 99 +41 (0)26 460 51 11 service@muenchen.tokheim.com +41 (0)26 460 51 12 As Tokheim regularly improves its prod- user@givisiez.tokheim.com ucts to ever better respond to evolving market and regulatory requirements, it Italy United Kingdom reserves the right to change any of the Tokheim Sofitam Italia S.r.l.

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

WWC T1

Calculator

Set Up & Maintenance

Manual

Document Ref 905675-001

Rev — 2

01/2006

Related Manuals for Tokheim WWC T1

Summary of Contents for Tokheim WWC T1

-

Page 1

WWC T1 Calculator Set Up & Maintenance Manual Document Ref 905675-001 Rev — 2 01/2006… -

Page 2: Document Ref

Tokheim shall not be liable for damage to the product, nor for personal or third party injury, caused by incorrect use of the product or by attempts to maintain or to repair the product by parties other than those fully trained by Tokheim or by its accredited third party representatives.

-

Page 3

WWC T1 Set Up & Maintenance Manual Revision Record REVISION RECORD Date Revision Page Issue Reason 01/07/2004 Original Issue 19/01/2006 3 to 6 Main Contents revised 19/01/2006 2-16,2-17 Updated Functionalities 19/01/2006 2-21 to 2-23 New info added (Input Type, Master PIN Code, Gallon Type, Cent Overshoot Hide, 4 position product indicator, Heavy Lei);… -

Page 4

Revision Record WWC T1 Set Up & Maintenance Manual This page is intentionally blank Document Ref 905675-001 Rev 2… -

Page 5: Table Of Contents

WWC T1 Set Up & Maintenance Manual Contents CONTENTS INTRODUCTION ………………….1-2 How to Use this Manual ………………1-2 Product Scope ………………… 1-3 Authorised Technicians ………………1-3 Contact Information ……………….. 1-3 Health & Safety ………………..1-3 1.5.1 Safety Checklist ……………… 1-3 1.5.2…

-

Page 6

Contents WWC T1 Set Up & Maintenance Manual LPG SET UP / Timing with Deadmans Button only & Motor Off Delay ≠ ≠ ≠ ≠ ≠ 0 …. 3-7 3.3.3 3.3.4 Timing with Deadmans Button only & Motor Off Delay = 0 …. 3-7 SERVICE KEYPAD …………………. -

Page 7

WWC T1 Set Up & Maintenance Manual Contents MAINTENANCE MODE / 6.20 Node Address ………………..6-18 6.21 Test Delivery ………………… 6-19 6.22 Emergency Manual Pumping Device (EMPD) ……….6-21 6.23 Product Relation ………………..6-21 6.23.1 Product Name by Character Input ………… 6-22 6.23.2… -

Page 8

Contents WWC T1 Set Up & Maintenance Manual INSPECTION FUNCTIONS / 11.7 Release Management ………………11-4 11.8 Maximum Time for a Filling …………….11-4 11.9 Time Between Two Fillings …………….11-4 11.10 Maximum Time of No Flow …………….11-4 11.11 Maximum Time a Filling can be Suspended …………. 11-5 11.12 Timer for Display TImeout ……………. -

Page 9

WWC T1 Set Up & Maintenance Manual Introduction CONTENTS INTRODUCTION ………………….1-2 How to Use this Manual ………………1-2 Product Scope …………………. 1-3 Authorised Technicians ………………1-3 Contact Information ………………… 1-3 Health & Safety ………………..1-3 1.5.1 Safety Checklist ………………. 1-3 1.5.2… -

Page 10: Introduction

Section 2 — Product Information This section contains the system description and operating principles of the WWC T1 Calculator. It also describes the main components, their configurations and functions including the service keypads.

-

Page 11: Product Scope

WWC T1 Set Up & Maintenance Manual Introduction Product Scope This manual is designed to cover the Quantium T range of dispensers including LPG. As functionality is equivalent to the Coca 1.1 functionality, reference is frequently made to the existing Coca Manuals.

-

Page 12: Duties Of The Employees

Introduction WWC T1 Set Up & Maintenance Manual 1.5.2 DUTIES OF THE EMPLOYEES • To ensure optimal accident prevention in our company, in addition to general rules applying to worker’s protection, it is necessary to take into account all the national protection of workers legislation and to actively support all measures which enhance safety standards.

