-

03-19-2014, 03:20 AM

#1

Registered

dear friends cnczone,

I have a problem with my machine cnc turning fanuc,

before lunch we used the machine no problem, We lunch and the machine turned off and after lunch appear operator message :

first = no 2057 Turret Clamp Error (A9.1)

and we try to change the tool, the turret only move just moment and stopped, in the display appear no 2018 Turret Run Alarm (A4.2),please help me, anyone know this problem ?

thank’s before.

Rudi, Batam Islands, Indonesia Country

-

03-19-2014, 01:32 PM

#2

Registered

You should write down all info concerning your machine. Anyways all corresponding valves and detectors should be checked, else maybe it needs reindexing, maybe the hydraulic/pneumatic pressure is wrong too.

-

03-20-2014, 02:06 AM

#3

Registered

ok thank you, I will try to checked the hydroulic system, some day ago the hydroulic pump any oil leak from side pump.

-

03-20-2014, 06:14 AM

#4

check the cable from the clamp/unclamp sensor ,this cable is staying in a non good position and in time this cable will break and the sensor will not work.

-

03-20-2014, 09:33 AM

#5

Registered

dear friends,

I checked hydroulic pressure,sensor,valve all ok,

but I checked the driver motor turret FANUC A06B-6132-H002 the batterai should 6v but only 2,3v,

the batterai any problem or still limit ok ?

-

03-20-2014, 01:49 PM

#6

Registered

Crystal clear that your battery is NOT ok, that you should replace it and that you will probably have to re-index your motor as well. Is your machine a Hyundai lathe or what brand is it?

-

03-21-2014, 03:16 AM

#7

Registered

our machine is «GOOD WAY», ok I try to change this battery

-

03-21-2014, 06:59 AM

#8

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

man do not do other things

trust me

go in the back of the machine were is the motor of x axes and there on the left you will see a snall white box with a wire in the plastic cover (i called copex cover)that cover has «U» form and because the x axis is going down and up houndreds of times ,the cable inside that cover is getting damage.

that small white wire that goes in the box is the sensor for turret clamp.

now the wire is broken and can not see turret clamp and that why is not turning the turret.in the diagnose the sensor is X3.0

must be 1 when turret is clamped.

i work everyday on goodway machines,we are dealers of GOODWAY so «go on my hand»there is a procedure to make turret reference

if you want that too just tell me.

after you finish with that if the tool no 1 is not coincident wit the number on the tool disc you have to reference the turret.

-

03-22-2014, 04:23 AM

#9

Registered

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

sir, I check the sensor turret ok and the turret in position. when we toolchange manual after press «tool» button shoul be turret move in front of and moving, but now condition after we press «tool» button, the turret move to in front of and go move back ( the motor turret not turn).

I try check other =

the servo amp. turret inside panel have 3 kinds alarm led indicator ( LED INDICATOR 4 LED GREEN ABOVE. AND 3 LED RED BELLOW)

(1). LED GREEN no 2 and 3, LED RED no 1

next

(2). LED GREEN no 4, LED RED no 1 and 3

next

(3). LED GREEN no 2, LED RED no 1 and 2

next back again to number (1)any problem with servo amp. turret ? or must be repair ?

-

03-24-2014, 06:17 AM

#10

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

you need to zero return you turret

give me an email adress and i will send you the procedure

-

03-24-2014, 10:20 AM

#11

Registered

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

this is my email : restuibu85@gmail.com

thank you so much before for your help.

-

03-25-2014, 05:46 AM

#12

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

email sent ,let me know if worked!

-

03-25-2014, 09:00 AM

#13

Registered

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

yes, succesfully. thank you so much.

Good luck always.!!

-

11-25-2014, 03:35 AM

#14

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

Can someone send me the reteach procedure for turret on Yama seiki? I replaced batteries but I do not have procedure.

-

11-27-2014, 12:05 PM

#15

Registered

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

Kindly send me too.

ahe_303@rediffmail.com

Originally Posted by zavateandu

you need to zero return you turret

give me an email adress and i will send you the procedure

-

04-08-2015, 03:18 PM

#16

Registered

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

send me please, my email ( aaagt78@gmail.com)

-

12-30-2015, 03:23 AM

#17

Junior Member

Re: #2057 Turret Clamp Error(A9.1) and #2018 Turret Run Alarm (A4.2)

Originally Posted by zavateandu

you need to zero return you turret

give me an email adress and i will send you the procedureDear sir,

May i request with you for turret procedure?

this is my email : sansgp@yahoo.com

Appreciate your help. thanks.

-

06-29-2018, 09:57 PM

#18

Junior Member

I have a yama Seiki gv1000 i can not find this box and wire.. I do see a set of small wires but just not sure if it’s what your describing

-

07-10-2018, 03:28 PM

#19

Junior Member

Can anybody please tell me how to rectify 2057 message in fanuc control cnc milling.

And also 1050, 1055 alarm. please send me procedure..

-

08-24-2018, 04:54 PM

#20

Junior Member

i need to zero return my turret

Would you mind sending me the procedure?