-

Page 13: Warning Signs

WWC T1 Set Up & Maintenance Manual Introduction At unattended service stations, every end-user should be able to read the User Instructions. They should be visible on a notice board or integrated into the DIT and should be sufficiently well lit so that they can be read at night.

-

Page 14: Personal Protective Equipment (Ppe)

Introduction WWC T1 Set Up & Maintenance Manual 1.5.5 PERSONAL PROTECTIVE EQUIPMENT (PPE) PROTECTIVE CLOTHING The following clothing should be worn at all times during installation and maintenance procedures:- • Protective helmet. • Protective shoes (conductive). • Protective gloves and/or protective hand cream.

-

Page 15: Nomenclature

WWC T1 Set Up & Maintenance Manual Introduction Nomenclature The various abbreviations used in thie manual are described as follows:- CoCa Today’s Common Calculator and base of the WWC CSD-F Common Sales Display — Ferranti CSD-L Common Sales Display — LCD…

-

Page 16

Introduction WWC T1 Set Up & Maintenance Manual This page is intentionally blank Page 1-8 Document Ref 905675-001 Rev 2… -

Page 17

WWC T1 Set Up & Maintenance Manual Product Information CONTENTS PRODUCT INFORMATION ………………2-2 System Description ………………..2-2 2.1.1 Operating Principles…………….2-2 Main Components of the WWC …………….2-2 2.2.1 External Power Supply ……………. 2-3 2.2.2 Mainboard ……………….. 2-3 2.2.3 I/O Board (version 3++) ………….. -

Page 18: Product Information

The WWC (World Wide Calculator) is a ‘measuring system’ built to conform to the international recommendations specified in the document OIML R117 Edition 1995. The WWC is also a peripheral within the different Tokheim filling station systems. As such, the WWC software and hardware can be configured without modifying the characteristics of the measuring system.

-

Page 19: External Power Supply

WWC T1 Set Up & Maintenance Manual Product Information ARCHITECTURAL OVERVIEW Valves, motors and sensors Displays CSD-L CSD-L CSD-F CSD-F Communication Mains Calculator Module Interfaces Battery I/O extensions Mainboard MB251 Nozzle Bus Dispenser light, Interface Electr totaliser Dipnet Low End Hydraulic…

-

Page 20: I/O Board (Version 3++)

Product Information WWC T1 Set Up & Maintenance Manual Since the release of Version 3 of the mainboard, the NBB board has been eliminated and the serial nozzle bus is directly controlled by the mainboard. Two optional modules can be directly connected to the mainboard (piggy-back):- •…

-

Page 21: Standard Dispensers With Up To Four Single Products

WWC T1 Set Up & Maintenance Manual Product Information 2.3.1 STANDARD DISPENSERS WITH UP TO FOUR SINGLE PRODUCTS Valves, motors and sensors Displays CSD-L CSD-L CSD-F CSD-F Communication Mains Calculator Module Interfaces Battery I/O extensions Mainboard MB251 Nozzle Bus Dispenser light,…

-

Page 22: Vapour Recovery Controller Board (Vrc)

Product Information WWC T1 Set Up & Maintenance Manual 2.3.3 VAPOUR RECOVERY CONTROLLER BOARD (VRC) The VRC is an independent module which communicates with the calculator module. After the VRC is initialised at each delivery start, it performs the open or closed loop vapour recovery process by controlling its own motors and valves.

-

Page 23: Functionalities Per Hose

WWC T1 Set Up & Maintenance Manual Product Information 2.5.1 FUNCTIONALITIES PER HOSE 40 (45) litres per minute — Petrol or Diesel Standard speed flow rate is achieved using one pump and one meter. 40 (45) litres per minute for two filling positions — Petrol or Diesel Standard speed flow rate is achieved using one pump and two meters.