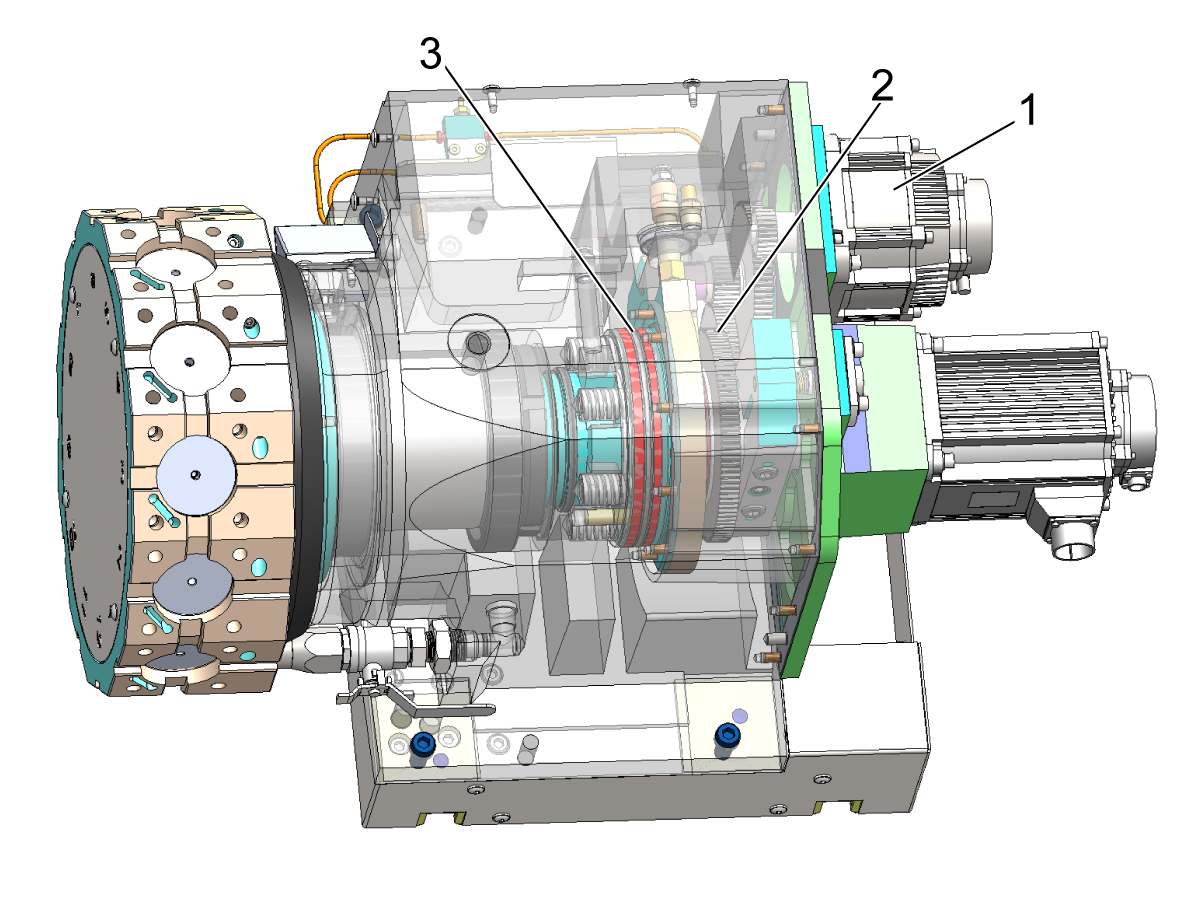

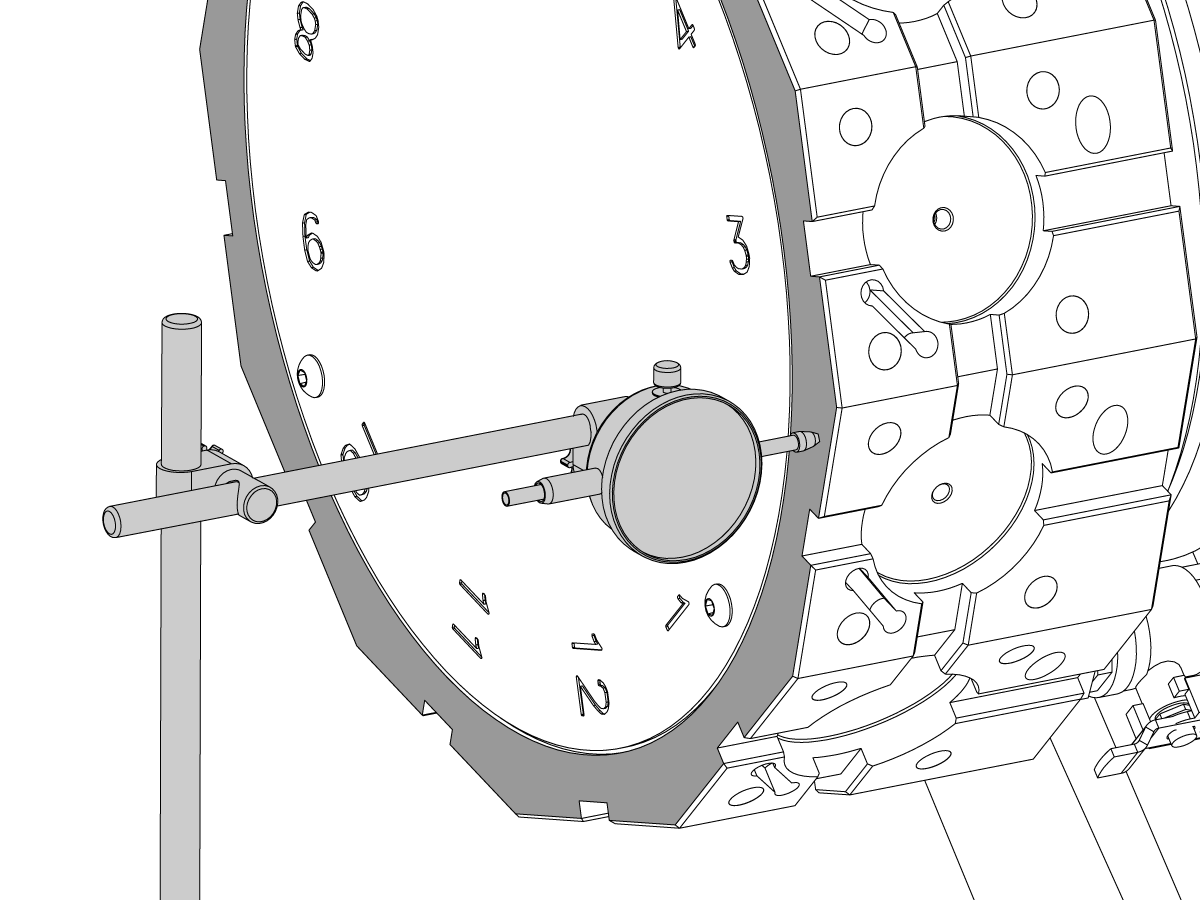

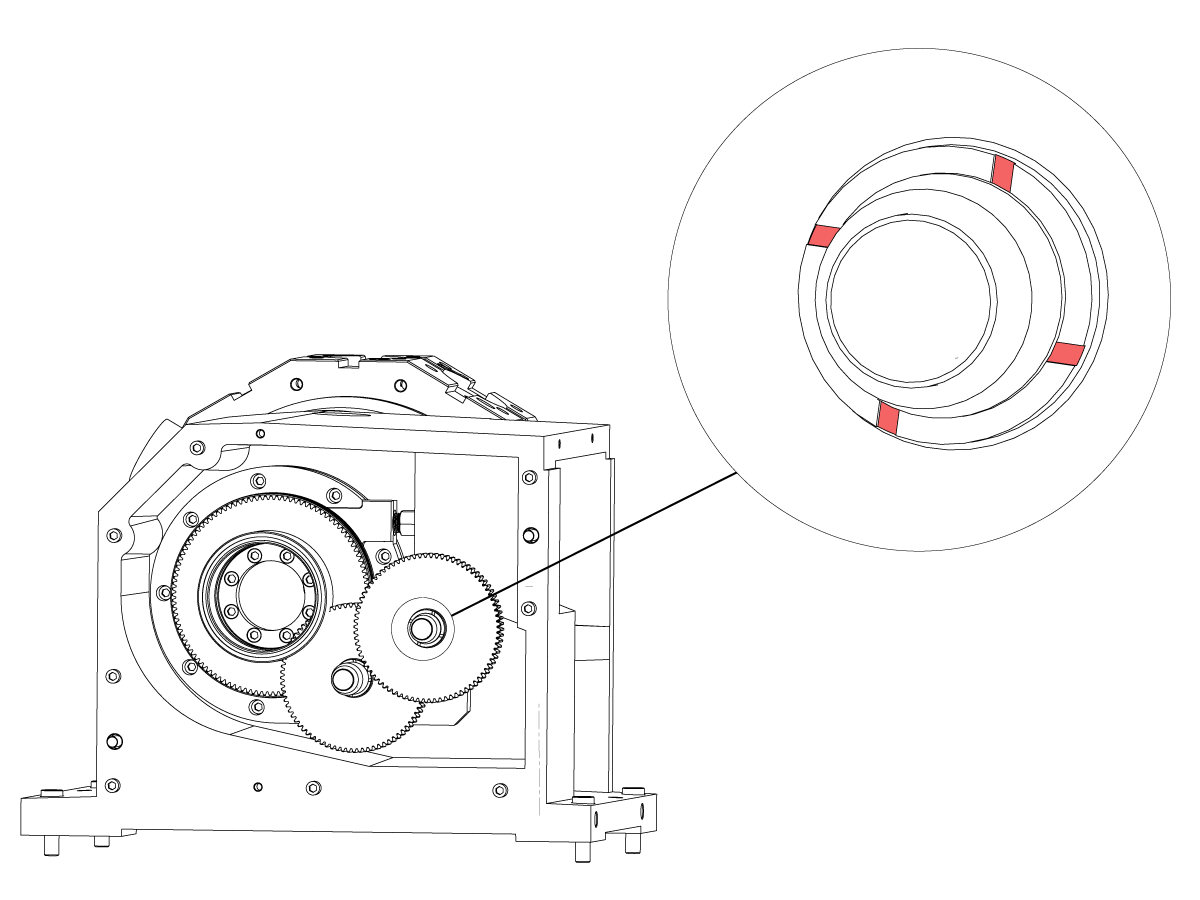

BMT — Turret Indexer Assembly — Troubleshooting Guide

Introduction

- Servo Motor

- Internal Gears

- Quad-Ring

- Turret Home Switch

- Turret Clamp/Unclamp Switch

Symptom Table

Incoming Air Supply

Make sure that the air compressor supplies the correct air pressure and air flow. For Haas machine air pressure specifications, go to New Machine Pre-Installation for your machine model. Select your machine and scroll to the the section labeled «Air/Coolant Requirements.»

Attempt a tool change on the machine. When the machine has the correct air pressure and flow, the needle on the air pressure gauge should not drop more than 10 PSI (0.70 bar) during a tool change. This test confirms that the air pressure and air flow into the machine are correct.