-

Page 24

Product Information WWC T1 Set Up & Maintenance Manual The choice is made by push button selection with product indication. There are two principles:- • 2 grades in, 3 grades out, 2 hoses • 2 grades in, 3 grades out, 1 hose Refer to section 6.18 for programming information. -

Page 25

WWC T1 Set Up & Maintenance Manual Product Information If detected, the leak error is forwarded to the system and will immediately block the complete dispenser. The calculator keeps track of the leak status. Parameter: — hose expansion volume :… -

Page 26: Functionalities Per Side

Product Information WWC T1 Set Up & Maintenance Manual If the nozzle is replaced with volume = 0 before the time out expires, the leak sequence counter is neither incremented nor reset i.e. this will not increase the volume lost if it is a real leak.

-

Page 27

WWC T1 Set Up & Maintenance Manual Product Information Push Button Methods — Push buttons connected to the sensor bus or direct connections — Push buttons connected to the IEB Up to four buttons (three amount or volume and one reset button) are available and can be connected to the sensor bus, direct connections or via IEB at each filling position. -

Page 28

Product Information WWC T1 Set Up & Maintenance Manual Keypad Methods — Keypad connected to the IEB — Keypad connected to the OCB preset clear CREDIT preset amount preset CASH volume When Local Preset is connected using a keypad method, a 4×4 keypad is available at each filling position to allow the entry of a preset amount or preset volume. -

Page 29

WWC T1 Set Up & Maintenance Manual Product Information displays last delivery filling is cashed and the volume and amount display show “0” filling is cashed and all displays show “0” 3 to 9 reserved for future implementations Satellite Nozzle Control Menu A high speed diesel dispenser can have a satellite nozzle on each side. -

Page 30

Product Information WWC T1 Set Up & Maintenance Manual Parameters:- • function is disabled 0000 • max. time 0959 (= 9 minutes and 59 seconds) • default value 0100 (certain applications may overrule this) Time Between Two Fillings Menu (Inter delivery time out) This is the minimum time to elapse between two successive fillings. -

Page 31

WWC T1 Set Up & Maintenance Manual Product Information Note: The request to program EMT positions for left-hand dispensers (PMR297) means that the EMT connector must always be used for 4/5 products on the Optional Peripheral Board (OPB). OCB Functionality When an OCB board is connected, the following functions can be selected:- •… -

Page 32: Functionalities Per Dispenser

Product Information WWC T1 Set Up & Maintenance Manual — volume unit (number of cl/pulse) 1 to 10 (default = 1) — volume period (value * 0.25 ms) 5 to 40 (default = 5) — amount unit (number of units/pulse currency unit)

-

Page 33

WWC T1 Set Up & Maintenance Manual Product Information Kernel Hydr Additional No of Sided Flow Rates/Products Drawing No Version Setup No Description Products 130 l/min/SAT and 4×40 l/min 5 right 9235110584 (right); > 01.09 Asymmetric 4 left 4 x 40 l/min (left) -

Page 34

Product Information WWC T1 Set Up & Maintenance Manual Backlight for LCD The backlight is standard with LCD displays. Switch Dispenser Lighting If defined in the application, the switch for the dispenser or calculator lighting is via a command from the forecourt controller system. -

Page 35

WWC T1 Set Up & Maintenance Manual Product Information Node Address Menu This function is required for multi drop communication links (e.g. IFSF) to select the address of the calculator on the network. Refer to section 6.20 for programming information. -

Page 36

Product Information WWC T1 Set Up & Maintenance Manual Kernel version >= 02.xx Option Controller Board Hydraulic Controller Module CS1R CSD 1 Right CS2R CSD 2 Right CS1L CSD 1 Left CS2L CSD 2 Left Sound Option Module VRC Module… -

Page 37: Weights & Measures Related Functionality

WWC T1 Set Up & Maintenance Manual Product Information Nozzle Input Type This function allows the selection between two different types of nozzle input:- • Value “no” — normal nozzle switch position i.e. always OPEN in idle and CLOSED when nozzle lifted — for all dispensers except Q500T1.