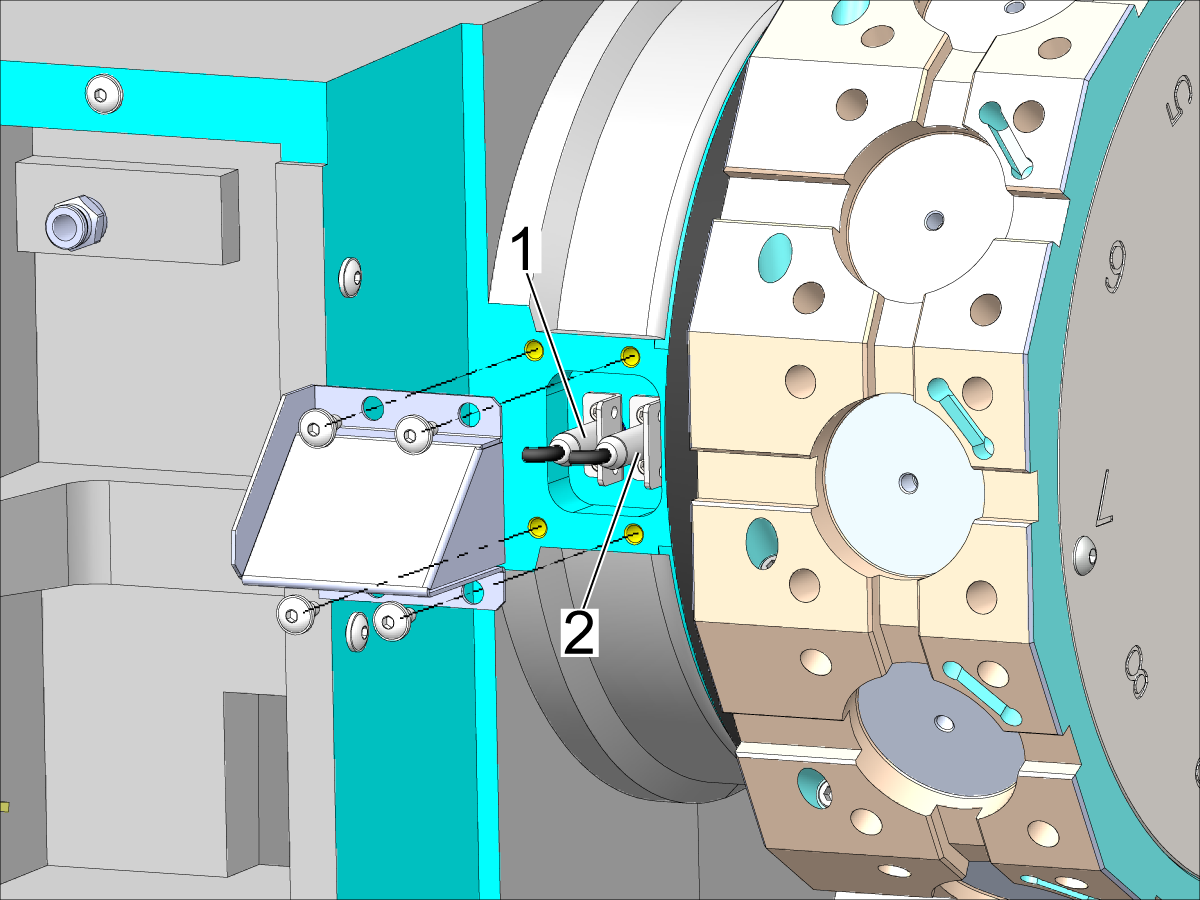

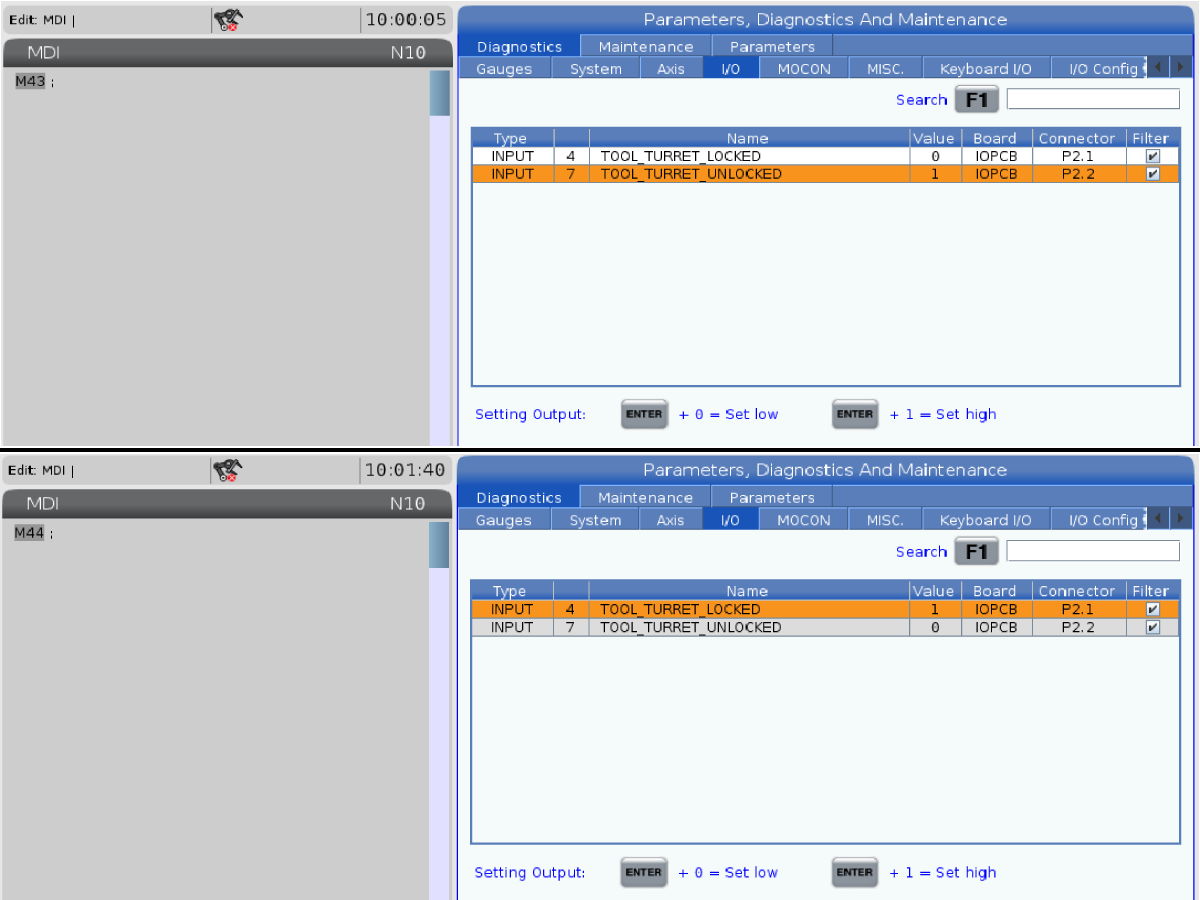

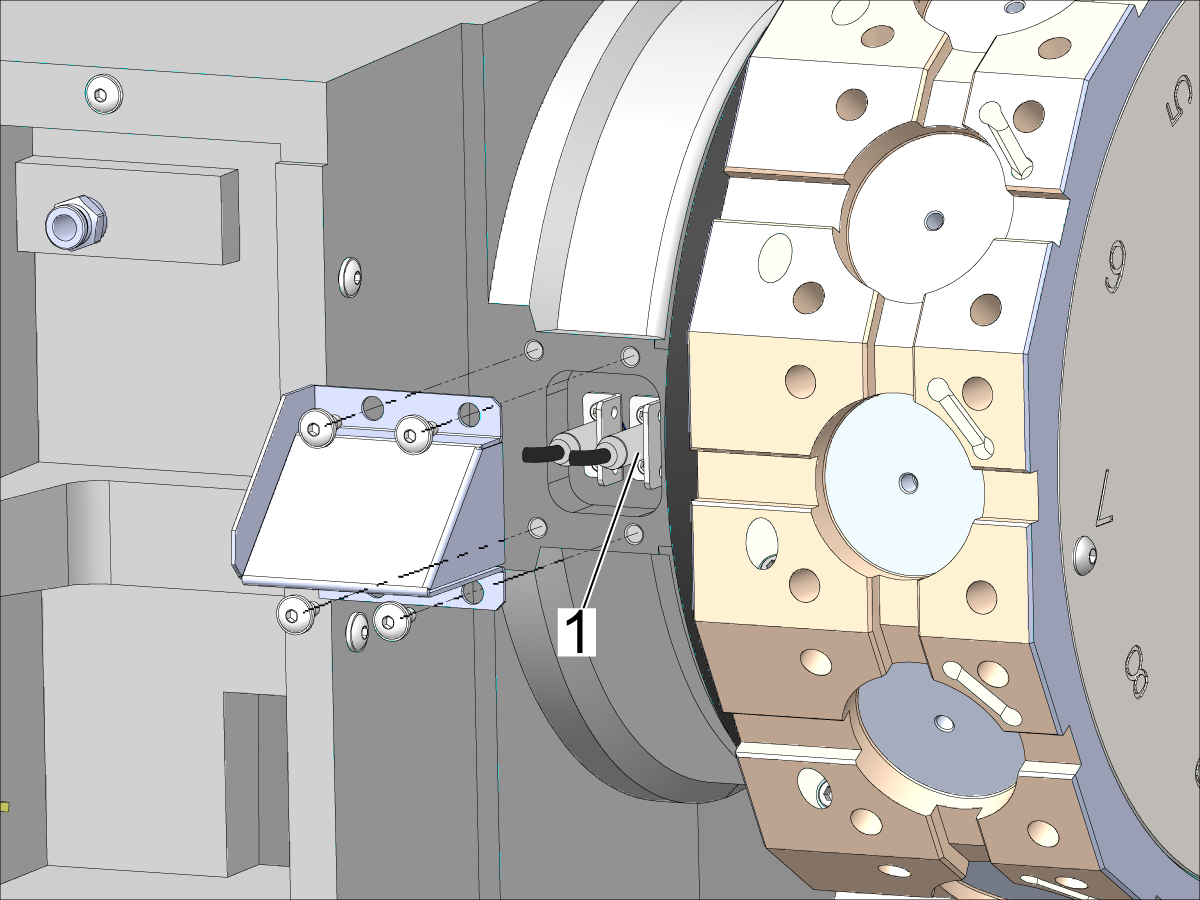

Clamp/Unclamp Proximity Sensor

Navigate to the Diagnostic screen on the pendant. Go to the I/O tab. Use an M43 (Unclamp) M44 (Clamp) code in MDI mode to troubleshoot the clamp/unclamp switch.

Check that Input 4 Tool Turret Locked and Input 7 Tool Turret Unlocked change states when the turret is commanded to unclamp/clamp.

Servo Motor

Corrective Action:

Disconnect the axis servo motor cables. Make sure they are not contaminated. Measure the resistance from the pins labeled A, B, and C at the motor power cable connector to chassis ground. The reading should show an open circuit. If there is resistance to ground, the cable is at fault.

Go to: Sigma 5 — Axis Servo Motor and Cables — Troubleshooting Guide to troubleshoot the SIGMA motor and SIGMA motor cables.

Turret Pop Out

If you commanded an M43 (Unclamp) and the turret moved, but did not move far enough to clear the coupler, measure the distance the turret traveled.

Set indicator to zero when turret unclamped M43. Command the turret to clamp M44. The indicator should measure 0.160″ — 0.200″.

If the turret does not travel far enough, the piston shaft, gears, or spring assembly could be at fault, these components must be inspected by your local HFO.

Clamp / Unclamp Solenoid Voltage

Measure the voltage of the clamp/unclamp solenoid. The solenoid is inside the Consolidated Air/Lubrication Manifold (CALM) Cabinet.

Run M43 (Unclamp) and M44 (Clamp) codes in MDI mode and measure the voltage of the solenoids. The voltage must measure 120 VAC.

If there is no voltage, refer to the Next Generation Control — I/O PCB — Troubleshooting Guide.

Internal Gears

The turret’s pop out and rotate function can fail because the tool changer gears are damaged. A machine crash can cause damage to the piston and gears, and must be inspected by your local HFO.

CNC SYSTEM

OSP-P300S/P300L

ALARM & ERROR LIST

(1st Edition)

Pub No. 5921-E (LE37-006-R1) Nov. 2011

5921-E P-(i)

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety devices: they must also become fully familiar with the safety guidelines presented below to ensure accidentfree operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which Okuma can predict. Be aware that they do not cover all possible hazards.

1.Precautions Relating to Installation

(1)Please be noted about a primary power supply as follows.

Do not draw the primary power supply from a distribution panel that also supplies a major noise source (for example, an electric welder or electric discharge machine) since this could cause malfunction of the CNC unit.

If possible, connect the machine to a ground not used by any other equipment. If there is no choice but to use a common ground, the other equipment must not generate a large amount of noise (such as an electric welder or electric discharge machine).

(2)Installation Environment

Observe the following points when installing the control enclosure.

Make sure that the CNC unit will not be subject to direct sunlight.

Make sure that the control enclosure will not be splashed with chips, water, or oil.

Make sure that the control enclosure and operation panel are not subject to excessive vibrations or shock.

The permissible ambient temperature range for the control enclosure is 5 to 40°C (41 to 104°F).

The permissible ambient humidity range for the control enclosure is relative humidity 50% or less at 40°C (104°F) (no condensation).

The maximum altitude at which the control enclosure can be used is 1000 m (3281ft.).

2.Points to Check before Turning on the Power

(1)Close all the doors of the control enclosure and operation panel to prevent the entry of water, chips, and dust.

(2)Make absolutely sure that there is nobody near the moving parts of the machine, and that there are no obstacles around the machine, before starting machine operation.

(3)When turning on the power, turn on the main power disconnect switch first, then the CONTROL ON switch on the operation panel.

5921-E P-(ii)

SAFETY PRECAUTIONS

3.Precautions Relating to Manual/Continuous Operation

(1)Follow the instruction manual during operation.

(2)Do not operate the machine with the front cover, chuck cover, or another protective cover removed.

(3)Close the front cover before starting the machine.

(4)When machining the initial workpiece, check for machine operations, run the machine under no load to check for interference among components, cut the workpiece in the single block mode, and then start continuous operation.

(5)Ensure your safety before rotating the spindle or moving a machine part.

(6)Do not touch chips or workpiece while the spindle is rotating.

(7)Do not stop a rotating part with hand or another means.

(8)Check that the condition of hydraulic chuck jaws as mounted, operating pressure, and maximum permissible revolving speed.

(9)Check the condition and location of the cutting tool as mounted.

(10)Check the tool offset value.

(11)Check the zero offset value.

(12)Check that the SPINDLE OVERRIDE and FEEDRATE OVERRIDE dials on the NC operation panel are set to 100%.

(13)When moving the turret, check the software limits for X- and Z-axes or the locations of limit switch dogs to prevent interference with the chuck and tailstock.

(14)Check the location of the turret.

(15)Check the location of the tailstock.

(16)Cut workpieces with a transmitted power and torque within the permissible range.

(17)Chuck each workpiece firmly.

(18)Check that the coolant nozzle is properly located.

4.On Finishing Work

(1)On finishing work, clean the vicinity of the machine.

(2)Return the ATC, APC and other equipment to the predetermined retraction position.

(3)Always turn off the power to the machine before leaving it.

(4)To turn off the power, turn off the CONTROL ON switch on the operation panel first, then the main power disconnect switch.

5921-E P-(iii)

SAFETY PRECAUTIONS

5.Precautions during Maintenance Inspection and When Trouble Occurs

In order to prevent unforeseen accidents, damage to the machine, etc., it is essential to observe the following points when performing maitenance inspections or during checking when trouble has occurred.

(1)When trouble occurs, press the emergency stop button on the operation panel to stop the machine.

(2)Consult the person responsible for maintenance to determine what corrective measures need to be taken.

(3)If two or more persons must work together, establish signals so that they can communicate to confirm safety before proceeding to each new step.

(4)Use only the specified replacement parts and fuses.

(5)Always turn the power off before starting inspection or changing parts.

(6)When parts are removed during inspection or repair work, always replace them as they were and secure them properly with their screws, etc.

(7)When carrying out inspections in which measuring instruments are used — for example voltage checks — make sure the instrument is properly calibrated.

(8)Do not keep combustible materials or metals inside the control enclosure or terminal box.

(9)Check that cables and wires are free of damage: damaged cables and wires will cause current leakage and electric shocks.

(10)Maintenance inside the Control Enclosure

a.Switch the main power disconnect switch OFF before opening the control enclosure door.

b.Even when the main power disconnect switch is OFF, there may some residual charge in the MCS drive unit (servo/spindle), and for this reason only service personnel are permitted to perform any work on this unit. Even then, they must observe the following precautions.

MCS drive unit (servo/spindle)

The residual voltage discharges two minutes after the main switch is turned OFF.

c.The control enclosure contains the NC unit, and the NC unit has a printed circuit board whose memory stores the machining programs, parameters, etc. In order to ensure that the contents of this memory will be retained even when the power is switched off, the memory is supplied with power by a battery. Depending on how the printed circuit boards are handled, the contents of the memory may be destroyed and for this reason only service personnel should handle these boards.

5921-E P-(iv)

SAFETY PRECAUTIONS

(11)Periodic Inspection of the Control Enclosure

a.Cleaning the cooling unit

The cooling unit in the door of the control enclosure serves to prevent excessive temperature rise inside the control enclosure and increase the reliability of the NC unit. Inspect the following points every three months.

Is the fan motor inside the cooling unit working?

The motor is normal if there is a strong draft from the unit.

Is the external air inlet blocked?

If it is blocked, clean it with compressed air.

6.General Precautions

(1)Keep the vicinity of the machine clean and tidy.

(2)Wear appropriate clothing while working, and follow the instructions of someone with sufficient training.

(3)Make sure that your clothes and hair cannot become entangled in the machine. Machine operators must wear safety equipment such as safety shoes and goggles.

(4)Machine operators must read the instruction manual carefully and make sure of the correct procedure before operating the machine.

(5)Memorize the position of the emergency stop button so that you can press it immediately at any time and from any position.

(6)Do not access the inside of the control panel, transformer, motor, etc., since they contain highvoltage terminals and other components which are extremely dangerous.

(7)If two or more persons must work together, establish signals so that they can communicate to confirm safety before proceeding to each new step.