-

Page 38

Product Information WWC T1 Set Up & Maintenance Manual Pulser Test Time Before starting a delivery, the pulser is tested during a specified ‘pulser test time’. During this test, the valves remain closed and the pulser is checked on consistent high/low values of both channels and there should be no pulses generated during this period. -

Page 39

WWC T1 Set Up & Maintenance Manual Product Information Note : For European Community countries, selection of the Euro is only possible up to kernel version 03.12. In later kernel versions, the Euro selection is fixed. Heavy Lei This function is designed to enable the conversion to Heavy Lei currency in Romania by simple (software) switch. -

Page 40

Product Information WWC T1 Set Up & Maintenance Manual Two EMT options are available for selection following a cold start:- • Value “d” = double-sided EMT (each nozzle of a product has an individual EMT total) • Value “s” = single-sided EMT (the left and right totals of the same product are… -

Page 41

WWC T1 Set Up & Maintenance Manual LPG Set Up CONTENTS LPG SET UP ……………………3-2 LPG Functionality ………………..3-2 3.1.1 LPG Pulse Menu …………….. 3-2 3.1.2 LPG Nozzle Flag Menu …………… 3-2 3.1.3 LPG Delay Timer Menu …………..3-3 3.1.4… -

Page 42: Lpg Set Up

LPG Set Up WWC T1 Set Up & Maintenance Manual LPG SET UP This section will cover the the hydraulic situation and the functional operation for LPG dispensers:- • LPG Functionality (refer to section 3.1) • LPG Hydraulic Functions (refer to section 3.2) •…

-

Page 43: Lpg Delay Timer Menu

WWC T1 Set Up & Maintenance Manual LPG Set Up • N = No nozzle switch present. The dispenser is activated by pressing the Deadmans Button. A delay timer is fitted (refer to section 3.1.3) to allow the customer to temporarily release the Deadmans Button without ending the delivery.

-

Page 44: Lpg Hydraulic Functions

LPG Set Up WWC T1 Set Up & Maintenance Manual LPG Hydraulic Functions In the LPG Hydraulic section, the basic flow is regulated by a valve in the liquid line, positioned before the break-away coupling and hose. For additional safety, the Hydraulic Chair option is available. The Chair hydraulic block may contain additional valves in the liquid line and vapour return line.

-

Page 45: Hydraulic Schematic

WWC T1 Set Up & Maintenance Manual LPG Set Up 3.2.2 HYDRAULIC SCHEMATIC RBU1 RNO1 RSV1 CHAIR RRV1 vapour liquid liquid WWC SET vapour LSV1 CHAIR LRV1 LNO1 LBU1 Note : The Hydraulic Chair block is an option. Where applicable, the additional valve in the vapour line (V…

-

Page 46: Functionality With Nozzle Switch

LPG Set Up WWC T1 Set Up & Maintenance Manual Functionality with Nozzle Switch TIMING WITH NOZZLE SWITCH & MOTOR OFF DELAY ≠ ≠ ≠ ≠ ≠ 0 3.3.1 nozzle button motor valve Start LPG Delay (Deadmans No action button)

-

Page 47: Functionality Without Nozzle Switch

WWC T1 Set Up & Maintenance Manual LPG Set Up Functionality without Nozzle Switch TIMING WITH DEADMANS BUTTON ONLY & MOTOR OFF DELAY ≠ ≠ ≠ ≠ ≠ 0 3.4.1 button motor valve Start LPG Delay (Deadmans button) Terminate Motor Off…

-

Page 48

LPG Set Up WWC T1 Set Up & Maintenance Manual This page is intentionally blank Page 3-8 Document Ref 905675-001 Rev 2… -

Page 49

WWC T1 Set Up & Maintenance Manual Set Up Modes CONTENTS SERVICE KEYPAD ………………… 4-2 User Access Keypad (UAK) …………….4-2 Infra Red (IR) Remote Control Keypad ………….. 4-4 Internal Configuration Keypad …………….4-4 Page 4-1 Document Ref 905675-001 Rev 2… -

Page 50: Service Keypad

Set Up Modes WWC T1 Set Up & Maintenance Manual SERVICE KEYPAD There are three types of keypads used in conjunction with the WWC:- • User Access Keypad (standard) — refer to section 4.1 • Inra-Red Remote Control (equal to CoCa) — refer to section 4.2 •…

-

Page 51

WWC T1 Set Up & Maintenance Manual Set Up Modes Symbol Calculator Function VRC Function Set unit price Start calibration Show totals Parameters keyboarding Application Set up Cancel current operation Set pincode Enter password Maintenance Functions Start maintenance Inspection Functions… -

Page 52: Infra Red (Ir) Remote Control Keypad

Set Up Modes WWC T1 Set Up & Maintenance Manual Infra Red (IR) Remote Control Keypad The IR Remote Control is available as an option for Station Managers to access the management functions of the calculator. Note: The IR option incurs an additional cost and is not suitable for VRC configuration or calibration.