5921-E P-(v)

SAFETY PRECAUTIONS

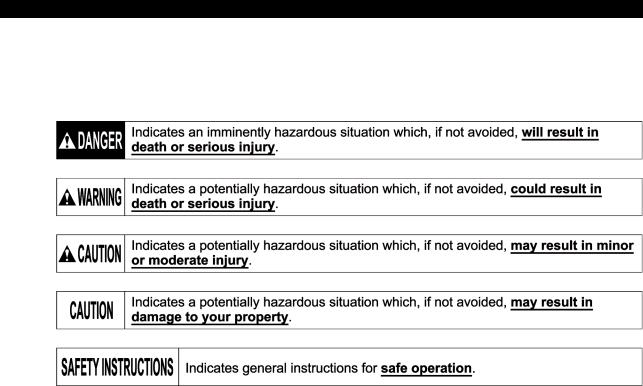

7.Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of particular importance. Read the instructions marked with these symbols carefully and follow them.

5921-E P-(i)

INTRODUCTION

INTRODUCTION

Before using this NC unit, read this manual thoroughly in order to ensure correct use.

This manual explains how to use and maintain the control so that it will deliver its full performance and maintain accuracy over the long term.

You must pay particular attention to the cautions given in this manual; read them carefully and make sure you fully understand them before operating the NC.

|

5921-E P-(i) |

|||

TABLE OF CONTENTS |

|||

|

TABLE OF CONTENTS |

|||

|

SECTION 1 CLASSIFICATION OF ALARMS ………………………………………………….. |

1 |

||

|

1-1. |

Alarm Classifications …………………………………………………………………………………………… |

1 |

|

|

1-2. |

Object Number and Object Message …………………………………………………………………….. |

2 |

|

|

1-2-1. |

Alarm Codes………………………………………………………………………………………….. |

3 |

|

|

1-2-2. |

Bit conversion method…………………………………………………………………………….. |

3 |

|

|

1-2-3. |

How to check alarm contents …………………………………………………………………… |

4 |

|

SECTION 2 |

ALARM P………………………………………………………………………………….. |

5 |

|

SECTION 3 |

ALARM A………………………………………………………………………………… |

74 |

|

SECTION 4 |

ALARM B………………………………………………………………………………. |

249 |

|

SECTION 5 |

ALARM C………………………………………………………………………………. |

464 |

|

SECTION 6 |

ALARM D………………………………………………………………………………. |

544 |

|

SECTION 7 |

ERROR…………………………………………………………………………………. |

645 |

|

SECTION 8 |

APPENDIX ……………………………………………………………………………. |

754 |

|

8-1. Factor Classification Code/Factor Parameter………………………………………………………. |

754 |

|

|

8-1-1. Factor Classification Code/Factor Parameter (for Machine) ……………………… |

754 |

5921-E P-1

SECTION 1 CLASSIFICATION OF ALARMS

SECTION 1 CLASSIFICATION OF ALARMS

Alarms related with the OSP are classified into five types such as Alarm P, A, B, C and D.

1-1. Alarm Classifications

|

Alarm |

Machine Conditions When ALARM Lamp |

Operative NC Functions Thereafter |

||

|

Comes ON |

||||

|

P |

Stops NC operation. |

All NC functions are inoperative. |

||

|

Concerning the control, cancel the alarm |

||||

|

axis feed |

||||

|

by turning power on again after turning it |

||||

|

Stops; |

spindle rotation |

|||

|

off once. |

||||

|

coolant supply |

||||

|

Shuts off power supply |

to X- and Z-axis |

|||

|

servo drives. |

||||

|

Alarm display is displayed on the operation |

||||

|

panel. |

||||

|

A |

axis feed |

Operations for display are possible. |

||

|

Stops; |

The machine remains inoperative until |

|||

|

spindle rotation |

||||

|

the control is reset and the alarm |

||||

|

coolant supply |

||||

|

canceled. |

||||

|

Shuts off power supply to X- and Z-axis |

||||

|

servo drives. |

||||

|

Alarm display is given on the operation |

||||

|

panel. |

||||

|

B |

The commands in the active block are |

Operations for display are possible. |

||

|

completed. |

The machine remains inoperative until |

|||

|

the control is reset and the alarm |

||||

|

Spindle rotation and coolant supply do not |

||||

|

stop. |

canceled. |

|||

|

Power supply to X- and Z-axis servo drives |

||||

|

is not shut off. |

||||

|

Alarm display is given on the operation |

||||

|

panel. |

||||

|

C |

The part program being run is executed to |

Operations for display are possible. |

||

|

the end (up to M02 command). |

No new program can be run until the |

|||

|

control is reset and the alarm is |

||||

|

Spindle rotation and coolant supply do not |

||||

|

stop. |

canceled. |

|||

|

Power supply to X- and Z-axis servo drives |

||||

|

is not shut off. |

||||

|

Alarm display is given on the operation |

||||

|

panel. |

||||

|

D |

This alarm does not have any influence on |

Operations on the operation panel are all |

||

|

the machine operation. |

operative. Alarm cannot be canceled |

|||

|

Alarm display is given on the operation |

unless the cause of the alarm is |

|||

|

panel. |

removed. |

|||

5921-E P-2

SECTION 1 CLASSIFICATION OF ALARMS

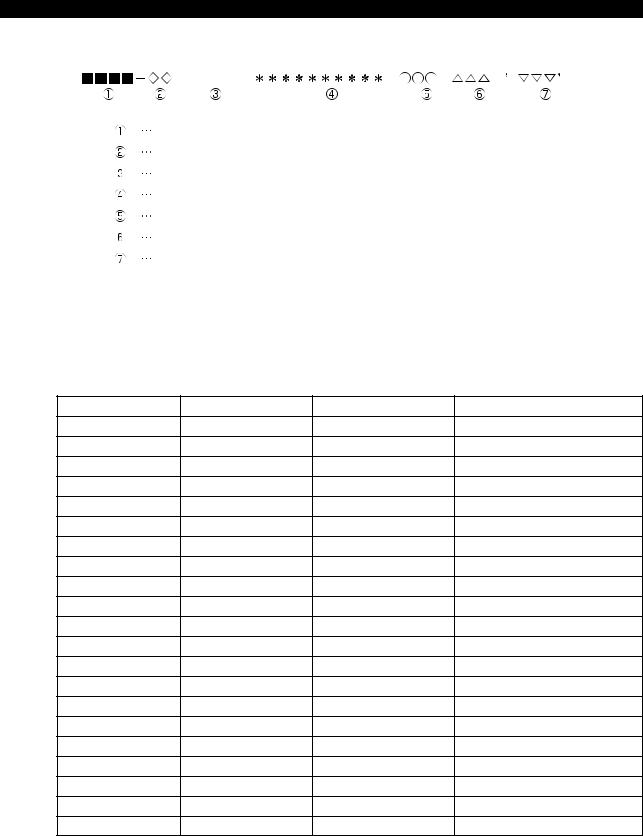

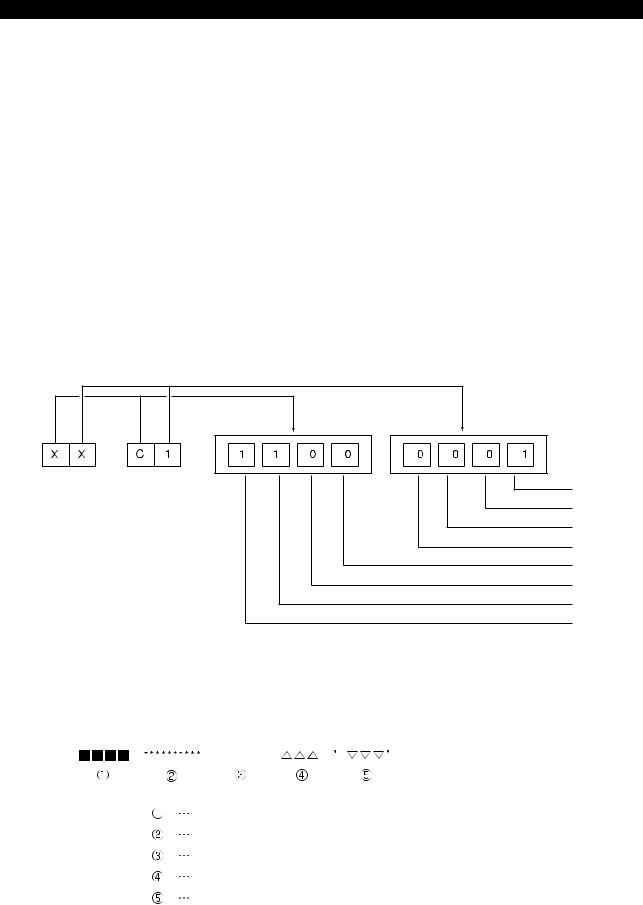

Display Format of Alarm P, A, B, C and D

ALARM-A

Alarm number

Object number

Alarm level

Alarm message

Object message

Alarm code

Alarm character-string

LE37006R0100300020001

1-2. Object Number and Object Message

The object number and the object message show the programming system and the control axis where the alarm has occurred by the number and message as shown in the table blow:

|

Object No. |

Meaning |

Object message |

Notes |

|

|

None |

No classification |

None |

||

|

01 |

System 1 |

“A side” or “1-A sd” |

1st spindle and turret A |

|

|

02 |

System 2 |

“B side” or “1-B sd” |

1st spindle and turret B |

|

|

03 |

System 3 |

“2-A sd” |

2d spindle and turret A |

|

|

04 |

System 4 |

“2-B sd” |

2d spindle and turret B |

|

|

11 |

1st X-axis |

“XAaxis” or “X-axis” |

||

|

12 |

1st Y-axis |

“YAaxis” or “Y-axis” |

||

|

13 |

1st Z-axis |

“ZAaxis” or “Z-axis” |

||

|

16 |

1st W-axis |

“W-axis” |

||

|

19 |

1st C-axis |

“C-axis” or “Caxis1” |

||

|

20 |

1st S-axis |

“SPDL” or “SPDL-1” |

||

|

21 |

1st T-axis |

“TAaxis” or “T-axis” |

||

|

22 |

1st M-axis |

“MAaxis” or “M-axis” |

||

|

31 |

2d |

X-axis |

“XBaxis” |

|

|

32 |

2d |

Y-axis |

“YBaxis” |

|

|

33 |

2d |

Z-axis |

“ZBaxis” |

|

|

39 |

2d |

C-axis |

“Caxis2” |

|

|

40 |

2d |

S-axis |

“SPDL-2” |

Sub spindle, pick-off spindle |

|

41 |

2d |

T-axis |

“TBaxis” |

|

|

42 |

2d |

M-axis |

“MBaxis” |

|

|

53 |

3d |

Z-axis |

“ZCaxis” |

LT series |

As indicated above, the object numbers and messages to be used are determined by the machine specifications.

5921-E P-3

SECTION 1 CLASSIFICATION OF ALARMS

1-2-1. Alarm Codes

In this manual, alarm codes are explained using such as «X», «XX», and «XXYY».

Explanation is given in the following methods:

(1)The alarm code indicated in this text can be used directly as the key to find the contents of error.

(2)The alarm code indicated in this text should first be converted into bit expression (pattern), which is then used as the key to find the contents of error.

In the case of 2), the procedure to convert the alarm code into bit pattern is shown below.

1-2-2. Bit conversion method

|

Alarm Code |

Alarm Code |

||||||||

|

(Expressed in |

Bit Pattern |

(Expressed in |

Bit Pattern |

||||||

|

hexadecimal) |

hexadecimal) |

||||||||

|

0 |

0 |

0 |

0 |

0 |

8 |

1 |

0 |

0 |

0 |

|

1 |

0 |

0 |

0 |

1 |

9 |

1 |

0 |

0 |

1 |

|

2 |

0 |

0 |

1 |

0 |

A |

1 |

0 |

1 |

0 |

|

3 |

0 |

0 |

1 |

1 |

B |

1 |

0 |

1 |

1 |

|

4 |

0 |

1 |

0 |

0 |

C |

1 |

1 |

0 |

0 |

|

5 |

0 |

1 |

0 |

1 |

D |

1 |

1 |

0 |

1 |

|

6 |

0 |

1 |

1 |

0 |

E |

1 |

1 |

1 |

0 |

|

7 |

0 |

1 |

1 |

1 |

F |

1 |

1 |

1 |

1 |

5921-E P-4

SECTION 1 CLASSIFICATION OF ALARMS

1-2-3. How to check alarm contents

The method to find the details of the alarm indicated by the bit pattern is explained below using an example.

Example:

[Code] XX

XX bit0->Battery error

bit1->EC I/O power shut off error

bit2->ECC error

bit3->Not used

bit4->Not used

bit5->EDRQ INT signal

bit6->ECP INT signal

bit7->ECP RUN signal

If an alarm occurs, a hexadecimal number is displayed.

If «$C1» is displayed, for example, first convert this «$C1» into bits.

bit 0 bit 1 bit 2 bit 3 bit 4 bit 5 bit 6 bit 7

After the conversion, it is known that Bit0, Bit6, and Bit7 are ON. See the information above and you will find that these error codes

correspond to «battery error», «ECP INT signal», and «ECP RUN signal», respectively.