-

Page 53

WWC T1 Set Up & Maintenance Manual Set Up Modes CONTENTS SET UP MODE ………………….5-2 General …………………… 5-2 Start Ups ………………….5-2 5.2.1 Cold Start ……………….. 5-2 5.2.2 Warm Start ………………5-3 5.2.3 Service Start ………………5-3 Initial Set Up Menu ………………… 5-3 5.3.1… -

Page 54: Set Up Mode

Set Up Modes WWC T1 Set Up & Maintenance Manual SET UP MODE General The set up of the calculator is a set of procedures which initialise the system according to the requirements of the dispenser itself and also individual customer requests. There are two main sequences to be followed:- •…

-

Page 55: Warm Start

WWC T1 Set Up & Maintenance Manual Set Up Modes After the 7 key is pressed, the initial setup will be mandatory (see section 5.3). Note : Remember to insert the jumper W201 after start up. 5.2.2 WARM START When jumper W201 is ON and W202 is OFF, the calculator performs a normal start up and all data from previous sessions is restored.

-

Page 56: Set Up Function Overview

5.3.1 SET UP FUNCTION OVERVIEW Function Kernel IFSF M3000 Dres K ER3 K S&B Country code Euro (always visible) > 01.12 Euro (European countries only) > 02.06 Scaling > 02.11 Gallon (always visible) > 01.12 Gallon (except country 001) > 02.06 Gallon type (if Gallon = yes only) >…

-

Page 57: Set Up Menu

WWC T1 Set Up & Maintenance Manual Set Up Modes 5.3.2 SET UP MENU The Set Up menu is executed when:- • A cold start is performed • Errors are detected with the set up during a warm start or a service start…

-

Page 58

Set Up Modes WWC T1 Set Up & Maintenance Manual Display Explanations/comments G A L L o n Gallon menu. Default no is flashing. Press 9 to toggle to yes to change the volume measurement to gallons. Press 7 to save and continue. -

Page 59

WWC T1 Set Up & Maintenance Manual Set Up Modes Display Explanations/comments Satellite/Slave Display menu. d I S P L The option for satellite/slave displays per dispenser side is defined within the set up code. Set satellite/slave display for the right side (side A):- The right 1 is flashing. -

Page 60

Set Up Modes WWC T1 Set Up & Maintenance Manual Display Explanations/comments EMT menu. e n n t Default d is flashing (double-sided). Press 9 to toggle to s for sigle-sided. Press 7 to save and continue. Combined Hose Product Preselection menu. -

Page 61

WWC T1 Set Up & Maintenance Manual Set Up Modes Display Explanations/comments Cent Overshoot Hide menu. n n A S Set the masking type:- t Y P E Use 9 to toggle between 1 (xxxx,x0 [default]) and 2 (xxxx,00) Note : France only (country code 33) Press 7 to save and continue. -

Page 62: Afm Set Up Menu

Set Up Modes WWC T1 Set Up & Maintenance Manual AFM Set Up Menu Display Explanations/comments AFM Set Up menu. Press 7 to skip AFM set up — this will disable any AFMs. S e t U P If AFM is not set, any attempt to start a delivery will generate error message 4 3 (pulser not connected).

-

Page 63

WWC T1 Set Up & Maintenance Manual Set Up Modes Y IS BLANK (INVALID OR MISSING AFM ADDRESS) Display Explanations/comments If the AFM address is invalid or not detected, y is blank. H o S E Check the following:- L E F t… -

Page 64

Set Up Modes WWC T1 Set Up & Maintenance Manual Y IS VALID ADDRESS Display Explanations/comments AFM Address menu. H o S E A valid address is displayed i.e. y is within the range 1 to 12. r I G H t Each AFM must be programmed according to the following procedures. -