Error Display Format

ERROR

Error number

Error message

Indication of ERROR

Error code

Error character-string

LE37006R0100300060001

5921-E P-5

SECTION 2 ALARM P |

|||

|

SECTION 2 |

ALARM P |

||

|

0700 |

NC start-up error ………………………………………………………………………………. |

10 |

|

|

0701 |

P100-Menu initialization failure …………………………………………………………… |

10 |

|

|

0702 |

Power failure upon start-up ………………………………………………………………… |

11 |

|

|

0703 |

Load information file not found …………………………………………………………… |

11 |

|

|

0704 |

File load error …………………………………………………………………………………… |

11 |

|

|

0705 |

Default scheduling table error …………………………………………………………….. |

12 |

|

|

0706 |

Backup data file error ………………………………………………………………………… |

12 |

|

|

0707 |

DTL link/unlink error …………………………………………………………………………. |

12 |

|

|

0708 |

RT thread stack overflow …………………………………………………………………… |

13 |

|

|

0709 |

Hardware exception ………………………………………………………………………….. |

13 |

|

|

0710 |

System call error ………………………………………………………………………………. |

13 |

|

|

0711 |

AlarmService library error ………………………………………………………………….. |

14 |

|

|

0712 |

AlarmService internal error (exception) ……………………………………………….. |

14 |

|

|

0713 |

AlarmService error ……………………………………………………………………………. |

14 |

|

|

0714 |

Blue screen ……………………………………………………………………………………… |

14 |

|

|

0715 |

P100-Menu error ………………………………………………………………………………. |

15 |

|

|

0716 |

Floating point exception …………………………………………………………………….. |

15 |

|

|

0717 |

PLC control error ……………………………………………………………………………… |

15 |

|

|

0718 |

Real time thread time over …………………………………………………………………. |

15 |

|

|

0719 |

HXCP thread error ……………………………………………………………………………. |

15 |

|

|

0720 |

AlarmService internal error ………………………………………………………………… |

16 |

|

|

0721 |

DeviceNet error ………………………………………………………………………………… |

16 |

|

|

0723 |

DeviceNet I/O data link file read …………………………………………………………. |

17 |

|

|

0725 |

M code data file ……………………………………………………………………………….. |

17 |

|

|

0726 |

Safety speed data error …………………………………………………………………….. |

17 |

|

|

0727 |

MCS firmware doesn’t support POS2 unit ……………………………………………. |

17 |

|

|

0728 |

FL-net error ……………………………………………………………………………………… |

18 |

|

|

0729 |

Non-responsive software detected. …………………………………………………….. |

18 |

|

|

0731 |

R Spec. error …………………………………………………………………………………… |

18 |

|

|

0732 |

Unable to execute lost motion compensation ……………………………………….. |

18 |

|

|

0735 |

MCS DD encoder link error ………………………………………………………………… |

18 |

|

|

0736 |

MCS DD encoder error ……………………………………………………………………… |

19 |

|

|

0737 |

MCS DD encoder (slave sensor) detected error ……………………………………. |

19 |

|

|

0738 |

MCS DD encoder initialization failure ………………………………………………….. |

20 |

|

|

0739 |

MCS DD encoder (slave sensor) initialization failure ……………………………… |

21 |

|

|

0741 |

MCS firmware version error ……………………………………………………………….. |

22 |

|

|

0742 |

Relocation detection error ………………………………………………………………….. |

22 |

|

|

0744 |

MCS power supply unit overload ………………………………………………………… |

22 |

5921-E P-6

|

SECTION 2 ALARM P |

||

|

0750 |

The spec.-code or select-soft. was wrong |

……………………………………………. 22 |

|

0752 |

VDU communication error …………………………………………………………………. |

23 |

|

0753 |

VDU detected error …………………………………………………………………………… |

23 |

|

0754 |

VDU initialization failure …………………………………………………………………….. |

24 |

|

0755 |

SIO link error ……………………………………………………………………………………. |

24 |

|

0756 |

PSC optical scale encoder error …………………………………………………………. |

25 |

|

0757 MF-SAFETY Error ……………………………………………………………………………. |

25 |

|

|

0758 |

Safety I/O Error ………………………………………………………………………………… |

26 |

|

0759 |

Safety Servo Link Error ……………………………………………………………………… |

28 |

|

0782 |

Magnetic encoder speed detection error ……………………………………………… |

29 |

|

0783 |

MCS Rotary encoder 5 initialization failure …………………………………………… |

29 |

|

0784 |

MCS Rotary encoder 5 error ………………………………………………………………. |

30 |

|

0785 |

MCS Rotary encoder 4 initialization failure …………………………………………… |

30 |

|

0786 |

MCS Rotary encoder 4 error ………………………………………………………………. |

30 |

|

0787 |

MCS Rotary encoder 3 initialization failure …………………………………………… |

30 |

|

0788 |

MCS Rotary encoder 3 error ………………………………………………………………. |

30 |

|

0789 |

MCS Rotary encoder 2 error ………………………………………………………………. |

31 |

|

0790 |

MCS Rotary encoder 1 initialization failure …………………………………………… |

31 |

|

0791 |

MCS Rotary encoder 1 error ………………………………………………………………. |

31 |

|

0792 |

MCS Linear scale 4 initialization failure ……………………………………………….. |

32 |

|

0793 |

MCS Linear scale 4 error …………………………………………………………………… |

32 |

|

0794 |

MCS Linear scale 3 initialization failure ……………………………………………….. |

32 |

|

0795 |

MCS Linear scale 3 error …………………………………………………………………… |

33 |

|

0796 |

MCS Linear scale 2 initialization failure ……………………………………………….. |

33 |

|

0797 |

MCS Linear scale 2 error …………………………………………………………………… |

33 |

|

0798 |

MCS Linear scale 1 initialization failure ……………………………………………….. |

33 |

|

0799 |

MCS Linear scale 1 error …………………………………………………………………… |

33 |

|

0800 |

Spindle D/A control data file read ……………………………………………………….. |

34 |

|

0801 |

TCP/IP board detected error ………………………………………………………………. |

34 |

|

0802 |

Load information file not found …………………………………………………………… |

35 |

|

0803 |

File load error …………………………………………………………………………………… |

35 |

|

0804 |

MSB file mismatch ……………………………………………………………………………. |

35 |

|

0805 |

MOP-Tool parameter PBU load ………………………………………………………….. |

35 |

|

0806 |

MOP-Tool tool data PBU load ……………………………………………………………. |

35 |

|

0807 |

ACP panel status receipt error ……………………………………………………………. |

36 |

|

0808 |

Speed change ratio failure …………………………………………………………………. |

36 |

|

0810 |

NC I/O data file read …………………………………………………………………………. |

36 |

|

0812 |

MCS initialization error ………………………………………………………………………. |

36 |

|

0813 |

MCS Communication error ………………………………………………………………… |

38 |

|

0814 |

MCS data file corrupt ………………………………………………………………………… |

39 |

5921-E P-7

|

SECTION 2 ALARM P |

||

|

0815 |

PLC real-time task loop error ……………………………………………………………… |

40 |

|

0816 |

PLC initialization error ……………………………………………………………………….. |

40 |

|

0817 |

MCS error ……………………………………………………………………………………….. |

41 |

|

0818 |

ADP initialization failure …………………………………………………………………….. |

41 |

|

0820 |

Machine data file read ………………………………………………………………………. |

41 |

|

0821 |

Spindle gear ratio ……………………………………………………………………………… |

42 |

|

0822 |

Wheel data file read ………………………………………………………………………….. |

42 |

|

0823 AXIS CONSTRUCTION DATA setting error …………………………………………. |

42 |

|

|

0824 |

Unit connection mistake …………………………………………………………………….. |

43 |

|

0825 AXIS CONSTRUCTION name not set …………………………………………………. |

43 |

|

|

0826 AXIS CONSTRUCTION DATA file read ………………………………………………. |

43 |

|

|

0827 |

Control axis not found ……………………………………………………………………….. |

43 |

|

0828 |

Wire feed axis No. error …………………………………………………………………….. |

43 |

|

0833 |

MCS option program file not sent ……………………………………………………….. |

44 |

|

0834 |

MCS servo data error ……………………………………………………………………….. |

44 |

|

0835 |

MCS communication error …………………………………………………………………. |

44 |

|

0836 |

Program request illegal ……………………………………………………………………… |

45 |

|

0837 |

Loader spec. code data error ……………………………………………………………… |

45 |

|

0838 |

Loader backup data file read error ………………………………………………………. |

45 |

|

0839 |

Specification conditions failure …………………………………………………………… |

45 |

|

0840 |

SuperHi-NC specification mismatch ……………………………………………………. |

46 |

|

0841 |

FCP4 board detected error ………………………………………………………………… |

46 |

|

0842 |

Safety monitor spec. error …………………………………………………………………. |

46 |

|

0845 |

Specification code setting failure ………………………………………………………… |

46 |

|

0846 |

Thermal deviation comp. backup data file read …………………………………….. |

47 |

|

0847 |

DNC-DT preload task start error …………………………………………………………. |

47 |

|

0848 |

PSCB error ……………………………………………………………………………………… |

47 |

|

0849 |

Synchronous axis tandem control initialization failure ……………………………. |

47 |

|

0850 |

MCS Undefined alarm number …………………………………………………………… |

48 |

|

0851 |

MCS Inverter unit fault ………………………………………………………………………. |

48 |

|

0852 |

Mistake in data from MCS to NC ………………………………………………………… |

49 |

|

0853 MCS CON APA deviation ………………………………………………………………….. |

50 |

|

|

0854 |

MCS Power supply unit error ……………………………………………………………… |

50 |

|

0855 |

MCS Converter link error …………………………………………………………………… |

51 |

|

0856 |

MCS DC-bus voltage alarm ……………………………………………………………….. |

51 |

|

0857 |

MCS Motor overcurrent …………………………………………………………………….. |

51 |

|

0858 |

MCS Power unit overheat ………………………………………………………………….. |

51 |

|

0859 |

MCS Power unit overload ………………………………………………………………….. |

52 |

|

0860 |

MCS Supply voltage flutter ………………………………………………………………… |

52 |

|

0861 |

MCS Inverter capacity differs from spec. ……………………………………………… |

52 |

5921-E P-8

|

SECTION 2 ALARM P |

||

|

0862 |

MCS Winding change failure ……………………………………………………………… |

52 |

|

0863 |

MCS Encoder link error …………………………………………………………………….. |

53 |

|

0864 |

MCS Encoder detected error ……………………………………………………………… |

53 |

|

0865 |

MCS Encoder initialization failure ……………………………………………………….. |

54 |

|

0866 |

MCS Encoder with shaft detected error ……………………………………………….. |

54 |

|

0867 |

MCS Encoder with shaft initialization failure …………………………………………. |

54 |

|

0868 MCS ABSO SCALE error ………………………………………………………………….. |

55 |

|

|

0869 |

MCS ABSO SCALE initialization failure ……………………………………………….. |

55 |

|

0870 |

MCS Magnetic encoder alarm ……………………………………………………………. |

55 |

|

0871 |

MCS Resolver alarm …………………………………………………………………………. |

55 |

|

0872 |

MCS Pulse generator count over ………………………………………………………… |

56 |

|

0873 |

MCS Motor overheat …………………………………………………………………………. |

56 |

|

0874 |

MCS Servo link error ………………………………………………………………………… |

56 |

|

0875 |

MCS Servo link disconnection ……………………………………………………………. |

57 |

|

0876 |

Mistake in data from NC to MCS ………………………………………………………… |

57 |

|

0877 |

MCS Servo data error ……………………………………………………………………….. |

57 |

|

0878 |

MCS Illegal command ……………………………………………………………………….. |

58 |

|

0879 MCS CON speed over ………………………………………………………………………. |

58 |

|

|

0880 MCS Speed command over ……………………………………………………………….. |

59 |

|

|

0881 MCS DIFF over ………………………………………………………………………………… |

59 |

|

|

0882 MCS APA speed over ……………………………………………………………………….. |

59 |

|

|

0883 |

MCS Full-closed APA error ………………………………………………………………… |

59 |

|

0884 MCS Over speed ……………………………………………………………………………… |

60 |

|

|

0885 |

MCS Speed deviation over ………………………………………………………………… |

60 |

|

0886 |

MCS Collision detected …………………………………………………………………….. |

60 |

|

0887 |

MCS Urgent-stop time over ……………………………………………………………….. |

61 |

|

0888 |

MCS Belt is broken …………………………………………………………………………… |

61 |

|

0889 |

MCS Axis change control error …………………………………………………………… |

61 |

|

0890 |

MCS Independent encoder initialization failure …………………………………….. |

61 |

|

0891 |

MCS Calculated current position lies outside range ………………………………. |

62 |

|

0892 |

MCS Motor overload …………………………………………………………………………. |

62 |

|

0893 |

MCS Safety speed monitor E-Link error ………………………………………………. |

62 |

|

0894 |

MCS ABSO SCALE sub-slider detected error ………………………………………. |

62 |

|

0895 |

MCS Tandem control communication error ………………………………………….. |

63 |

|

0896 |

MCS Full abso scale link error ……………………………………………………………. |

63 |

|

0897 |

MCS Full abso scale error …………………………………………………………………. |

64 |

|

0898 |

MCS Full abso scale initialization failure ……………………………………………… |

64 |

|

0899 |

MCS Axis stop signal error ………………………………………………………………… |

65 |

|

0940 |

Time sharing task control …………………………………………………………………… |

65 |

|

0941 |

Real-time task control ……………………………………………………………………….. |

65 |

5921-E P-9

|

SECTION 2 ALARM P |

||

|

0942 |

Real-time task loop error …………………………………………………………………… |

65 |

|

0943 |

Main processor name incorrect ………………………………………………………….. |

66 |

|

0944 |

Slave processor name incorrect …………………………………………………………. |

66 |

|

0945 |

Memory board/battery life ………………………………………………………………….. |

66 |

|

0951 |

SMP error ……………………………………………………………………………………….. |

66 |

|

0952 |

Not equipped with processor board …………………………………………………….. |

67 |

|

0954 |

Peripheral processor start ………………………………………………………………….. |

67 |

|

0955 |

Spec. code: data file …………………………………………………………………………. |

67 |

|

0956 |

Backup data file read ………………………………………………………………………… |

68 |

|

0957 |

Graphic backup data file read …………………………………………………………….. |

68 |

|

0958 |

Pitch compensation data file read ……………………………………………………….. |

68 |

|

0965 |

Configuration file format error …………………………………………………………….. |

69 |

|

0971 |

Cache data: Initialization error ……………………………………………………………. |

69 |

|

0988 |

Cache data: Operation error ………………………………………………………………. |

69 |

|

0989 |

CPU information table data incorrect …………………………………………………… |

69 |

|

0990 |

TASK generate error …………………………………………………………………………. |

70 |

|

0991 |

TASK information table data incorrect …………………………………………………. |

70 |

|

0992 |

PLC backup data file read …………………………………………………………………. |

70 |

|

0993 |

TCP/IP board illegal ………………………………………………………………………….. |

71 |

|

0994 |

TCP/IP configuration file ……………………………………………………………………. |

71 |

|

0995 |

Machine axis data file ……………………………………………………………………….. |

71 |

|

0996 |

PLC axis data file ……………………………………………………………………………… |

71 |

|

0997 |

PLC monitor backup data file read ……………………………………………………… |

72 |

|

0998 |

PLC sequence program load ……………………………………………………………… |

72 |

|

0999 |

Synchronous tap data file read …………………………………………………………… |

73 |

5921-E P-10

SECTION 2 ALARM P

0700 NC start-up error

An error occurred when NC started up.

[Object] None

[Character-string] None

[Code]

0x10000000: NC Configuration read error 0x10003000: Spec code read error 0x20000000: ServoLink board initializing error 0x3XXX00YY: NC data file read error

XXX:

0x002: HD backup status file 0x004: Parameter data file 0x008: Machine data file 0x010: PLC backup data file 0x020: PLC-HMI data file 0x040: Alarm History data file 0x080: PLC AXIS data pbu file

0x100: POT TOOL data pbu file (M/C only) 0x200: MOP TOOL Tool data file (M/C only) 0x400: MOP TOOL Parameter file (M/C only) 0x800: Thermal deviation compensation data file

YY:

0x01: File read open error 0x02: File read error 0x03: Version check error 0x04: Check sum error

0x05: Double check sum error 0x06: Backupped Memory error 0x07: File write open error 0x08: File write error

0x40000000: Axis information initializing error -More than 8 axis

0x50000000: PLC data file read error -Read failed M code data file

0x60000000: I/O Initializing error -PLC variable backup file read error -I/O forced data file read error

0x70000000: ServoLink Initializing error 0x80000000: Operation buffer get error 0x90000000: PBU data file read error 0xA0000000: Shared memory size definition error 0xA1XXXXXX: AlarmService start error

XXXXXX: Error code of AlarmService library function 0xA2400002: Alarm History read error 0xA3000000: Thread monitor initializing error

0xA9000000: Initialization processing of the safety logic was not completed within 20 seconds 0xA9000001: Axis construction definition file open error

0xA9000002: Axis construction definition file read error 0xA9000003: Axis construction definition file mismatch 0xFFFFFFFF: Debug information file read error

0701 P100-Menu initialization failure

An error occurred in P100-Menu while system startup.

[Object] None

[Character-string] None

[Code]

1:NC Control file was not found.

2:PLC Control file was not found.

3:NC-HMI was not found

5921-E P-11

SECTION 2 ALARM P

4:3D real sim file was not found.

5:MacMan file was not found.

6:Version mismatch between P100-Menu and PLC Control

7:Version mismatch between P100-Menu and MacMan

8:Version mismatch between P100-Menu and NC Control

11:Conf-P100-menu read error

12:An error occurred at RTOS

13:An error occurred at UPS Service

21:NC Control start failure

22:Error in obtaining shared objects

23:PLC Control start failure

24:NC-HMI start failure

25:3D real sim start failure

26:MacMan start failure

101:Startup sequence 0x10 receive failure

200:Startup sequence 0x10 send failure

201:Startup sequence 0x20 receive failure

300:Startup sequence 0x20 send failure

301:Startup sequence 0x30 receive failure

400:Startup sequence 0x30 send failure

401:Startup sequence 0x60 receive failure

500:Startup sequence 0x60 send failure

501:Startup sequence 0x70 receive failure

600:Startup sequence 0x70 send failure

601:Startup sequence 0x7C receive failure

700:Startup sequence 0x7C send failure

701:AlarmService start failure

702:Activation sequence 0x80 receive failure

[Probable Faulty Locations]

1.Execution file name failure 2.Data file name failure 3.RTOS failure

4.UPS function failure 5.Software failure 6.Software Version failure

0702 Power failure upon start-up

[Object] None

[Character-string] None

[Code] None

[Probable Faulty Locations]

1.Power failure during while system startup 2.Power shutoff during while system startup

0703 Load information file not found

A load information file was not found.

[Object] None

[Character-string] None

[Code] None

0704 File load error

An object file was not loaded correctly.

[Object] None

[Character-string]

5921-E P-12

SECTION 2 ALARM P

None

[Code]

1:A file was not found

2:The attribute of file was not correct.

3:The load address information of file was not correct 4:An error occurred when file was loaded

FFFFFFFF:The details of alarm was displayed by message from OS

0705 Default scheduling table error

A default scheduling table error was detected.

[Object] None

[Character-string] None

[Code]

0x00010001: RTIN default scheduling table error (element number) 0x00010002: RTIN default scheduling table error (end element) 0x00020001: TSMN default scheduling table error (element number) 0x00020002: TSMN default scheduling table error (initial attribute)

[Probable Faulty Locations] 1.NC software failure

0706 Backup data file error

Error occurred when load/save the backup file.

[Object] None

[Character-string] None

[Code] XXXXYYYY

XXXX

0x0002:HD backup status file 0x0004:Low speed NC backup data file 0x0008:High speed NC backup data file 0x0010:PLC backup data file 0x0020:PLC-HMI data file 0x0040:Alarm history data file 0x0080:PLC axis data file

0x0100:POT TOOL data file

0x0200:MOP TOOL Tool data file (M/C only) 0x0400:MOP TOOL Parameter data file (M/C only) 0x0800:Thermal deviation compensation data file

YYYY

1:File read open error 2:File read error 3:Version check error 4:Check sum error 5:Double check sum error

6:Backup memory check error 7:File write open error

8:File write error

0707 DTL link/unlink error

An error occurred in DTL link or unlink.

[Object] None

[Character-string] None

[Code]

1:RTIN refresh error

5921-E P-13

SECTION 2 ALARM P

2:TSMN refresh error

[Probable Faulty Locations]

1.Hardware failure 2.Software failure

0708 RT thread stack overflow

Stack overflow of RT thread was detected.

[Object] None

[Character-string]

Occurred RT thread name

[Code] None

[Probable Faulty Locations] 1.NC software failure

0709 Hardware exception

Hardware exception was occurred.

[Object] None

[Character-string]

Occurred RT thread name

[Code]

Hardware exception code 0x5555: CPU Diagnose error 0x8100:Divide by 0 error

0x8101:Unexpected Single Step Interrupt 0x8102:Unexpected NMI 0x8103:Unexpected Debug Interrupt 0x8104:Overflow error

0x8105:Array Bounds error 0x8106:Invalid Opcode error 0x8107:NPX Device not present 0x8108:Double Fault error 0x8109:Unknown Device error 0x810A:Invalid TSS error 0x810B:Segment not Present error 0x810C:Stack Fault error 0x810D:General Protection error 0x810E:Page Fault error 0x8110:Unknown Device error 1 0x8111:Alignment error

[Probable Faulty Locations] 1.Hardware failure 2.Software failure

[Note]

Alarm information is also displayed also in the console window.

0710 System call error

An error occurred in the INtime system call.

[Object] None

[Character-string]

Occurred RT thread name

[Code] XXXXYYYY

XXXX:INtime system call code

YYYY:Return value or status of INtime system call [Probable Faulty Locations]

5921-E P-14

SECTION 2 ALARM P

NC software failure

[Note]

Alarm information is also displayed also in the console window.

0711 AlarmService library error

An error occurred in the AlarmService library function.

[Object] None

[Character-string] Occurred thread name

[Code]

XXYYYYYY

XX:AlarmService library function code YYYYYY:AlarmService library function error code

[Probable Faulty Locations] NC software failure

[Note]

Alarm information is also displayed also in the console window.

0712 AlarmService internal error (exception)

An error occurred inside of AlarmService.

[Object] None

[Character-string] «ALMS»

[Code]

AlarmService internal error code

[Probable Faulty Locations] NC software failure

[Note]

Alarm information is also displayed also in the console window.

0713 AlarmService error

P100-Menu detected AlarmService error.

[Object] None

[Character-string] None

[Code] None

[Probable Faulty Locations] 1.NC software failure

0714 Blue screen

Blue screen (kernel stop error) occurred.

[Object] None

[Character-string] None

[Code] None

[Probable Faulty Locations] 1.Win32 application failure 2.Windows failure 3.Windows driver failure

5921-E P-15

SECTION 2 ALARM P

0715 P100-Menu error

An abnormal condition of P100-Menu was detected.

[Object] None

[Character-string] None

[Code] None

[Probable Faulty Locations] 1.P100-Menu failure

0716 Floating point exception

Floating point exception was occurred.

[Object] None

[Character-string]

Occurred RT thread name

[Code] XXXXYYZZ

XXXX:Exception code YY:Not used (0 fixed) ZZ:FPU status word

bit5:PE (Precision Exception Flag) bit4:UE (Underflow Exception Flag) bit3:OE (Overflow Exception Flag) bit2:ZE (Zero Divide Exception Flag)

bit1:DE (Denormalized Operand Exception Flag) bit0:IE (Invalid Operation Exception Flag)

[Probable Faulty Locations] NC software failure

0717 PLC control error

Error occurred on PLC Control.

[Object] None

[Character-string] None

[Code] XXXXYYYY

XXXX:PLC Control status YYYY:PLC Control error code

[Probable Faulty Locations] 1.PLC software failure

0718 Real time thread time over

Real time-type thread did not finish within the stated time

[Object] None

[Character-string]

RT thread name that was exceeded the stated time

[Code] None

[Probable Faulty Locations] 1.NC software failure

0719 HXCP thread error

5921-E P-16

SECTION 2 ALARM P

An abnormal condition of HXCP thread was detected.

[Object] None

[Character-string] None

[Code] None

[Probable Faulty Locations] 1.NC software failure

0720 AlarmService internal error

An error occurred inside of AlarmService.

[Object] None

[Character-string] «ALMS»

[Code]

AlarmService internal error code

[Probable Faulty Locations]

1.NC software failure 2.P100-Menu failure

0721 DeviceNet error

Error occurred on DeviceNet.

[Index] None

[Character-string] CH* SC$

* : Channel number where the error occurred. S : Sequence counter

[Code] XXYYZZZZ

XXSlave station MacID where the error occurred

YYSlave station

0x00 Normal or nonexistent slave station

0x46 Duplicate MacID error

0x48 Communication stop

0x49 Discrimination information was not compatible with scan list 0x4D Data size was not compatible with scan list

0x4E No response in the connection check.

0x4F Other slave stations are nonexistence on network 0x50 Idle condition

0x53 Error received in the connection check

0x54 Timeout occurred in the connection check

0x56 Turn into the idle mode 0x5B Bus off

0x5C Network power supply off

( XXXX became 0xFFFF,if its not caused by slave station, such as communication delay.) ZZZZ Scanner error status

bit 0 Memory check error bit 1 Scan list initialize error

bit 2 Scan list mismatch error(MacID) bit 3 Scan list mismatch error(Input data)

bit 4 Scan list mismatch error(Output data) bit 5 Duplicate MacID error

bit 6 Network power supply status error bit 7 Memory parity error

bit 8 Input data reception error(single) bit 9 Input data reception error(dowble)

bit10 Output data transmission error(single) bit11 Output data transmission error(dowble)

5921-E P-17

SECTION 2 ALARM P

bit12 Slave station communication delay error(single) bit13 Slave station communication delay error(dowble) bit14 Bus off

bit15 Diagnostic information access error

[Probable Faulty Locations]

1)Hardware failure 2)Software failure

0723 DeviceNet I/O data link file read

The NC failed to read DeviceNet IO data link file.

[Code]

I/O data file load status (in hexadecimal) 2 ->File open error (no file)

3 ->File read error (no data)

4 ->File attribute error (not «PBU1»)

5 ->File close error

6 ->File size error (too small)

7 ->File size error (too large)

100->Wrong PLC machine type

200->Wrong PLC class

300->Wrong file version

1002 ->DN SCAN LIST CHANGE FILE OPEN ERROR

1003 ->DN SCAN LIST CHANGE FILE READ ERROR (NO DATA)

1004 ->DN SCAN LIST CHANGE FILE ATTRIBUTE ERROR (NO ‘PBU1’) 1005 ->DN SCAN LIST CHANGE FILE CLOSE ERROR

1006 ->DN SCAN LIST CHANGE FILE SIZE ERROR (SIZE SMALL)

0725 M code data file

Establishment data of reading M-code file is bad.

[Code]

1->The denial data is bad.

[Character string]

The number is M-code which is established bad data.

[Measures to Take]

Please correct the bad data of M-code.

0726 Safety speed data error

The safety speed data was in abnormal state in the machine without the CE marking safety speed monitor.

[Index]

Axis name or none (spindle)

[Character-string] None

[Code]

X

X=1:The guard number of the safety speed data was outside the range from -0 to 9.

[Measures to Take]

Change the safety speed monitor data file for axis control. Relevant specifications:Without CE mark safety speed monitor type

[Related Specifications]

Without CE mark safety speed monitor type

0727 MCS firmware doesn’t support POS2 unit

This alarm occurs when the firmware ROM version of the NC axis/ machine(PLC) axis MIV unit is not 511 or later when the new POS unit is installed.

[Character-string] None

[Code] None

5921-E P-18

SECTION 2 ALARM P

0728 FL-net error

An error occurred during startup of the FL-net card.

[Object] None

[Character-string] None

[Code]

Y000XXX

Y:0

XXXX: 7F00:System error

7F01:Flash memory error 7F02:DRAM test error 7F03:NICE test error 7F04:EEPROM sum check error 7F05:CPU BUS error 7F06:illegal Instruction

Y:1

XXXX:

0004:Timeout error for 4 sec or longer Y:F

XXXX:

FFFF: FL-net card is not mounted

[Probable Faulty Locations] FL-net card is defective.

0729 Non-responsive software detected.

Non-answered software was detected.

[Object] None

[Character-string] None

[Code]

NT Process name

[Probable Faulty Locations] NC software failure

0731 R Spec. error

It is the illegal of «R SPEC».

[Index] None

[Code]

1:»NON R SPEC» of NC is OFF, and «R-SPEC» of SVDN-ID is OFF. 2:»NON R SPEC» of NC is ON, and «R-SPEC» of SVDN-ID is ON.

3:When there are 2 SVDN-boards in the machine, «R-SPEC» of one board is ON, other is OFF. 4X:»NON R SPEC» of NC is OFF, and «R-SPEC» of SVDN-ID is ON, and Restriction-Spec is ON.

0732 Unable to execute lost motion compensation

0735 MCS DD encoder link error

An error occurred in the encoder communication link.

[Object]

Axis name or none (spindle)

[Character-string] None

[Code] XXYYZZZZ

5921-E P-19

SECTION 2 ALARM P

XX= $FF (fixed)

YY= $00: Error is detected at the DD encoder.

$01: Error is detected at the DD encoder(slave sensor). ZZZZ = Encoder link error status at the time of error detection

bit15: Undefined bit14: Undefined

bit13: Error in communication with the DD encoder (slave sensor) bit12: Error in communication with the DD encoder

bit11: MT buffer error

bit10: Transmission loop error in AT mode

bit9 : Data over error in data receiving part of interface bit8 : Undefined

bit7 : Undefined

bit6 : Modulation code error bit5 : CRC error

bit4 : Format error

bit3 : Double transmission error bit2 : Double reception error bit1 : Parity error

bit0 : Time-out error

This alarm occurs only at ICB-H.

[Probable Faulty Locations]

DD encoder of DD encoder (slave sensor) of the pertinent axis Encoder link cables or connectors Inverter unit control board

0736 MCS DD encoder error

The DD encoder has become undetectable.

[Object]

Axis name or none (spindle)

[Character-string] None

[Code] XXYYZZZZ

XX= Positional data status bit7 : Error bit (1:error)

bit6 : Absolute position sensor margin error.(0:Normal, 1:Warning) bit5 : Gap-Warning (1:Gap-small,Toggle:Gap-big)

bit4 : Inclination-Warning (1:CCW-big, Toggle:CW-big) bit3 : Auto set mode (0:Normal, 1:Auto mode)

bit2 : Communication error (Toggle by detecting)

bit1,0: Error bit number of absolute position code.(It is indicated by 2bits.)

YY= Alarm code

01: Stop command has stopped. 02: Control parameter error

04: Absolutization error

05: Initialization speed too high 08: Auto-set-data error

0D: Speed too high

0E: Synchronization error

20:Absolutization mismatch (Only Format-5)

21:Communication-error of Master-sensor (Only Format-5) 3E: Code-error by Absolute-position-sensor

3F: Check-errotr by Absolute-position-code

40:Inclination-error (for plus)

41:Inclination-error (for minus)

42:Gap is narrow

43:Gap is wide

ZZZZ= 0000 fixed

This alarm occurs only at ICB-H.

[Probable Faulty Locations] DD encoder

0737 MCS DD encoder (slave sensor) detected error

The DD encoder (slave sensor) has become undetectable.

5921-E P-20

SECTION 2 ALARM P

[Object]

Axis name or none (spindle)

[Character-string] None

[Code] XXYYZZZZ

XX= Positional data status bit7 : Error bit (1:error)

bit6 : Absolute position sensor margin error.(0:Normal, 1:Warning) bit5 : Gap-Warning (1:Gap-small,Toggle:Gap-big)

bit4 : Inclination-Warning (1:CCW-big, Toggle:CW-big) bit3 : Auto set mode (0:Normal, 1:Auto mode)

bit2 : Communication error (Toggle by detecting)

bit1,0: Error bit number of absolute position code.(It is indicated by 2bits.)

YY= Alarm code

01: Stop command has stopped. 02: Control parameter error

04: Absolutization error

05: Initialization speed too high 08: Auto-set-data error

0D: Speed too high

0E: Synchronization error

20:Absolutization mismatch (Only Format-5)

21:Communication-error of Master-sensor (Only Format-5) 3E: Code-error by Absolute-position-sensor

3F: Check-errotr by Absolute-position-code

40:Inclination-error (for plus)

41:Inclination-error (for minus)

42:Gap is narrow

43:Gap is wide

ZZZZ= 0000 fixed

This alarm occurs only at ICB-H.

[Probable Faulty Locations] DD encoder (slave sensor)

0738 MCS DD encoder initialization failure

An error occurred in the initialization of the DD encoder.

[Object]

Axis name or none (spindle)

[Character-string] None

[Code] XXYYZZZZ

XX= Encoder link initialization sequence number (1B) at the time of the error detection

0:Reset

1:Network address setting

2:Request to send the basic information for communication

3:Change of communication software version

4:Acquisition of device information

5:Parameter change

6:Position detection start

7:AT mode start

YY= Error content (1B)

0:Communication error

1:Transmission start time over

2:Transmission finish time over

3:Reception finish time over

4:Abnormal response address

5:Abnormal response code

6:Parameter error

ZZZZ = Data (2B)

If YY = 0,

The encoder link error status C2ERR at the time of error detection appears.

If YY = 1, 2 or 3,

5921-E P-21

SECTION 2 ALARM P

The transmitted frame information QC2MTINF appears.

If YY = 4,

The network address of the responding device appears.

If YY = 5,

Alarm code + positional data status

Refer to MCS DD Encoder error (alarm 1136).

If YY = 6,

Parameter number at which the error is detected

1:Reception of insufficient number of parameters

2:Basic information for communication being incompatible

3:Multi-turn detection range over

4:Communication protocol version being incompatible

5:Positional data format being incompatible

6:Abbreviated data mode being incompatible

However, when abnormal voltage is detected at the encoder fuse XXYY = $FFFF fixed

ZZZZ = Detected voltage value of the encoder fuse (12[V] = $9980) Normal range: 10.6[V] to 13.8[V]

Allowable range: $8800 to $B000 This alarm occurs only at ICB-H.

[Probable Faulty Locations] DD encoder

Encoder link cables and connectors Inverter unit control board

0739 MCS DD encoder (slave sensor) initialization failure

An error occurred in the initialization of the DD encoder (slave sensor).

[Index]

Axis name or none (spindle)

[Character-string] None

[Code] XXYYZZZZ

XX= Encoder link initialization sequence number (1B) at the time of the error detection

0:Reset

1:Network address setting

2:Request to send the basic information for communication

3:Change of communication software version

4:Acquisition of device information

5:Parameter change

6:Position detection start

7:AT mode start

YY= Error content (1B)

0:Communication error

1:Transmission start time over

2:Transmission finish time over

3:Reception finish time over

4:Abnormal response address

5:Abnormal response code

6:Parameter error

ZZZZ = Data (2B)

If YY = 0,

The encoder link error status C2ERR at the time of error detection appears.

If YY = 1, 2 or 3,

The transmitted frame information QC2MTINF appears.

If YY = 4,

The network address of the responding device appears.

If YY = 5,

Alarm code + positional data status

Refer to MCS DD Encoder error (alarm 1136).

If YY = 6,

Parameter number at which the error is detected

1:Reception of insufficient number of parameters

2:Basic information for communication being incompatible

3:Multi-turn detection range over

5921-E P-22

SECTION 2 ALARM P

4:Communication protocol version being incompatible

5:Positional data format being incompatible

6:Abbreviated data mode being incompatible

However, when abnormal voltage is detected at the encoder fuse XXYY = $FFFF fixed

ZZZZ = Detected voltage value of the encoder fuse (12[V] = $9980) Normal range: 10.6[V] to 13.8[V]

Allowable range: $8800 to $B000 This alarm occurs only at ICB-H.

[Probable Faulty Locations] DD encoder (slave sensor)

Encoder link cables and connectors Inverter unit control board

0741 MCS firmware version error

The MCS software version was not correct.

[Object] None

[Code]

1-> The MCS software version of the XA axis is not since ICBH590 in the premium thread cutting function spec.

[Probable Faulty Locations] Specification code error MCS software version error

[Measures to Take]

Reinstall the software or reissue the install disk. MCS software Upgrade

0742 Relocation detection error

Relocation detection error occurred [Character-string]

|

ComErr |

:Communication error |

|

PBU |

:PBU data error |

|

PJ |

:PJ discord |

|

PwdTout |

:Password application timeout |

|

PwdChk |

:Password check error |

PwdTerm:Password application terminate

[Code]

ComErr:

bit2 Atmega error bit1 RTC error

bit0 Relocation detection module error PwdChk:

Password check error code

0744 MCS power supply unit overload

Power Supply Unit over load

[Object]

Axis name or none (spindle)

[Character-string] None

[Code]

1(fixed)

[Probable Faulty Locations] Power unit

Overload operation

0750 The spec.-code or select-soft. was wrong

The combination of NC-software and PLC-software was wrong. Or, the combination of specification-code was wrong.

5921-E P-23

SECTION 2 ALARM P

[Object] None

[Character-string] None

[Code]

1:PLC-software is not effective for the specification of «TOOL OFFSET 999» 4:It can’t be combined with spindle command unit 0.1.

5:Overlapped PLC axis number

[Probable Faulty Locations]

(1)Mistake of select for specification-code (2)Mistake of select for PLC-software-version

0752 VDU communication error

An error occurred in the VDU(Vibration Detect Unit) communication link, disabling the VDU from detecting acceleration.

[Object]

Axis name or none (spindle)

[Character-string] None

[Code] XXYYZZZZ

XX= FF [HEX] (fixed)

YY= 00 [HEX] (fixed)

ZZZZ = VDU link error status at the time of error detection. (Each bit represents the kind of communication error.)

bit 15 Undefined bit 14 Undefined bit 13 Undefined

bit 12 1: Error in communication with VDU(AT mode) bit 11 1: Error in communication with VDU(MT mode) bit 10 1: Transmission loop error in AT (auto) mode

bit 9 1: Data over error in data receiving part of interface bit 8 Undefined

bit 7 Undefined

bit 6 1: Modulation code error bit 5 1: CRC error

bit 4 1: Format error

bit 3 1: Double transmission error bit 2 1: Double reception error bit 1 1: Modulation code error

bit 0 1: Time-out error [Probable Faulty Locations]

—VDU

—Encoder link cables

—VFA unit

0753 VDU detected error

The VDU(Vibration Detect Unit) has become unable to detect acceleration data.

[Object]

Axis name or none (spindle)

[Character-string] None

[Code]

XXYYZZZZ

XX = VDU error status

|

bit7 |

1: Error bit (1 is error) |

|

bit6 |

1: Empty bit |

|

bit5 |

1: Latest acceleration data is overflow(Y axis) |

|

bit4 |

1: Latest acceleration data is overflow(X axis) |

|

bit3 |

1: Empty bit |

|

bit2 |

1: Error in communication (toggled detecting each error) |

|

bit1 |

1: Previous acceleration data is overflow(Y axis) |

5921-E P-24

SECTION 2 ALARM P

|

bit0 |

1: Previous acceleration data is overflow(X axis) |

YY= VDU alarm code

01:Stop command halt

02: Control parameter error

07: User parameter check sum error 0E: Synchronous miss error

15:Acceleration sensor signal error (X axis)

16:Acceleration sensor signal error (Y axis)

17:Acceleration sensor signal error (X and Y axis) ZZZZ= 0 (fixed)

[Probable Faulty Locations]

— VDU

0754 VDU initialization failure

An error occurred in initialization of VDU(Vibration Detect Unit).

[Object]

Axis name or none (spindle)

[Character-string] None

[Code] XXYYZZZZ

XX= Encoder link sequence number at the time of error detection

0:Reset

1:Network address setting

2:Request of basic information on communication

3:Change of communication version

4:Acquisition of device information

5:Parameter change

6:AT (auto) mode start

YY= Error content

0:Communication error

1:Transmission start time over

2:Transmission finishes time over

3:Reception finishes time over

4:Abnormal response address

5:Abnormal response code

6:Parameter error

ZZZZ = Additional data If YY=0,

the encoder link error status C2ERR at the time of error detection appears. If YY=1, 2, or 3,

the transferred frame information C2MTINF appears. If YY=4,

the network address of the responding device appears. If YY=5,

the received frame information C2RXINF appears. If YY=6,

the number of parameter that caused the alarm appears. 1 = Not all the necessary parameters are received.

2 = Basic information on communication is incompatible.

4 = Protocol version on communication is incompatible. [Probable Faulty Locations]

—VDU

—Encoder link cables

—VFA unit

0755 SIO link error

An error occurred in the SIO link.

[Object] None

[Character-string] None

5921-E P-25

SECTION 2 ALARM P

[Code]

During steady processing FFFFFFFF:

Recieved the same data from MFU twice XXXXYYYY:

XXXX: command & data length 0303: recieved error with frame 0

YYYY:The second byte of reception data 1303: recieved error with frame 1

YYYY:The second byte of reception data 05FF: Error status besides 0

YYYY:Error status During setup processing XXYYZZZZ:

XX:frame

YY:command 00: reset

01: intelligence

02: time-out time setting 05: file-transfer

ZZZZ:error cause

0007: Data reception response is not sent within 0.15 second after data transmission. 0008: Data transmission does not end within 0.15 second.

0009: Communication error occurred after reception of data.

000A: Communication error occurred while the NC was waiting for data reception. 000B: Communication error occurred while the NC was waiting for data transmission. 000C: Data transmission was attempted during data transmission.

000D: Data transmission was attempted in the state of communication error. 000E: An error command was received.

000F: Transmission command and reception command were not same.

[Probable Faulty Locations]

1.SSIO card 2.Safety module 3.I/O slave

0756 PSC optical scale encoder error

An error was detected by the position encoder of optical scale.

[Character-string] None

[Code] XXYYZZ

XX:Value of the J-type endoder and value of the optical scale are too different. bit1:It is too different by a negative sign.

bit0:It is too different by a positive sign. YY:Pulse count value of optical scale

bit0:A-phase pulse and B-phase pulse have changed at the same time. ZZ:The amplitude of the optical scale signal is wrong.

bit1:The amplitude of B-phase is wrong. bit0:The amplitude of A-phase is wrong.

[Probable Faulty Locations]

—Breakdown of optical scale

—Breakdown of optical scale cable

[Measures to Take]

—Exchange of optical scale

—Exchange of optical scale cables

0757 MF-SAFETY Error

An error was detected by the MF-SAFETY.

[Object] None

[Character-string] None

5921-E P-26

SECTION 2 ALARM P

[Code]

0x1000XXXX->CPU Exception was occurred in the MF-SAFETY XXXX->Exception number

0x1100XXXX->NMI was occurred in the MF-SAFETY XXXX->NMI code

bit15->An error was occurred bit9 ->Voltage drop for CPU1

bit8 ->Watchdog timer overflow in CPU0 bit1 ->Voltage drop for CPU0

bit0 ->Watchdog timer overflow in CPU1 0x1200XXXX->CPU bus error was occurred in the MF-SAFETY

XXXX->CPUID

bit15->CPUID (0:CPU0, 1:CPU1) 0x130000XX->No response in CPU1 request

XX->CPU1 request number

0x170000XX->Normal process in the MF-SAFETY did not end within a specific period. XX->End time of normal process (1bit=62.5us)

0x1800XXXX->An Error was detected by the MF-SAFETY XXXX->Error Code

bit15->MFU I/O unit error bit14->MFU I/O Bus parity error bit12->Synchronization error

bit11->Wrongly set synchronous signal timing 0x19000000->Stack overflow in the MF-SAFETY CPU 0x1A00XXXX->Illegal address is in the label table

XXXX->Index of label table

0x1B000000->NC starts up with software update mode in the MF-SAFETY 0x1C0000XX->Mode setting is mismatch between NC and MF-SAFETY

XX->Mismatch location 01->MF-SAFETY mode setting is wrong 02->NC mode setting is wrong

[Probable Faulty Locations] MF-SAFETY MF-SAFETY mode setting NC mode setting

I/O unit in MFU

[Measures to Take]

Replace the MF-SAFETY unit Replace the I/O unit in MFU

Switch(SW1) of the MF-SAFETY turns off Update the MF-SAFETY software (safety logic)

0758 Safety I/O Error